Super User

Anellotech Demonstrates New Direct Route to Light Olefins and BTX from Conversion of Mixed Plastic Waste in 0.5 TPD Pilot Plant

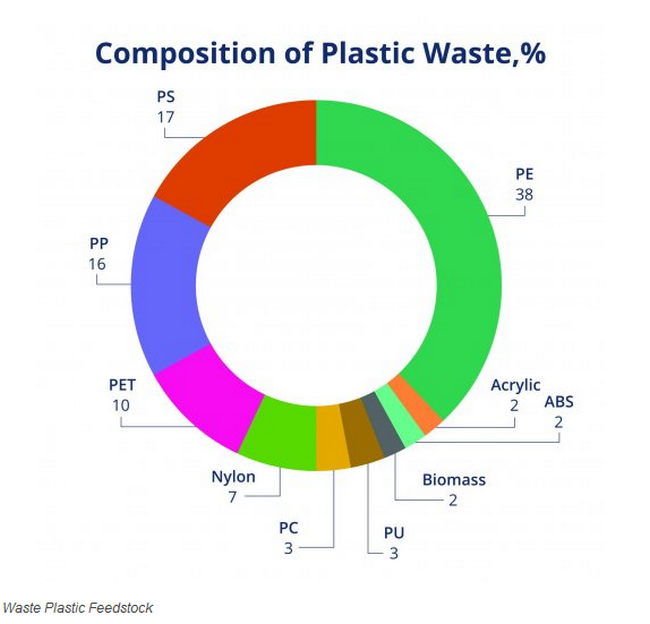

Anellotech is pleased to announce that it has, for the first time, continuously processed solid, post-consumer plastic waste into light olefins and aromatics using its Plas-TCat™ catalytic pyrolysis technology. The waste consisted of a mixture of all major plastic types (Figure 1), with the exception of polyvinyl chloride (PVC).

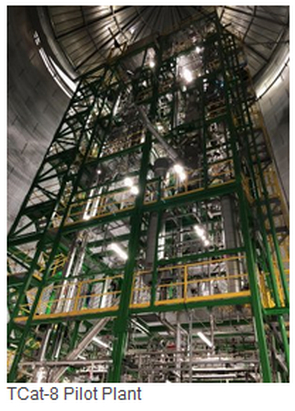

The processing trial took place at Anellotech’s TCat-8TM fully automated, 30 meter tall pilot plant near Houston, Texas (Figure 2, video here). That plant’s nameplate capacity is 0.5 tons per day, and Plas-TCat’s scalable fluidized bed reactor design provides a path to larger commercial production plants capable of addressing substantial global recycling goals.

Plas-TCat employs one thermal catalytic reactor to convert a broad range of mixed waste plastics into the same valuable chemical feedstocks used today to make virgin plastics. These include benzene, toluene and xylene (BTX) as well as ethylene, propylene and butylene (light olefins). Based on a proprietary catalyst and fluid bed reactor-regenerator system, Plas-TCat provides a new, direct route to light olefins and aromatics from heterogeneous plastic waste streams—without the need for steam cracker furnaces.

Plas-TCat employs one thermal catalytic reactor to convert a broad range of mixed waste plastics into the same valuable chemical feedstocks used today to make virgin plastics. These include benzene, toluene and xylene (BTX) as well as ethylene, propylene and butylene (light olefins). Based on a proprietary catalyst and fluid bed reactor-regenerator system, Plas-TCat provides a new, direct route to light olefins and aromatics from heterogeneous plastic waste streams—without the need for steam cracker furnaces.

The technology can effectively process a wide range of waste plastics, alone or within composites. This includes polyolefins, polyamides (nylon), PET, polycarbonate and polystyrene. With the completion of these continuous process runs Plas-TCat is now at Technology Readiness Level (“TRL”) 6. Trials planned for later in 2022 will be run to confirm promising laboratory yields for Plas-TCat (see Plas-TCat update and Anellotech presentation).

“Plas-TCat is advantageous due to its high olefin and aromatic hydrocarbon selectivity, high scalability, broad feedstock tolerance, as well as its substantial carbon dioxide emissions savings compared to industrial steam crackers,” says David Sudolsky, President and CEO of Anellotech. “The TCat-8 unit will be used in future month-long 24/7 trials to prove the robustness of the process and generate process performance data over an equilibrated catalyst, which are required to design a commercial plant.”

About Anellotech

Founded in 2008, Anellotech (http://www.anellotech.com) is a sustainable technology company focused on commercializing the innovative production of cost-competitive renewable chemicals and fuels from non-food biomass or waste plastics. It’s fully-developed and patented Bio-TCat™ technology is an efficient thermal catalytic process for converting biomass into benzene, toluene and xylene, which are chemically identical to their petroleum-based counterparts. In addition to BTX, Bio-TCat produces heavier aromatics, which can be used to make high-quality biofuels blendstock for transportation fuel to help decarbonize transportation fuels supply chains. Anellotech’s R&D team is now focused on Plas-TCat™, an emerging process technology that converts mixed waste plastics into commodity chemicals such as olefins and aromatics, the primary chemicals used to make plastic packaging and other products

PulPac continues to push the Dry Molded Fiber technology development forward – EPO announces new intention to grant patent

PullPac has received yet another intention to grant from the EPO (European Patent Office), further refining its pioneering cellulose forming technology for competitive fiber-based packaging and single-use products

The new intention to grant comprises a method for producing discrete three-dimensional cellulose products from an air-formed cellulose blank structure in a rotary forming mould system.

Peter Ekwall, Chief Intellectual Property Officer at PulPac explains “We continue to use the already established air-formed cellulose blank structure, but now it is fed to the rotary forming mould and we apply a forming temperature in the range of 100°C to 300°C and a forming pressure of at least 1 MPa, preferably 4-20 MPa”

Dry Molded Fiber sample lids - showing examples of applications that can be made with the pioneering fiber forming technology developed by PulPac.

Dry Molded Fiber sample lids - showing examples of applications that can be made with the pioneering fiber forming technology developed by PulPac.

PulPac continuously develops its already established Dry Molded Fiber technology, and the rotary forming system will pose a viable alternative for certain products going forward.

“We continue to add value to Dry Molded Fiber and keep our licensees at the forefront of fiber forming by constantly pushing technology development forward. In addition to the 30 patent families with 119 granted national patents and plus 50 pending patent applications, I expect an average of two new patent applications a month going forward”, Ekwall continues.

Dry Molded Fiber is a fiber forming technology that can replace single-use plastic with sustainable fiber-based alternatives at low cost.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy – using renewable pulp and cellulose resources to produce low cost, high performance, fiber-based packaging, and single-use products. Dry Molded Fiber gives up to 80-90% lower CO2 footprint at similar cost as plastic. It is up to ten times as efficient as conventional fiber molding invented over 100 years ago. The dry process also saves massive amounts of valuable water resources. In addition, energy savings are significant - as the molded products need no drying.

MRCE orders 14 Vectron locomotives from Siemens Mobility

Mitsui Rail Capital Europe (MRCE), a full-service locomotive leasing company, has ordered 14 Vectron MS multisystem locomotives from Siemens Mobility on the basis of an existing contract. With this order, MRCE will have a fleet of 147 Vectrons. MRCE plans to use the locomotives in Germany, Austria, Hungary, Poland, the Czech Republic, Slovakia, Romania, and the Netherlands.

- Delivery of 14 Vectron MS multisystem locomotives

- MRCE fleet includes 147 Vectron locomotives

“We are especially pleased that our long-standing customer MRCE is further expanding its fleet of Vectrons. MCRE’s trust in us shows that our Vectron locomotives stand for reliability and flexibility in European passenger and freight transport,” said Albrecht Neumann, CEO Rolling Stock at Siemens Mobility.

"We believe that Vectron will be the solution in the long run for meeting future cross-border needs in the European market, and we intend to steadily increase our Vectron fleet as a main asset in our portfolio," said Hayato Yanagisawa, CEO of MRCE.

The multisystem locomotives ordered by MRCE have a maximum power at wheel of 6.4 megawatts and a top speed of 160 km/h. The locomotives will be manufactured at the Siemens Mobility plant in Munich-Allach, and equipped with the European Train Control System (ETCS) as well as the required national train control systems.

Since their introduction, Siemens Mobility has sold more than 1,500 Vectron locomotives to 62 customers in 16 countries. The Vectron fleet has covered more than 600 million kilometers in service to date and the locomotives are approved for operating in 20 European countries.

Siemens Mobility is a separately managed company of Siemens AG. As a leader in transport solutions for more than 160 years, Siemens Mobility is constantly innovating its portfolio in its core areas of rolling stock, rail automation and electrification, turnkey systems, intelligent traffic systems as well as related services. With digitalization, Siemens Mobility is enabling mobility operators worldwide to make infrastructure intelligent, increase value sustainably over the entire lifecycle, enhance passenger experience and guarantee availability. In fiscal year 2021, which ended on September 30, 2021, Siemens Mobility posted revenue of €9.2 billion and had around 39,500 employees worldwide. Further information is available at: www.siemens.com/mobility.

Mitsui Rail Capital Europe (MRCE) has the biggest fleet of modern cross-border locomotives in Europe. The fleet consist of over 300 electric locomotives. The product offered by MRCE is special as it combines the leasing and maintenance management of locomotives. MRCE is a subsidiary of the Japanese Mitsui & Co., Ltd. and has strategically divided its business over the headquarters in Amsterdam and Munich. The MRCE Head office in Amsterdam is responsible for operational leasing, procurement, financing and sales of locomotives. The office in Munich manages the maintenance and technical servicing of the locomotive fleet. https://www.mrce.eu/

Norway: Northern Lights Project Signs World's First Commercial Agreement on Cross-Border CO2 Transport and Storage

TotalEnergies announces the signature of a commercial agreement between Northern Lights and Yara to transport and store CO2 captured from Yara Sluiskil, an ammonia and fertilizer plant in the Netherlands.

From early 2025, 800,000 tons of CO2 per year will be captured, compressed, and liquefied in the Netherlands and then transported to the Northern Lights site to be permanently stored in geological layers some 2,600 meters under the seabed off the coast of Øygarden, in Norway.

This agreement, the first of its kind worldwide, is a major milestone in the decarbonization of heavy industry in Europe, paving the way for international CO2 transport and storage as a service. It sets a new standard for European industrial companies looking to use Northern Lights solutions as part of their decarbonization strategies.

"Developing CO2 transportation and storage services is crucial for decarbonizing European industry: we are pleased to welcome Yara as first commercial partner for Northern Lights, which will help support its decarbonization strategy," said Patrick Pouyanné, Chairman and Chief Executive Officer of TotalEnergies. " TotalEnergies aims to develop a CO2 storage capacity of more than 10 million tons per year by 2030, both for its own facilities and for its customers, in line with its ambition to get to net zero by 2050, together with society."

"Yara, our first commercial customer, will fill the available capacity of Northern Lights Phase 1. This agreement will establish a market for CO2 transport and storage. From early 2025, we will be shipping the first tons of CO2 from the Netherlands to Norway. This will demonstrate that CCS is a climate tool for Europe," said Børre Jacobsen, Northern Lights Managing Director.

"We urgently need to take action to decarbonize industry, and Yara is a frontrunner in the field. I am very pleased to announce that we are now on our way to removing CO2 emissions from our production plant in Sluiskil. This will take us a step closer to carbon-free food production and accelerate the supply of clean ammonia for fuel and power production," said Svein Tore Holsether, CEO of Yara International.

The Northern Lights Project

As the first project to create a cross-border value chain, Northern Lights is designed to give European industrial companies a solution for safely and permanently storing their CO2 emissions underground. The Phase 1 installations are scheduled to come on stream in 2024, with the ability to handle 1.5 million tons of CO2 per year. Several industries have shown growing interest in these services. As a result, additional capacity will be developed to accommodate rising demand, up to 5 million tons per year. Northern Lights is owned in equal shares by TotalEnergies, Equinor and Shell.

TotalEnergies and Carbon Capture and Storage (CCS)

TotalEnergies’ focus is first to avoid then to reduce its emissions by developing and deploying a systematic approach, asset-by-asset, to implement the best available technologies. In particular, the Company is developing industrial projects for carbon capture, transport, and storage (CCS). Backed by core competencies in large-scale project management, gas processing and geosciences, TotalEnergies is on track to achieve its ambition of developing storage capacity of 10 million metric tons of CO2 per year by 2030 through significant industrial projects such as Northern Lights in Norway and Aramis in the Netherlands. Through all its CCS projects, the Company will reduce its own emissions and those of its customers.

Flexibility Key to Addressing Rising Colo Energy Costs

Deteriorating bottom line costs for colocation data centres (colos) caused by market uncertainty has further underlined the need for facility stakeholders to consider flexible energy models in the future, according to Aggreko

It follows a new report from FTI Consulting showing energy prices in UK data centres rising by over 600% since January 2021. With this figure tracking markedly higher than Germany (270%), France (400%) and the Netherlands (360%), the impact on data centre providers using all-in customer models could be sharp and wide-ranging.

It follows a new report from FTI Consulting showing energy prices in UK data centres rising by over 600% since January 2021. With this figure tracking markedly higher than Germany (270%), France (400%) and the Netherlands (360%), the impact on data centre providers using all-in customer models could be sharp and wide-ranging.

Taking this market turbulence into account, Aggreko is encouraging retail colo providers to put steps in place to address what could become a pressing crisis as fixed-price energy contracts expire. Billy Durie, Global Sector Head for Data Centres at Aggreko, explains: “Though the UK data centre market has previously been able to use these previously-agreed terms to largely guard against rising energy costs, this state of affairs cannot continue forever.

“Providers in the colo market working under all-in pricing agreements are especially vulnerable to this encroaching problem, so energy professionals in the sector must ask themselves – how can we guard against this cost? Faced with this question, we anticipate moves toward decentralised energy models to mitigate against the fragility of the national grid, especially as current price hikes are not showing signs of easing.”

Energy-related market turbulence identified in FTI Consulting’s report could further supercharge an already-competitive colo marketplace, driven by exponential demand for data centre services. According to Aggreko, current volatility cannot be translated into a race-to-the-bottom cost mentality, and the deprioritisation of environmental goals that may ensue.

“It cannot be denied that the data centre market is currently in a delicate position, but these pressing concerns should not be met at the cost of long-term sustainability strategies,” Billy concludes. “Instead, stakeholders must look for packages and services that can bridge the energy gap while lowering emissions. Green technologies such as Stage V generators and hybrid battery systems, provided through innovative hire strategies, offer an effective way of achieving both objectives.”

For more information on Aggreko’s data centre services, click here.

Mitsubishi Electric to Establish New Factory in India for Factory Automation Control System Products

Mitsubishi Electric Corporation (TOKYO: 6503) announced on 7th June 2022 that it will invest approximately 3.1 billion yen, or 21.8 million euros, in its subsidiary Mitsubishi Electric India Pvt. Ltd. to establish a new factory in India. Expected to start operations in December 2023, the new factory will manufacture inverters and other factory automation (FA) control system products, expanding the company´s capabilities to meet the growing demand in India. The rapidly growing Indian market is expanding at an annual rate of about 8% mainly in industries such as automobiles, food & beverage, pharmaceuticals, data centers, and textiles, with further market expansion expected in the future.

Mitsubishi Electric´s FA control systems business in India began in the mid-1990s, and since acquiring a local manufacturer of FA control systems in 2012, the company has continued to strengthen its local business structure by establishing a local engineering team, expanding service and support capabilities, and in 2013, starting local manufacturing of products.

The new two-floor, 15,400 square-meter factory will be built on 40,000 square meters of land near Pune, Maharashtra, and will help expand Mitsubishi Electric´s production capabilities to meet local demand for products, and also contribute to the Make in India initiative promoted by the Indian government.

Mitsubishi Electrics New Factory in India

Mitsubishi Electrics New Factory in India

In addition, the new factory will incorporate various features aiming to achieve carbon neutrality by reducing carbon dioxide emissions through the use of highly efficient air conditioning systems and LED lighting equipment and meet sustainable development goals (SDGs) by reusing wastewater through underground filtration treatment and greening.

About Mitsubishi Electric Corporation

With more than 100 years of experience in providing reliable, high-quality products, Mitsubishi Electric Corporation (TOKYO: 6503) is a recognized world leader in the manufacture, marketing and sales of electrical and electronic equipment used in information processing and communications, space development and satellite communications, consumer electronics, industrial technology, energy, transportation and building equipment. Mitsubishi Electric enriches society with technology in the spirit of its “Changes for the Better.” The company recorded a revenue of 4.476,7 billion yen (U.S.$ 36,7 billion*) in the fiscal year ended March 31, 2022. For more information please visit http://www.MitsubishiElectric.com.

About Mitsubishi Electric Factory Automation Business Group

Offering a vast range of automation and processing technologies, including controllers, drive products, power distribution and control products, electrical discharge machines, laser processing machines, computerized numerical controllers, and industrial robots, Mitsubishi Electric helps bring higher productivity – and quality – to the factory floor. In addition, our extensive service networks around the globe provide direct communication and comprehensive support to customers.

About Factory Automation EMEA

Mitsubishi Electric Europe B.V., Factory Automation EMEA has its European headquarters in Ratingen near Dusseldorf, Germany. It is a part of Mitsubishi Electric Europe B.V. that has been represented in Germany since 1978, a wholly owned subsidiary of Mitsubishi Electric Corporation, Japan.

The role of Factory Automation EMEA is to manage sales, service and support across its network of local branches and distributors throughout the EMEA region. For more information, please visit: emea.mitsubishielectric.com/fa

About e-F@ctory>

e-F@ctory is Mitsubishi Electric’s integrated concept to build reliable and flexible manufacturing systems that enable users to achieve many of their high speed, information driven manufacturing aspirations. Through its partner solution activity, the e-F@ctory Alliance, and its work with open network associations such as The CC-Link Partners Association (CLPA), users can build comprehensive solutions based on a wide ranging “best in class” principle.

In summary, e-F@ctory and the e-F@ctory Alliance enable customers to achieve integrated manufacturing but still retain the ability to choose the most optimal suppliers and solutions.

Further Information:

https://emea.mitsubishielectric.com/fa

Kemi Shipping orders eight Konecranes E-VER electric forklifts to its fleet in northern Finland

Kemi Shipping Oy, owned by Finnish Metsä Group, has ordered eight award-winning Konecranes E-VER fully electric forklifts including full service contracts for their operations in the Port of Kemi. Highly impressed with an E-VER delivered early in 2022, the Finnish logistics company is strengthening operations with an additional order. The order was received in June 2022 and will be delivered in the first half of 2023.

Kemi Shipping provides a range of harbor services for customers in the region. With Metsä opening a new mill for bioproducts in the north, Kemi Shipping is taking the step to invest in new lift trucks for their new warehouse operations. The port facility is big and will benefit from the eight Konecranes E-VER electric forklifts that will serve the mill with their product handling as it reaches full production capacity.

“Sustainability is at the core of our business, so the first thing that attracted us to the Konecranes E-VER was the fact that it is fully electric,” says Kari Lundell, CEO of Kemi Shipping. “We had one Konecranes E-VER delivered earlier this year for paper board handling, and we could see its advantages immediately. Besides eliminating tailpipe emissions, it offers outstanding efficiency, and our drivers love it. Once all eight E-VER electric forklifts are on-site, they will mark another big step on our journey to greater productivity and lower emissions.”

“Kemi Shipping has been a loyal Konecranes customer for over two decades, sharing our mutual commitment to the environment” says Klaus Kaukovalta, Product Manager, Lift Trucks for Konecranes Finland. “Konecranes E-VER, that won the sawmill industry Product Novelty Competition for improving the environmental performance, gives us the perfect opportunity to provide Kemi Shipping equipment that meets their specific requirements in a demanding industry.”

The eight additional lift trucks are Konecranes E-VER 16-1200C forklifts, with a fully-electric driveline and a capacity of 16 tons. Lithium-ion batteries manufactured with clean energy power each truck, taking just 45 minutes to fully recharge and re-generating brake energy back to its battery. With less heat, oil and fewer moving parts, the electric forklift requires less maintenance, and produces less chemical waste. The trucks will be supplied with special bale clamps to securely handle wood pulp.

These Konecranes E-VER electric forklifts are also Smart Connected Lift Trucks, in which TRUCONNECT® Remote Monitoring follows each truck’s performance and maximizes battery life through analytics such as charge optimization and energy consumption.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totaled EUR 3.2 billion. The Group has around 16,600 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

PP Control & Automation launches PP+ to help bridge ‘valley of death’

One of the UK’s leading strategic manufacturing outsourcing specialists is aiming to help domestic businesses cross the well-publicised ‘valley of death.

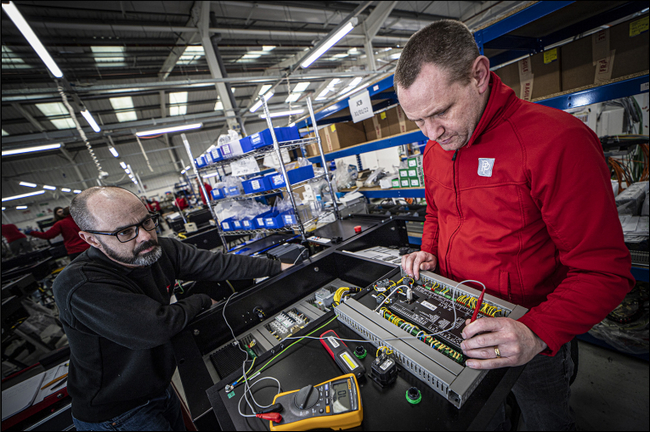

PP Control & Automation (PP C&A), which already works with over 20 of the world’s leading machinery manufacturers, is launching PP+, a unique ecosystem of experts that will help start-ups, SMEs and multi-nationals take advantage of scale-up opportunities and the commercialisation of new technologies.

The initiative works by offering a single point of contact for management teams that, after an initial consultation, will be connected to market leaders in design, engineering, legislation and approvals, sales and marketing and PR.

They will also receive support in accessing funding, management coaching and a clear route to some of the best academic and R&D knowledge in the UK.

Already signed up to deliver their expertise are Cucumber PR, Institute for Clean Growth & Future Mobility at Coventry University, the Manufacturing Assembly Network (MAN), Product Approvals, S2F Marketing and the Silverstone Technology Cluster.

Tony Hague, CEO of PP C&A, said: “The UK has a wealth of innovative engineering and manufacturing companies that often come up with new concepts and ideas that have true commercialisation potential and the opportunity to scale – however, they simply don’t have the capacity or additional expertise to realise these fantastic ideas.

“We have seen first-hand these challenges are often down to lack of available resource, advice and ‘bandwidth’ and we want to do something to change this.”

He continued: “Utilising our wider network of partners, we have put some real thought and energy into how we can develop our unique outsourcing offer so we can help support and signpost as many organisations as we can to ensure growth and prosperity within UK manufacturing.”

The PP+ ecosystem starts with an initial discovery session to outline the business goals of the client, the market opportunity and any potential barriers to success.

This is facilitated by PP C&A, S2F Marketing and Cucumber PR, with a clear strategy formulated that identifies where access to the wider network of experts is required.

To unlock their potential, they’ll need scaling-up coaching, sales consultation, and marketing and PR strategy.

Furthermore, as they grow, there will be opportunity to enter international markets where legislative demands bring new challenges and complexity, as well as a need to make efficiencies through design optimisation and access to academia and engineering groups.

“PP C&A can be the key to this sought-after access thanks to its well-established partner network,” continued Tony.

“New market footholds generally exist where disruptive innovations originate, and novel technologies can be deployed to change the way a sector or even the world behaves.

“This disruption is often the starting point, but there is only a small window of opportunity to make sure this same disruption becomes a sustainable business.”

He added: “PP+ is here to deliver immediate expertise, knowledge and a track record of bringing new products to market. It’s all about unlocking and commercialising the ideas to make UK manufacturing stronger and more successful.”

Pim van Baarsen, CEO of Silverstone Technology Cluster (STC), offered his support: “I’m delighted that we can be part of this venture and we look forward to working with Tony and the rest of the team to help the UK prosper.

“It’s great to see PP C&A setting up initiatives like PP+, which will undoubtedly prove valuable for early-stage innovators and fast-growing companies that could really use the expertise on offer.

“The STC has a vast network of relevant businesses that we can connect people to, in order to get their projects off the ground, both from a technological, as well as a management and finance point of view.”

Just a week into the launch and PP Control & Automation is already in conversation with several potential users of the new ecosystem.

It is also exploring extending the network even further to encompass even more specialisms.

For further information, please visit www.ppcanda.com

Puntomaq SA becomes the latest representative of the Metso Outotec distribution network for Bolivia

Puntomaq SA has joined the aggregates community as the latest member of the Metso Outotec distribution network. Puntomaq will represent Metso Outotec’s full range of fixed and mobile equipment, such as Nordtrack™ mobile crushers, screens and conveyors and NW Rapid™ portable crushers and screens, in addition to aftermarket support and services, including screening media and O-Series spare and wear parts.

“Metso Outotec is excited to be part of the growing demand for aggregates solutions in Bolivia,” shares Benjamin Lhorente, Head of Distribution Sales for Mexico, Central & South America at Metso Outotec. “Puntomaq’s customer base already shows interest in our offering, and we are confident this partnership will continue to be a successful match.”

“We have a dedicated heavy machinery market that relies on Puntomaq for access to premium products and technical support,” says Daniel Subieta, General Manager, at Puntomaq. “Metso Outotec products and services complement our current expertise and will allow us to expand our business into the aggregates sector.”

Puntomaq also serves construction, oil and mining customers. Learn more at their website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies. Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Vattenfall and St1 form a new partnership

Vattenfall and St1 have signed a Letter of Intent to develop a fossil-free value chain for the production of synthetic electro fuel and the next step is to jointly conduct a feasibility study. The study aims at addressing the full value chain for the production of electro fuel from offshore wind, starting in 2029 and gradually growing towards the target of one million cubic meters.

Vattenfall and St1 will jointly conduct a feasibility study with the ambition to develop a fossil-free value chain for the production of electro fuel, through offshore wind. In the partnership, Vattenfall aims to develop an offshore wind power-based hydrogen supply infrastructure on the west coast of Sweden and St1 plans to produce one million cubic meters of electro fuels, primarily targeted for sustainable aviation fuel using fossil-free hydrogen. Such volumes equal for example the annual aviation fuel demand of Arlanda airport. First drops starting from 2029 and onwards.

"I’m very glad we are partnering with St1, two companies sharing the ambition to fight climate change. For Vattenfall, the electrification of society and industry is at the core of our business strategy. The development and optimisation of value chains based on offshore wind and fossil-free hydrogen is an interesting way forward. Our strong and growing Swedish offshore wind development portfolio of currently more than 20 TWh offers ample opportunities”, says Anna Borg, President and CEO of Vattenfall.

Two-thirds of Swedish carbon dioxide emissions today come from industry and transport. Together with industries, Vattenfall works actively with direct electrification and indirect electrification, using fossil-free hydrogen gas. Vattenfall sees huge potential for decarbonisation on the Swedish West coast for industries like refinery and petrochemicals.

“Energy companies need to show leadership in bravely promoting and developing scalable game-changing solutions. We are very proud of the partnership with Vattenfall, as we share true dedication to deliver together this significant breakthrough in the energy transition. Strategic long-term partnerships in various areas are the key elements in the implementation of St1’s sustainable fuels investment program and it shows the importance of industry collaboration across several value chains to meet the ambitious Nordic climate targets”, says Henrikki Talvitie, CEO of St1 Nordic Oy.

In the spirit of its vision, St1 is already investing in energy transition through scalable renewable energy production. A new biorefinery is under construction on the St1 refinery site in Gothenburg. The biorefinery will have an annual capacity of 200,000 tonnes of renewable fuel production and is expected to commence its operations in 2023. It is designed to optimize the production of renewable diesel and sustainable aviation fuel. St1 already produces advanced ethanol and biogas from waste.

Vattenfall is a leading European energy company, which has electrified industries, supplied energy to people’s homes, and modernised our way of living through innovation and cooperation for over 100 years. We now want to make fossil-free living possible within one generation. That's why we are driving the transition to a sustainable energy system through initiatives in renewable production and climate smart energy solutions for our customers. We employ approximately 19,000 people and our operations are mainly based in Sweden, Germany, the Netherlands, Denmark and the UK. Vattenfall is owned by the Swedish state. For more information: corporate.vattenfall.se

St1 Nordic Oy is an energy group whose vision is to be the leading producer and seller of CO2-aware energy. The Group researches and develops economically viable, environmentally sustainable energy solutions. St1 focuses on fuel marketing activities, oil refining and renewable energy solutions such as waste-based advanced biofuels and industrial wind power. The Group has 1290 St1 and Shell branded retail stations and gas filling points in Finland, Sweden and Norway. Headquartered in Helsinki, St1 employs currently more than 1200 people. www.st1.com