Super User

Mitsubishi Power Selects Emerson Software and Technologies for Advanced Clean Energy Storage Hydrogen Hub

Integrated control and safety platform optimizes world’s largest green hydrogen production and storage facility and supports reliable, clean power generation

Mitsubishi Power Americas, Inc. has selected Emerson (NYSE: EMR), a global software and engineering leader, to automate the world’s largest green hydrogen production and storage facility. The industry-leading hub will help integrate renewable energy by producing and storing green hydrogen for long duration energy storage. Mitsubishi Power will leverage Emerson’s hydrogen production experience and automation software expertise to increase safety, decrease costs and simplify maintenance across the life cycle of the facility.

Excess renewable energy generated during the winter and spring is difficult and costly to store in its native state for use during the peak summer season and, as a result, is wasted. The Advanced Clean Energy Storage hub will use renewable electricity to power electrolyzers to produce green hydrogen. The produced hydrogen will be stored underground in salt caverns so that it can be dispatched when required to generate clean electricity from hydrogen-fueled turbines, which will help stabilize the grid with sustainable sources and create a new pathway to decarbonization of the western United States.

“Generating, storing and transmitting electricity with zero carbon emissions is critical to meeting the world’s sustainable power generation needs,” said Michael Ducker, senior vice president of Hydrogen Infrastructure for Mitsubishi Power Americas and president of Advanced Clean Energy Storage I. “Emerson’s hydrogen expertise and digitally connected architecture design will help shorten time to start up, while also developing a safe, reliable and easily scalable transmission system to meet our goals for renewable energy production and storage.”

“Generating, storing and transmitting electricity with zero carbon emissions is critical to meeting the world’s sustainable power generation needs,” said Michael Ducker, senior vice president of Hydrogen Infrastructure for Mitsubishi Power Americas and president of Advanced Clean Energy Storage I. “Emerson’s hydrogen expertise and digitally connected architecture design will help shorten time to start up, while also developing a safe, reliable and easily scalable transmission system to meet our goals for renewable energy production and storage.”

The Advanced Clean Energy Storage hub will convert renewable energy through the 220-megawatt (MW) electrolyzer bank to produce up to 100 tons of green hydrogen per day. The facility will have storage for 300 gigawatt hours (GWh) of energy in two salt caverns. In comparison, the battery storage capacity across the United States is 2-GWh via lithium-ion batteries. The Advanced Clean Energy Storage hub has space for up to 100 caverns.

This first-of-its-kind integrated facility will provide short- and long-duration hydrogen storage for use during peak seasons and throughout the year at the nearby 840-MW Intermountain Power Project (IPP Renewed). IPP Renewed will use 30% (vol) hydrogen fuel in Mitsubishi Power M501JAC gas turbines at start up, transitioning to 100% (vol) hydrogen by 2045. Emerson and Mitsubishi Power are collaborating on digital solutions for IPP Renewed to optimize plant performance, improve reliability and create cleaner, more reliable power.

“One of the most complex issues in power distribution is successfully managing variability of demand and supply to reduce stress on the grid,” said Bob Yeager, president of Emerson’s power and water business. “Mitsubishi Power has successfully leveraged the digital automation stack to develop an innovative, sustainable way to solve that problem, enabling providers to consistently use peak-production renewable energy in peak-consumption hours.”

Mitsubishi Power will use Emerson’s Ovation™ integrated control and safety platform to optimize the Advanced Clean Energy Storage hub’s production efficiency and help ensure safe operations. The Ovation platform will provide reliable control and monitoring of the renewable hydrogen production process and emergency shutdown, fire and gas protection. The platform will also gather and contextualize data from the plant’s wide variety of third-party systems to help eliminate complexity and risk. Emerson’s PACSystems™ RSTi-EP I/O will provide easier field connectivity and help facilitate project changes without extending timelines or increasing cost, while AMS Device Manager will help monitor the health of plant assets to improve safety, reliability, efficiency and sustainability.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and software company providing innovative solutions for customers in industrial, commercial and residential markets. Our Automation Solutions business helps process, hybrid and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency and create sustainable infrastructure. For more information visit Emerson.com.

Sulzer to write off assets in Russia and Poland

Following the Board’s decision to initiate the process of exiting the Russian market and the closing of the Polish businesses, the company has decided to write off most of its assets in both countries. After careful analysis of all options, Sulzer expects a one-time impact in the range of CHF 125m to CHF 135m at current foreign exchange rates. CHF 125m will be recognized in H1 of 2022.

Following the Board’s decision to initiate the process of exiting the Russian market and the closing of the Polish businesses, the company has decided to write off most of its assets in both countries. After careful analysis of all options, Sulzer expects a one-time impact in the range of CHF 125m to CHF 135m at current foreign exchange rates. CHF 125m will be recognized in H1 of 2022.

The one-time asset write-offs will have no significant impact on Sulzer’s operational results, however on Net Income, which was CHF 86m for H1 2021 and CHF 141m for the full year, respectively. Sulzer will report its H1 results on July 29, 2022.

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and purification technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com

Investor Relations: Christoph Ladner, Head of Investor Relations

Phone +41 52 262 30 22, This email address is being protected from spambots. You need JavaScript enabled to view it.

Edge Solutions looks to USA with Rope Partner tie up

Scots firm Edge Solutions has announced a partnership with Colorado wind turbine maintenance specialist Rope Partner to roll out their Armour Edge leading edge protection in the USA.

Scots firm Edge Solutions has announced a partnership with Colorado wind turbine maintenance specialist Rope Partner to roll out their Armour Edge leading edge protection in the USA.

Armour Edge is a highly durable leading-edge protection shield that uses an ultra-tough thermoplastic material created specifically for wind turbine blades.

The shields are operating successfully at a number of offshore wind farms in the Baltic and North Seas and the company is now targeting the US onshore market.

It is understood Rope Partner and Armour Edge are targeting customer trials this year, with the goal of new orders in 2023.

“Feedback from technicians in Europe has been uniformly positive and we believe the durability of Armour Edge coupled with the speed and ease of installation will be of strong appeal to the US market,” says Edge Solutions Managing Director David Urch.

“Feedback from technicians in Europe has been uniformly positive and we believe the durability of Armour Edge coupled with the speed and ease of installation will be of strong appeal to the US market,” says Edge Solutions Managing Director David Urch.

“Rope Partner is an innovative company with a strong commitment to safety and training and we are working closely with their expert technicians to ensure they are fully trained in the application of Armour Edge. We look forward to seeing rollout commence in the field.”

Eric Stanfield, CEO of Rope Partner says:

“This new collaboration underscores our ongoing commitment to deliver the highest quality services to our customers to maximize the value of their projects.

“Based on Armour Edge’s success in Europe, we’re confident in the immense value these innovative shields will offer our US customers.”

A recent study by the UK ORE Catapult predicted the shields could have an operational lifetime in excess of 50 years.

About Edge Solutions

Scottish company Edge Solutions has developed its Armour Edge shield which is a game-changing approach to the costly problem of leading-edge erosion on wind turbine blades. Its precision engineered shields securely bond to the leading edge of blades to provide a simple to install, aerodynamically optimal, full-life protection that minimizes maintenance costs and maximizes energy production and return on investment.

About Rope Partner

Rope Partner is the premier provider of rope access maintenance, inspection and performance enhancement services for wind turbines, with a reputation for uncompromising safety and high-quality results. The rapid-response WindCorps® technicians have completed many thousands of projects for every major manufacturer and the majority of wind farm owners. By partnering with clients, applying safe, cost effective, and environmentally appropriate solutions Rope Partner is reducing turbine downtime, increasing production-based availability and ultimately the life-span of its client’s turbines.

TAQA Group successfully completes large-scale offshore decommissioning project in Brae Field

Removal, dismantling and disposal of Brae Alpha West Drilling Rig and removal of Brae Bravo upper main jacket completed successfully

Abu Dhabi National Energy Company PJSC (TAQA), one of the largest listed integrated utility companies in the Europe, the Middle East and Africa region, today announced it has completed the safe and successful removal of the Brae Alpha West drilling rig (Rig 1) and the Brae Bravo upper main jacket in the Northern North Sea.

The operation, which was the latest in TAQA’s extensive UKCS decommissioning programme, involved the removal and transport of more than 12,000 tonnes of material from the Brae field in the UK North Sea.

The HAF Consortium, Heerema Marine Contractors and AF Offshore Decom, were contracted to execute the operation on behalf of TAQA.

The Heerema-operated Sleipnir semi-submersible crane vessel first removed the 1,000 tonne Brae Alpha Rig 1, in a single lift on 20 June.

Sleipnir then moved to Brae Bravo to remove the 11,000-tonne upper main jacket. This forms part of TAQA’s decommissioning obligations and follows the removal of the Brae Bravo topsides modules and flare bridge, jacket and tower last summer – one of the largest topsides removals in the UK North Sea.

The operation was completed with zero health and safety incidents.

Both Rig 1 and the Brae Bravo jacket have been safely offloaded at the AFOD Environmental Base in Vats, Norway, and are being processed with the aim of reusing or recycling 95% or more of the material, which is expected to be completed in 2023.

Commenting on this milestone, Donald Taylor, TAQA Managing Director for Europe, said: “TAQA’s extensive late-life portfolio positions us at the forefront of decommissioning in the UK. By adopting valuable lessons learned during last year’s successful Brae Bravo topside removal campaign, we are continuing to develop our skills and capabilities supporting the transition from operations to removals and disposal.

“The coming years offers some of the most interesting challenges and opportunities for our workforce and wider industry. TAQA is proud to pioneer this change while maximising the value of our assets and playing a valuable role in the energy transition.”

Prior to cessation of production in 2018, Brae Bravo produced more than 500 million barrels of oil equivalent over its 33-year life. Brae Alpha began production in 1983 and continues through present.

About TAQA

Established in 2005, TAQA is a diversified utilities and energy group headquartered in Abu Dhabi, the capital of the United Arab Emirates, and is listed on the Abu Dhabi Securities Exchange (ADX: TAQA). TAQA has significant investments in power and water generation, transmission and distribution assets, as well as upstream and midstream oil and gas operations. The company's assets are in the United Arab Emirates as well as Canada, Ghana, India, Iraq, Morocco, Oman, the Netherlands, Saudi Arabia, the United Kingdom and the United States. For more information, please visit: www.taqa.com

About the Brae area

TAQA operates three platforms in the Brae Area in the central North Sea. This includes Brae Alpha, East Brae and Brae Bravo. The Brae Bravo topsides and upper main jacket have been decommissioned.

The owners of the Brae Fields are TAQA Bratani Limited, TAQA Bratani LNS Limited, Spirit Energy Resources Limited and NEO Energy Petroleum Limited. Equity in the Brae Area varies by field. On average TAQA holds 53.6% of the Brae Area and the other JV partners hold 46.4%.

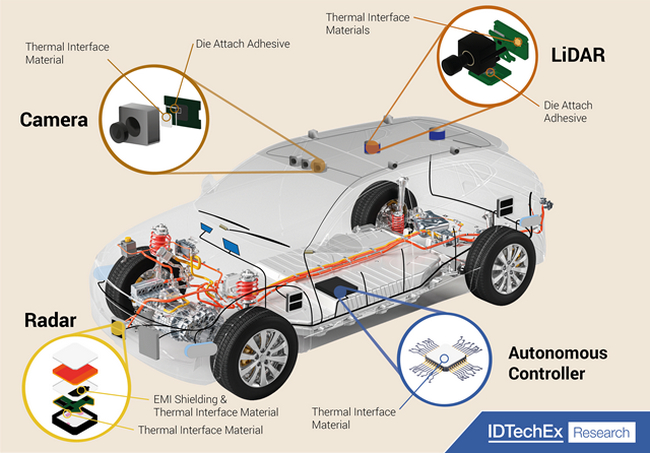

Automotive Autonomy: A New Opportunity for Thermal Materials, Says IDTechEx

The automotive market is trending towards greater levels of autonomy with advanced driver-assistance systems (ADAS) becoming increasingly adopted to improve the safety of drivers and pedestrians or even just to make driving a more convenient experience. ADAS encompasses a huge variety of functions from automatic emergency braking all the way to fully autonomous driving. Something that all ADAS features have in common is the need for high-quality sensors and the associated processing of their data. The quantity of sensors per vehicle also increases rapidly with greater levels of autonomy. These sensors and their evolution provide new markets for thermal management materials within the automotive industry. In fact, IDTechEx’s new report, “Thermal Management for Advanced Driver-Assistance Systems (ADAS) 2023-2033” finds that the yearly market value for thermal interface materials (TIMs) in ADAS will increase 11-fold over the next 10 years.

What’s Changing with ADAS Components?

Cameras and radars are already ubiquitous in vehicles, but greater levels of autonomy will require larger sensor suites with greater capabilities in each sensor. IDTechEx is predicting that there will be more than a 6-fold increase in the yearly demand for automotive sensors including cameras, radars, and LiDARs by 2033. A key factor is integration, to fit more sensors to vehicles in an aesthetically pleasing fashion, the units will require smaller form factors leading to densification of components and hence thermal management challenges.

ADAS sensors are also often used in non-ideal environments for electronics requiring resistance to shock and vibration and, in certain cases, having to withstand heat from a combustion engine. For many sensor locations, active cooling will not be viable and in hot climates the temperatures of sensors could increase significantly whilst the vehicle is stationary.

Another factor to consider is data processing. More sensors and sensors with greater fidelity will generate more data that needs processing by the vehicle. Some parts of this will be done within the sensor units themselves, but a central computer or electronic control unit (ECU) will be required to communicate this information to the relevant vehicle controls. The greater data requirements lead to using more power-dense ICs (integrated circuits) and hence a greater thermal management requirement. We have already seen this with Tesla’s adoption of a liquid cooling circuit for their computer highlighting the heat generated.

Each sensor in the ADAS system has its own thermal material opportunities. Source: IDTechEx - “Thermal Management for Advanced Driver-Assistance Systems (ADAS) 2023-2033”

Each sensor in the ADAS system has its own thermal material opportunities. Source: IDTechEx - “Thermal Management for Advanced Driver-Assistance Systems (ADAS) 2023-2033”

What are the Material Trends?

Like any modern electronics component, ADAS sensors and computers require thermal interface materials (TIMs) to help spread heat from the heat generating element to a heat sink or unit enclosure. Cameras, radars, LiDARs, and ECUs all have their own TIM requirements and as their designs evolve, so too do their TIM needs. Whilst the average ECU now may use a fairly typical TIM with 3-4 W/m×K thermal conductivity, the increased processing power required for autonomous functions could see this rise significantly.

Many of the sensors spread throughout the vehicle will be relatively small and low power, hence not necessarily needing a high-performance TIM. However, the rapidly growing market for ADAS features means that the volume demands for TIMs will increase significantly. IDTechEx is forecasting an increase in TIM demand of 3 times in just the next 5 years for ADAS sensors.

Concluding Thoughts

The rapid adoption of ADAS features and autonomy in the automotive market presents great opportunities for thermal management material suppliers with sensor design evolving and a growing market for ADAS components. IDTechEx’s report, “Thermal Management for Advanced Driver-Assistance Systems (ADAS) 2023-2033”, uses both primary and secondary research to cover these trends for ADAS sensor and computer evolution with a focus on thermal interface materials and die attach with additional chapters on combined EMI and thermal materials and radar radome materials. Company profiles/interviews are also included along with 10-year market forecasts in terms of material area, tonnage, and market value.

About IDTechEx

IDTechEx guides your strategic business decisions through its Research, Subscription and Consultancy products, helping you profit from emerging technologies. For more information, contact This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.IDTechEx.com.

Chevron Achieves Top Certification Scores for Environmental Performance

Chevron Corporation (NYSE: CVX) announced that the company’s participating North American upstream assets earned Project Canary’s highest ratings on operational and environmental performance. Project Canary’s independent analysis was conducted on Chevron assets in Texas and Colorado by the Denver-based climate tech and environmental assessment company.

As a result of the certification process, 82 wells achieved “Platinum” status and 3 wells received “Gold” status, Project Canary’s highest ratings and confirmation of Chevron’s industry-leading practices, including continuous monitoring. Chevron plans to market RSG from the certified assets in the second half of 2022.

“This certification is an important milestone in our journey to deliver affordable, reliable, ever-cleaner energy to a growing world. Chevron deploys several technologies to detect and measure methane emissions and certified responsibly sourced gas is part of our broader commitment to lowering the carbon emissions intensity of our operations,” said Steve Green, president, Chevron North America Exploration and Production. “In addition to demonstrating transparency, an independent assessment provides validation of our current practices and insights to inform and shape how we continue to achieve our lower carbon aspirations.”

“This certification is an important milestone in our journey to deliver affordable, reliable, ever-cleaner energy to a growing world. Chevron deploys several technologies to detect and measure methane emissions and certified responsibly sourced gas is part of our broader commitment to lowering the carbon emissions intensity of our operations,” said Steve Green, president, Chevron North America Exploration and Production. “In addition to demonstrating transparency, an independent assessment provides validation of our current practices and insights to inform and shape how we continue to achieve our lower carbon aspirations.”

The pilot project focuses on two sites in the Midland Basin of the Permian in Texas and three sites in Chevron’s Mustang Development Area of the DJ Basin in Colorado. The five sites produce a total of approximately 80 million cubic feet of natural gas per day. Project Canary's TrustWell™ program accounts for operational impacts on water, air, land, and community.

“The results of our independent assessment and certification of Chevron’s operations in the Permian and DJ basins demonstrate strong performance across its operating assets, positioning Chevron in the fast-emerging markets for differentiated gas,” said Chris Romer, CEO and co-founder, Project Canary. “Buyers of RSG certified by Project Canary can have confidence that each producing well has been reviewed and verified for aspects of Chevron’s environmental and social performance.”

In 2020, Chevron’s U.S. onshore production methane intensity was 85% lower than the U.S. industry average. The company continues to design, construct, and operate facilities with strategies to limit fugitive emissions. For example, it has reduced fugitive methane and volatile organic compound emissions in U.S. onshore operations through leak detection and repair, low-/no-emissions pneumatic devices, and centralized production facilities in addition to utilizing continuous monitoring. The company is also expanding its methane detection capabilities to identify the best opportunities to further lower emissions and is on track to reduce methane emissions intensity by more than 50% from 2016 levels by 2028.

About Chevron

Chevron is one of the world’s leading integrated energy companies. We believe affordable, reliable and ever-cleaner energy is essential to achieving a more prosperous and sustainable world. Chevron produces crude oil and natural gas; manufactures transportation fuels, lubricants, petrochemicals and additives; and develops technologies that enhance our business and the industry. We are focused on lowering the carbon intensity in our operations and seeking to grow lower carbon businesses along with our traditional business lines. More information about Chevron is available at www.chevron.com.

About Project Canary

Project Canary is a SaaS-based data analytics company focused on accurate corporate climate ESG data for emission-intensive industrial companies. We are the leaders in holistic environmental assessments (air, water, land, and community). Project Canary scores responsible operations, delivering independent emission profiles via high-fidelity continuous monitoring technology to provide actionable environmental performance data. Our sensor portfolio includes high-fidelity spectroscopy-based methane detection and emissions quantification for the oil and gas sectors, plus Aeris Technologies’ laser-based gas analyzers covering other emissions, including ethane, nitrous oxide, formaldehyde, ethylene oxide, benzene, and more. Formed as a Public Benefit Corporation, Project Canary’s Denver-based team of scientists, engineers, and seasoned industry operators identify and quantify areas to reduce emissions. www.projectcanary.com

Digitalisation in hazardous industries

~ How digital solutions can reduce downtime and improve safety in hazardous environments ~

Industries operating in hazardous areas must consider standard safety practices and ensure all equipment meets the requirements for flammable or explosive atmospheres. Effective monitoring, predictive maintenance and rapid response to failure is crucial for engineers managing these assets. Here, Marek Lukaszczyk, European and Middle East marketing manager at global motor manufacturer WEG, discusses how digitalisation can reduce risk and improve efficiency in hazardous industries.

A hazardous area is any area with an atmosphere containing, or potentially containing, gases, vapours or dust which are flammable or explosive. Industries such as oil and gas, chemical production, fuel storage and even paper production are all classed as hazardous. These areas are rigorously analysed when installing equipment to minimise the risk to individuals and assets.

It’s crucial that equipment operating in these conditions are effectively monitored to pre-empt any issues before they occur. Unlike most industries, these issues not only result in downtime but present a significant safety risk.

Monitoring matters

Condition monitoring is integral in industrial operations to avoid downtime, to implement maintenance and to reduce the risk of failure. Remote condition monitoring has previously been limited in hazardous areas due to the lack of cost-effective and easy-to-install solutions — and the often-challenging environments in which this equipment exists. For example, equipment used in subsea applications or on offshore operations cannot be monitored as frequently or easily.

Using digital solutions can offer a viable and safe way to address the challenges involved with hazardous area monitoring, minimising the need for manual inspection and intervention. WEG Motion Fleet Management (MFM) is a robust digital solution for data collection and condition monitoring of industrial assets. Using cloud computing, operators can easily access the operational status of equipment including motors and drives in any industry or location. MFM collects and processes data regularly both at the edge and in the cloud to generate important information on asset operation. Operators can use these insights to develop predictive maintenance plans and carry out condition-based maintenance.

Periodic data collection gives a more thorough overview of asset conditions, removing the need for maintenance teams to carry out observations and collect data manually. Having access to this data more frequently can allow maintenance teams to make informed decisions quickly and minimise unplanned stops. This is especially important in hazardous areas, where failure can result in loss of production. According to Kimberlite Oilfield Research, even a 1% increase in downtime can cost an oil and gas company up to $5.037 million. With a current average of 27 days of downtime on offshore platforms annually, this adds up to $38 million in financial losses, making it even more important to reduce the potential for error. Planning and carrying out repair operations may be time-consuming in hazardous areas and can require specialist resources or procedures which may not be immediately available, making effective monitoring even more advantageous.

MFM works in combination with WEG Motor Scan and WEG Drive Scan — sensors which can be installed in assets to measure their vibration, temperature and running hours and to upload this data to the cloud via the WEG Motor Scan Gateway. All sensors in the plant can be connected and the data can be accessed remotely and in real-time, and users can configure tolerances to generate alerts in case of errors.

The platform also offers increased fleet visibility remotely, allowing engineers to monitor assets from anywhere in the world. This is key in hazardous areas, for example, in offshore oil and gas operations where assets may not be easily accessible. WEG MotorScan also has Inmetro, ATEX, IECEx and MASC hazardous area certifications Ex ia I Ma, Ex ia IIC T4 Ga and Ex ia IIIC T135°C Da.

These codes refer to the level of safety when installing the product in a hazardous area, and WEG Motor Scan is classed as intrinsically safe for Category 1 environments with a continuous risk of explosion due to the presence of gas or dust. This is due to its low power requirements and thus low temperature and minimal energy of sparks, reducing the chance of an explosion.

Digitalisation is increasingly present in industrial settings and is proving to be an invaluable addition to many operations. Using digital solutions in hazardous industries can not only improve efficiency and reduce downtime and maintenance costs, but can offer significant benefits in safety and risk mitigation.

For more information on WEG’s products and services, visit the website here.

About WEG: Founded in 1961, WEG is a global electric-electronic equipment company, operating mainly in the capital goods sector with solutions in electric machines, automation and paints for several sectors, including infrastructure, steel, pulp and paper, oil and gas, mining, among many others.

WEG stands out in innovation by constantly developing solutions to meet the major trends in energy efficiency, renewable energy and electric mobility. With manufacturing units in 12 countries and present in more than 135 countries, the company has more than 33,800 employees worldwide. WEG’s net revenue reached R$ 17.47 billion in 2020, 56% from external markets. For more information, visit www.weg.net

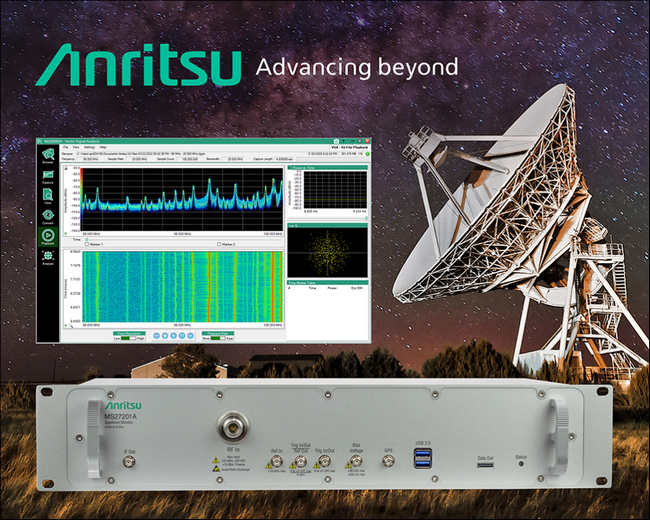

Anritsu Introduces Software to Expand IQ Measurement and Analysis Capabilities of Field Spectrum Analysis Solutions

– Comprehensive Suite of Tools Aids Government Regulators, Security Agencies, Spectrum Owners, and Defense Electronics Companies to Better Analyze RF Signals –

Anritsu Company introduces the IQ Signal Master MX280005A Vector Signal Analysis software that delivers expanded post processing measurements and analysis of IQ data files captured on Anritsu Field Master Pro™ MS2090A, Remote Spectrum Monitor MS27201A, and Remote Spectrum Monitor MS2710xA spectrum analyzers. Designed for challenging field environments, the software assists government regulators inspect the RF spectrum, security agencies track illegal or nefarious signals, spectrum owners protect their licensed spectrum, and defense electronics companies analyze radar and EW signals.

A comprehensive suite of enhanced functions in the new VSA software allows users to analyze the modulation of captured signals or replay the captured IQ data with enhanced resolution. It includes an IQ file browser with a detailed view of IQ file metadata, as well as an IQ data capture control that allows users to quickly and easily configure the spectrum analyzer for IQ data capture. A basic IQ data viewer that provides a quick and easy method to interpret images of any captured IQ data file to validate that the file contains information of interest is also included in the software.

An optional IQ file format converter enables IQ data captured using an Anritsu spectrum analyzer to be converted to the format required by the Anritsu Vector Signal Generator MG3710E and downloaded for playback to enable simulation of captured signals in a controlled lab environment. The VSA mode of the new MX280005A features the same modulation quality measurements included in the initial release of the software.

With the expanded MX280005A, Anritsu offers a complete end-to-end solution for IQ capture and analysis. It enhances the best-in-class performance of the Field Master Pro MS2090A, and Remote Spectrum Monitors MS27201A and MS2710XA. The MS2090A with continuous frequency coverage from 9 kHz to 54 GHz and a 110 MHz real-time option delivers a displayed average noise level (DANL) of -164 dBm, and Third Order Intercept (TOI) of +20 dBm (typical).

Wide area spectrum monitoring up to 43.5 GHz can be conducted with the MS27201A. Anritsu offers three models of remote spectrum monitors in the MX2710XA family. The MS27101A is housed in a half-rack enclosure with 1U height, while the MS27102A is an IP67-rated device for outdoor applications. The MS27103A is a multi-port spectrum monitor for applications requiring the use of multiple antennas.

About Anritsu

Anritsu Corporation (www.anritsu.com), a global provider of innovative communications test and measurement solutions for 125 years. Anritsu’s philosophy engages customers as true partners to help develop wireless, optical, microwave/RF, and digital solutions for R&D, manufacturing, installation, and maintenance applications, as well as multidimensional service assurance solutions for network monitoring and optimization. Anritsu also provides precision microwave/RF components, optical devices, and high-speed electrical devices for communication products and systems. The company develops advanced solutions for 5G, M2M, IoT, as well as other emerging and legacy wireline and wireless communication markets. With offices throughout the world, Anritsu has approximately 4,000 employees in over 90 countries.

Growth in Cyber Attacks Boosts Global Demand for Endpoint Security

The changing landscape and significant surge in cyber threats have contributed to the high demand for endpoint security solutions globally, finds Frost & Sullivan’s recent analysis. Endpoint security is the practice of using host-based software products to secure computing devices such as laptops and smartphones. The global endpoint security market will likely reach $31.1 billion by 2026 from $17.4 billion in 2021, registering expansion at a compound annual growth rate (CAGR) of 12.3%.

“With the rise in the volume of cyber threats due to the pandemic and remote working requirements, the world witnessed a significant increase in endpoint security needs,” said Sarah Pavlak, Security Industry Principal at Frost & Sullivan. “To mitigate attacks, endpoint security solutions—endpoint protection platform (EPP) and endpoint detection and response (EDR)—are vital as they help identify unprotected assets.”

Pavlak added: “Adopting an artificial intelligence (AI)-based protection approach allows the identification of endpoints in need of updating and their associated risk levels. Further, wider AI adoption will incorporate self-healing endpoints and become more comprehensive during the next few years.”

Pavlak added: “Adopting an artificial intelligence (AI)-based protection approach allows the identification of endpoints in need of updating and their associated risk levels. Further, wider AI adoption will incorporate self-healing endpoints and become more comprehensive during the next few years.”

To reap the benefits of the growing endpoint security industry, market participants should:

- Develop an effective strategy for detecting and mitigating zero-day attacks. This should include a defensive plan with prevention technology and a response method for potential attacks.

- Consider implementing on-device AI/ML (machine learning) capabilities on endpoint agents to support detection capacity and deliver collective intelligence competencies.

- Focus on cloud-based endpoint security. It offers opportunities to extend product services, either on-demand or fully managed, and leverage Big Data for high-fidelity advanced threat detection.

- Incorporate mobile threat defense into endpoint solutions to secure endpoints and track device behavior to detect and stop malicious activity.

Global Endpoint Security Growth Opportunities is the latest addition to Frost & Sullivan’s Security research and analyses available through the Frost & Sullivan Leadership Council, which helps organizations identify a continuous flow of growth opportunities to succeed in an unpredictable future.

About Frost & Sullivan

For six decades, Frost & Sullivan has been world-renowned for its role in helping investors, corporate leaders and governments navigate economic changes and identify disruptive technologies, Mega Trends, new business models, and companies to action, resulting in a continuous flow of growth opportunities to drive future success. Contact us: Start the discussion

UNTHA UK awarded ‘Leading Light’ prestige in national tech list

Industrial shredder manufacturer UNTHA UK has been listed in the prestigious Digital Enterprise Top 100 list for the third consecutive year. And for 2022, the Boroughbridge-headquartered firm has also received esteemed ‘Leading Light’ recognition as a top ten performer.

The initiative seeks to identify companies leading the way in digital innovation, transformation, and resilience, before sharing their stories across the UK and internationally to drive and inspire success amongst others.

The accolade – which follows a detailed written submission and judging process – reflects UNTHA UK’s six-figure investment in an ever-evolving Microsoft Dynamics solution. The technology has proven transformational throughout every department in the fast growth business, with judges particularly drawn to the efficiency, productivity and data intelligence benefits achieved.

But as UNTHA UK’s data analyst Sharon Annat explained, colleague morale and customer satisfaction has rocketed too: “While our continued push for better has had a crucial impact on our products and processes, it has also proven to be a key driver for the fulfilment of our people.

“A strong grasp of business intelligence and management information, coupled with improved collaboration between departments, has translated into better customer experience, higher satisfaction levels, repeat business and reputational growth in a really crowded market. And we couldn’t be prouder.”

Managing director Marcus Brew added: “Following a consecutive year of 25%+ growth , we’re recouping the value of our investments more than ever, and look forward to pushing for £17m turnover this year. A special thanks must be extended to our partners Spark365, Scriba PR and The Bigger Boat too.”

As well as attending the celebratory event on 16 June – which saw the 2022 Digital Enterprise Top 100 list unveiled in central Leeds – Marcus also took to the stage to speak to fellow delegates, industry partners and policy-makers about the company’s digital journey to date.