Super User

Grandblue Bioenvironment Technology successfully starts up two ANDRITZ ADuro QZ shredders for kitchen waste treatment

Grandblue Bioenvironment Co., Ltd. has successfully started up two ANDRITZ ADuro QZ1600-BIO shredders at its mills in Jinjiang City, Fujian Province, and Xiaogan City, Hubei Province, China.

The two new ADuro QZ1600-BIO shredders process kitchen waste at a design capacity of 15 t/h each and pulp the organic fraction effectively by means of rotating chains. Non-organic material like plastics remains largely intact enabling optimum separation in subsequent process steps. The machines do not use any cutting tools, but gently and quickly break up the input material per impact forces. Compared to conventional cutting systems, the ADuro QZ offers significant advantages in terms of performance and wear.

Yang Rongmei, Technology Manager, Grandblue Bioenvironment Technology says: “In 2016, we collaborated with ANDRITZ for the first time, as part of a pilot project for kitchen waste treatment. This was later followed by another successful project for our Zhangzhou mill. ANDRITZ equipment has shown excellent performance. Especially the gas formation is more efficient due to shorter fermentation times, resulting in an overall higher gas yield in the fermenter.”

ADuro QZ1600BIO shredder for kitchen waste treatment © ANDRITZ

ADuro QZ1600BIO shredder for kitchen waste treatment © ANDRITZ

Grandblue Bioenvironment will soon start up two more ADuro QZ1600-BIO shredders and equipment for compacting delivered by ANDRITZ for additional kitchen waste treatment plants in Hebei and Hubei provinces, China.

Grandblue Bioenvironment Technology Co., Ltd. is a wholly owned subsidiary of Grandblue Environment Co., Ltd., a listed company focusing on environmental industry. Grandblue Environment focuses on several business fields, including solid waste treatment, energy, and water supply, as well as drainage. The company operates 12 treatment plants for kitchen waste and animal manure with a total capacity of about 3,000 t/d.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ RECYCLING

The ANDRITZ plant range offers recycling solutions for a wide variety of different applications: Electronic and electrical waste, refrigerators, cables and flexible wires, metals, end-of-life vehicle parts like oil filters, motor blocks and tires, household, industrial, organic and wood waste as well as rejects from the pulp and paper industry. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment.

Grand Opening of Peljesac Bridge in Croatia

MCI® Technology Applied on One of the World’s Most Demanding Construction Projects!

On 26 of July, Pelješac Bridge, the largest ever EU infrastructure investment in Croatia, officially opened in grand ceremony. The bridge, providing a road link between two parts of the country is of strategic importance and is one of the most substantial EU infrastructural investments ever. It connects the region of Southern Dalmatia with the rest of the country's mainland. The bridge will cut travel time by 37 minutes along the Adriatic coastline, improving people’s lives and increasing economic opportunities for the region. It has 13 spans, five of which are 285 meters long, six centrally placed reinforced concrete pylons with a height of 33 meters, and two lanes together with a stop lane that will serve for bridge maintenance.

Peljesac bridge is ranking among the most demanding bridges in the world—in complexity of construction and design. Bridge is 2,404-m (7,887.14-ft) long.

ln order to meet the main criteria of quality design, such as stability, durability, economy and integration into the environment, the design proposed the construction of an extra dosed bridge with an integrated hybrid structure. Structure is comprised of five central spans, each 285-m long, and six low pylons. Especially careful approach was taken to ensure durability for the extended lifespan of over 130 years. Cortec’s MCI® 2018 was specified on this project during the design phase as a silane-based impregnation with a migrating inhibitor property to protect against the harmful effects of corrosion, thus extending the service life of the bridge. MCI® 2018 is a 100% silane-based concrete sealer, containing migrating corrosion inhibitors that allow deep penetration into concrete and provides water repellence by chemically reacting with the cementitious substrate. It seals surface pores, preventing the intrusion of chlorides, reduces carbonation, and protects from the ingress of wind-driven rain. Treated concrete surfaces are fully breathable and their natural moisture-vapor transmission is not affected. After repair of surface damage and cleaning of discolorations and other surface defects, the concrete surface of the pylons needed to be protected with a colorless silane coating to improve durability and increase the resistance of the concrete surface to long-term external influences. MCI®-2018 carries CE certification that indicates conformity with health, safety and environmental protection standards for products sold within the European Economic Area (EEA).

Application of Cortec’s MCI®-2018

A combination of AC coatings, cathodic protection of steel reinforcement in piles and pile heads, a concrete cover of 65–85 mm stainless steel reinforcement and impregnation of all concrete surfaces with MCI®-2018 was selected. This was chosen as the strategy to help the bridge achieve a 130-year service life. MCI®-2018 was applied on the entire substructure of the bridge. All concrete parts were coated with MCI®-2018 by a spraying technique. The work was performed in accordance with the project requirements and after surface preparation to full functionality.

This included:

- Access to pylons

- Rehabilitation of the concrete surface of the pylons

- Cleaning the concrete surface of the pylon (washing the pillars with water)

- Impregnation of the concrete surface of the pylon with MCI®-2018.

MCI®-2018 contains time-proven Migrating Corrosion Inhibitors (MCI®). The silane component provides water repellency by chemically reacting with the cementitious substrate under proper application, decreasing the ingress of aggressive materials. The product penetrates deep into concrete, providing corrosion protection to reinforcing steel from existing water and chloride ions, or other contaminants. Continuous monitoring of the condition of the structure at one central place was done during the construction phase and will be done at the exploitation phase to examine parameters of structural behavior, time, seismic activity, and structural durability. The designer of the bridge specified corrosion protection for all concrete segments in order to achieve a 130-year service life.

Cortec’s CEO, Boris Miksic, Croatian-American businessman is proud that his patented technology was used on this historic project to connect two parts of his country. “Our MCI® technology is used in largest construction projects throughout the globe. Witnessing its application in my home country on this monumental bridge structure is truly a special. Peljesac bridge is huge step forward for all of us.” A strategic investment such as this bridge, demonstrates European Commission’s commitment to bring people together and unite territories, while reinforcing the territorial cohesion of the region and helping other neighboring countries.

You can learn more about Migrating Corrosion Inhibitors (MCI®) here: https://www.cortecmci.com/

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide. ISO 9001, ISO 14001:2004, & ISO 17025 Certified.

Cortec Website: http://www.cortecvci.com

Slicker Recycling announces second US acquisition

One of the UK’s leading specialists in the recycling and treatment of waste lubricating oils has expanded its US division through a second acquisition in just six months.

Slicker Recycling has announced the acquisition of Ohio-based high voltage metal recycling company, Cleveland Industrial Recycling, which will be integrated into Slicker’s US business, Hydrodec.

The expansion deal promises multiple carbon-cutting benefits for customers, with the joint expertise of both businesses set to play a greater role in helping companies offset carbon emissions, conserve fossil fuels and gain Carbon Credits to help meet their sustainability goals.

The deal is the latest positive news for Slicker after it acquired Hydrodec in November last year.

The expanded company, which now counts over 50 employees, will be led by Gary Smith who becomes CEO of the US business – promoted from his role as Slicker’s operations director. Jim Szoka, former owner of Cleveland Industrial Recycling, will become the executive chairman of the new-look company.

Cleveland Industrial Recycling

Cleveland Industrial Recycling

Mark Olpin, Executive Chairman of Slicker Recycling said: “This is an exciting acquisition for us and maintains our ongoing, rapid growth in the US market.

“We saw so many synergies between Hydrodec and the team at Cleveland and we can now closely integrate our expertise. There are efficiencies we will gain for used oil extraction and metal recycling, but the deal will also allow us to work with more businesses to help them achieve their green objectives and be awarded by gaining sought-after Carbon Credits.

“There are so many compatibilities between both companies. Cleveland’s specialist team decommission tonnes of high voltage scrap metal and transformers every day, but now they can work hand-in-hand with our team at Hydrodec to ensure used oil is extracted, refined and recycled back into the market.

“It is a merger which means we are extending the value chain, and offering a closed-loop, end-to-end solution for companies across the United States.”

Jim Szoka, executive chairman of Hydrodec North America added: “This merger is the next logical step for Cleveland Industrial Recycling and will not only extend the

value chain, but give a complete, closed loop process when it comes to us recycling various types of metals and ensuring oil is extracted.

“We see a great fit with Slicker Recycling and Hydrodec so it is an exciting time for everyone involved.”

Cleveland Industrial Recycling has 29 employees. Aside from its 74-acre Ashtabula Ohio facility which processes high voltage scrap metal, the company also has sites in Mercer, Pennsylvania and Akron, Ohio which also process and drain transformers and high voltage electrical equipment.

The merger sees Slicker Recycling, which is headquartered in Stourport-on-Severn, Worcestershire, further building its circular economy credentials after the 2020 opening of its $95 million base oil re-refinery in Denmark through a joint venture with its German partner, Avista AG.

Readers can visit www.slickerrecycling.com for further information on the company’s services and expertise.

Brammer Buck & Hickman launches new Bore and Keyway Machining Service

Buck & Hickman, the UK’s leading supplier of industrial maintenance, repair and overhaul (MRO) products and services, has launched a new fast and flexible Bore and Keyway Machining Service.

This latest addition to the company’s range of engineering services has seen new bore, keyway and grubscrew machinery installed, operated by experienced in-house engineers. Now, Brammer Buck & Hickman can rework products to suit customers’ specific requirements and within a short time frame.

The new Bore and Keyway Machining Service encompasses horizontal and vertical adaptations. The service that is expected to have the greatest demand is machining customer bore and keyways into pilot bored products such as sprockets and couplings. Sprockets are stocked either pre-bored to receive a taper lock bush, or as pilot bored versions that can be machined with multiple bore sizes. In addition, a bespoke service is offered enabling modification to off the shelf products.

Darren Smart, Category Director - MRO at Brammer Buck & Hickman, commented: “Whilst we have been providing a basic Bore and Keyway Machining Service to customers, up until now this has been outsourced. By investing in state-of-the-art machinery, and staff training, we are delighted to bring this service in-house, for a far more flexible service and a considerably faster turnaround. We can now meet customers’ bespoke requirements and specific tolerances, regardless of whether it is non-standard or has a slightly different fit.”

The new Bore and Keyway Machining Service joins Brammer Buck & Hickman’s range of engineering services which include specialist workshop, gearbox repair and other engineering services geared towards saving customers money.

Brammer Buck & Hickman is part of the Rubix group, Europe’s largest supplier of industrial MRO products and services. For more information, please go to uk.rubix.com/en/service/engineering-services

About Brammer Buck & Hickman

Brammer Buck & Hickman is the UK’s leading technical specialist distributor of maintenance, repair and overhaul (MRO) products, as well as supplying multiple value-added services. Branches across the breadth of the UK provide customers with quick and easy access to more than 5 million products, from bearings, power transmission and fluid power through to tools and health & safety products. This extensive product portfolio is underpinned by specialist engineering services as well as condition monitoring. At the heart of Brammer Buck & Hickman’s service is a commitment to providing customers with cost savings through:

- reducing total acquisition costs

- improving production efficiency

- reducing working capital.

Brammer Buck & Hickman is part of the Rubix group, Europe’s largest supplier of industrial MRO products and services.

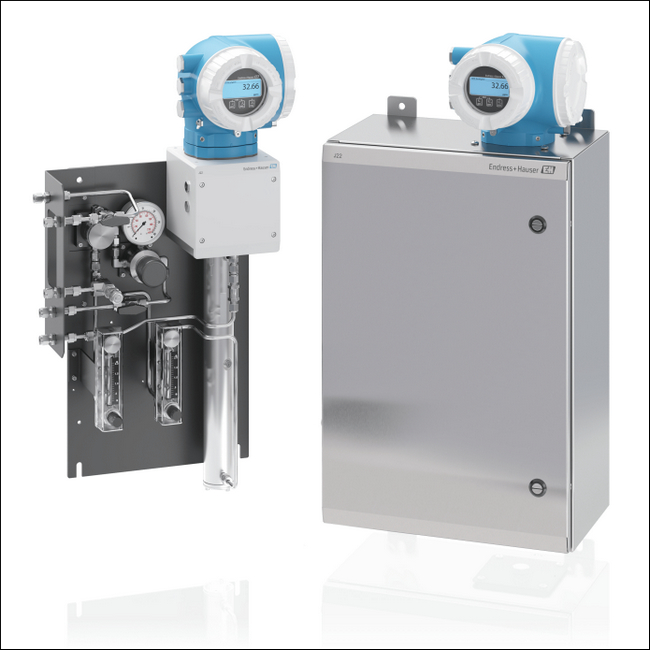

Endress+Hauser enhances J22 natural gas analyzer with advanced features and hardware

Proven measurement technology for monitoring water content in natural gas gets an upgrade with better data handling and network connectivity, an improved user interface, and enhanced modularity for optimal field serviceability.

August 2, 2022 – Endress+Hauser announced a new version of its J22 TDLAS gas analyzer, an update to the initial release in 2021. The J22 tunable diode laser absorption spectroscopy (TDLAS) analyzer continues the tradition established by its predecessor with best-in-class accuracy, a user-friendly interface, integrated diagnostics, and a host of modular hardware.

The latest updates include support for the Modbus TCP/IP protocol, which enables users to communicate with their analyzers from a central network location in a bidirectional, secure point-to-point manner. Combined with the addition of a native web server, this enables users to easily monitor, configure, and service the analyzer remotely.

“Modularity and increased uptime are functional designs unique to this analyzer. The J22 was designed to be almost 100% field serviceable,” said Alan Garza, Endress+Hauser advanced analysis product expert. “The goal is to allow users the freedom to repair their analyzer without the need to send it back to us, giving the customer the ability to decide when and where to service their analyzer if needed.”

Enhancements in analyzer interface and hardware

In addition to field-service and Modbus communication, Endress+Hauser implemented a user-friendly web server into the J22, which can be used to configure, service, and optimize the analyzer for efficient operation in every process stream. End users can perform these functions from any device with a web browser on the Modbus TCP/IP Ethernet network or connected to the RJ45 service port.

The J22 offers selectable and modular hardware, including:

- Membrane separator

- Pressure relief valve

- Bypass armored flow indicator & control

- Analyzer armored flow indicator & control with flow switch

- Thermostat

- Check valve

“We are always looking for ways to partner with our customers to understand how we can improve their day-to-day processes,” Garza explains. “Our customers provided great feedback on how these enhancements can improve their experience – so we took that and ran with it.”

The updated J22 TDLAS gas analyzer is available now.

For more information, please visit https://eh.digital/3QIwX2y.

About Endress+Hauser

Endress+Hauser is a global leader in measurement and automation technology for process and laboratory applications. The family company, headquartered in Reinach, Switzerland, achieved net sales of approximately 2.9 billion euros (3.3 billion U.S. dollars) in 2021 with a total workforce of more than 15,000 worldwide. Endress+Hauser devices, solutions and services are at home in many industries. Customers thus use them to gain valuable knowledge from their applications. This enables them to improve their products, work economically and at the same time protect people and the environment. For further information www.us.endress.com.

First power generated by Hollandse Kust Zuid offshore wind farm

The Hollandse Kust Zuid wind farm, which is currently under construction, has successfully generated its first electricity.

While still in their testing phase, the first operating turbines are already producing electricity, which is transferred to shore via an offshore transformation station and fed into the Dutch grid.

Already completed wind turbines of the wind farm Hollandse Kust Zuid.

Already completed wind turbines of the wind farm Hollandse Kust Zuid.

The wind farm is located in the North Sea about 18-35 kilometers off the coast between The Hague and Zandvoort and is owned by BASF, Vattenfall and Allianz.

So far, 36 turbines have been installed. When fully operational in 2023, Hollandse Kust Zuid will be the largest subsidy-free offshore wind farm in the world with 140 turbines and an installed capacity of 1.5 GW.

Floating Offshore Wind in France: TotalEnergies, Corio Generation and Qair Join Forces to Bid for Mediterranean Tender

A consortium of TotalEnergies, Corio Generation and Qair has been pre-selected by the French Directorate General for Energy and Climate (DGEC) to participate in a competitive tender to develop two floating windfarms in the Mediterranean Sea.

The two projects of about 250 MW each could supply enough clean energy to meet the annual electricity consumption of almost one million people.

Opportunity to develop an innovative value chain

The TotalEnergies, Corio Generation and Qair consortium is delighted with this new call for tenders, which will help to achieve France’s objective of 40 GW of offshore wind capacity by 2050.

The partners intend to support the development of a local Mediterranean industrial value chain for offshore wind power. To this end, the consortium plans to consult regional stakeholders, promote the local economy and ensure communities benefit from employment opportunities.

Combining complementary expertise

The consortium will leverage each company’s technical expertise, strong financial resource and extensive experience in the offshore wind sector:

- TotalEnergies, a multi-energy company, has expertise in offshore operations and maintenance through its historical activities. TotalEnergies is already developing offshore wind projects with a combined capacity of more than 11 GW, including more than 2 GW of floating projects in France, the United Kingdom and South Korea.

- Corio Generation,a global specialist offshore wind developer, has more than 20 GW of projects under development worldwide, including 2.5 GW in floating wind. Corio is a portfolio company, operating on a standalone basis, of Macquarie’s Green Investment Group (GIG).

- Qair, a European renewable energy producer, is a French pioneer in floating wind energy. With over 30 years of experience and a strong local presence in France, Qair operates 1 GW of assets and is developing a pipeline of 20 GW.

Proven cooperation in offshore wind

The consortium’s joint bid is based on a productive track-record and partnership history, including on the following projects:

- The 250 MW floating windfarm tender in France’s South Brittany region (Qair, TotalEnergies and Corio Generation),

- The 30 MWEolmed floating offshore wind pilot project in France (Qair and TotalEnergies)

- Over 2 GW of floating wind projects in South Korea (Corio and TotalEnergies)

- The 2 GW West of Orkney Windfarm project in Scotland (Corio and TotalEnergies)

- The 1.5 GW Outer Dowsing Offshore Wind project in the UK (Corio and TotalEnergies)

"After Brittany’s tender, we are delighted to renew our partnership with Qair and Corio to contribute to the development of floating wind in the Mediterranean and thus to the energy transition in France. If successful, we intend to mobilise our collective expertise to provide the best solutions to meet the technical, commercial and societal challenges of the project," said Olivier Terneaud, VP Offshore Wind at TotalEnergies.

“Corio Generation is delighted to combine forces with TotalEnergies and Qair. We truly believe France can become a world leader in the development of offshore wind. With its deep waters and industrial heritage, the Mediterranean is fantastically placed to benefit from floating wind technology, creating significant job and investment opportunities. Deploying new projects at scale will be critical to realising the full potential of France’s wind resources and unlocking a significant clean, reliable and affordable source of electricity for generations to come,” said Jonathan Cole, CEO of Corio Generation.

“We are happy to bring once again our partners TotalEnergies and Corio together around their complementary expertise in the development, financing and construction of offshore wind projects. In association with the Mediterranean territories, we will be keen to participate in the acceleration of the energy transition by developing locally the French floating offshore wind industry to come," said Jérôme Billerey, France Managing Director at Qair.

ABB launches five axis Delta robot fastest for lightweight product picking, packing & re-orientation

ABB is expanding its FlexPicker® Delta robot portfolio with the IRB 365. With five axis and 1.5kg payload, the IRB 365 is both flexible and the fastest in its class for reorientating packaged lightweight products such as cookies, chocolates, peppers, candies, small bottles, and parcels.

- New FlexPicker® IRB 365 picking robot fastest-in-class for picking and packing applications up to 1.5kg

- Flexibility to be used in a range of applications, from shelf ready packaging to parcel sorting and bottle handling

- Commissioning time reduced from days to hours with ABB PickMaster® Twin software

Responding to the rise in e-commerce and growing demand for shelf ready packaged goods, the IRB 365 has been developed for applications including food and beverage, pharmaceuticals and consumer goods, where production line speed and adaptability are essential.

“The IRB 365 can pick, reorientate and place 1kg products at 90 picks per minute,” said Roy Fraser, Global Product Manager for ABB Robotics. “Our customers saw that the growth in online shopping was driving the demand for shelf ready packaged goods, so we developed a new Delta robot that would rise to the challenge. By handling more products per minute, the IRB 365 robot increases productivity, while saving time and energy to make production more efficient.”

From product reorienting, top-loading and secondary packaging, to bottle handling, unscrambling, 3D picking, feeding and parcel sorting, the IRB 365 meets a wide variety of applications. Powered by the OmniCoreTM C30 controller - the smallest Delta robot controller on the market - the system offers best-in-class motion control, built-in digital connectivity, and 1000+ additional software hardware functions ready to meet future demands and requirements.

From product reorienting, top-loading and secondary packaging, to bottle handling, unscrambling, 3D picking, feeding and parcel sorting, the IRB 365 meets a wide variety of applications. Powered by the OmniCoreTM C30 controller - the smallest Delta robot controller on the market - the system offers best-in-class motion control, built-in digital connectivity, and 1000+ additional software hardware functions ready to meet future demands and requirements.

Through ABB’s PickMaster® Twin software, the IRB 365 can be integrated into packaging lines in a matter of hours rather than days, using digital twin technology, which also reduces changeover times from hours to just minutes.

As the latest member of ABB’s portfolio of robots for picking and packing, the IRB 365 can be paired with other robots including the IRB 390 to pick, handle and pack payloads weighing from a few grammes up to 15kg.

ABB Robotics & Discrete Automation is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the world’s leading robotics and machine automation suppliers, we have shipped more than 500,000 robot solutions. We help our customers of all sizes to increase productivity, flexibility and simplicity and to improve output quality. We support their transition towards the connected and collaborative factory of the future. ABB Robotics & Discrete Automation employs more than 11,000 people at over 100 locations in more than 53 countries. go.abb/robotics

CERULEAN WINDS AND PING PETROLEUM SIGN AGREEMENT TO CREATE ONE OF THE UK’S FIRST WIND-POWERED OIL AND GAS PRODUCTION FACILITIES

UK green energy infrastructure developer, Cerulean Winds, and Ping Petroleum UK today announced the signing of an agreement to create one of the UK’s first oil and gas facilities powered mainly by offshore wind.

- Cerulean Winds and Ping Petroleum UK sign agreement to create one of the UK’s first offshore oil and gas facilities powered by offshore wind.

- The pioneering project marks a critical step in the journey towards making oil and gas production the cleanest in the world and is welcomed by UK Government.

- The deal will deliver the UK’s first Floating Offshore Wind unit manufacturing and assembly in the UK, kick-starting the much-anticipated floating offshore wind supply chain.

Under the agreement signed in a meeting hosted by Secretary of State, Kwasi Kwarteng, the production facility at Ping Petroleum’s Avalon site, located in the UK Central North Sea, will be mainly powered by floating offshore wind. The pioneering project will help meet the emissions reduction targets agreed between government and industry in the North Sea Transition Deal in March 2021.

The provision of wind power will remove up to 20,000 metric tonnes of CO2 emissions every year from the offshore production facility – the equivalent of taking over 4,000 cars off the road.

The project will demonstrate the use of floating offshore wind in decarbonising oil and gas production. Later this summer, applications will open to developers for seabed leases to drive the decarbonisation of other oil and gas assets across the North Sea.

Ping Petroleum UK acquired a 100% stake in the Avalon site in August 2021, with production expected to begin in 2025. The field has a total estimated recovery of 23 million barrels of oil. The proposed development concept for the plans have already been cleared by the North Sea Transition Authority (NTSA), and a field development plan is to be submitted later this year.

Secretary of State Kwasi Kwarteng observes the signing between Zainal Abidin Abd Jalil and Rob Fisher of Ping Petroleum, Dan Jackson of Cerulean Winds and Tan Sri Syed Zainal Abidin Syed Mohamed Tahir of DNeX

Secretary of State Kwasi Kwarteng observes the signing between Zainal Abidin Abd Jalil and Rob Fisher of Ping Petroleum, Dan Jackson of Cerulean Winds and Tan Sri Syed Zainal Abidin Syed Mohamed Tahir of DNeX

Under these plans, Cerulean Winds with its consortium of Tier 1 industrial partners will provide a large floating offshore wind turbine which will be connected, via a cable, to Ping Petroleum’s Floating Production & Storage vessel.

This will be one of the largest floating wind turbines built in the UK and will provide the majority of power required by the production & storage vessel. It is expected that green power produced by the turbine will exceed the energy needs of the production vessel, with the partners exploring options to supply excess energy to other nearby production facilities. The production vessel is a 60-metre diameter facility with a storage capacity of 270,000 barrels of oil and is capable of producing up to 30,000 barrels of oil per day.

As part of the agreement with Ping, Cerulean Winds have committed to fully manufacturing and assembling the offshore wind turbine in the UK. The project is expected to realise between £80-100 million in investment in the development and in the UK’s renewable energy supply chain. The project was enabled by a grant to Cerulean Winds through the Floating Offshore Wind Demonstration Programme from the UK Government’s Department of Business, Energy and Industrial Strategy (BEIS) to support the innovation and optimisation of the technology that will be deployed.

Tan Sri Syed Zainal Abidin Syed Mohamed Tahir, Group Managing Director of DNeX, said: “As the world transitions to a low-carbon future, Ping is excited to be an early implementor of this revolutionary technology in the UK North Sea for our new greenfield project, Avalon. This project which uses offshore wind to power operations demonstrates our long-term commitment to establish a low carbon development concept. It will substantially lower the emissions intensity of our operations which supports long term climate change goals globally.”

“In addition, it enables us to seize market opportunities arising from the energy sector’s low-carbon transformation and development. The creation of an additional revenue stream via the supply of excess energy to nearby facilities will positively contribute to our financial performance. “

“Furthermore, we will gain experience and exposure to the relevant markets and stakeholders within the renewable energy sector which may lead to strategic business developments ahead.”

Dan Jackson, Founding Director of Cerulean Winds, said: “Our partnership marks a significant milestone for the oil and gas industry in creating one of the UK’s first production facilities to be powered by clean, green and affordable offshore wind energy.

“This innovative and pioneering project will be ‘Made in the UK’ and through our delivery partners, we will be realising significant investment in UK fabrication yards and ports. This is a critical step in scaling the UK supply chain and building experience and a track-record to exploit future opportunities in the fabrication, assembly and servicing of offshore wind developments.

“This project will demonstrate how we can harness the power of affordable, offshore wind to deliver significant reductions in the carbon emissions of oil and gas production. The UK has a golden opportunity to make our domestic oil and gas production the cleanest in the world - scaling the green economy and creating thousands of jobs in the process. We are thankful to BEIS for encouraging research and development which highlights to potential investors that the UK Government endorses the rapid development of integrated floating offshore wind technologies to support industrial decarbonisation."

This important step in progressing the Avalon project was today welcomed by the UK Government.

Business and Energy Secretary Kwasi Kwarteng said: “The North Sea oil and gas sector has been a major British industrial success story for decades. We must keep supporting production on the UK Continental Shelf for security of supply as we transition to clean, affordable, home-grown energy. In the meantime, we need to cut emissions from production. Platform electrification projects such as this are a welcome step forward to reduce emissions from oil and gas production, secure jobs and new skills and deliver on the commitments of the landmark North Sea Transition Deal.”

Cerulean Winds has previously announced a floating offshore wind and green energy proposal for Crown Estate Scotland’s Innovation & Targeted Oil and Gas seabed leasing round. The initiative provides seabed leases to green energy developers to support the electrification and decarbonisation of oil and gas facilities in the UK Continental Shelf. Cerulean Winds’ plans to bid for multiple sites at 1.5 GW scale of floating offshore wind would unlock £6 billion proposed investment per site, and would abate significant CO2 emissions of UKCS oil and gas assets from 2027.

Granite River Labs and Anritsu Announce Complete Automated Test Solution for PCI Express® 5.0 Specification

Granite River Labs (GRL), the world’s leading firm for digital connectivity test solutions and services, and Anritsu Corporation announced that their jointly-developed PCI Express® (PCIe®) 5.0 automated test solution has been approved by PCI-SIG® for “gold suite” product compliance testing. The solution combines Anritsu’s Signal Quality Analyzer-R MP1900A BERT series with GRL’s PCI Express 5.0 CEM Specification Receiver and PLL Peaking and Bandwidth test automation software. The Anritsu and GRL solution offer product developers a fast and flexible way to test PCIe 5.0 Host and Add-In Card designs with any Tektronix or Keysight real-rime oscilloscope. The solution compliments GRL’s PCIe 5.0 CEM Transmitter test automation software, also approved by the PCI-SIG for “gold suite” compliance testing, and PCIe 5.0 Base Specification Receiver software , both compatible with Tektronix and Keysight scopes.

Reducing equipment calibration and test time

The GRL software’s simple user interface automates complex PCIe specification testing and significantly reduces the time requires for equipment calibration and testing. In accordance with the PCIe 5.0 CEM specification, the software features automated calibration of signal impairments to achieve stressed Receiver Eye Height and Eye Width, and performs PCIe TX and RX Link Equalization (Link EQ) and PLL Peaking and Bandwidth tests at 8, 16, and 32GT/s. All PCIe CEM compliance tests are automated in a single software framework.

Controlling the cost of test infrastructure

The Anritsu Signal Quality Analyzer-R MP1900A series is a multi-channel BERT for designing and testing next-generation network interfaces, such as 200G/400G/800G Ethernet and high-speed bus interfaces like PCI Express 4.0/5.0 specifications, USB3.2, USB4™, and Thunderbolt™.

Built in PPGs (pulse pattern generators) and error detectors (EDs) allow the MP1900A BERT to generate high-quality waveforms with low intrinsic jitter (115 fs). The instrument also features an integrated jitter generation source (SJ, RJ, SSC, BUJ) and a CM-I/DM-I/white-noise generation source. Along with compliance tests, margin tests, and troubleshooting, the unit also supports variety of other applications, including Link Training and Link Training Status State Machine (LTSSM) analysis functions.

In addition to testing PAM4 optical modules, SERDES, and other technologies used by data center 200G/400G/800G Ethernet systems, the MP1900A BERT also tests PCIe 6.0 (PAM4 32 Gbaud) devices under development to ensure compliance with the latest PCI-SIG standard. This allows enterprises to keep the cost of test infrastructure under control.

"The PCI-SIG appreciates GRL’s continued contributions to the development of PCI Express technology," said Al Yanes, Chairperson and President of PCI-SIG. "GRL's support of PCIe 5.0 Compliance Testing helps our members deliver products to market that are compliant to the specification, interoperable, and robust in applications.”

“Anritsu’s partnership with GRL offers a versatile PCI Express compliance test environment for multi-scope vendors,” said Kohei Ota, General Manager of Anritsu’s Service Infrastructure Solutions Division. “Looking ahead, we also plan to support PCIe 6.0 specification at 64 GT/s to drive innovation in 5G, cloud computing, hyperscale data centers.”

“GRL works closely with PCI-SIG and Anritsu Corporation to help our customers ensure that their products seamlessly interoperate across the entire electronics ecosystem,” said Miki Takahashi, GRL Executive Vice President of Engineering. “Our automated test solution for PCI Express 5.0 specification is part of that vision. It simplifies and accelerates testing designs to the PCIe Base and CEM Specifications, and offers product developers unprecedented flexibility to choose equipment while reducing technical risks and delivering consistent test results.”

About Granite River Labs

Founded in Silicon Valley in 2010, Granite River Labs (GRL) is the world’s leading Engineering Services and Test Automation Solutions firm for connectivity and charging. GRL helps engineers solve tough design and validation challenges. GRL was founded with a vision to provide affordable test services to help hardware developers implement digital interface technologies as they become faster, more complex, and more challenging to test. Today, GRL has worked with hundreds of companies supporting the adoption of new and emerging technologies from their worldwide test facilities and R&D centers.

GRL's combination of market-leading technical expertise, broad capabilities across connectivity and charging technologies, and intense focus on quality and customer service excellence has led to rapid growth and recognition as the "go to" expert.

For more information, visit https://bit.ly/3z9nRFu

About PCI-SIG

PCI-SIG is the consortium that owns and manages PCI specifications as open industry standards. The organization defines industry standard I/O (input/output) specifications consistent with the needs of its members. Currently, PCI-SIG is comprised of over 900 industry-leading member companies. To join PCI-SIG, and for a list of the Board of Directors, visit www.pcisig.com.

PCI-SIG, PCI Express, and PCIe are trademarks or registered trademarks of PCI-SIG. All other trademarks are the property of their respective owners.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 125 years. Anritsu’s philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems. The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 4,000 employees in over 90 countries.