Super User

Cerulean Winds reveals scale of offshore wind bid to make UK’s oil and gas production cleanest in the world

Green energy infrastructure developer Cerulean Winds has revealed it will bid for four seabed lease sites to decarbonise the UK’s oil and gas sector as this scale will remove more emissions quickly, keep costs lower for platform operators and provide the anchor for large scale North-South offshore transmission.

The floating offshore wind and green energy proposal for Crown Estate Scotland’s Innovation and Targeted Oil and Gas leasing round (INTOG) includes four 1.5 GW sites of floating wind power.

With well over £6 billion of investment proposed for each 100-turbine site, the scheme would abate tens of millions of tonnes of CO2 in line with North Sea Transition Deal targets.

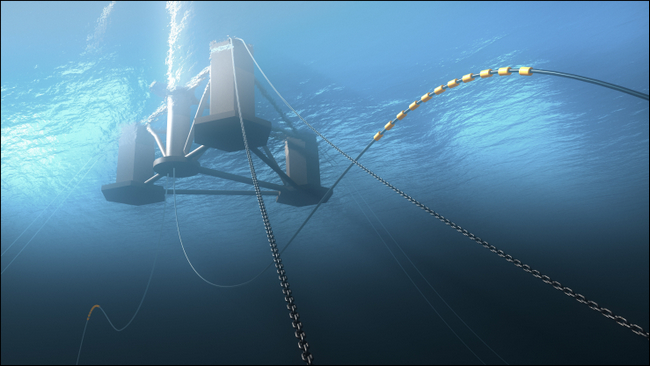

NOV’s Tri-Floater design is custom built from a modular configuration for the most extreme environments

NOV’s Tri-Floater design is custom built from a modular configuration for the most extreme environments

Cerulean Winds, with its selected delivery partner NOV, has been engaging the supply chain for over 18 months and has a live request for information (RFI) with UK yards for the fabrication and assembly of its tri-floater technology.

The steel floating bases would constitute hundreds of thousands of tonnes of steel, which unlike cement fixtures, can be floated out from shore which is ideal for the UK.

The development would create over 10,000 jobs many of which would be high value manufacturing jobs in Scotland as a new generation of automated and hi-tech fabrication and assembly is established.

Dan Jackson, founding director of Cerulean Winds said: “We have a big, bold bid, which is ready to go on scaling the green economy, creating thousands of jobs and making Scotland’s oil and gas production the cleanest in the world.

“The scale we are proposing makes the project economics appealing for providing affordable green power to the platforms to replace gas and diesel generation through a combination of green electrons from wind and molecules from hydrogen.

Unlike cement fixtures, the NOV Tri-Floater base structure design can be floated in very shallow water depths suitable for the UK

Unlike cement fixtures, the NOV Tri-Floater base structure design can be floated in very shallow water depths suitable for the UK

“We are absolutely committed to the local supply chain benefitting from this development and far surpassing local content targets. Our base structure design can be floated in very shallow water depths suitable for the UK, unlike alternative cement floating wind structures which require 90 metres so can’t be built here.”

The Cerulean Winds team is led by serial entrepreneurs Dan Jackson and Mark Dixon, who have more than 25 years’ experience working together on large-scale offshore infrastructure developments in the energy industry.

A consortium of tier 1 contractors are in place as well as a number of industrial and financial partners, leading financial services groups Société Générale and Piper Sandler, who have robustly engaged the financial markets. The development requires no subsidies so there is no expectation on the public purse. INTOG is for a very specific purpose and cleaning up the oil and gas industry does not need to be subsidised by the taxpayer, say Cerulean.

Jackson added: “There is a lot of concern about rising energy prices and energy security. Wind and green energy at this scale are a big part of the solution. We are engaging with oil and gas operators and can see the appetite is there to get behind cleaning up production, and we can deliver in a way that minimises disruption. Whilst smaller piece meal wind developments are useful for testing concepts or innovations, it will take a UK wide solution to remove the emissions at the pace required to hit the net zero targets governments. Furthermore, our large scale scheme lowers the LCOE – cost of the power – which is highly attractive to the operators.”

About Cerulean Winds

Cerulean Winds is a green infrastructure developer founded by Dan Jackson and Mark Dixon, who have together, over 25 years, led large scale offshore infrastructure developments. With exclusive Tier 1 contractor relationships in place, Cerulean Winds has a market funded infrastructure construct to deliver integrated floating wind and hydrogen developments at scale.

Dan and Mark have extensive experience in the offshore sector including establishing successful global subsea engineering consultancy DeepSea Engineering, which was acquired by McDermott International. DeepSea advised clients across the market from the outset of the deep water era from 2000 onwards. DeepSea was engaged with almost all the deep water projects at the time representing the different stakeholder groups; operators, contractors, banks and investors. Various spin off companies and technologies associated with deep water from this time are very relevant to the Cerulean proposition and included the development of patents and IP for floating technologies and mooring systems.

Another notable venture created by the founders is the joint venture between McDermott and Baker Hughes (formerly GE Oil & Gas), io oil & gas consulting. Its purpose at launch in 2015 was to bring integrated contracting to the upstream oil and gas sector including contractor-backed project finance. Whilst the oil price was at an all-time low at the time the new venture secured several multibillion dollar projects for the parent companies by providing suitably economic development plans to the oil and gas companies when these projects would otherwise have languished until the oil price recovered.

Both Mark and Dan have held a variety of leadership roles across multinational corporations advising on the planning, construction, and operation of some of the largest offshore projects. They have significant experience managing integrated contracting and project finance to enable funding of major capital projects from the financial markets, including both UK and international development with a variety of commercial models and Build Own Operate Transfer (BOOT) funding constructs.

ANDRITZ to supply SMART power boiler remote service using Metris BOA web platform to the Netherlands

International technology group ANDRITZ has received a five-year SMART service contract from BMC Moerdijk in the Netherlands to supply a Metris BOA platform including KPI dashboards and boiler operator advisor apps as well as automatically generated performance reports.

The SMART power boiler service uses the Metris BOA web platform – developed by ANDRITZ – to build KPI dashboards and operator advisor apps based on live as well as historical data to optimize and analyze power plant processes and monitor the equipment installed.

ANDRITZ Metris BOA digital advisor for power boilers

ANDRITZ Metris BOA digital advisor for power boilers

The tailored operation advisor apps will actively support the operator in increasing the efficiency of the boiler, detect opportunities to improve consumption values, and help start processes according to operational needs. Furthermore, automatically generated daily and bi-monthly performance reports comparing current data with data from previous periods will provide information at a glance for overall management of the power plant. The Metris BOA platform will be integrated into the control architecture as a third layer of automation and control together with the boiler protection and plant automation systems (DCS).

This is the third time that a Metris BOA platform will be installed in an existing plant and demonstrates the need for support tools to improve operations in the power plant market.

ANDRITZ is proud to provide another step from digital advisor to digital operator for power boilers. The order is an important part of ANDRITZ’s roadmap towards autonomous power boilers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Automation in the chocolate factory

~ How automating the food industry can reduce waste and ruined food ~

In 2006, the Department for Environment, Food and Rural Affairs published the Food Industry Sustainability Strategy, which outlined actions to decrease the building food waste. In 2018, non-profit organisation Waste and Resources Action’s programme reported food waste from UK food manufacturers was around 1.5 million tonnes. This strategy has provided a good start at reducing food waste, but considering total food waste still values around £19 billion a year, there is still a lot left to be done. In this article, Adnan Khan, manager of food & beverage industries at Beckhoff UK, discusses how automating the food industry can reduce food waste.

Automation can help boost the food industry’s traceability, efficiency and quality control. All these benefits can help companies reduce food waste and damaged products.

The UN Food and Agriculture Organization (FAO) calculated that 14 per cent of the food produced globally gets lost in transit to retailers. Automation can help reduce these product losses in transit by using automated tracking system monitors. Using automated tracking systems, businesses can trace transported food with little manual input, allowing them to monitor what is happening at any point, from supply to delivery.

The data from these tracking systems also enables food manufacturers to improve supply chain management by showing inefficiencies and unnecessary expenses. Additionally, tracking systems will alert supply chain managers to any problems during the supply, production or delivery process, helping businesses act quickly before food is wasted or damaged.

For example, a 2019 study by Jagtap and Rahimifard in the journal Waste Management, found that installing an IoT-based digital food waste monitoring system in a ready meal food factory reduced food waste by almost 60.7 per cent.

Standardising quality control

One of the most important parts of food processing is quality control to meet health and safety requirements. If a serious mistake is made during quality control, it could mean contaminated food reaches consumers, causing costly recalls, unnecessary food waste and reputational damage. Automation technology, such as sensors, can make the quality control process more efficient and standardised, ensuring every product receives the same level of inspection and quality control.

Like automated tracking systems, automating quality control allows businesses to be alerted to problems within the production process earlier. This enables larger issues to be avoided later in the process. However, the greatest benefit comes from the superior precision machines provide in comparison with human workers. Human beings can tire, make mistakes and are more prone to inconsistency or errors during quality control processes when compared to machines. Automation can therefore ensure businesses meet quality checking standards consistently and efficiently.

With food wastage such a vital issue, automation can provide the food industry with the tools to reduce food waste while optimising operations. Food manufacturers who haven’t already automated their process should consider doing so to save on company costs and limit the growing amount of food waste in landfills.

To find out more about automation technology for the food industry, visit the food industry page on the beckhoff.com/en-gb/ or contact us at +44 1491 4105-39.

About Beckhoff: Beckhoff Automation implements open automation systems based on PC Control technology. The product range covers Industrial PCs, I/O and Fieldbus components, drive technology and automation software, and all products can be used as separate components or integrated into a complete and seamless control system are available for all industries. Its New Automation Technology philosophy represents universal and open control and automation solutions that are used worldwide in a wide variety of different applications, ranging from CNC-controlled machine tools to intelligent building automation.

ZipCharge wins the Shell.ai Decarbonising Cities Award at the 2022 CogX Festival

ZipCharge, the pioneer in portable everyday EV charging, have won the CogX 2022 Decarbonising Cities Award, an award backed by Shell. The award for best Decarbonising Cities StartUp was given in recognition of the ZipCharge portable EV power bank through which the company aims to democratise access to energy to provide clean, low-cost energy wherever people need it – to charge an EV, power the home or access energy on the go.

The CogX Festival is a celebration of innovation and change makers having a positive impact on the world. The CogX Awards champion the innovators and change making a positive impact on our world. The Decarbonising Cities award recognises the start-up community who are leading the pathway to a cleaner-energy future for cities. Shell, together with CogX, looked for novel, out-of-the-box solutions to systematically integrate the energy generation and storage in cities, on a significant scale.

ZipCharge Co-founder Jonathan Carrier “We are delighted to win the Decarbonising Cities competition at CogX. The team at ZipCharge are passionate about improving our environment and building more resilient cities through innovation and this award underlines our commitment to delivering on that promise. We are grateful to the panel which comprised leading innovators and investors from Shell Ventures, Startupbootcamp, Lakestar and Energy Unlocked”.

Shell VP Computational Science & Digital Innovation Dan Jeavons “ZipCharge are a prime example of a start-up with the vision and technical ability to produce a product that could transform the urban environment. Their portable EV power bank will help democratise EV ownership and significantly reduce carbon in cities”.

Launched publicly in November 2021, ZipCharge have developed to Go from a concept to B Sample prototype, ready for real-world trials and are on track to enter production and deliver the first units to customers in quarter two of 2023.

ZipCharge is developing the Go based upon the same rigorous engineering approach as major car manufacturers. It is building several iterations of prototypes from validation through to pre-production, all of which will undergo an extensive testing regime. The company’s engineers are currently optimising the performance of the portable EV charger’s key system components, including the NMC lithium-ion battery cells and the ZipCharge-designed bi-directional AC-DC converter. This is to evaluate thermal behaviour, charging performance, safety, durability and full functionality to ensure a seamless and safe ownership experience for everyday charging.

The Go is the first element of a global platform, which also includes the recently announced GoHub public infrastructure concept, that combines hardware, software, machine learning and innovative ownership models to bring affordable, practical EV charging to more people than ever. The platform also provides intelligent energy management to help lower energy costs in the home, while providing increased flexibility and resilience for the national power grid.

Realising that widespread EV adoption would be hampered by the inability to charge near or at home, ZipCharge co-founders Richie Sibal and Jonathan Carrier identified and developed a solution. Using their decades of experience in automotive electronics systems engineering and product development gained at cutting-edge businesses like McLaren Automotive, Jaguar Land Rover, Lotus, Gordon Murray Group and LEVC – their answer is the Go.

About ZipCharge

Our mission at ZipCharge is to democratise access to clean, low-cost energy wherever people need it – to charge an EV, to power the home or access energy on the go. ZipCharge provides smart energy storage solutions that integrate hardware, software and innovative services so anyone can store and access their personal energy in a smarter, more sustainable and lower cost way. With the Go portable powerbank and GoHub energy point network, ZipCharge will provide individuals, communities and businesses with the flexibility to store, access and distribute energy to make EV charging and access to energy more sustainable, convenient and affordable. ZipCharge is part of the energy transition, connecting distributed energy resources (DER) in the Go and GoHubs together to store renewable energy and provide a range of flexibility and resilience services to the grid through the ZipCharge energy management platform. ZipCharge’s unique focus on distributed personal energy management will ensure everyone can use energy in smarter, more efficient, and sustainable ways to deliver energy democratisation, local grid resiliency and lower energy costs for all. For more information, please visit zipcharge.global

Reichmuth orders 35 Vectron locomotives for SBB Cargo

Reichmuth & Co Investment Management AG has ordered 35 Vectron AC locomotives from Siemens Mobility through its investment vehicle LokRoll 3 AG. LokRoll 3 will lease the locomotives to SBB Cargo for eight years through its asset manager Northrail GmbH, which it commissioned for the deal. The entire transaction was arranged and structured by Paribus Rail Investment Management GmbH. The lease also includes local maintenance of the locomotives by Siemens Mobility for eight years. The Vectrons will be manufactured at the Siemens Mobility plant in Munich-Allach and delivered in 2024.

- Siemens Mobility delivers Vectron AC locomotives

- Contract includes maintenance for eight years

“The fact that we are again delivering locomotives for Switzerland confirms the high level of reliability and performance of our Vectron platform. Although the AC locomotives will primarily operate in Switzerland, they can also be used for cross-border service in Germany and Austria. This enables our customer to plan for the future in a long-term and flexible manner,” said Albrecht Neumann, CEO Rolling Stock of Siemens Mobility.

“The fact that we are again delivering locomotives for Switzerland confirms the high level of reliability and performance of our Vectron platform. Although the AC locomotives will primarily operate in Switzerland, they can also be used for cross-border service in Germany and Austria. This enables our customer to plan for the future in a long-term and flexible manner,” said Albrecht Neumann, CEO Rolling Stock of Siemens Mobility.Nordic Paper explores further improved barriers for packaging

Nordic Paper is world leading within natural greaseproof papers used in different food applications, for example as baking papers, for baking cups or for food containers. The paper has natural barrier properties achieved without the addition of fluorochemicals, so called PFAS. To further develop these natural barriers and to expand the markets for natural greaseproof papers, Nordic Paper has entered into a two-year cooperation with Centre Technique du Papier, CTP, in France.

Nordic Paper produces and develops natural greaseproof papers for the food industry without addition of fluorochemicals. Barrier properties are important characteristics for these paper grades in order that the grease of the packaged foodstuff does not go through the paper. The initiated cooperation project with CTP focuses on exploring and developing further improved natural grease barriers without addition of fluorochemicals.

Nordic Paper produces and develops natural greaseproof papers for the food industry without addition of fluorochemicals. Barrier properties are important characteristics for these paper grades in order that the grease of the packaged foodstuff does not go through the paper. The initiated cooperation project with CTP focuses on exploring and developing further improved natural grease barriers without addition of fluorochemicals.

- Our papers are equipped with good and natural barriers for many application areas, but we are eager to push the limits and to increase the grease resistance even further of our products, says Henrik Kjellgren, product manager Natural Greaseproof.

CTP is a leading research institute for the paper industry with a specific competence in treatment of fiber surfaces and in barrier properties. Several laboratory tests will be conducted in the project which is expected to result in valuable information for the continued development work of Nordic Paper regarding further improved barriers. The ambition is to expand the market for greaseproof papers so that the customers of Nordic Paper would be able to produce packaging solutions for food that is currently packaged in plastic or aluminum-based solutions.

- One example of an application we are looking into is food trays for frozen lasagna where the packaging requires very good barrier properties as the food and its packaging undergoes heating, explains Henrik Kjellgren.

Nordic Paper is already today, with its greaseproof papers, able to offer more sustainable alternatives to packaging manufacturers currently using packaging solutions based on plastics or on materials with added fluorochemicals.

- We can contribute to the ongoing phasing out of the use of PFAS and to reduce plastics consumption in society. It is important that we take further steps to develop us into neighboring application areas where our papers are currently not present to increase our contribution to a sustainable society, concludes Henrik Kjellgren.

Nordic Paper is a leading specialty paper producer with its base in Scandinavia. We have been manufacturing top-quality kraft papers and natural greaseproof papers since the 19th century. Our products are based on renewable raw material from local forests. From our five paper mills, four in Scandinavia and one in Canada, we supply customers in about 80 countries. Nordic Paper had in 2021 net sales of approximately SEK 3,100m, about 690 employees and is listed on Nasdaq Stockholm. www.nordic-paper.com

Power quality in remote locations

When they are based in remote locations, transformers and other power equipment are vulnerable to harmonics and noise caused by insufficient dampening and exposure to surrounding electrical currents. If these issues aren’t addressed, they can cause component failure and severe damage to the local power supply. When Fairfields Control Systems, a systems integrator specialising in unique control and automation systems, experienced failures at two recently-upgraded sites, it approached power quality specialist CP Automation for a solution.

Fairfields Control Systems provides turnkey mechanical, electrical, instrumentation, control and automation (MEICA) solutions for a range of industries including flood defence and factory automation.

Transformer in actionAs a contractor for the Environment Agency (EA), Fairfields had recently upgraded the borehole pumps on seven of its groundwater sites in the UK with variable speed drives that were fed from transformers. Each transformer helped to power a pumping station, that are used to alleviate low river flows.

Transformer in actionAs a contractor for the Environment Agency (EA), Fairfields had recently upgraded the borehole pumps on seven of its groundwater sites in the UK with variable speed drives that were fed from transformers. Each transformer helped to power a pumping station, that are used to alleviate low river flows.

Transformers and harmonics

Transformers are common in many industrial settings, reducing the voltage of conventional power circuits to operate low-voltage devices. They can also be used in remote locations to transmit power to more isolated sites. When situated in more remote outdoor locations, transformers are generally smaller and installed high-up on concrete or wooden poles or platforms.

Fairfields had recently upgraded the borehole pumps at seven of the EA’s sites. But, soon after the upgrade, the surge protection devices (SPD) that limit transient voltages by diverting or limiting surge current began to fail on two of them. It was clear that abnormal supply characteristics were present, and that harmonic distortion levels were too high.

Voltage distortion is any deviation from the nominal sine waveform of the AC line voltage. It is caused when current harmonics increase the voltage and electric currents in a circuit and can overheat the power system, destabilise the voltage and damage equipment. It was also important that Fairfields resolve the issue to stay compliant with the Engineering Recommendation G5/4, which specify the planning levels for harmonic voltage distortion.

Revcom passive filtersTurning a corner

Revcom passive filtersTurning a corner

Fairfields already had a relationship with CP Automation, as the company had carried out various surveys and consulted on different projects in the past.

“CP Automation’s power quality expertise has been crucial for protecting our systems,” explained Peter McMorrow, engineering director at Fairfields Control Systems. “The ground water project was different. While we can often foresee issues with noise and power quality, in this case, we were already experiencing issues. Once they were identified, our priorities were to determine the source of the abnormal supply and its characteristics. Our plan was to retrofit equipment to mitigate the effects.

“The total harmonic distortion (THDi) was falling outside its normal rage and the voltage was becoming unstable, so long-term damage to the transformer and its components was a real risk,” explained John Mitchell, global business development manager at CP Automation. “After surveying the situation, we suggested replacing the failed SPDs with two SineTamer transient voltage surge suppression (TVSS) devices, which protect from surges and transient spikes.”

After proving that the SineTamer could function effectively in the high harmonic environments where the original SPDs failed, CP Automation agreed to fit the new devices across all the EA sites. Meanwhile, it supplied two REVCON Harmonic Filters (RHF) for the high-harmonic sites to help protect the transformer and other nearby equipment. The RHFs prevent the harmonic distortion of nonlinear loads and sources, reducing the THDi to below five per cent, which is essential for staying within G5/4 levels.

A stable power supply

Fairfields purchased two RHF-5P double stage passive filters. As well as reducing the THDi of variable frequency drives (VFD) and other non-linear loads, the filters can reach an efficiency of up to 99.5 per cent. As a result, power losses are up to 75 per cent less than those produced by alternative devices.

Ever since Fairfields installed SineTamer and the RHFs, the transformers have been running as normal across the EA’s ground water sites. By minimising voltage distortions, the technologies supplied by CP Automation have prevented issues like voltage notching, motor vibration, nuisance tripping, electromagnetic interference (EMI) and overheating. Furthermore, the sites are now compliant with G5/4 standards, because the RHFs limit frequency voltage harmonics.

To find out more about how to mitigate harmonics by visiting the CP Automation website.

About CP Automation: CP Automation is a specialist in the repair and replacement of automation equipment including electronic boards, PLCs and Ac and DC drives. It was established to provide an independent maintenance service, without exclusive ties to any manufacturer. However, it does have strong relationships with the principal inverter, encoder, resistors and motor manufacturers.

Metso Outotec to deliver key concentrator plant equipment to a copper mine in Africa

Kamoa Copper S.A. has selected Metso Outotec to supply key concentrator plant equipment to the company’s copper mining complex expansion in the Democratic Republic of Congo. The value of the order, which is not disclosed, has been booked in Minerals’ Q2/2022 orders received.

Metso Outotec’s scope of delivery consists of Planet Positive processing equipment, including energy-efficient HIGmillTM regrind mills with polyurethane wear linings. The delivery also includes Larox® PF 60 Series concentrate filters and TankCell® flotation cells for the efficient recovery of valuables.

Metso Outotec HIGmill grinding mills

Metso Outotec HIGmill grinding mills

“One of the key missions for Kamoa Copper S.A. is to implement low-carbon technology to advance sustainable production of copper. Metso Outotec’s Planet Positive offering supports our customer’s ambition, allowing us to be a true partner for positive change,” says Charles Ntsele, Vice President, Minerals Sales for Metso Outotec in Africa.

Read more about our offering for the mining industry on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Huntsman Starts Commercial Operation of New Splitter at its Geismar, Louisiana Polyurethanes Plant

Splitter will enable the production of more high-value, differentiated grades

Huntsman Corporation (NYSE: HUN) has just announced the start of commercial operation of a new methylene diphenyl diisocyanate (MDI) splitter at its Geismar site in Louisiana. The $180 million splitter gives Huntsman the ability to produce more high-value, differentiated grades from the crude MDI manufactured at the plant, thereby enabling growth in key customer applications.

“The new splitter reinforces our strategy of delivering value over volume by creating a more differentiated product portfolio,” said Tony Hankins, President of Huntsman’s Polyurethanes division. “It enables us to provide our customers in automotive, furniture, construction, adhesives and coatings markets with more options for innovative, sustainable polyurethanes products.”

The completion of the MDI splitter project was celebrated at a special event on Wednesday, July 13, at the Geismar facility hosted by Huntsman Chairman, President and CEO, Peter Huntsman. Guests included Attorney General of Louisiana Jeff Landry, local officials, key customers, suppliers, members of Huntsman’s senior leadership team, and Geismar employees.

Speaking at the event, Jan Buberl, Polyurethanes’ Vice President for the Americas region said “Our new splitter bridges the gap between our upstream MDI manufacturing assets and the downstream needs of our customers – both domestic and international. Our mission is to deliver what our customers need to help them innovate and grow. This investment will strengthen our ability to meet, and exceed, those expectations.”

Pictured left to right:

- Jan Buberl - Vice President Americas, Huntsman Polyurethanes

- Tony Hankins - President, Huntsman Polyurethanes

- Mark Dearman - Director Americas Operations, Huntsman Polyurethanes

- Peter Huntsman - Chairman, President and CEO, Huntsman Corporation

- U.S. Navy Retired Vice Admiral Jan E. Tighe - Board Director, Huntsman Corporation

- Jeff Landry - Attorney General of Louisiana

- Max van der Meer – Vice President Global Operations, Huntsman Polyurethanes

Mark Dearman, Site Leader at Geismar, recognized the hard work of the many people associated with the project. “Our thanks go to our construction partners, suppliers and every associate and contractor involved in the new splitter,” he said. “Even without factoring in the additional health and safety measures we needed to put in place for COVID, and the extreme weather events such as Hurricane Ida, the construction of a new splitter is a major undertaking. The project was completed on time, incident-free, demonstrating Huntsman’s focus and commitment to safe working practices.”

About Huntsman:

Huntsman Corporation is a publicly traded global manufacturer and marketer of differentiated and specialty chemicals with 2021 revenues of approximately $8 billion. Our chemical products number in the thousands and are sold worldwide to manufacturers serving a broad and diverse range of consumer and industrial end markets. We operate more than 70 manufacturing, R&D and operations facilities in approximately 30 countries and employ approximately 9,000 associates within our four distinct business divisions. For more information about Huntsman, please visit the company's website at www.huntsman.com

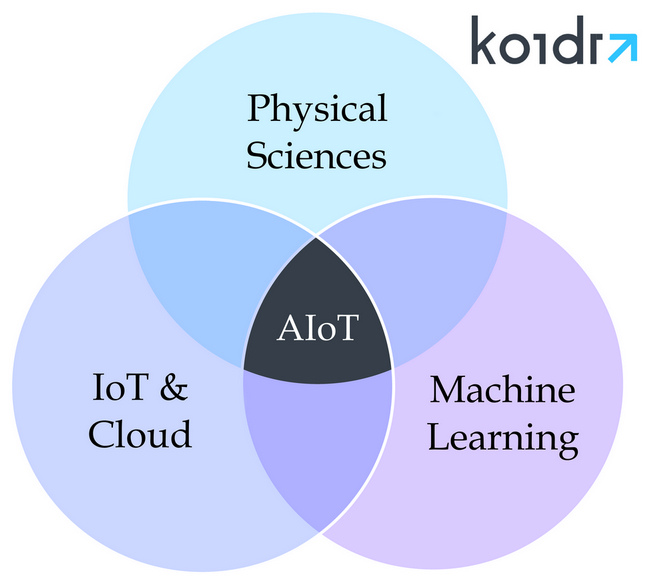

Global Greenhouse Challenge Winner Koidra Hires the Veteran Business Leader from Microsoft to Support Growth

Koidra, an artificial intelligence of things (AIoT)-enabled industrial automation platform company, announces two significant developments. First, Team Koala, led by Koidra, won the third edition of the Autonomous Greenhouse Challenge (AGC) at Wageningen University & Research (WUR) in Bleiswijk. Team Koala was the only AI team that outperformed the Dutch reference growers, providing 27.8% more in net profit than the reference growers, along with the lowest operating cost. Second, Koidra announces the hiring of Soojung Smith as their Chief Business Officer.

AGC Win

In this third edition of the competition, five international finalists were selected out of 43 teams from 23 countries. Each of the finalists grew a lettuce crop using a fully autonomous algorithm. The goal was to use the lowest feasible input of resources, such as energy and CO2, while producing the maximum number of good-quality heads of lettuce. Each team created their own AI algorithms to autonomously determine the set points for temperature, amount of daylight and artificial light, heating, and CO2 concentration—along with other cultivation-related parameters, such as crop density, spacing moments, and day of harvest.

Koidra’s founder, Kenneth Tran, led teams winning the first AGC competition in 2018, the online challenge in 2021, and the growing round of the third challenge in 2022. Seeing the potential of AIoT in transforming greenhouses, Kenneth launched Koidra with a mission to build an autonomous growing technology scalable across greenhouses, vertical farms, and crops—and more broadly across process-based manufacturing industries.

Soojung Smith brings a wealth of strategy, sales & marketing, and operations experience in the U.S. and globally to Koidra in her new role as Chief Business Officer. Her experience includes time spent with AT&T as a Director of Marketing & Sales, and with the international consulting firm PricewaterhouseCoopers as their Head of Strategy Consulting Unit, Southeast Asia Practice. During a 10-year tenure at Microsoft, Smith launched and scaled Office Cloud business and Office 365, and she led the global Enterprise sales group’s transformative change to cloud initiatives by building a new worldwide sales planning and operations team. She also founded two startups, while coaching startup founders and their leadership teams, providing an ideal base for her current position with Koidra.

The AGC win, coupled with the hiring of Smith, provides impetus and a strong base for Koidra as it continues its growth not only in indoor farm automation, but also in the wider field of industrial automation.

About Koidra Inc.

Koidra is a VC-backed and AIoT-enabled automation startup based in Seattle and focused on industrial IoT for agricultural and industrial applications. Koidra was founded by Kenneth Tran, a former principal applied scientist at Microsoft, with a mission to transform controlled environment agriculture, sustainable agriculture at large, and traditional automation using AIoT technology. For more information, please visit www.koidra.ai