Ian Melin-Jones

Coretrax’s ReLineWL expandable technology restores well for Gulf of Mexico operator

Coretrax, the global well integrity and production optimisation leader, is delivering significant operational efficiencies for operators with its latest expandable technology.

The ReLineWL straddle is a one-trip, rigless system developed to address common well integrity issues and has enabled a Gulf of Mexico operator to troubleshoot an inoperable safety valve, passing through a restriction that conventional straddles could not pass through.

The ReLineWL delivers a 700% greater flow area when compared to traditional straddles

The ReLineWL delivers a 700% greater flow area when compared to traditional straddles

The tool is proven to deliver a 700% greater flow area when compared to traditional straddles, allowing operators to install a patch without creating a restriction and to unlock greater commercial value from existing wells.

The ReLineWL was recently deployed for an independent operator in the Gulf of Mexico when a safety valve malfunctioned on a producing well. With no control of the flapper valve and no way of hydraulically or mechanically forcing it to stay open, the device was implemented to remediate the issue.

ReLineWL straddle is a one-trip, rigless systemUnlike conventional straddles, the ReLineWL’s slim outer diameter meant it could bypass various ID restrictions to reach the flapper valve. Once in position at 8,675 ft, the patch was expanded to permanently open the valve. This resulted in full well access so upper completion removal could be facilitated. This saved significant rig-time when compared to costly and time-consuming traditional milling operations.

ReLineWL straddle is a one-trip, rigless systemUnlike conventional straddles, the ReLineWL’s slim outer diameter meant it could bypass various ID restrictions to reach the flapper valve. Once in position at 8,675 ft, the patch was expanded to permanently open the valve. This resulted in full well access so upper completion removal could be facilitated. This saved significant rig-time when compared to costly and time-consuming traditional milling operations.

Using a light intervention vessel, the wireline deployed patch creates a large ID to optimise access to the wellbore. This can negate integrity issues caused by water, gas and sand shut off; corrosion isolation; collar leaks and perforation shut off. Thereby allowing a maximum production conduit to the surface.

Scott Benzie, Chief Technology Officer at Coretrax said: “Our expandable technology is disrupting the traditional well intervention market. By creating a maximum production conduit and eliminating the requirement for complex and costly well intervention methods, the ReLineWL straddle is unlocking production in wells which were previously seen as uneconomical and delivering significant results for operators.”

As part of Coretrax’s range of Mohawk expandable technology, the tool has a high expansion ratio of 75%. It is designed for stackability to create a longer, integrated straddle to be deployed, without losing ID. This also allows operators to gain access below if well intervention is required at a later date.

Available in various CRA materials, the tool can be configured to smart completion products such as autonomous inflow devices (AICDs) to enhance production by selectively eliminating gas andwater production and provide a comprehensive workover solution.

Mr Benzie continued: “As the industry continues to focus on enhanced oil recovery and production efficiencies, the ReLineWL successfully overcomes well integrity issues. We are already seeing increasing demand for this technology in North America, the North Sea and Norway with operators keen to gain greater recovery and revenue from mature fields.”

About Coretrax

Coretrax is a global leader in oil and gas well integrity and production optimisation. The company joined forces with Churchill Drilling Tools and expandable tubular well specialist Mohawk Energy in March 2020 to offer the global oil and gas industry an integrated and boundary pushing approach to well lifecycle integrity and production optimisation.

The company has a portfolio of over 50 technologies offered through three innovation platforms with bases in key oil and gas hubs across the UK, North America, United Arab Emirates, Saudi Arabia and Malaysia.

Bearing specialist publishes steel bearings guide

To counteract confusion over the many steel bearing variations available, specialist bearing supplier, SMB Bearings has published a new materials guide to provide a helpful resource. The guide, Steel bearings: an essential guide to this essential workhorse, also provides practical application advice when choosing a steel bearing, which can be downloaded for free on the SMB Bearings website.

To ensure design engineers understand the technical capabilities of the different steel bearings available, SMB Bearings’ guide simplifies the decision-making process with clear, comparable information. Common questions are addressed, such as ‘what’s the difference between stainless steel and chrome steel bearings?’ along with other common customer queries.

“With materials science constantly evolving, particularly with new developments in the lubricant and bearing coatings fields — choosing a humble bearing can feel like a colossal decision,” explained Chris Johnson, managing director at SMB Bearings. “This steel bearings guide is our final guide in our bearing materials miniseries, which also encompasses our ceramic and plastic bearings guides.

Steel bearings

Steel bearings

“Bearing failure can have a devastating effect, resulting in overall equipment failure and costly downtime. If a bearing material and design is correctly matched to its application in the first instance, this shouldn’t be a problem.

“A common question we get asked by our customers is, ‘when is it worth investing in stainless steel bearings?’ This guide breaks down specific operating conditions including load, speed, corrosion resistance and temperature requirements, allowing design engineers to make an informed decision, and not splurge if they don’t need to.

“Corrosion is often known as the natural enemy of bearings, often caused when bearings are not properly matched to their operating conditions. In fact it is estimated that the global cost of corrosion is US$2.5 trillion globally. Chrome steel bearings will rust easily so in the presence of moisture or chemicals, for example in the food and beverage industry, we’d recommend opting for stainless steel.”

Further information on SMB Bearings’ full product line can be found on the company website. For further advice, download the technical guide, Steel bearings: an essential guide to this essential workhorse, here

About SMB Bearings: SMB Bearings originally specialised in miniature bearings, thin-section bearings and stainless steel bearings. By natural progression, the company expanded the range to include other corrosion resistant bearings such as plastic bearings, 316 stainless bearings and ceramic bearings.

Remaining a specialist business, SMB Bearings provide a high level of product knowledge, providing bearing and lubrication solutions to existing or potential customers, whether individuals or large corporations. SMB Bearings does not just sell bearings, but helps to solve your problems.

For further information please visit www.smbbearings.com / Ref: SMB237/07/20

Over 700 CK modular actuators installed at Chinese wastewater treatment plant

In order to comply with these new regulations, three new sewage treatment plants and 300 sewage intercepting wells will be built in Chaonan district, Shantou city. The installation of the CK actuators was a critical part of this enhancement. They have been installed on gate valves around the new sewage treatment plants, where they will be controlling the flow of raw sewage in and out of the sewage interceptors, where contaminants are separated from the wastewater, which can then continue the purification process until it is safe to return into the environment. 100,000 tonnes of wastewater will be processed every day.

The CK modular actuators will control the flow of raw sewage in and out of the sewage interceptors.

The CK modular actuators will control the flow of raw sewage in and out of the sewage interceptors.

The CK actuators were selected due to their performance and economical price reliability. Rotork Site Services were able to have the actuators commissioned within the tight timeframe specified for this project and will continue to provide maintenance services following the installation.

Rotork’s CK range of actuators is ideal for valves in the water industry and the modular nature of the actuators means that they can be configured to meet the needs of many different applications. With a multi-turn output torque of up to 10,800 Nm (8,000 lbf.ft), these actuators can provide continuous valve position indication, even on loss of power. They have a secure handwheel fully independent of the motor drive train and have an IP68 O-ring double sealed rating (8 m for 96 hours).

Konecranes to deliver over 40 lifting products to Wärtsilä's Smart Technology Hub in Vaasa, Finland

Konecranes has won an order to deliver over 40 next-generation lifting products to the Smart Technology Hub, a new integrated center of research, product development and production in Vaskiluoto, Vaasa owned by Wärtsilä Finland, with a preliminary agreement for additional lifting products. The order was booked in September 2020.

”Wärtsilä is moving closer to turning our visions of a Smart Marine Ecosystem and a 100% renewable energy future into reality by designing and establishing the Smart Technology Hub. It is a technology, innovation and validation centre with leading manufacturing and life-cycle capabilities to maximize the value proposition for our Marine and Energy customers. This unique setup brings together Wärtsilä’s global Centres of Excellence along with world class partners like Konecranes to create an agile and integrated ecosystem for solution development and deployment in marine and energy industries,” said Vesa Riihimäki, Director, Delivery Management at Wärtsilä.

The order comprehensively covers Konecranes’ benchmark products including the award-winning S- and C-series lifting products, up to 400-ton engineered-to-order open winch cranes, overhead cranes with a lifting capacity between 2-32 tons, workstation lifting systems, and manual hoists. Konecranes’ integrated Smart Features such as Active Sway Control and its modern digital service platform represent the most advanced crane technology on the market today by improving process efficiency, speed, safety and quality while assuring the total control of material flow.

Wärtsilä is a global leader in smart technologies and complete lifecycle solutions for the marine and energy markets. Konecranes is a proud new partner for Wärtsilä at the innovative Smart Technology Hub, which Wärtsilä is building in Vaskiluoto, Vaasa.

“Being the selected technology partner for Wärtsilä’s Smart Technology Hub is definitely a milestone for us at Konecranes and having such a unique environment for joint partnerships and innovation is a milestone for the whole EMEA region,” said Aku Lehtinen, VP, Industrial Cranes EMEA East, Konecranes.

Wärtsilä’s Smart Partner Campus in Vaskiluoto aims to bring people and companies together and speed up ecosystem co-creation. The research and product development work are done together with Wärtsilä’s customers and suppliers, start-ups and universities. This partnership has clear benefits: Konecranes will provide the latest in lifting equipment technology, which can be developed even further with the help of Wärtsilä and other partnering technology forerunners.

The order will be delivered in several batches, with the first deliveries starting during this fall and running until the end of 2021.

Further information:

Aku Lehtinen, Vice President, Industrial Cranes EMEA East, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +358 40 514 4447

Further information for investors and analysts:

Kiira Fröberg, Investor Relations, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +358 20 427 2050

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2019, Group sales totaled EUR 3.33 billion. Including MHE-Demag, the Group has around 17,300 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Metso Outotec introduces next-generation Courier® on-stream analyzer for direct measurement of gold concentration

Metso Outotec is launching its next-generation Courier® 6G SL on-stream analyzer for direct measurement of gold, platinum and other valuable metal concentrations from ore feed, concentrate, and tailings streams. The new analyzer enables accurate real-time elemental analysis measurement, which is critical for establishing efficient process control to improve process stability and maximize recovery. “Agnico Eagle Kittilä has used the new on-stream analyzer for flotation control and optimization since October 2019. Measurement information provided by the Courier 6G SL has enabled more efficient control of the pre-flotation circuit and helped to reduce gold losses,” says Lauri Veki, Metallurgist, Agnico Eagle Kittilä”.

The Courier 6G SL on-stream analyzer builds on the Outotec Courier 6X SL analyzer with a more powerful X-ray tube and measurement channels optimized for direct on-line measurement of gold and other elements from calcium to uranium. This makes it particularly suitable for applications where gold is recovered with other metals such as silver or copper.

Metso-Outotec-Courier-6G-SL-analyzer

Metso-Outotec-Courier-6G-SL-analyzer

The system can measure up to 24 individual process streams – each with an individually adjustable measurement time – to ensure optimal measurement accuracy and sampling frequency in even the most complex polymetallic flotation circuits.

The new next-generation on-stream analyzer combines Wavelength Dispersive X-ray Fluorescence (WDXRF) and Energy Dispersive X-ray Fluorescence (EDXRF) technologies with a high-power X-ray tube for unparalleled measurement performance. It also features an automatic internal reference measurement for guaranteed stability under changing environmental conditions.

Metso Outotec Courier 6G SL analyzer – key benefits in brief

- Direct measurement of gold concentrations down to 0.2 g/t

- Rapid results from up to 24 sample streams

- Improvements in recovery and minimization of precious metal losses

- Possibility to upgrade your previous generation Courier analyzers into Courier 6G SL analyzers

- Remote support with condition monitoring

Find out more from our website: Courier® 6G SL on-stream analyzer.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Introducing the Memor™ K - a powerful, pocketable companion for any data capture application

Datalogic is pleased to introduce the new Memor™ K mobile computer, a powerful, pocketable companion for any data capture application, whether in the retail store, manufacturing floor, or distribution centre. The Memor K stands out in the market for its unique features, combining high performance with very small dimensions and excellent ergonomics.

When carrying out their tasks, workers can increase their productivity by running simultaneous applications smoothly. The speed, security, stability and use of Android™ 9 OS is guaranteed by the superior computing power of the Memor K. It features an extremely powerful octa-core CPU running at 2.2 GHz, and 3 GB of memory.

Personnel can use the device all day long without any stress or fatigue as the Memor K is very light weight and has great ergonomics. Thanks to its small size, it can be kept in the pocket and easily taken out whenever needed. They can instantly read 1D and 2D codes in any orientation and on any surface, including mobile screens, as the Memor K comes with a very fast and robust imaging technology.

This new device is designed to handle plenty of applications and to last several shifts for uninterrupted work activities. If users run out of power, they can simply take a newly charged 3,800 mAh Li-on battery from the docking station, and quickly swap it out for another 12 hours of seamless work. This operation is made in seconds with the Memor K’s easy-to-replace battery design.

The Memor K simplifies the capture of any data for every scanned item in many ways. It is ergonomically designed, with a large 4-inch touchscreen display and a backlit soft rubber keypad. This keypad provides comfortable, tactile feedback and ensures fast and correct typing even in the darkest conditions, reducing the chance of error for the user. The device also comes with two comfortable side scan buttons to allow the scanning of items using only the thumb. In addition, to accelerate and ease repetitive actions, any desired function can be assigned to two other programmable side buttons.

The Memor K combines its ultra-thin design with a highly rugged assembly. It can sustain repeated drops up to 1.2 m / 4 ft onto concrete, and its IP54 rating guarantees high protection from dust and water.

Users have access to fast download and upload connections through powerful Wi-Fi communications (includes the AC standard), while the USB-C assures rapid data transfer and high charging speeds.

Learn more at https://www.datalogic.com/eng/manufacturing-transportation-logistics/mobile-computers/memor-k-pd-876.html

ABB completes commissioning of the world’s most powerful conveyor system

ABB, working with TAKRAF, has completed commissioning and testing for the world's highest-powered gearless conveyor drive system, enabling continuous operations at Chuquicamata copper mine in Chile

ABB has provided engineering design, gearless conveyor drives, electrical equipment for power supply, energy distribution and automation of a new underground and overland conveyor system at the world's largest open pit copper mine.

Project management and engineering for the full electrical, control and instrumentation (EC&I) scope was led by ABB in Germany, with long spells on site in northern Chile to work side-by-side with TAKRAF to equip the site’s new underground operation with a large conveying system that overcomes an altitude difference of 1,200m and covers a distance of almost 13km.

Project management and engineering for the full electrical, control and instrumentation (EC&I) scope was led by ABB in Germany, with long spells on site in northern Chile to work side-by-side with TAKRAF to equip the site’s new underground operation with a large conveying system that overcomes an altitude difference of 1,200m and covers a distance of almost 13km.

The three principal 11,000tph conveyors feature gearless conveyor drives (GCDs) equipped with large ABB AC synchronous motors with a rated power of 5MW each, resulting in a motor shaft torque of about 900kNm. With every line in constant use, high availability and low maintenance are essential. Designed with a minimum of transfer stations, just one was required underground, saving a significant project cost.

Based on continuous conveying technology, the infrastructure is completely truckless, eliminating the need for 120 large haul trucks. This results in saving around 130 million liters of gasoline consumption per year, bringing the carbon emissions from 340,000t p.a. down to 100,000t p.a. It is also the first transportation system in the world to employ premium steel cable belt technology, ST10000, for use on uphill tunnel conveyors.

“This mega project achieves a number of firsts, from the system’s installed drive power to the application of the ST10000 conveyor belt,” said Marc Hollinger, TAKRAF Project Manager. “With this project, we firmly establish TAKRAF as one of the world’s only providers capable of delivering a mega project of this nature incorporating advanced technologies that push the boundaries of what has been done before. This is a complex project of the highest magnitude demanding global cooperation between internal and external parties.”

“This is a new milestone in underground applications for continuous mining. It is the highest drive power ever installed on a conveyor and uses a wide range of features for data aquisition, equipment assessment and process optimization.” said Ulf Richter, Global Product Manager for Belt Conveyor Systems, at ABB. “In piloting this gearless drive application with TAKRAF we have overcome tremendous technical and logistical challenges due to underground situations, elevation change and capacity requirements.”

ABB liquid-cooled MV voltage-source frequency converters, together with large synchronous motors, deliver a decrease in active and reactive power consumption. This is highly energy efficient, and without additional network filters.

ABB’s Mining Conveyor Control Program (MCCP) ensures smooth belt operation and safe synchronization between High Power Motors and High Power Hydraulic Brakes, necessary for secure operation of steep uphill conveyors. The drive systems also work without mechanic backstops.

A novel embedding concept, developed jointly by TAKRAF and ABB, enables straightforward installation and alignment of the GCD motors, saving installation time and longer deployment of maintenance teams. This was considered a major benefit compared to existing GCDs in cantilevered construction. The concept also meant motors were 100% factory assembled and tested. They can also be be mechanically disconnected from the drive pulley quickly so operations can continue if drive failure occurs. The total installed drive power for the entire system, including multiple feeder conveyors, totals 58 MW, of which there are 11 x 5 MW gearless synchronous motors.

ABB has also installed ABB Ability™ Ventilation Optimizer at Chuquicamata reducing carbon emissions and providing clean air to workers in line with the strict HSE requirements.

Commissioning was completed in four months. The new underground project is expected to extend operations at Chuquicamata for the next 40 years.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

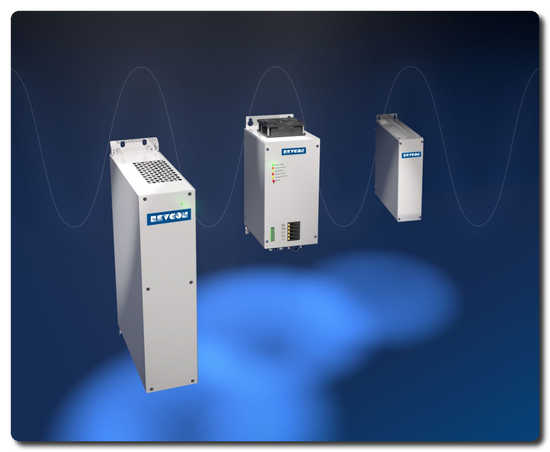

New range of ultra-compact harmonic filters

Supply installation and repair specialist, CP Automation has announced its new range of small-footprint Revcon harmonic filters and regen units. To ensure equipment longevity and efficient energy consumption across oil and gas, water treatment and data centre sectors, the extended product offering includes the Revcon RLD regen unit, Revcon Harmonic Filter RHF-5P and Revcon RHF-Active.

With a focus on efficiency and power quality, these compact products offer the same reliable performance as their predecessors, but in a smaller size. The RLD regen unit comes in the new size of 0/220 covering the range from 2-20kW. Similarly, the Revcon harmonic filter RHF-5P and RHF-8P range now encompasses three new sizes the 2A, 4A and 6A covering 1.1kW to 630kW.

CPA189 - New product line

CPA189 - New product line

Due to the silicon carbide (SiC) based technology, the RHF-Active enters the market as the most compact active harmonic filter of its kind, capable of reducing harmonic current distortion of non-linear loads to any required total harmonic distortion (THDi) level. This SiC technology allows for a switching frequency of 60kHz, and therefore prevents any acoustic or electric noise such as high order harmonics. This makes it possible to reach vigorous standards such as IEEE 519-2014: Recommended practice and requirements for harmonic control in electric power systems.

“Harmonic distortion of the mains voltage has extremely detrimental effects on equipment lifespan,” explained John Mitchell, global business development manager at CP Automation. “If harmonics go untreated, they can cause electrical systems to overheat, resulting in costly equipment damage. The new additions to our harmonic protection range enable facilities to mitigate harmonics, even when space is at a premium.

“Equally, don’t let the new super-small RLD regen unit fool you. While extremely compact, its high efficiency of 99 per cent guarantees extremely low energy losses across electrical systems. Over time, this small product could result in huge cost and energy savings for businesses, without taking up valuable space.”

These products can be used in various applications including construction, oil and gas, water treatment, marine, data centres and general industry. They can be retrofitted into existing applications or added to new lines, to protect against harmful harmonics and reduce energy losses.

For further information about CP Automation’s full range of power quality products, visit the website.

About CP Automation: CP Automation is a specialist in the repair and replacement of automation equipment including electronic boards, PLCs and Ac and DC drives. It was established to provide an independent maintenance service, without exclusive ties to any manufacturer. However, it does have strong relationships with the principal inverter, encoder, resistors and motor manufacturers.

Sparrows Group secures five-year UKCS contract with major UKCS operator

Sparrows Group has secured a five-year contract with a major UK Continental Shelf (UKCS) operator to provide inspection services across all its assets in the region.

The project, which also has two one-year extension options, will seetheglobal provider of engineering and maintenance solutionsresponsible for fixed lifting equipment and lifting accessories across the operator’s 11 assets in the region.

Awarded through a competitive tender process, the work scope covers the inspection and thorough examination of loose and fixed lifting and safety equipment, including runway beams, padeyes, personnel descent device stations and accessories. The work will be delivered from the company’s base in Aberdeen.

Sparrows inspector undertaking NDT inspection

Sparrows inspector undertaking NDT inspection

Technical support will also be provided by Sparrows, involving themanagement and execution of safe lifting operations on-site, as well as advice on lifting plans, procedures and relevant legislation and guidance.

Stewart Mitchell, chief executive officer of Sparrows said: “We have worked on this operator’s assets for a number of years, delivering crane management services on several UKCS platforms, so have a strong understanding of their working practices. This new contract will see us working across additional assets in the North Sea and we look forward to delivering our extensive technical expertise in inspection and maintenance across their entire portfolio.

“Despite challenges presented by the Covid-19 pandemic this year, our skilled people have continued to provide a first-class service to all our clients and this award demonstrates our dedication to delivering safe and efficient operations.

“While we have been making significant strides in the renewable and onshore industrial markets, the North Sea remains a core area in the business. With more than 45-years’ experience in the region, we have an unrivalled knowledge of the market and the demands on the safety critical lifting equipment in the field.”

The Sparrows Group is a global provider of specialist engineering, inspection, operations and maintenance services to the renewables, industrial and oil and gas markets. The firm supports customers by delivering a broad range of expert solutions that optimise efficiency and ensure the performance, reliability and safety of critical equipment and people.

Indoor air company Halton Group opens new R&D center for its Lahti plant in Finland

Halton will open the company's 10th product development center, the Halton Innovation Hub, on the grounds of its Lahti plant. The Hub will focus on the target environments of the company's Marine business: galleys and cabins, as well as energy production and industrial environments. In addition to physical demo facilities, the center will use VR technology to model solutions.

The implementation project for the product development center is divided into three phases.

In the spring of 2020, the first section of the premises, with a focus on galleys, was completed. There, the company will present and test its patented, highly efficient galley hoods; its adaptive, energy-saving ventilation solutions; and its integrated, adjustable lighting designed for kitchen environments.

Towards the end of the year, a demonstration space specializing in ship cabins and air-conditioning beams, cabin ventilation, replacement air solutions and user-friendly air conditioning control systems will be introduced, where VR technology will be used to model solutions.

In the third phase, in the first half of 2021, a facility will be completed specializing in fire dampers for air conditioning ducts in industrial and marine environments. In addition to product development and demonstrations, the facility will enable the testing of shutoff dampers and fire dampers, including combustion tests, and the functional testing of conformity with CE standards.

“Our customer-oriented, innovative product development has provided us with global market leadership in our Marine business. Together with our other international product development centers, the new Halton Innovation Hub in Lahti will help us further strengthen our position and ability to produce efficient, safe solutions that best meet the specific needs of customer environments,” says Sami Piirainen, Director, Halton Marine.

Today, Halton Group operates 10 Innovation Hubs in 8 countries on 3 continents.

Further information:

Sami Piirainen, Director, Halton Marine

Tel. +358 40 527 9278

sami.piirainen(at)halton.com

Halton Group is a global technology leader in indoor air solutions for demanding commercial and public premises, workspaces, healthcare institutions and laboratories, professional kitchens and ships as well as energy production and industrial environments. Halton's mission is to provide its end-users with safe, comfortable and productive indoor environments that are energy-efficient and comply with sustainable principles. The company was founded in Finland in 1969. Today, Halton Group employs 1,600 people in 37 countries. The company’s turnover in 2019 was approximately 237 million euros. www.halton.com.