Super User

180,000 bugs in every fully autonomous vehicle are like an open door to cyber criminals, says GlobalData

Many autonomous vehicles are not fully protected against cyberattacks, with GlobalData, a leading data and analytics company, estimating that there may be up to 180,000 bugs in the code operating a level 5 autonomous vehicle*— potentially leaving hackers with 15,000 security vulnerabilities to choose from.

GlobalData’s latest report, ‘Cybersecurity in Automotive – Thematic Research’, stresses the importance of defending all of the infrastructures upon which connected cars rely, noting that we are entering a ‘Code War’ era, where every digital device—no matter how small—can be weaponized.

Emilio Campa, Analyst on the Thematic Research team at GlobalData, comments: “Autonomous vehicle manufacturers may be making sure the physical doors lock, but as it stands, the digital doors are wide open. Over the past decade, hackers have accessed the vehicles of numerous major brands: remotely unlocking doors, collecting sensitive data, and even taking control of vehicles. This just isn’t good enough, and autonomous vehicles won’t be safe enough until these gaps are plugged.”

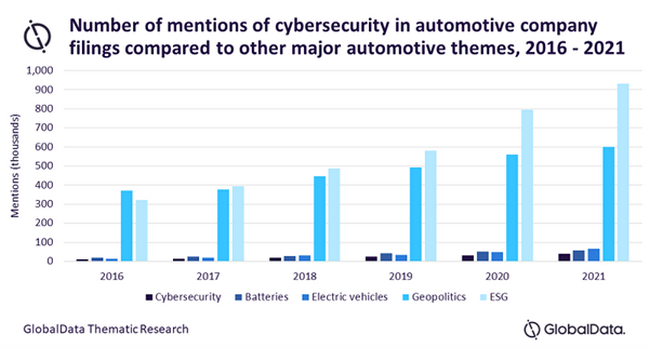

Automotive businesses are increasingly talking about cybersecurity in their financial reports, according to GlobalData’s Company Filing Analytics. The number of mentions of ‘cybersecurity’ expanded almost fourfold between 2016 and 2021. However, the number of mentions is relatively small when compared to other major themes in the sector—especially environmental, social, and governance (ESG) issues. In 2021, the number of mentions of ‘ESG’ was over 20 times bigger than the number of ‘cybersecurity’ mentions.

Campa continues: “Cybersecurity is competing for attention with other major issues such as ESG and geopolitics. While these are also pressing matters, the importance of comprehensive cybersecurity in automotive cannot be overstated. Public safety aside, cyber breaches and cyberattacks directly affect the value and integrity of car manufacturers’ brands. New vulnerabilities are also constantly coming to light, and they can be difficult to fix.”

Cybersecurity-related regulation is being implemented in different ways around the world. The UN Economic Commission for Europe (UNECE) Regulation 155 comes into force in July 2022, the ISO/SAE 21434 standard has been developed, and countries from the US to China are adopting local regulations and oversight. As a result, auto players must be aware of the regulatory landscape to ensure compliance.

Campa adds: “There is a real requirement for manufacturers to get up to speed on cybersecurity, and to do so quickly. The auto industry will face more cyberattacks as it introduces more connected, digital, and electronic systems to new vehicles and as companies themselves become more digital. With cyberattacks causing severe reputational damage and being expensive to remediate, automotive cybersecurity cannot be ignored.”

- Level 5 autonomous vehicles are fully self-driving vehicles that can handle all driving tasks in all circumstances. These vehicles probably won't feature human controls and must be able to safely handle any situation they might encounter.

Quotes provided by Emilio Campa, Analyst on the Thematic Research team at GlobalData

GlobalData’s latest report, ‘Cybersecurity in Automotive – Thematic Research’, provides an invaluable guide to this extremely disruptive theme. It includes comprehensive lists of the leading players across all aspects of the cybersecurity value chain, helping companies identify the right partners.

The report also includes a guide to the major challenges the automotive industry is facing and how they impact the need for comprehensive cybersecurity in vehicles.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

AEG Power Solutions provides DC power supplies for the electrolysis process of the world’s largest green hydrogen plant

AEG Power Solutions, a global provider of power supply systems and solutions for all types of critical and demanding applications, have just announced that it will deliver 8 Thyrobox DC-3 systems to Siemens Energy. The DC systems will provide the power supply for the hydrogen production process of the CEOG (Centrale Électrique de l’Ouest Guyanais) power plant project.

- 8 high efficiency rectifier systems power the 16 MW electrolysis platform of the CEOG power plant in French Guiana

- High efficiency, Integrated grid compliance in combination with compact design were key factors for the choice of Siemens Energy

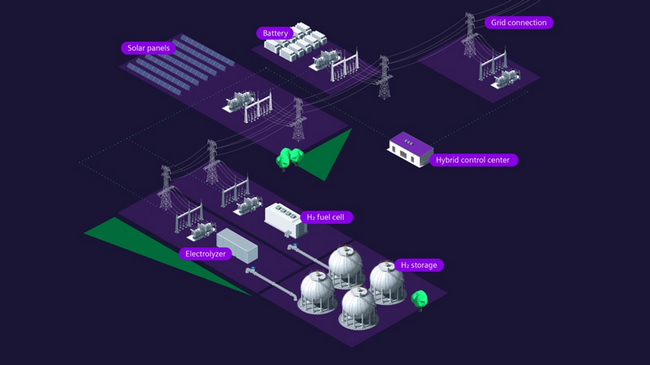

The world's largest power plant CEOG project which combines photovoltaic with green hydrogen energy storage, is located in Western French Guiana and stores up to 128 MWh. The hydrogen yield of 860 tons per year will be produced by a 16 MW electrolysis platform, stored under pressure in hydrogen storage tanks and then provide secure and 24/7 available electricity via high-power fuel cells in a reverse electrolysis process – enough to power 10,000 households in French Guiana at a competitive price compared to local thermal power plants.

AEG PS will deliver 8 Thyrobox power supply systems to Siemens Energy as EPC of the project. Each system consists of 4 power modules Thyrobox DC-3 to increase reliability and efficiency in partial load and to support container integration. The B12 thyristor rectifiers have an IGBT bridge for the DC/DC conversion and will be delivered in 8 transformer rectifier units (TRU) forming a 21,5 MVA / 18,6 MW power supply solution to power the electrolyzer system. The rectifier modules will be provided on power frames to allow forklift and crane handling for easy installation and decreased handling costs and support the required Safety Integrity Level (SIL). A Profinet interface will allow the Integration of the rectifier control into the electrolyzer control system.

AEG PS will deliver 8 Thyrobox power supply systems to Siemens Energy as EPC of the project. Each system consists of 4 power modules Thyrobox DC-3 to increase reliability and efficiency in partial load and to support container integration. The B12 thyristor rectifiers have an IGBT bridge for the DC/DC conversion and will be delivered in 8 transformer rectifier units (TRU) forming a 21,5 MVA / 18,6 MW power supply solution to power the electrolyzer system. The rectifier modules will be provided on power frames to allow forklift and crane handling for easy installation and decreased handling costs and support the required Safety Integrity Level (SIL). A Profinet interface will allow the Integration of the rectifier control into the electrolyzer control system.

Besides AEG PS as expert for the power conversion system, each stakeholder of the project will bring its expertise in the fields of production, distribution, and storage of green energies:

- Hydrogène de France (HDF): a global pioneer in hydrogen energy, HDF develops and operates multi-megawatts Hydrogen- to-Power power plants, incorporating its high-power fuel cells, to provide continuous or on-demand electricity from intermittent renewable energies.

- Meridiam: a leader in public infrastructure investment and asset management for public authorities.

- SARA (French West Indies refinery limited company, Group Rubis): a key player in energy production in the French West Indies and French Guiana for over 50 years.

- Siemens Energy: a strong global specialist in power plant construction for sustainable future and innovative technologies, who will cover the 24/7 support from its Remote Control Center.

“We are very enthusiastic about this project. It will proof the usability of green hydrogen in large scale power plants. Our power supply solution in combination with the electrolyzer has already been proven in previous projects. Thanks to its compactness, Siemens Energy will be able to integrate all components in a containerized solution. The decisive factors for the choice were the low installation and assembly costs, reduced cabling, and our technical know-how. CEOG will benefit from its high efficiency and the good grid compatibility”, states Andreas Becker, Head of Grid & Storage at AEG Power Solutions.

“The CEOG power plant produces economical, clean and reliable electricity that will be fad into the national grid non-stop. Half of the energy demand of the population of Saint-Laurent-du-Maroni and Mana will be covered this way. The residents of French Guiana can look forward to a sufficient energy supply - without fuel imports, without greenhouse gas emissions and almost entirely noiseless”, added Mario Hüffer, Sales Director Hybrid Solutions at Siemens Energy.

After completion of the construction work and the subsequent test operation, the power plant should be feeding into the grid in the second quarter of 2024. Based on renewable energy sources, CEOG will avoid 39,000 tons of CO2 emissions per year compared to a fossil fuel power plant.

About AEG Power Solutions

AEG Power Solutions ensures continuous power availability and the safe operation of critical applications thanks to with a wide portfolio of power supply systems and services: AC and DC UPS, battery chargers, rectifier systems, service and maintenance on 24/7 basis, as well as fully customized UPS systems to customer specifications.

AEG Power Solutions has developed a distinctive expertise and world-class engineering capacities that bridge both AC and DC power technologies and span conventional and renewable energy platforms. AEG Power Solutions has decades of experience with UPS and power electronics, and grid integration, and is leveraging its conversion expertise to engineer and deliver solutions for the energy transition.

AEG Power Solutions is the sole subsidiary of the holding company 3W Power. For more information, visit www.aegps.com.

Strohm supports Shell with fast-track delivery of a TCP Riser

Strohm has supplied Shell with a static Thermoplastic Composite (TCP) Riser to support operations at one of its Southern North Sea assets. The availability of TCP through Strohm’s “TCP on Demand” model and the ability to install end-fittings offshore enabled flexible, quick and easy installation.

Strohm was able to offer a fast-track delivery (January ’22) of their 2.0-inch 10ksi stock product, including all ancillaries, to support Shell’s tight schedule.

In a mature basin such as the North Sea, the pipeline infrastructure is ageing and, in some cases, pipelines are in need of replacement. For such a situation, TCP is an attractive solution. In this particular case for Shell, the TCP could be terminated above the J-tube, allowing for a smaller existing J-tube to be used, avoiding the need for any welding or curing. Strohm, together with their trusted partners, included a fast-track supply of the J-tube bellmouth, centralizer, bend restrictors, hang-off clamps, providing a full solution with a quick turnaround.

Strohm has the largest track record globally for the production and delivery of TCP. It is a strong, corrosion resistant composite pipe solution with a long, maintenance free service life. TCP is spoolable and delivered in long lengths allowing operators to use existing field support vessels on long-term charter rather than mobilising dedicated pipelay assets, making significant efficiencies and supporting lower carbon emissions targets. TCP has a 100% track record of no failures on installed pipe.

Strohm’s TCP Flowline features Subsea Energy Solutions’ bend restrictor, topside clamps and subduct for a fast turnaround project with Shell. Image supplied courtesy of Subsea Energy Solutions

Strohm’s TCP Flowline features Subsea Energy Solutions’ bend restrictor, topside clamps and subduct for a fast turnaround project with Shell. Image supplied courtesy of Subsea Energy Solutions

The technology is increasingly being considered in the renewables sector, including offshore hydrogen and carbon capture and storage, as well as in conventional oil and gas applications. The project for Shell saw the technology being delivered on a subsea pallet.

As well as passing on cost savings for the fully installed package, in parallel, TCP also allows clients to reduce their own C02 emissions whilst contributing to an overall reduction in C02 footprint. DNV has conducted an in-depth analysis of the CO2 footprint related to the manufacture and installation of a TCP Flowline and found that it results in a 50+% reduction compared to that of a steel alternative. The company is continuing this work to assess the operational life, including assessing the impact of the non-corrosive nature of TCP which negates the need for any injection of chemicals related to inspection and pigging.

Martin van Onna, Strohm’s managing director said: “We are proud to have supported Shell with this fast-track project. This award by Shell demonstrates a growing confidence from energy companies in TCP and the benefits the product offers in terms of quick response, installation and reduced Opex. “

About Strohm:

Leading composite pipe technology company Strohm (formerly known as Airborne Oil & Gas) has the world’s largest track-record for Thermoplastic Composite Pipe (TCP) after being the first to bring the technology to the Oil & Gas industry in 2007. TCP reduces total installed and life cycle cost for subsea flowlines, jumpers and risers and has proven to reduce the CO2 footprint of pipeline infrastructures by more than 50%.

The company is committed to driving sustainability with its range of TCP solutions which enable clients towards their net-zero carbon emissions targets and supports the renewables sector.

TCP is a strong, non-corrosive, spoolable, lightweight technology which is delivered in long lengths, resulting in a significant reduction of transportation and installation costs. TCP is installed using small vessels or subsea pallets, significantly reducing CO2 emissions. It is also 100% recyclable.

Strohm’s shareholders are Chevron Technology Ventures, Shell Ventures, Evonik Venture Capital, Aker Solutions, Saudi Aramco Energy Ventures, Subsea 7, Sumitomo Corporation and the private equity investor, HPE Growth.

The firm’s manufacturing facility is located at its headquarters in IJmuiden in The Netherlands. Strohm also has offices in Houston (US), Rio de Janeiro (Brazil) and Kuala Lumpur (Malaysia).

Visit the Strohm website here

Innovation & inspiration: World-leading ingredients show Fi & Hi Europe set to attract over 20,000 global attendees

Fi Europe co-located with Hi Europe returns to France this year from 6-8 December. For the first time, the leading ingredients exhibition will take place at Paris Expo Porte de Versailles – occupying four halls with more than 1,200 exhibitors, ranging from leading ingredients suppliers through to highly specialized newcomers. The in-person show will be framed and supported by an extensive online event, giving attendees countless opportunities and greater flexibility to source, connect and innovate – be it virtually, in-person or both.

In Paris, Fi & Hi Europe is set to attract exhibitors and attendees from over 135 countries around the world. Located in the heart of the city, Paris Expo Porte de Versailles is within walking distance of many hotels, restaurants and bars – making the event more visitor-friendly than ever before.

Fi & Hi Europe is the culmination of a year of Fi Global engagement with the ingredients industry, including a series of webinars, in-person events around the world, and the marketplace solution Ingredients Network.

This December the world-leading ingredients show Fi & Hi Europe returns to France, promising more Parisian flair than ever before.

This December the world-leading ingredients show Fi & Hi Europe returns to France, promising more Parisian flair than ever before.

Digitally enabled event concept

With this year’s show, Informa Markets continues its hybrid journey, setting the bar even higher with more advanced technology. The combination of online and in-person events offers attendees the best of both worlds, covering a huge variety of live and on-demand content, as well as data-driven matchmaking options, enabling a seamless all-round show experience. For example, all exhibitors will have an online profile that allows them to connect and network ahead of the event and gather leads onsite using the integrated lead scanning system. This means it has never been easier to find and connect with relevant contacts and schedule virtual or in-person meetings using the online event platform.

“We’re looking forward to welcoming thousands of visitors and exhibitors from around the world to an event which all those involved in the ingredients industry simply cannot afford to miss,” says Julien Bonvallet, Brand Director at Informa Markets. “After many months of disruption and uncertainty, there’s a strong aspiration for meeting in-person again, and so the excitement is already gathering pace. But for those who would prefer to join online, sophisticated technology means our online event will merge seamlessly with the in-person show.”

Packed conference programme

The online event will begin on 28 November, the week before doors open at Paris Expo Porte de Versailles. It features a packed conference programme covering the hottest industry topics including plant-based, health & wellbeing and reformulation, as well as category updates on some of the key trending segments. These include bakery and snacks, dairy & dairy alternatives, sustainability and much more.

The physical show will once again include popular features such as the Innovation Hub, the New Product Zone in collaboration with Innova Market Insights, and the Fi Europe Innovation Awards. The all-new Sustainability Hub will focus on sustainable food solutions from farm to fork, giving visitors the opportunity to learn about food waste, circular economy, regenerative agriculture and more.

Unique gathering of suppliers

Lots of key ingredients suppliers have already confirmed their attendance in Paris, including ADM, Beneo, Brenntag, Cargill, DSM and Ingredion, to name just a few. The four halls at the venue are already 85 per cent booked with a variety of exhibitors – both old and new – all eager to showcase the latest trends and products driving the industry. There will also be more country pavilions than ever before.

Julien adds: “I am so excited that Fi & Hi Europe will once again open its doors in Paris – this time at an impressive new venue. Bringing the world of food and beverage ingredients together has always been our main purpose, and our entire team is looking forward to providing the perfect platform for both visitors and exhibitors to source, connect and innovate.”

For more information on the show, please visit: https://www.figlobal.com/fieurope/en/home.html.

About Fi Global

Food ingredients Global was launched in Utrecht, The Netherlands, in 1986. Its portfolio of live events, extensive data, digital solutions and high-level conferences is now established throughout the world and provides regional and global platforms for all stakeholders in the food ingredients industry. Over 500,000 people have attended our shows over the years, with billions of Euros worth of business created as a result. With more than 30 years of excellence, the events, digital solutions and supporting products deliver a proven route to market, with a truly global audience. Since 2018 Food ingredients Global has been part of the Informa Markets portfolio. For more information about, please visit: www.figlobal.com.

About Informa Markets

Informa Markets creates platforms for industries and specialist markets to trade, innovate and grow. Our portfolio is comprised of more than 550 international B2B events and brands in markets including Healthcare & Pharmaceuticals, Infrastructure, Construction & Real Estate, Fashion & Apparel, Hospitality, Food & Beverage, and Health & Nutrition, among others. We provide customers and partners around the globe with opportunities to engage, experience and do business through face-to-face exhibitions, specialist digital content and actionable data solutions. As the world’s leading exhibitions organiser, we bring a diverse range of specialist markets to life, unlocking opportunities and helping them to thrive 365 days of the year. For more information, please visit www.informamarkets.com.

Vattenfall and Air Liquide sign long-term electricity supply agreement for offshore wind

Air Liquide has signed its largest long-term Power Purchase Agreement (PPA) to date in the Netherlands with Vattenfall, for 115 MW or around 500 GWh per year, of renewable electricity from the offshore wind farm Hollandse Kust Zuid. This PPA comes in addition to a 100 GWh-PPA with Air Liquide announced in March 2021, expanding the long-term partnership.

The 15-year PPA starting in 2025 enables Air Liquide to supply its existing industrial and medical gas production assets in the Netherlands and more generally in the Benelux region with renewable energy.

Erik Suichies, Executive at Vattenfall’s Business Area Markets: “This Power Purchase Agreement is an important step for the Hollandse Kust Zuid project. Long-term commitments such as PPAs will make a significant contribution to the decarbonization goals of our industrial partners and help to bring closer Vattenfall’s ambition to create a fossil-free living within one generation at the same time.”

Hollandse Kust Zuid: Vattenfall/Ties van der Horst

Hollandse Kust Zuid: Vattenfall/Ties van der Horst

Hollandse Kust Zuid is the first and largest offshore wind project in the world to be developed without subsidy. Long-term contracts, such as the PPAs concluded with Air Liquide, provide financial security for the project’s investors and provide access to renewable energy for the purchasing party.

Hollandse Kust Zuid is located in the North Sea, about 18-35 kilometres off the Dutch coast between The Hague and Zandvoort. The offshore wind project, consisting of 140 wind turbines with a total capacity of 1,500 megawatts, is scheduled to be fully operational in 2023. Hollandse Kust Zuid is owned by Vattenfall, BASF and Allianz.

Vattenfall is a leading European energy company, which for more than 100 years has electrified industries, supplied energy to people’s homes and modernised our way of living through innovation and cooperation. We now want to make fossil-free living possible within one generation. That's why we are driving the transition to a sustainable energy system through initiatives in renewable production and climate-smart energy solutions for our customers. We employ approximately 19,000 people and have operations mainly in Sweden, Germany, the Netherlands, Denmark, and the UK. Vattenfall is owned by the Swedish state. For more information: group.vattenfall.com

Valmet to deliver two chip washing and defibrator systems to Siempelkamp

Valmet will deliver two chip washing and defibrator systems to Siempelkamp Maschinen- und Anlagenbau GmbH as part of Siempelkamp’s panelboard plant deliveries to two different end customers, one in Europe, one in Asia. The start-ups of the systems are planned for 2023 and the beginning of 2024.

The orders were included in Valmet’s orders received of the first quarter 2022. The value of the orders will not be disclosed.

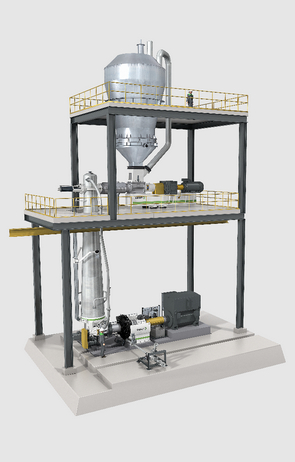

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Valmet EVO 64 Defibrator System“Siempelkamp is well known as a supplier to the panelboard industry, and we are pleased to once again deliver defibrator systems to them. Together with Valmet’s market leading defibrator systems, Siempelkamp can offer high performing complete fiberboard plants to their end customers,” says Jonas Franzén, Sales Manager, Fiber Processing Business Unit, Pulp and Energy business line, Valmet.

Technical information about the delivery

Valmet’s delivery will include all main machinery of the second-generation EVO 64 Defibrator system and chip washing, related motors, a control system as well as installation and start-up advisory.

Valmet’s defibrators are equipped with a patented grinding house that is unique in the industry. This feature enables both energy and resin savings, providing low operating costs and resulting in an environmentally friendly defibrator system for the production of high-quality wood fibers to MDF and HDF boards.

Information about the customer Siempelkamp Maschinen- und Anlagenbau GmbH

Siempelkamp is the leading global technology supplier for the panelboard industry with focus on machine and plant engineering, foundry technology, and engineering and services. Siempelkamp machine and plant engineering is a systems supplier of press lines and complete plants for the wood-based panel industry, the metal forming industry as well as the composite and rubber industry.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Metso Outotec launches Planet Positive Filtration Plant Units for sustainable performance

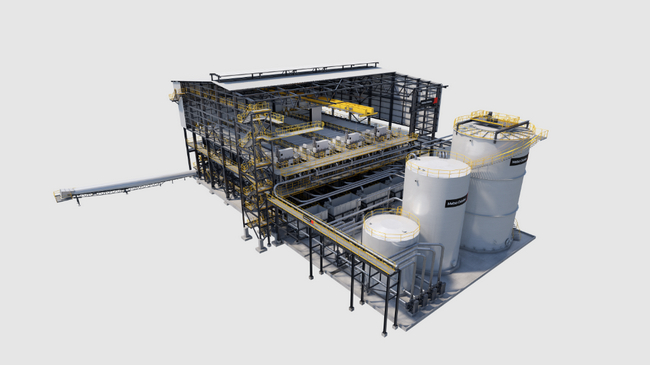

Metso Outotec is launching a comprehensive Filtration Plant Unit offering to maximize operational reliability in different types of dewatering applications where superior process performance combined with energy and water efficiency is required.

The offering consists of three major plant units around Metso Outotec’s Larox® PF and Larox® FFP, and Metso Outotec CC filter technologies, all designed for the dewatering of concentrates and tailings. The latest addition to the offering is the Larox® FFP3716 Filter Plant Unit, which represents the most advanced technology for the safe high-volume processing of tailings. All Metso Outotec Filtration Plant Units are scalable and come as complete customizable solutions to meet even the most stringent customer requirements.

“We have been supporting our customers with filtration solutions for almost 100 years. Today, our selection of filtration technologies is the largest in the field, and their energy, emission, and water efficiency is in a league of its own. The Filtration Plant Units combine all this knowledge to provide our customers with unrivalled dewatering performance,” says Toni Kuisma, Product Manager, Filtration Plant Units at Metso Outotec. He continues: “We have also optimized the engineering and delivery process. The new plant unit concept provides the fastest time-to-volume for our customers. Special attention has also been paid to the units’ maintainability through, for example, advanced digitalization. Their high level of automation enables easy optimization and remote support.”

Metso Outotec Larox FFP3716 Filtration Plant Unit

Metso Outotec Larox FFP3716 Filtration Plant Unit

The Metso Outotec Filtration Plant Units consist of advanced filters, screens, filter feed tanks, slurry pumps and conveyors coupled with process control system and various ancillary products and expert services, supported by Metso Outotec Dewatering Technology Center (DTC) in Lappeenranta, Finland. The integrated service offering provided by the company’s global network ranges from filter inspection and dewatering optimization to spares and wears and remote support and Life Cycle Services.

Core benefits

- Offering from equipment to turnkey supply of plant units

- Compact footprint and minimized elevation

- Pre-engineered package for faster project execution

- Process guarantees to de-risk customer’s investment

- Safe & superior plant design using industrial best practices

- Integrated service offering with global network

- Testwork capabilities with strong focus on innovation and R&D

- Automation and digital tools

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Discover more about Filtration Plant Units on our website.

Building Permit Granted for Keliber’s Concentrator Plant

The municipalities of Kaustinen and Kronoby have granted a building permit for Keliber’s Päiväneva concentrator plant. The decision was taken by the Environmental Protection Committee of Kaustinen and the Building Control of Kronoby in June 2022.

The permit applies to the concentrator building and a related, combined laboratory and control room building. A second permit was granted for an office building, including a repair shop and storage space. The total floor area of the three buildings is 11,948 m2.

The permit applies to the concentrator building and a related, combined laboratory and control room building. A second permit was granted for an office building, including a repair shop and storage space. The total floor area of the three buildings is 11,948 m2.

Keliber will build the concentrator plant on the border of the Kaustinen and Kronoby municipalities, next to the Päiväneva peat bog. The concentrator will produce spodumene concentrate from lithium ore mined in the area. The concentrate will be processed further at the Kokkola lithium chemical plant, where it will be converted into battery-grade lithium hydroxide monohydrate, for use in electric vehicles batteries, among other things.

The building permit for the lithium chemical plant entered into legal force in June 2022. The company aims to begin construction this summer and production in 2024.

Keliber in Brief

Keliber is a Finnish mining and battery chemical company that aims to start the sustainable production of battery-grade lithium hydroxide, utilising its own ore, in 2024.

Wyndridge Brewery Solves Dissolved Oxygen Headaches with PTFE-Lined Hoses

The Wyndridge Farm craft brewery and cidery had an urgent problem that needed to be solved before it could fulfill a large order. The family-owned business, set in bucolic York County, Pennsylvania, is not only a popular destination with its restaurant and beer garden events, but it also serves as a contract manufacturer of craft beer, hard cider, hard seltzer, and non-alcoholic beverages.

“We detected unacceptably high levels of dissolved oxygen, a problem we urgently needed to correct prior to packaging an order for 21,000 cases of craft beer from a European wholesaler,” explained Scott Topel, the Beverage Production Manager at Wyndridge.

Leaky Hoses

Managing the level of dissolved oxygen (DO) is an essential part of the art and science of brewing beer. After the fermentation process is complete, the presence of elevated levels of oxygen will degrade the quality and taste of the final product and shorten shelf life. Mitigating the risk of exposure to oxygen is especially critical during the packaging process that transfers the beer to cans, bottles, or kegs.

“High levels of DO can reduce the shelf life to less than three months, especially with IPAs where the effect of oxygen on the hops character is quite noticeable,” said Topel. “Ensuring a long shelf life is always important, but was absolutely necessary for this European order because the product would have to be shipped across the ocean and pass through customs prior to being distributed to stores and homes.

“We were able to diagnose the problem by taking measurements all along the production line. DO readings before and after the silicone hoses in the can-filling machine allowed us to pinpoint the location of the oxygen pick up. After a lot of research, we found that silicone hoses actually do allow some measure of permeability.”

Ideal Hose for Breweries

Topel reached out to Bill Winard, the U.S. Business Development Manager at Aflex Hose, a division of Watson-Marlow Fluid Technology Solutions (WMFTS), who visited the Wyndridge facility and recommended Aflex’s new FaBLINE SI PTFE hose. As the FaBLINE name denotes, the hoses are specifically designed for the Food and Beverage industry, including brewery applications.

Developed to meet the latest hygiene standards, the patented PTFE-lined hose with standard 316 stainless steel braid ensures efficient product transfer and handling while simultaneously offering an exceptionally long service life.

The design allows the PTFE liner to expand around the outside and compress around the inside of a bend. This helps to retain a smooth circular bore throughout the hose, without distortion, resulting in smooth, consistent flow with minimal turbulence.

This construction is ideal for the repetitive up-and-down action of food and beverage processing equipment, like the can-filling machine at Wyndridge. Laboratory tests have demonstrated that the FaBLINE hose construction can withstand more than 100,000 cycles of repetitive action, with small bending radii, at maximum working pressure, compared to competitor hoses that fail after less than 13,400 cycles.

Improving Quality and Extending Shelf Life

Improving Quality and Extending Shelf Life

“We received the FaBLINE hoses in the nick of time,” said Topel. “Within a day, we were able to reduce our dissolved oxygen levels from 100-150 parts per billion to well under 50, and therefore we were quite relieved to be able to ship the European order on time.”

The decision to replace the silicone hoses was originally driven by the need to reduce DO levels in order to preserve product quality and extend shelf life. After installation, the new FaBLINE hoses have brought other important benefits as well.

Reducing Product Loss

The new hoses have significantly reduced product loss in two different ways. The first reduction occurs continuously. With silicone hoses, at a microscopic level, there is enough undulation to cause some turbulence of carbonated products, making them foam over continually, resulting in a cumulative loss of 4% of the product to the ground. The FaBLINE hoses, with their smooth, circular bore, have reduced this type of loss to 2.3%.

A second way that the FaBLINE hose reduces loss occurs during the startup of the hard cider can-filling process. Previously, with the silicone hoses, it was necessary to bring the temperature of the lines down to below 40° F to avoid generating foam. A scale measures the weight of each filled can, and if it contains too much foam, the can is automatically discarded — resulting in a loss of 2.5 or 3 cases at the beginning of each run. Now, with the FaBLINE hoses, the cider can move through the filling machine at 40-43° F without generating foam. Only one or two cans are now discarded at the start of each run.

Topal said: “We replaced the hoses due to an urgent need to bring down the dissolved oxygen in our beer, and the FaBLINE hoses immediately allowed us to achieve that goal. What we did not expect, but have come to really appreciate, is how the hoses have also allowed us to more smoothly run the canning operation for all our products, with much less waste.”

Mauritania and the European Investment Bank strengthen renewable energy and green hydrogen cooperation

Mauritanian President El Ghazouani today met Werner Hoyer, President of the European Investment Bank, to discuss cooperation with the world’s largest international public bank and agreed to strengthen cooperation to scale up wind, solar and green hydrogen investment.

- President El Ghazouani and EIB President Werner Hoyer sign declaration on green hydrogen

- Scaling up wind and solar energy generation key to reduce impact of global energy price shocks

- EIB to support Mauritania green hydrogen investment plans

“Development of Mauritania’s huge renewable energy potential can both enhance access to affordable energy in our country and allow clean energy to be converted to green hydrogen. Closer cooperation with the European Investment Bank will allow Mauritania to benefit from the EIB’s unique technical experience and financial strength.” said Mohammed Ould Ghazouani, President of the Islamic Republic of Mauritania.

“The European Investment Bank is committed to supporting climate action and clean energy investment across Africa. Today’s discussions with President El Ghazouani will unlock closer cooperation between the EIB and Mauritanian partners and builds on 54 years of EIB engagement in the country. We are committed to bring this cooperation to the next level, by harnessing Mauritania’s renewable energy potential and through our partnership through the Sahel Alliance.” said Werner Hoyer, President of the European Investment Bank.

“The European Investment Bank is committed to supporting climate action and clean energy investment across Africa. Today’s discussions with President El Ghazouani will unlock closer cooperation between the EIB and Mauritanian partners and builds on 54 years of EIB engagement in the country. We are committed to bring this cooperation to the next level, by harnessing Mauritania’s renewable energy potential and through our partnership through the Sahel Alliance.” said Werner Hoyer, President of the European Investment Bank.

Jutta Urpilainen, European Commissioner for International Partnerships, commented: “With the joint declaration signed today at the European Development Days, Mauritania and the European Union are strengthening their cooperation to accelerate clean energy investment, drive renewable hydrogen innovation and address global energy turmoil. This demonstrates how the European Union’s Global Gateway, working in a Team Europe approach, can unlock investment to harness Africa’s renewable energy potential.”

President El Ghazouani and President Hoyer also discussed support for telecom, transport and industrial investment in Mauritania, with a special focus on national and regional electrical interconnection, and investment priorities across the Sahel and the EIB’s new dedicated development finance branch, EIB Global, launched in January this year.

The European Investment Bank is a leading financier of energy investment across Africa. Since 1965 the EIB has provided more than EUR 16 billion for energy investment in more than 49 African countries, with EUR 5.6 billion of energy financing provided over the last decade.

The European Investment Bank (EIB) is the long-term lending institution of the European Union owned by its Member States. It makes long-term finance available for sound investment in order to contribute towards EU policy goals.

EIB Global is the EIB Group’s new specialised arm dedicated to increasing the impact of international partnerships and development finance. EIB Global is designed to foster strong, focused partnership within Team Europe, alongside fellow development finance institutions, and civil society. EIB Global brings the Group closer to local people, companies and institutions through our offices across the world.