Ian Melin-Jones

Nexans to supply nuclear rated cables to Hinkley Point C project to bring carbon-free electricity to six million uk homes

Nexans will play a key role in the UK’s energy transition with a contract worth around €20 million to supply specialized nuclear cables for the Hinkley Point C new nuclear power station. Over a six-year contract, Nexans will design and manufacture a total of 3,000 kilometers of cables developed to ensure safety, reliability and long life.

- Hinkley Point C is the first nuclear power plant to be constructed in the UK for over 25 years.

- The project will make a major contribution to reducing the country’s carbon emissions and will have the capacity to supply six million UK homes with electricity.

- Nexans ENERGEN NUC power and control cables will ensure continuous fail-safe operation for critical services at the plant’s two EPR reactors.

Hinkley Point C, under construction in the UK County of Somerset, marks a significant milestone in the revitalization of the UK’s nuclear power sector. With two EPR reactors producing 3,200 megawatts of power for the national grid, the plant will be capable of supplying around 6 million UK homes with low-carbon electricity. This will make a major contribution to the UK’s move to net zero and will offset 9 million tons of carbon dioxide emissions a year over the plant’s 60-year lifespan.

Oliver Dervout, Nexans Market Segment Director for Power Generation said: “We are very excited to be involved in this ground-breaking project for the UK’s nuclear power program. We have already gained considerable experience as a supplier of nuclear-qualified cables for EPR projects worldwide, such as Flamanville (FA3) in France and Taishan in China. Winning the contract for Hinkley Point C confirms our solid reputation in the nuclear segment. The key to our success is the ability to combine technical expertise, high level products and extensive industrial design and manufacturing capability.”

Nexans is supplying a variety of custom-designed, nuclear-rated cables for the Hinkley Point C site, including medium voltage (MV) and low voltage (LV) power, control and instrumentation cables for pumps, valves, safety systems, power supplies and control room monitoring. They will be installed inside and outside of the nuclear containment area. It is vital that the cables continue to perform safely and reliably under the demanding environmental conditions corresponding to normal, accidental and/or post-accidental plant operating conditions.

To satisfy the most rigorous safety standards, Nexans ENERGEN NUC halogen-free cables that comply with the Euroclass requirements for reaction to fire. They will be manufactured at the Nexans factory in Mehun-sur-Yèvre, France.

About Nexans

Nexans is a key driver for the world’s transition to a more connected and sustainable energy future. For over 120 years, the Group has brought energy to life by providing customers with advanced cable technologies for power and data transmission. Today, Nexans goes beyond cables to offer customers a complete service that leverages digital technology to maximize the performance and efficiency of their critical assets. The Group designs solutions and services along the entire value chain in three main business areas: Building & Territories (including utilities and emobility), High Voltage & Projects (covering offshore wind farms, subsea interconnections, land high voltage), and Industry & Solutions (including renewables, transportation, oil and gas, automation, and others).

Corporate Social Responsibility is a guiding principle of Nexans’ business activities and internal practices. In 2013 Nexans was the first cable provider to create a Foundation supporting sustainable initiatives bringing access to energy to disadvantaged communities worldwide. The Group’s commitment to developing ethical, sustainable and high-quality cables also drives its active involvement within leading industry associations, including Europacable, the NEMA, ICF and CIGRE.

Nexans employs nearly 26,000 people with an industrial footprint in 34 countries and commercial activities worldwide. In 2019, the Group generated 6.7 billion euros in sales.

Nexans is listed on Euronext Paris, compartment A.

For more information, please visit www.nexans.com

Automation pioneer ABB confirmed as #1 DCS market leader

Customer focus, digital innovation and remote services were drivers for ABB’s leadership position in Distributed Control Systems (DCS) for the 21st consecutive year, according to analyst

Distributed Control Systems (DCS) are central to automation in the energy and process industries, playing a key role within Industry 4.0 and representing a global market valued at $15 billion. A recent report published by the ARC Advisory Group confirmed that, in a highly competitive landscape, ABB remains the #1 DCS market leader for the 21st year running.

Holding an overall share of 19.2%, ABB leads the field thanks to its domain knowledge in multiple industries, extensive service network and a continued investment in technology and digital solutions that meet rapidly changing customer requirements. This puts ABB more than two points ahead of the nearest DCS competitor.

The largest share of 2019 DCS market growth came from oil and gas, chemicals, mining, pharmaceuticals and biotechnology, followed by food & beverage, metals, cement, and pulp & paper. With its two main DCS offerings, ABB Ability™ System 800xA and ABB Ability™ Symphony Plus, ABB has a strong presence in each of these segments. ABB is also a leader in several of the key DCS trends identified in the report, including Modular Automation, Batch, Characterizable I/O and Remote Services.

As the DCS leader, ABB continuously develops new control benefits for customers. For example, by processing the massive amounts of data generated by the DCS, ABB continues to develop new data analytics that help customers to increase production efficiency, and leverage machine learning capabilities that improve problem predictability and extend asset life.

“I want to thank our customers for their longstanding support, helping us to shape ABB’s automation offering and expertise into what it is today,” said Bernhard Eschermann, Chief Technology Officer, ABB Industrial Automation. “Automation makes a difference in the world around us. The DCS is the backbone for much of the digitalization transforming our customers’ industries. It helps to provide many of the elements essential to modern society, such as the water we drink, the energy we consume or the materials used to build our homes.”

“During more robust economic times, process industry producers often rely on new production machinery to increase output. In the current highly demanding economic environment, customers are squeezing as much value as they can out of existing assets, running as efficiently as possible to protect profit margins. Maximizing assets and efficiencies is what DCS do,” he said. “We see it as our duty to continue to develop solutions that offer these benefits and more for our customers.”

A key focus of ABB’s annual $1.5 billion research & development investment is the further expansion of DCS and other digital and automation capabilities in the context of Industry 4.0. In July, ABB brought two new offerings to market that use DCS data with value-added applications to improve customer production availability, process performance and product quality. The ABB AbilityTM Edgenius Operations Data Manager gleans value from DCS data, while the ABB AbilityTM Genix Industrial Analytics and AI Suite combines data from operations (e.g. DCS), engineering and information technology for multi-dimensional data analytics and decision support.

Services saw the highest growth in relation to software and hardware in the ARC report. This trend accelerated in 2020, which created a high need for remote services. One such service, ABB AbilityTM Collaborative Operations, a remote-enabled network of ABB experts and technologies, uses many ABB DCS technologies to remotely monitor and support customer assets and processes. ABB experts in ABB Collaborative Operations centers globally are available 24/7 to assist customers. The Collaborative Operations network continues to provide remote support for customers in travel-restricted situations.

As the world looks to Smart Cities, Green Energy and Vertical Farming in support of trends such as Urbanization, ABB DCS will play a key role in ensuring their realization.

https://new.abb.com/control-systems/system-800xa

https://new.abb.com/power-generation/systems/power-plant-automation/abb-ability-symphony-plus

ARC Advisory Group

Founded in 1986, ARC Advisory Group is the leading technology research and advisory firm for industry, infrastructure, and cities due to its in-depth coverage of operational technologies (OT), engineering technologies (ET) and associated business trends. ARC’s analysts and consultants have the industry knowledge and first-hand experience to help clients find the best answers to the complex OT, ET and business issues facing organizations today. ARC provides technology suppliers with strategic market research, and helps end-user clients develop appropriate adoption strategies and select the best technology for their needs.

ABB’s Industrial Automation business area offers a broad range of products, systems, and solutions for customers in the process and hybrid industries. These include industry-specific services, as well as measurement and analytics, marine and turbocharging offerings. ABB’s Industrial Automation business is #2 in the market globally. With deep domain knowledge, experience and expertise, ABB Industrial Automation helps customers increase competitiveness, improve return on investment and run safe, smart, and sustainable operations.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

Lab lobster is Shiok Meats’ hope for capitalizing on $92.6bn Asian fish and seafood sector, says GlobalData

Shiok Meats is banking on its new cell-based cultured lobster and shrimp meat to help commercialize cultured crustacean by 2022. Leading data and analytics company GlobalData notes that cultured lobster should appeal to Asian shellfish consumers and break into the profits of the Asian fish and seafood sector, which is expected to value $92.6bn in 2020.

Ryan Whittaker, Consumer Analyst at GlobalData, comments: “Luxury seafood such as lobster and shrimp can damage the environment as much as lamb and beef, so more options like this need to be explored. Seafood is a largely overlooked category when it comes to developing new meat.”

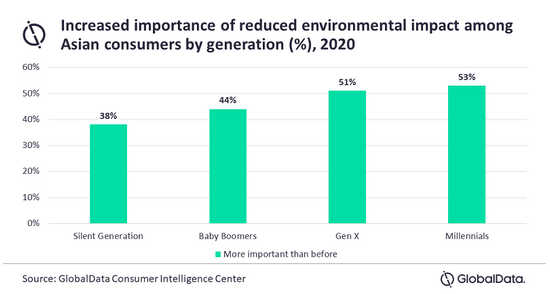

According to research by GlobalData, products that attend to environmental concerns may be more readily adopted by APAC consumers, when compared with two years ago. According to GlobalData’s consumer survey, 52%* of Asian consumers consider the reduction of environmental impact to be more important than before the pandemic. This shift in attitude may well be down to the pandemic itself, which has disrupted modern life and has often made people reconsider what is truly important.”

Whittaker adds: “There are significant increases in environmental awareness across all age groups in APAC, which is impacting how they buy. New product development in Asia that focuses on delivering meat alternatives to the more environmentally damaging seafood almost certainly has a target audience in the region, especially among younger consumers.”

As Asian consumers are becoming more affluent and discerning about environmental impact, companies such as Shiok Shrimp are working on the inefficiencies around global protein production. Lobster is a high-status food that is in high demand in Hong Kong and China. This prompts energy intensive imports from the US and Australia to meet demand. Developing ways to culture the meat locally may be part of several solutions at once, assuming the company can satisfy the taste test.

*COVID-19 recovery tracker consumer survey, published 7 December, combining answers “It is now my top priority”, “significantly more important than before” and “slightly more important than before”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

New waste shredder transforms co-processing capabilities of Geocycle Argentina

An UNTHA XR3000C mobil-e shredder is now in operation at Geocycle’s co-processing facility in Córdoba, Argentina, as the innovative waste handler continues to progress towards a zero-waste future.

The team – a 100% daughter company of cement manufacturer LafargeHolcim – is now transforming 100 tonnes of waste per day into an on-specification alternative fuel, for use within the company’s cement kiln only 5km away. And plans are already underway to double fuel production volumes by the end of Q1 2021.

World-renowned for its flexibility, the single shaft UNTHA XR is handling a wide range of input materials – collected from a 100km radius – including Municipal Solid Waste (MSW), wood, plastics and tyres. With no pre-shredding required, Geocycle can produce a homogenous 50mm output granulate in one pass, to significantly reduce the company’s reliance on ever-depleting fossil fuels, while diverting thousands of tonnes of waste from landfill.

UNTHA XR3000C mobil-e shredder

UNTHA XR3000C mobil-e shredder

The investment in this latest machine means Geocycle has now commissioned more than 10 UNTHA shredders on 3 continents globally.

“Geocycle Argentina is no stranger to waste shredding for alternative fuel production,” explained director Mariano Bollo. “We previously used a dual-shaft machine manufactured by a competitor of UNTHA’s, but the capacity and reliability of our machine continued to cause us problems.

“UNTHA’s low speed, high torque drive means this is a powerful machine with impressive uptime, ease of maintenance and proven capabilities. This – combined with the shredder’s versatility – meant the business case to switch to an XR was strong.”

With the help of LafargeHolcim’s technical support group – based in Switzerland – Geocycle Argentina developed the specification for the new machine.

“While we think carefully about every decision we make, to ensure each shredder we invest in has absolutely the right configuration for every single plant, we now run a number of UNTHA machines, across our global group,” continued Mariano.

“The whole life operating costs of this shredder are extremely low, which means we can consistently produce a profitable, environmentally-sound fuel. It therefore comes as little surprise that we’re looking to standardise the technology we use across our business. This has benefits when it comes to procuring and sharing spare and wear parts too.”

Working in collaboration with UNTHA’s local engineering specialists, Geocycle is now optimising the design and layout of the waste processing line to double throughputs in the early part of 2021.

“This XR investment aligns with our global alternative fuel production strategy, which doesn’t just improve our cement manufacturing footprint worldwide – it transforms the environmental status of our local communities too,” Mariano concluded.

Since 1990, LafargeHolcim has reduced its net carbon emissions per tonne of cement, by 25%.

Nexans joins RE100

Nexans joins the Climate Group's RE100 initiative and is committed to achieving 100% renewable electricity by 2030.

RE100 is a global initiative bringing together the world's most influential companies leading the transition to 100% renewable electricity.

In line with the Paris agreements (COP21), which set a limit of 1.5°C warming by 2030, Nexans has unveiled its roadmap towards carbon neutrality. As part of this plan, the Group is aiming for an average annual reduction of 4.2% in its greenhouse gas emissions (in particular on scopes 1 and 2[1]) and plans, among other things, to use renewable energy through local production or the purchase of decarbonated energy for all sites, and that 100% of R&D projects will be dedicated to energy transition and energy efficiency.

“Our ambition is to contribute to the energy transition by being a player in the sustainable electrification of the world," says Christopher Guérin, CEO of Nexans. "More than a strategic axis, renewable energy is part of our purpose: "Electrify the future". Joining the RE100 demonstrates Nexans’ commitment to bring a sustainable future for all.”

“I am delighted to welcome Nexans to RE100. By committing to 100% renewable electricity by 2030, Nexans is joining a growing number of companies committed to driving market change. This sends a powerful message that renewable electricity makes good business sense, and we encourage others to follow,” says Sam Kimmins, Head of RE100, the Climate Group.

On December, 8th, Nexans has been recognized with prestigious ‘A’ score for climate change by CDP. To learn more, click here.

About Nexans

Nexans is a key driver for the world’s transition to a more connected and sustainable energy future. For over 120 years, the Group has brought energy to life by providing customers with advanced cable technologies for power and data transmission. Today, Nexans goes beyond cables to offer customers a complete service that leverages digital technology to maximize the performance and efficiency of their critical assets. The Group designs solutions and services along the entire value chain in three main business areas: Building & Territories (including utilities and emobility), High Voltage & Projects (covering offshore wind farms, subsea interconnections, land high voltage), and Industry & Solutions (including renewables, transportation, oil and gas, automation, and others).

Corporate Social Responsibility is a guiding principle of Nexans’ business activities and internal practices. In 2013 Nexans was the first cable provider to create a Foundation supporting sustainable initiatives bringing access to energy to disadvantaged communities worldwide. The Group’s commitment to developing ethical, sustainable and high-quality cables also drives its active involvement within leading industry associations, including Europacable, the NEMA, ICF and CIGRE.

Nexans employs nearly 26,000 people with an industrial footprint in 34 countries and commercial activities worldwide. In 2019, the Group generated 6.7 billion euros in sales.

Nexans is listed on Euronext Paris, compartment A.

For more information, please visit www.nexans.com

Xodus Group invests in emissions team to support drive to Net Zero

Global energy consultancy Xodus Group has invested in expanding their emissions team to support clients and the wider energy industry in achieving its Net Zero goals.

Xodus has added experienced atmospherics expert Natasha Howlett to lead an in-house emissions management division, which will support clients’ emissions reduction initiatives around the world.

Natasha HowlettThis new offering will build on Xodus’ existing services by including offshore energy assessments, exhaust stack sampling, emissions management and forecasting, ESOS compliance, BAT assessments, gas turbine and compressor performance testing and training packages.

Natasha HowlettThis new offering will build on Xodus’ existing services by including offshore energy assessments, exhaust stack sampling, emissions management and forecasting, ESOS compliance, BAT assessments, gas turbine and compressor performance testing and training packages.

Natasha will be joined by Christopher Smith and Vicky Milne, who join from energy and emissions consultancy, PI, and boast more than 15 years of dedicated emissions experience between them. Throughout that time, the team has built an extensive international database of emissions data compiled from hundreds of global offshore tests and assessments.

Christina Horspool, UK Environment Division Manager for Xodus, said: “As the global energy industry steps up to its commitment to significantly reduce and improve the management of emissions, we have a clear role to play in enabling our clients to achieve their Net Zero goals.

“We are committed to investing in the very best talent and technology to remain as the go-to energy consultancy of choice and today’s announcement reflects just that. The experience of Natasha, Victoria and Chris enables us to provide the industry with unparalleled emissions expertise and services.”

As the industry tries to balance challenging economic demands with the need to significantly improve sustainability, the emissions team will work closely with clients to set priorities internationally.

Natasha added: “I have admired the ethos and approach of Xodus for many years and it’s great to now be part of such an exciting company. As well as our continued support to familiar clients, we are looking forward to establishing a range of new relationships. As the most experienced team in our field, we are trusted advisors to many of the world’s leading operators and industry bodies.”

For further info contact:This email address is being protected from spambots. You need JavaScript enabled to view it.

Experts with Energy

As a leading global energy consultancy, we help clients overcome challenges, add value to opportunities and maximise returns on investments, responsibly. Our values of trust, responsibility and excellence underpin our vision. They are at the heart of decision making and inform our future strategy.

In offering expert advice and solving complex problems, our multi-skilled specialists work across the energy spectrum to address industry problems. By combining technology with our knowledge, we create better business outcomes whether it is advisory, project development or in operational support.

Together, we will deliver a responsible energy future -www.xodusgroup.com

Headquartered in Aberdeen, Scotland with a global operations centre in London, Xodus has offices in Edinburgh, Glasgow, Orkney, Egypt, Perth, Australia and Boston and Houston in the US.

AMADA WELD TECH announces new Jupiter series of modular systems for precision joining

AMADA WELD TECH announces the availability of the Jupiter series of modular systems for precision joining, available for laser welding, laser marking, resistance welding, micro arc welding, and hot bar bonding applications. Jupiter modular systems can be equipped with all joining process modules available from AMADA WELD TECH to provide solutions to customers.

With the Jupiter series, customers purchase an automation platform from a global joining equipment leader and receive intensive process development support in AMADA WELD TECH application development centers. Joint early stage process development in AMADA WELD TECH labs ensures that customers receive the ideal system solution for years of high-quality production. Any welding, soldering, bonding, brazing, laser micromachining, and laser marking application can be handled by equipment in the Jupiter series.

The Jupiter modular system platform is a flexible system that comes in four sizes, so it is adaptable to specific production requirements. The stable platform enables connections of very high quality and accuracy. The modular design is configurable to fit all process components and modules. The Jupiter models feature an ergonomic system design with high quality components, designed for 24/7 continuous production. All models are equipped with a human-machine interface (HMI) with touchscreen for easy programming and standard safety features.

Control systems, based upon a programmable logic controller (PLC) or industrial PC, collect all available process parameters and process data into one control system. The data can be stored in local and remote storage areas, all engineered to seamlessly integrate with an Industry 4.0 factory concept.

Optional features for the Jupiter systems include a combustion suppression unit (CSU) for battery pack welding; a transport system with two individual belts that can be configured for a wide range of product carriers, including transfer systems; an automatic cleaning station for electrodes and thermodes; a “Not OK” bin to separate products outside the control limits from those within control limits; and a range of water cooling options. Also available are upgraded data collection and traceability functionalities, including a barcode reader or a label printer; and interfaces for a variety of robotic systems.

AMADA WELD TECH offers its expertise to all of its customers to correctly match any welding, soldering, bonding, brazing, laser micromachining and laser marking application inside the Jupiter series.

Robots replacing jobs

Robots replacing jobs, reduced reliance on China and consumers shunning fast fashion will be the long term effects of COVID on the supply chain, predict industry leaders

UK logistics industry claim British businesses will see big changes as a result of COVID, largely resulting from the Government’s confused handling of the pandemic

NEWS, 15th December 2020: The UK logistics industry claims British businesses will have to rethink their reliance on China and its importance to international supply chains (32 per cent) as a result of the COVID-19 crisis. Logistics industry leaders, polled by IMHX, the UK’s leading logistics and supply chain event, also forecast a move toward increased warehouse automation and robotics (29 per cent), which could help to address challenges presented by social distancing as well as labour shortages fuelled by Brexit.

The biggest challenge facing their businesses during the COVID-19 crisis was the Government’s confused handling of the pandemic, according to half (48 per cent) of businesses operating in the sector, who criticise Parliament for lack of guidance.

Reduced reliance on China

The survey of industry leaders found a third of respondents (32 per cent) believed the supply chain industry would need to seriously rethink its reliance on China and its importance to international supply chains.

This comes as shipping container rates in December jumped to $7500 to the UK from China meaning its very costly to obtain stock now from the region.

The research also revealed an additional 43 per cent cited increased demand on already overstretched facilities as a considerable challenge during the pandemic, with nearly two thirds (63 per cent) agreeing their business has been negatively impacted by COVID-19.

Supply chains in lockdown

Against a backdrop of uncertainty at Government level, 77 per cent of those polled confirmed they have made changes to their business as a direct result of COVID-19. While the majority of these changes were employee related, including enforced homeworking and furloughing staff, 90 per cent have introduced social distancing measures in their locations, causing some industry experts to warn of the implications for future warehouse design and logistics real estate, and what this might mean for consumers.

Peter Ward, CEO of the UK Warehousing Association said “It’s easy to join the blame culture, pointing the finger at government and to possibly overlook the many positive opportunities facing our sector at this pivotal time. The pandemic has driven opportunity for our sector, as online shopping and demand for home delivery soars. With grocery retailers in particular re-evaluating their warehouse and logistics strategy, take up of warehousing space for the first half of this year is already 20 per cent higher than in 2019 and set to grow. Now is the time to stiffen resolve, look for the positives that flow from the tough times we face and seize the undoubted opportunities ahead.”

Logistics - the new normal

In the face of job losses and a drop in consumer spending, two thirds think it will take up to two years for the logistics and supply chain sectors to get back to normal, while one quarter don’t believe it will ever be the same again.

“Looking to the post-pandemic era, two thirds of logistics businesses (69 per cent) also share concerns about the impact COVID-19 will continue to have on the supply chain. However, according to our research, it is clear that this impact could instigate change which in turn will lead to increased efficiencies for logistics operations,” said Rob Fisher, IMHX Group Director.

Shane Brennan, Chief Executive, Cold Chain Federation, said: “Despite the huge pressure on businesses, the main story of COVID-19 is how resilient and responsive they have proved to be. I fear the biggest challenges are yet to come. As the government withdraws economic support and the ‘new normal’ establishes, the businesses that make decisive action will survive.

“This means taking a sober look at all short term costs, especially, regrettably, labour costs in existing operations, but also bringing forward investment plans to modernise buildings and establish new locations wherever possible; and above all responding to the fast-changing consumer demands and opportunities of automation and digital solutions.”

Silver linings

Uncertainty about the future in the face of COVID-19 is shared by many sectors, including logistics. However, there were also a number of encouraging signals to come from the research: 31 per cent of businesses operating across UK supply chains confirmed the pandemic has had a positive impact, with 38 per cent of all respondents citing the boost in in e-commerce and internet fulfilment as a lasting driver for consumer demand. An additional 88 per cent claim they would be prepared if ‘faced with a similar situation again’, indicating a confidence in future supply chain resilience

Rob Fisher continued: “With the UK Government’s lockdown exit strategy now taking shape and a decrease in global supply chain disruption, there is a tangible feeling of pride among respondents at how the pandemic was handled, as 59 per cent said they believe the UK logistics industry’s response was a reflection of its agility, flexibility and innovation. A further 32 per cent applauded the way logistics and supply chain businesses had pivoted to help NHS and key workers.”

*Based on a poll of 185 supply chain and logistics industry professionals conducted in July 2020.

About IMHX

https://www.imhx.net/en/home.html%22%20%5Ct%20%22_blank">IMHX is the UK’s largest logistics exhibition and acts as a meeting place for those involved in the handling, movement or transportation of goods throughout the supply chain to come together and do business. The next edition of IMHX will take place between 14 - 16 September 2021 at the NEC, Birmingham.

Evergreen Landia Chopper Pump stands the test of time for Severn Trent

More than a decade on since its installation, a Landia Chopper Pump is continuing to enhance the throughput at a Severn Trent pumping station that has to deal with high levels of rags.

Demonstrating the TOTEX (total expenditure) benefits of investing in equipment designed for longevity, the 18.5kW Chopper Pump has drastically reduced downtime at Powick in Worcestershire, from when traditional prop-shaft pumps and later, dry-well submersibles used to operate, but kept blocking.

Still going strong. The Landia Chopper Pump at Severn Trent

Still going strong. The Landia Chopper Pump at Severn Trent

Designed with an external knife system that prevents solids from entering the unit’s casing, the Chopper Pump (invented by Landia in 1950) has in turn reduced maintenance costs, requiring only periodic replacement of its cutters, and typical routine oil changes.

Dan Hicks, Senior Technician at Severn Trent for Worcester and Malvern, said: “The Landia Chopper Pump is clearly very good quality and extremely reliable, because despite the large volumes of rag that come in from two neighbouring villages, as well as Powick itself, it gives us very good performance and is also easy to work on”.

Back in 2009, the Severn Trent team had increased the cleaning regimes at the Powick pumping station to try and give the previous equipment a helping hand, but saw that a much tougher, durable pump was needed - with the Landia MPTK-I model Chopper Pump put through its paces during an extensive 10-month trial.

Landia 01948 661 200

This email address is being protected from spambots. You need JavaScript enabled to view it.

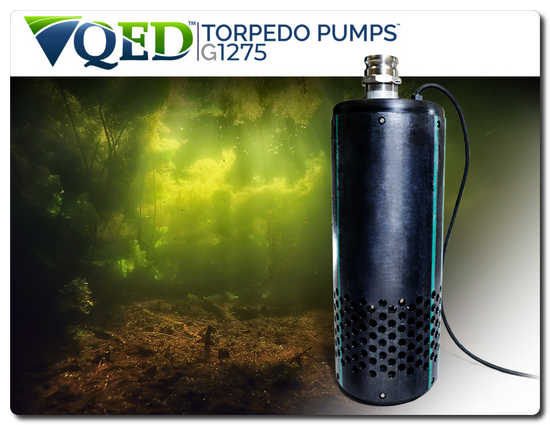

Q.E.D. Highlights Torpedo™ G1275 Pumps for Aggressive Pumping Applications

Heavy-duty slurry and solids pumps with cast iron and stainless steel construction for corrosive environments

Q.E.D. Environmental Systems, Inc., a leading manufacturer of innovative environmental products and subsidiary of Graco Inc., announces its Torpedo™ G1275 pumps, a series of large-body pumps designed for aggressive pumping applications. These pumps work by means of a powerful stirring motion in the influent stream to allow slurries and solids to pass through. These pumps are designed for use in applications including landfill liquid management and remediation pumping applications.

The Torpedo G1275 pumps handle pumping conditions that would cause many other types of pumps to fail. To prevent failure, the pumps are constructed of cast iron and stainless steel, and fitted with heavy-duty bearings and seals. The hardened, high-chrome impeller assembly can pass solids that would stall using most pumps available on the market.

Torpedo G1275 pumps feature hardened impellers which resist abrasion and wear, preventing wear and tear. This ensures a long pump life in aggressive situations. The pumps resist corrosion by means of an HDPE-encapsulated body, stainless steel water jacket and polymer power cable. The pumps boast a five-horsepower motor to provide the torque required for pumping silt, slurry and solid contaminants.

For more information, visit QED online at www.qedenv.com.

About Q.E.D. Environmental Systems, Inc.

Q.E.D. Environmental Systems, Inc., a subsidiary of Graco Inc., is a leading manufacturer of innovative environmental pumping systems, landfill products, landfill gas products, and air strippers for use at landfills, mines, oil refineries and other industrial sites, as well as hazardous waste cleanup sites. Our products are used around the world for a wide range of environmental applications, including groundwater sampling, groundwater remediation pumping, landfill leachate and condensate pumping, landfill gas collection and control, landfill and biogas analysis, air stripping and VOC removal, and wireless data acquisition. Based in Dexter, MI, QED serves customers from support centers in Michigan, California and England. For more information, call 734-995-2547 or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..