Ian Melin-Jones

ExxonMobil is set to strengthen its position to provide for the future of oil and gas demand, says GlobalData

Following ExxonMobil’s Q3 earnings release;

Steven Ho, Oil & Gas Analyst at GlobalData, a leading data and analytics company, offers his view:

“ExxonMobil is very confident that it could potentially outperform its peers if the company is able to optimize its assets - preparing to capture a bigger market share once oil demand recovers closer to pre-pandemic levels by year 2022, as forecast by the IEA. The company is focused on the short-to-medium-term outlook with no indication of shifting away from oil. In any case, ExxonMobil could also sustain and profit marginally at lower price environment, given its aggressive measure to reduce operating cost by approximately 20% from 2019.

“Indeed, the company is betting big on the future mismatch of supply and demand of oil, due to underinvestment and project delays across the whole value chain of the sector caused by COVID-19 economic crisis. In this context, ExxonMobil’s narrative is fully aligned on preparing to take on the role of providing for future hydrocarbons demand, in contrast to European counterparts that clearly state their goals in pivoting towards low carbon cleaner energy.

“Indeed, the company is betting big on the future mismatch of supply and demand of oil, due to underinvestment and project delays across the whole value chain of the sector caused by COVID-19 economic crisis. In this context, ExxonMobil’s narrative is fully aligned on preparing to take on the role of providing for future hydrocarbons demand, in contrast to European counterparts that clearly state their goals in pivoting towards low carbon cleaner energy.

"Despite a lower guidance for capital spending in 2021 down to approximately $16-19bn, ExxonMobil remains focused to invest in high-value investment such as Guyana and Brazil, while pacing the development of Permian and Mozambique LNG. The company also believes that there is a significant upside in downstream and chemicals segment as the current profit margin is at the bottom of the cycle. Furthermore, ExxonMobil is leveraging on its operational scale by integrating downstream and chemical segment to further improve margin.

“Additionally, ExxonMobil is planning to further high grade its asset portfolio by expanding the current divestment program which could return up to approximately $35 billion. However, the company recognizes the competitive market in asset sale currently and modestly pursuing this opportunity.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Metso Outotec introduces a full line of mill discharge pumps for efficient slurry handling in the concentrator plants

Metso Outotec introduces a full line of mill discharge pumps for reliable and efficient slurry handling in minerals processing.

”Slurry handling is vital in maximizing a minerals processing plant’s productivity and efficiency. Insufficient slurry handling may bring the whole plant to a halt or lead to inefficiencies in different parts of the process, causing major production losses. A large concentrator plant can have up to 150 different types of pumps in operation. Metso Outotec mill discharge (MD) pumps are robust and have been designed to operate reliably in highly abrasive environments, providing optimal solutions for each part of the process,” says Diwakar Aduri, Product Manager, MD Pumps at Metso Outotec.

”Slurry handling is vital in maximizing a minerals processing plant’s productivity and efficiency. Insufficient slurry handling may bring the whole plant to a halt or lead to inefficiencies in different parts of the process, causing major production losses. A large concentrator plant can have up to 150 different types of pumps in operation. Metso Outotec mill discharge (MD) pumps are robust and have been designed to operate reliably in highly abrasive environments, providing optimal solutions for each part of the process,” says Diwakar Aduri, Product Manager, MD Pumps at Metso Outotec.

Keeping the industry’s ever evolving needs in mind, Metso Outotec MD Series pumps offer outstanding uptime and sustained efficiencies. The MD pumps have been designed for efficient operation and longest wear life to match the mill’s uptime.

Metso Outotec’s MD Series pumps come in two tailored solutions, MDM and MDR. The MDM (Mill Discharge Metal) pumps are available in size ranges of 250-700, and the MDR (Mill Discharge Rubber) models come in size ranges of 250-700. Both pump types are suited for heavy-duty use in concentrator plants offering excellent resistance to abrasion and erosion.

Analysis service for selecting the correct pump

When selecting a slurry pump for a mine, one should look for the most robust and technologically advanced pump in terms of performance, wear resistance, uptime and total cost of ownership. Metso Outotec offers analysis service for this purpose with a detailed summary report and guidance on how to minimize total cost of ownership. It is also possible to check an initial fit using Metso Outotec’s 3D models available on the webpage.

Find out more about the Metso Outotec MD Series pumps on our webpage.

Further information, please contact:

Diwakar Aduri, Product Manager, MD Pumps, Metso Outotec, tel. +1 803.210.7577, email: diwakar.aduri(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its pro forma sales for 2019 were about EUR 4.1 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Major oil and gas EPC players are aligning strategies for energy transition, says GlobalData

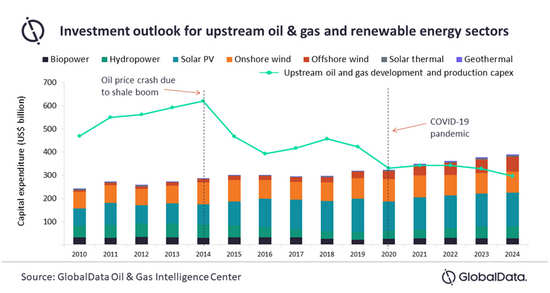

Leading oil and gas engineering, procurement, and construction (EPC) companies are increasingly shifting their strategies towards cleaner energy segments, according to GlobalData, a leading data and analytics company. Major oil and gas EPCs have traditionally relied on projects within the oil and gas value chain, building relatively little exposure to renewables. However, with a bleak investment outlook for the sector post-COVID-19 and major oil and gas companies making strategic shifts for the energy transition, these EPCs are looking to renewables and other clean energy sectors for future growth.

Will Scargill, Managing Oil & Gas Analyst at GlobalData, comments, “COVID-19 brought a major oil and gas demand shock, delayed projects and raised additional questions about the potential for future oil demand growth. Oil and gas investment is likely to flatline at best over the coming years and companies will need to look to the growth markets of new energy sectors to support their businesses.”

EPC companies are adopting diverse strategies to position themselves for the energy transition. Aker and TechnipFMC have restructured their businesses to create dedicated units for low-carbon projects. Meanwhile, Petrofac is aiming to achieve net zero in Scope 1 and Scope 2 emissions by 2030. Despite these varying approaches, the most common target segments among major oil and gas EPC companies are offshore wind and carbon capture and storage.

Scargill adds: “The targeting of offshore wind and carbon capture is common theme among companies from the oil and gas sector looking to adapt for the energy transition due to the potential for knowledge synergies. Oil and gas EPCs looking to target new segments will also hope to benefit from existing partnerships with clients making a similar transition. However, their growth plans will face a challenge from incumbent players in the renewables space.”

- Quotes provided by Will Scargill, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s expert insight: ‘Energy Transition Strategies of Major Oil & Gas EPC Companies’

- Scope 1- Direct emissions e.g. from production processes; Scope 2- Indirect emissions e.g. the source from where the energy is purchased

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

HARTING to showcase modular solutions at Smart Factory Expo 2020

HARTING will be discussing their range of innovative connectivity solutions at the online Smart Factory Expo from the 9th to the 13th November 2020.

Their product and market specialists will be on hand to discuss the benefits of modularisation in the modern smart factory, including adaptable production methods, reduced maintenance downtimes and shortened set up times.

HARTING are renowned for their modular solutions, which improve flexibility and allow users to perform non-disruptive maintenance. The Han-Modular® range enables you to produce a bespoke connector by combining individual modules for different transmission media, such as signals, data and power. You can even use the innovative Han® Configurator tool to quickly design interfaces for your specific applications.

Create a bespoke connector by combining individual modules for different transmission media from the Han-Modular® range.

Create a bespoke connector by combining individual modules for different transmission media from the Han-Modular® range.

In addition, there will be areas dedicated to robust and space-saving solutions for fast Ethernet, device connectivity and industrial cabling. The ix Industrial® is a compact interface that delivers Cat. 6A performance for 1/10Gbit/s Ethernet. The ix complies with IEC 61076-3-124 and conforms to the shock and vibration resistance levels set out in EN 50155 railway specifications, making it the perfect solution for a range of markets.

There will also be information about Single Pair Ethernet (SPE), one of the technological cornerstones that will shape the success of the IIoT. The factory of the future will require high data streams and the industrial sector needs connectivity solutions which adapt themselves to increasingly growing demands.

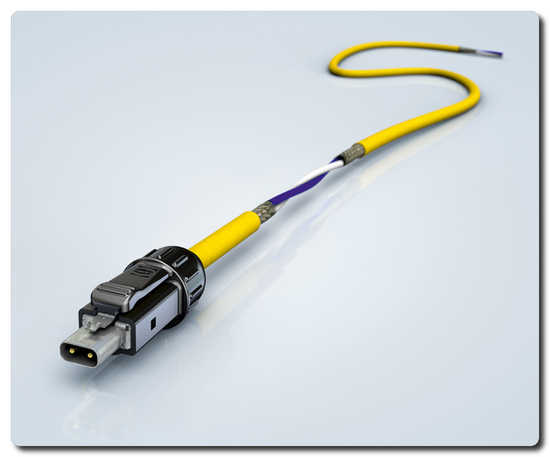

SPE, delivered via HARTING’s T1 Industrial connector, allows equipment to connect via end-to-end IP-based communications right up into the field level. The T1 Industrial supplies both data and power via Power over Data Line (PoDL) across a single pair of wires in an IEC 63171-6 industrial interface, bringing Ethernet from the cloud to every sensor and enabling Industry 4.0.

Space-saving and weight reduction benefits achieved by the move to a single pair of wires mean the compact T1 can be easily incorporated into smaller products and Ethernet interfaces can be designed onto simple sensors, cameras, reading/ID devices or similar miniaturised equipment.

The T1 Industrial can be easily designed onto simple sensors, cameras, reading/ID devices or similar miniaturised equipment.

The T1 Industrial can be easily designed onto simple sensors, cameras, reading/ID devices or similar miniaturised equipment.

In addition, you can learn more about HARTING Customised Solutions, which combines market-leading products and expertise to develop components tailored to specific requirements. They work closely with customers to plan, design, test and produce a wide range of bespoke products such as cable assemblies, hoods, housings and cabling from their manufacturing facility in Northampton.

To learn more about our products and solutions and register for your FREE ticket to Smart Factory Expo, please visit: https://www.harting.com/UK/en-gb/smart-factory-expo . We look forward to meeting you and discussing your requirements at Smart Factory Expo.

About HARTING:

The HARTING Technology Group is one of the world's leading providers of industrial connection technology for the three lifelines of Data, Signal and Power and has 14 production plants and 44 sales companies. Moreover, the company also produces retail checkout systems, electromagnetic actuators for automotive and industrial series use, charging equipment for electric vehicles, as well as hardware and software for customers and applications in automation technology, mechanical and plant engineering, robotics and transportation engineering. In the 2018/19 business year, some 5,300 employees generated sales of EUR 750 million. Founded on 1 September 1945, the company celebrates its 75th anniversary this year.

For further information visit https://www.harting.com/UK/en-gb/smart-factory-expo

The New Moog Modular Electrohydrostatic Actuation System (EAS) Combines the Best of Two Worlds: Electrohydraulic (EH) and Electromechanical (EM) Actuation

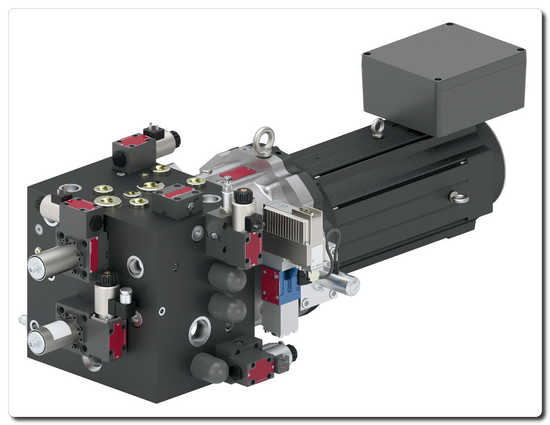

Moog Industrial Group, a division of Moog Inc., (NYSE: MOG.A and MOG.B) today announced the market introduction of the new Modular EAS System. The Modular EAS is a highly flexible system with excellent scalability and variability and can be easily adapted to most types of industrial manufacturing machinery.

Standardized Modular EAS Solution

The Moog Modular Electrohydrostatic Actuation System (Modular EAS) features standardized modules with a wide number of customization options available. This process allows for extensive application potential by meeting the specific requirements of the customer. The system’s smallest scope of delivery consists of a basic manifold and an Electrohydrostatic Pump Unit (EPU) which Moog delivers as an assembled and tested unit.

Moog Modular Electrohydrostatic Actuation System (Modular EAS).

Moog Modular Electrohydrostatic Actuation System (Modular EAS).

To expand the system, the basic module can be combined with various options or adapted with additional standardized high-speed manifolds in order to build a complete motion control system. With the Modular EAS System the localized power allows for improved energy efficiency due to the elimination of the flow control valving and centralized piping, which reduces the amount of wasted energy commonly found on traditional hydraulic systems.

Modular EAS Benefits

- High force capability and force density that provide a compact and performant alternative to EH and EM actuation

- Environmentally clean due to up to 90% lower oil requirement compared to the standard systems and low noise emission for quiet machine operation

- Small number of components to reduce the risk of breakdown and allow for faster maintenance

- Decentralized system that eliminates the need for a large Hydraulic Power Unit (HPU) and reduces piping

- 4-quadrant operation technology allows for universal suitability for a large range of challenging applications as well as for effective energy management with reduced consumption due to energy recuperation

- Low mass inertia of the EPU provides high system dynamics

Applications

The Modular EAS System is suitable for a wide range of industrial manufacturing machinery. It can be used on metal pressing applications from forging, powder and sheet metal presses to hot forming, punching and isostatic press machines. In wood and paper milling, testing and power generation applications the Modular EAS System allows for improved decentralization of the machine axes. Additional high-performance applications can be realised in the industrial marine sector, on operational mobile machinery and on injection and blow molding machinery in the plastics sector. The system simultaneously reduces oil requirements for HPU by 90%, thereby reducing machine cost of ownership significantly.

More details about the product under: https://www.mooginfo.com/ModularEAS.

Amazon Filters to reveal manganese removal success at Dwr Cymru Welsh Water Innovation Event

The use of cartridge filters to remove manganese from the municipal water supply is the focus of a presentation at the Dwr Cymru Welsh Water Innovation Event on 29 October 2020.

David Ridealgh, Marketing Manager at filter manufacturer Amazon Filters, will discuss the benefits of substituting cartridge filtration for traditional sand beds to remove the mineral.

The presentation will give an update on ongoing Welsh trials that have already indicated a potential 25% cost efficiency using cartridges.

FILTER SUCCESS. David Ridealgh, Amazon Filters Marketing Manager, is presenting at the Dwr Cymru Welsh Water Innovation Event.

FILTER SUCCESS. David Ridealgh, Amazon Filters Marketing Manager, is presenting at the Dwr Cymru Welsh Water Innovation Event.

David said: “Sand beds typically entail high capital costs especially when planning treatment processes across multiple bore holes or reservoirs.

“To try a more viable solution, Welsh Water commissioned us to design a system of polymer cartridge filters.

“It involves fibres made via a computer-controlled process which accelerate the seeding of manganese clusters that can then be taken out through catalytic removal.

“Our challenge has been to ensure the filter harnesses the optimum combination of fibres, and maintains water flow alongside the usual treatment processes of chlorination and pH adjustment.

“The results have been highly encouraging, with discoloration avoided and manganese levels as low as one part per billion.

“As water companies in England and Wales look to AMP7, our trials with Welsh Water indicate how quality filtration solutions can help achieve both cost efficiencies and environmental improvements at the same time.”

Amazon Filters is the only water filter manufacturer presenting at the Innovation Event conference and exhibition, being held digitally this year due to the pandemic.

The keynote address will be given by the Chief Scientific Advisor for Wales, Professor Peter Halligan, and Ofwat’s Senior Director of Strategy and Planning, John Russell.

For more information on the event, visit https://www.dcwwinnovation.com/programme.

For more details of the manganese removal trials, visit https://www.amazonfilters.com/manganese-removal-municipal-water-dc.

Founded in 1985, UK-based Amazon Filters Ltd is one of Europe’s leading manufacturers and suppliers of filter cartridges and housings. Our comprehensive range of products support critical liquid and gas applications in industries such as oil and gas, automotive, pharmaceuticals, food and beverage, chemicals and coatings, water treatment and building services. We operate a range of ISO-accredited Quality Management Systems to ensure excellence in customer service. For more information, visit www.amazonfilters.com or call 01276 670600.

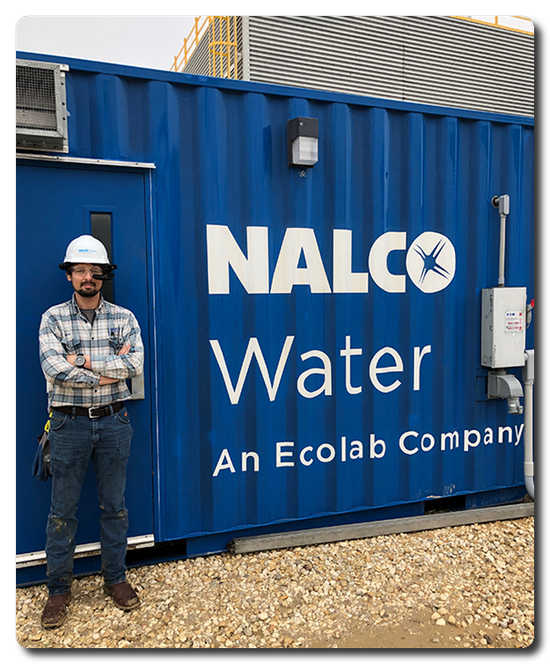

Ecolab completes its first major equipment installation enabled by mixed reality at U.S. energy plant

With COVID-19 reducing in-person access to energy plants around the world, Ecolab is using new digital solutions to deliver its water, energy and sanitization solutions.

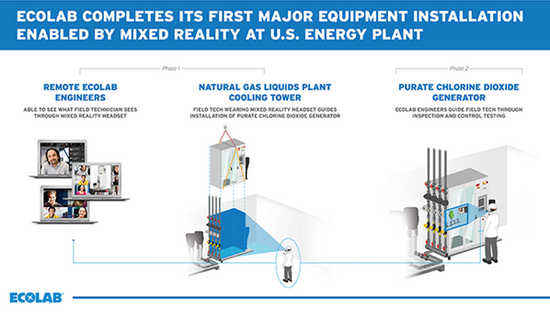

- With COVID-19 causing restricted access to facilities, Ecolab used mixed reality to safely install a PURATE™ chlorine dioxide generator at a leading midstream company’s facility.

- Mixed reality enabled Ecolab engineers to remotely “see” inside the plant and guide a single on-site field representative through installation, testing and implementation.

- With PURATE, this midstream company safely reduced costs, improved efficiency and simplified logistics for natural gas processing operations while improving sustainability.

Ecolab used mixed reality to guide the installation of PURATE chlorine dioxide generators at multiple facilities for one of the largest independent midstream energy infrastructure companies in the U.S. These installations mark Ecolab’s first use of mixed reality to install, test and deliver a chlorine dioxide generator solution for cooling tower operations at an energy plant.

Ecolab used mixed reality to guide the installation of PURATE chlorine dioxide generators at multiple facilities for one of the largest independent midstream energy infrastructure companies in the U.S. These installations mark Ecolab’s first use of mixed reality to install, test and deliver a chlorine dioxide generator solution for cooling tower operations at an energy plant.

Mixed reality combines elements of virtual reality and augmented reality to create a blend of the physical and digital world that users experience through mixed reality headsets. Ecolab leveraged the technology to install three PURATE generators, which generate ClO2 and can be more effective than bleach or bromide solutions in controlling the fouling and microbial problems that can reduce the efficiency of heat exchangers in cooling towers (EPA Reg. No. 1706-242).

“Due to the travel, social distancing and plant access restrictions in effect for COVID-19, a typical installation process that involves several on-site engineers was not possible for this company,” said Steve Kramarczyk, a corporate account manager for the Global Heavy division of Ecolab. “Still, the company wanted to realize the cost and logistics savings PURATE offers, so we were able to use mixed reality to safely oversee its installation.”

By wearing a mixed reality headset, a single Ecolab field representative was able to transmit on-site visuals and critical data to a team of Ecolab engineers working remotely. Similar to a guided space mission, the engineers, whose combined experience totaled more than 50 years, were then able to guide the representative through a variety of operations at the plant that included:

- Inspection and planning

- An installation process in the cooling towers that involved lifting the PURATE generator into place with a crane

- Inspecting valves, monitors, electronics and checking for leaks

- Mechanical and control testing of the PURATE generator, wet testing it with water, and finally, testing it with its chlorine dioxide chemical solution

The installations took approximately 1.5 days each and the results were near instantaneous. The PURATE ClO2 solution is more effective than competitive products, which results in fewer shipments of chemicals to the company’s plants. This means there is less time spent onboarding supplies, reducing logistics and labor needs, as well as the time spent handling chemicals, which contributes to the customer’s health and safety goals. Fewer chemicals on site enables the company to better optimize its available plant space. PURATE also operates in a wider pH balance than bleach or bromide, which will offer the midstream company more flexibility in its treatment options in the future.

“Digital technologies like mixed reality will have a transformative effect in the energy sector,” Kramarczyk said. “Not only will companies that embrace them be able to perform major equipment installations, they will be able to better assess risk, monitor their operations and improve their efficiency. Ecolab has spent decades building relationships with our customers and learning about the innerworkings of their operations. It’s this intimate knowledge that enables us to leverage our digital solutions effectively for our customers.”

Ecolab Field Representative Daniel Reed shows off the mixed reality headset that enabled the remotely-guided PURATE installations.

Ecolab Field Representative Daniel Reed shows off the mixed reality headset that enabled the remotely-guided PURATE installations.

Global power industry contracts in Q3 2020: Hydro technology down 4%

Hydro technology contracts activity in Q3 2020 saw 53 contracts announced, marking a drop of 4% over the last four-quarter average of 55, according to GlobalData’s power industry contracts database.

Looking at global power contracts activity divided by the type of technology, hydro held the fourth position in terms of number of contracts during Q3 2020 with a 5.5% share.

The proportion of contracts by category in the Hydro technology tracked by GlobalData in the quarter was as follows:

The proportion of contracts by category in the Hydro technology tracked by GlobalData in the quarter was as follows:

- Supply & Erection: 19 contracts and a 35.8% share

- Power Purchase Agreement: 11 contracts and a 20.8% share

- Consulting & Similar Services: eight contracts and a 15.1% share

- Project Implementation: seven contracts and a 13.2% share

- Repair, Maintenance, Upgrade & Others: six contracts and an 11.3% share

- Electricity Supply: two contracts and a 3.8% share.

Asia-Pacific leads hydro contracts activity in Q3 2020

Comparing contracts activity in hydro technology in different regions of the globe, Asia-Pacific held the top position with 23 contracts and a share of 43.4% during Q3 2020, followed by Europe with 15 contracts and a 28.3% share and South and Central America with seven contracts and a 13.2% share.

In fourth place was Middle East and Africa with six contracts and an 11.3% share and in fifth place was North America with two contracts and a 3.8% share.

Hydro technology contracts in Q3 2020: Top issuers by capacity

The top issuers of contracts in Hydro technology for the quarter in terms of power capacity involved were:

- Government of Pakistan (Pakistan): 700.7MW from one contract

- Walcha Energy (Australia): 500MW from one contract

- Teck Resources (Canada): 72MW capacity from one contract.

Hydro technology contracts in Q3 2020: Top winners by capacity

The top winners of contracts for the quarter in terms of power capacity involved were:

- China Gezhouba Group (China): 732.7MW from two contracts

- GE Renewable Energy (France): 500MW from one contract

- AES Gener (Chile): 72MW capacity from one contract.

All publicly-announced contracts are included in this analysis drawn from GlobalData’s Power database, which covers power plants, T&D projects, equipment markets, analysis reports, capacity and generation, and tracks tenders and contracts on a real-time basis.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

Metso Outotec’s HPGR flanged roll kit with mechanical skew control is available for all equipment manufacturers’ machines

Metso Outotec is launching the mechanical skew control HPGR (High Pressure Grinding Roll) retrofit kit for improved throughput and energy efficiency on the heels of the new HRC™e HPGR release. The industry standard was set when the HRC™ HPGR was launched back in 2014 pioneering the use of flanges and non-skewing design. Now, those same industry-leading benefits can be had on existing, non-Metso Outotec machines.

HPGR flanged roll kit with mechanical skew control is available for all equipment manufacturers’ machines. (Image: Metso Outotec)

HPGR flanged roll kit with mechanical skew control is available for all equipment manufacturers’ machines. (Image: Metso Outotec)

The new HPGR retrofit kit takes the key components responsible for minimizing skew from our HRC™ and makes the technology more accessible without the major investment or need to acquire a new machine.

“We are very excited to introduce the new flanged roll with mechanical skew control HPGR retrofit kit which allows customers to maximize the performance of their existing equipment without the CAPEX investment of purchasing expansion machines. This is truly a value option for an extended customer reach,” says Jack Meegan, Product Director, SVS, Stirred Mills and HPGR at Metso Outotec.

Key benefits of Metso Outotec HPGR retrofit kit

- Increased throughput

Achieve up to +20% more throughput

- Improved energy efficiency

Flanges ensure even breakage rates across the whole width of the roll

- Reduced circulating loads

Less material bypasses the rolls and more ore continues to the next stage of your process

- Reduced wear costs

Flanges allow harder studs for longer tire life

Register for the webinar

On November 10, 2020, Metso Outotec will host two free webinars where the HPGR retrofit kit will be presented in more detail.

You can register to the webinars here.

Jack Meegan, Product Director, SVS, Stirred Mills and HPGR, Metso Outotec Corporation, tel. +1 435 241 9916, email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Next level EV charging – the most used interoperability protocol is released in version 2.3

High dynamics and short innovation cycles characterize the eMobility market. The continuous and collaborative development of cross-linked organizations within the ecosystem of eMobility is essential in such an agile market environment. To meet market demands, Hubject and all its intercharge partners are continuously developing the Open Intercharge Protocol, OICP, releasing the newest version 2.3.

The OICP – an open source and therefore easy to implement - created in 2012 to make an easy-to-use and reliable interoperability solution, has a business and IT connection to over 250,000 charging points, and more than 750 companies in 43 countries over four continents by one API connection. This is stimulating positively all companies using it, by reducing resources needed as well as increasing reliability and security by using one of the most mature eRoaming protocols. These changes support the Hubject mission to make EV charging easy and seamless for drivers in an open and transparent approach with all market participants jointly.

The feedback and experience of all the contributors were incorporated to develop new functionalities, focusing on four main targets:

- Improving the POI quality in an upscaling market,

- Realizing calibration law compatibility,

- Offering more transparency on the different charging use cases,

- Improving data process performance.

Carsten Puhl, CTO of Hubject is saying: “With this process, we and the whole industry have taken an important step jointly for an open, widely supported protocol, being the most used eRoaming protocol in Europe and other markets. Based on the open source status, we encourage other companies and stakeholders to contribute to the development, which is even easier now, that the protocol has been published via GitHub.”

In addition to these specific changes, Hubject also implemented another valuable feature specifically for all CPO partners, offering a set of so-called remote testing functionalities, to consider testing complex use cases.

Due to the value of the new version, Hubject will deprecate the version of OICP2.1 on July 1st, 2021.

Every partner can start implementing it since October 1st, 2020. For more information, please visit github.com/hubject/oicp.

About Hubject

Hubject simplifies the charging of electric vehicles. Through its eRoaming platform, called intercharge, the eMobility specialist connects Charge Point Operators or CPOs and eMobility Service Providers or EMPs, thus providing standardized access to charging infrastructure regardless of any network. With over 250,000 connected charging points and more than 750 B2B partners across 43 countries and four continents, Hubject has established the world’s largest cross-provider charging network for electric vehicles by connecting CPO networks. In addition, Hubject is a trusted consulting partner in the eMobility market, advising automotive manufacturers, charging providers, and other EV-related businesses looking to launch eMobility services or implement Plug&Charge using ISO 15118. In essence, Hubject promotes eMobility and its advancement worldwide. Founded in 2012, Hubject is a joint venture of the BMW Group, Bosch, EnBW, Enel X, Mercedes-Benz, innogy, Siemens and the Volkswagen Group. Hubject’s headquarters is located in Berlin, with subsidiaries in Los Angeles and Shanghai.

HUBJECT — Heading for the future.

For more information on Hubject and its services, please visit www.hubject.com