Displaying items by tag: UNTHA

UNTHA partners with Heidelberg to manufacture alternative fuel in India

The world’s number one aggregates and ready-mixed concrete firm Heidelberg Materials has revealed a new single-step alternative fuel production line in India, with the help of UNTHA shredding technology.

The system has been installed at the Yerraguntla cement plant in Andhra Pradesh, owned and operated by Zuari Cement — a Heidelberg Materials Group company. This well-known Indian firm has a cement manufacturing capacity of 7.1 million tonnes per annum.

Handling both pre-sorted and unsorted municipal solid waste collected from throughout the region, it can process 20 tonnes of 100-500kg/m³ density material per hour, to produce a renewable fossil fuel substitute, used to fuel the cement plant.

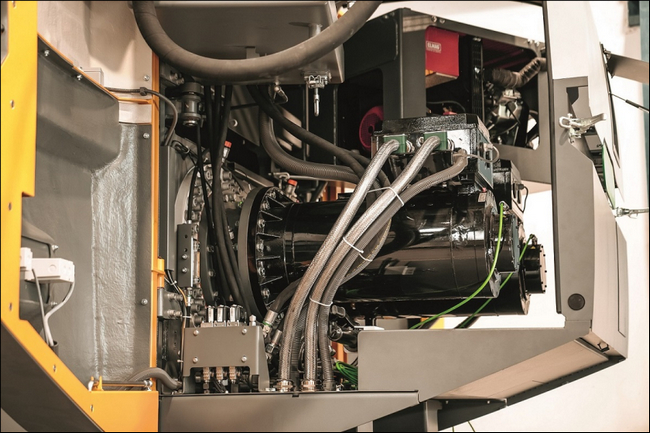

An UNTHA XR3000C shredder designed for continuous operation in 50°C temperatures, lies at the heart of the facility. With in-feed and discharge conveyors including a magnetic belt for metal separation, the plant can achieve a high-quality, homogenous 80mm output in a single pass. The segregated metal content is separated and the residual on-specification fraction is used by Zuari Cement as RDF (refuse derived fuel).

Commenting on this co-processing project, Heidelberg Materials’ AF expert Robert Sweigart, said: “When we began the search for a shredder for this facility, we had stringent requirements. We sought heavy duty technology that can withstand the pressures of shredding unsorted waste, and achieve refined fuel, in impressive quantities, in only one step. Our global experience was helpful in drawing up a shortlist, then we found the UNTHA XR3000C to have a number of technical advantages over competitors. The machine operates at a lower speed without compromising on capacity, for example, which results in lower wear. This means more uptime and lower whole life running costs.”

Mr Manish Shah, Head of the India Technical Center, added: “This shredder is easy to install, operate and maintain, meets our expectations in terms of performance and allows us to vastly improve our flexibility to co-process various kinds of alternative fuels available in the market. The goal is for our co-processing facility to produce 8000-10,000 tonnes of RDF per year.”

The versatile UNTHA XR3000C shredder has been engineered to handle a range of input materials with ease — including those notoriously considered too difficult to process or economically unshreddable. Zuari Cement has already proven the machine’s flexibility, having shredded MSW, as well as industrial plastics, textiles, tyres, rubber, paper and biomass materials requiring further refinement for optimal co-processing.

Co-processing is an emerging market in India, and one that Zuari Cement and Heidelberg are keen to spearhead, concluded Technical Director Vimal Jain.

“We are passionate about driving environmental progress throughout our business, and the use of alternative fuels is one way to do that,” he explained. “But this waste-to-energy feedstock comes at a cost, which is why co-processing makes so much sense. When designing this plant, we needed to ensure versatility to allow for changing market conditions, and an investment in technology that makes commercial sense and is built to last.”

Commenting on the project, UNTHA's business development manager Taner Topcu said: "As a brand, we are working hard to further develop our relationships with cement manufacturers on a global basis, with recent success in countries ranging from Türkiye, France to Brazil – as well as now, India. I am delighted to be working with an organisation as prestigious as Heidelberg, and I look forward to seeing how our collaboration progresses in future."

UNTHA has commissioned alternative fuel production shredders in countries throughout Asia, with more than 13,000 shredders now in operation worldwide.

UNTHA launches cutter reconditioning service to boost shredder profitability and sustainability

UNTHA shredding technology has launched an innovative new cutter refurbishment service, to further improve its environmental performance – and reduce customers’ wear costs by up to 50%.

Cutting discs from UNTHA’s four shaft shredders can now be returned to the firm’s Austrian HQ for hardfacing and re-assembly – restoring them to their original dimensions with the same manufacturer quality seal.

The launch of the reconditioning service follows a €1.000.000 investment in a state-of-the-art CNC line and specially-adapted welding additives. It means customers can now repeat the hardfacing process several times, extending the overall service life and sustainability credentials of UNTHA’s shredding technology, and reducing the whole life running costs of UNTHA’s machines. The process is up to 50% more cost-effective than the price of a new cutter set, and such savings can be reaped multiple times.

“Some customers will know when the time is right for cutters to be refurbished, without our input, whereas others will be reliant on an inspection from our engineers – either way, we can support with the end-to-end process,” commented Bernhard Walkner, UNTHA’s key account manager. “Crucially, our original manufacturing quality standard is maintained, which means so too are the performance levels you could expect from one of our four shaft shredders, without having to invest in new cutters.”

Cutter Reconditioning

Cutter Reconditioning

The cutter reconditioning process follows five key steps – the visual inspection and cleaning of the cutting set, preparation of the welding seam, hardfacing along the cutting geometry, precision milling, and final inspection and dispatch.

“The actual saving potential will vary depending on every individual customer’s operating hours, throughputs and application type,” continued Bernhard. “But an RS100 with an average cutter life of 900 hours, for example, can easily show 40% cost savings, when reconditioning instead of replacing. If you recondition three times, it soon add up to impressive five-figure numbers.

“If anyone needs help determining when the time is right for reconditioning, calculating the potential financial savings, and understanding the environmental benefits, let’s talk it through.”

There are more than 12,000 UNTHA shredders in operation worldwide. Earlier this year, the company – now with over 300 employees – announced record turnover in excess of €70m.

For further information about this service, please contact UNTHA UK on This email address is being protected from spambots. You need JavaScript enabled to view it. or call 0330 056 4455.

Renova and UNTHA collaboration produces RDF in single step

Brazil’s industrial waste specialist Renova Group has advanced its alternative fuel capabilities, in a state-of-the-art collaboration with industrial shredder manufacturer UNTHA Iberica.

The family-owned business has commissioned a single-step RDF (refuse-derived fuel) production line, enabling it to transform waste into a renewable energy source, using only one shredding machine. A UNTHA XR30000C waste shredder now lies at the heart of the plant, producing a homogenous 50mm fuel for the cement industry.

Renova Group is no stranger to the reuse, recycling and recovery of commercial and industrial ‘waste’. The business has been collecting and treating varied materials – including metals, textiles, plastics, rubber and wood – for 36 years, and has five industrial sites throughout the country.

But passionate about investing in cutting-edge technology to advance Brazil’s waste handling capabilities – while minimising the environmental and fiscal impact of the process – Renova Group’s CEO is always looking for continuous improvement.

Aware of UNTHA Iberica’s growing profile in the complex Waste to the Energy market, the team conducted business trips to Europe to see exactly what the technology is capable of. UNTHA Iberica demonstrated the XR’s performance handling a number of different input materials to produce an on-specification RDF.

Impressed with the productivity of the machine – not to mention its low operating costs – Renova Group made the switch to UNTHA Iberica.

“We quickly realised that the UNTHA XR would increase our RDF production capacity and give us more process flexibility because the robust machine can handle a number of very difficult materials that prove too tough for most other shredders,” commented Renova Group’s CEO Eduardo Pirani.

“But we also knew that the profitability of our operation would be further improved because the UNTHA XR is so efficient. Consuming up to 75% less energy than diesel hydraulic equivalent shredders, the fuel savings are vast. The machine is also very easy to maintain, with little downtime, meaning general ongoing running costs are very affordable. In fact, our operating costs have already fallen by 40%.

“All of this with such a small footprint, given a single shredder is all you need. It’s very impressive!”

The XR is currently processing 15 tonnes of material per hour, to suit Renova Group’s requirements.

“Everything about this plant, has been designed with Renova Group in mind,” continued Eduardo. “Yes, the XR is very popular worldwide, but UNTHA Iberica took their time to carefully understand our requirements and configure the shredder to suit our exact requirements.

“The machine is now up and running but this is proving to be a fantastic ongoing partnership – our operators work well with UNTHA Iberica’s customer service experts, ensuring our shredder is always in optimum running condition, and we have quick and easy access to spare and wear parts when we need them. All of these factors matter when investing in shredding technology, and UNTHA Iberica tick all the boxes.”

UNTHA prepares for shredding showcase at IFAT 2022

UNTHA Polska will be heading to the renowned waste and recycling trade fair – IFAT – in late May, as the shredding technology business prepares for one of its largest machinery showcases in years.

The huge five-day event – which will take place in Munich from 30 May to 3 June – will enable delegates to get up close to a range of UNTHA machines, watch live demonstrations of the shredders tackling a range of materials, visit a neighbouring customer’s site to see an operational facility in action, discover more about UNTHA’s service packages, and meet some of the firm’s most knowledgeable colleagues from all over the world.

And UNTHA Polska’s sales manager Pawel Pietowski will be at the heart of it all.

Visitors to UNTHA’s vast stand – hall B6, 127/226 – will be met with:

- The new ZR two-shaft pre-shredder which boasts the lowest total operating costs in its class, and with two key cutting concepts, is perfect for the high-volume shredding of bulky wastes, wood, metals and WEEE.

- The ultra-flexible, tried-and-tested XR class which is available as both a static and mobile machine. This high performance waste shredder has transformed recycling, biomass and alternative fuel production facilities across five continents.

- The globally-acclaimed RS four-shaft recycling technology – which marked the start of UNTHA’s story over 50 years ago. With a number of machines in this range from compact to heavy duty solutions, the UNTHA RS40 and RS30 for document and data destruction, will be on show at IFAT.

- The intelligent condition monitoring system UNTHA GENIUS – a cloud-based data-rich tool which helps monitor, measure and optimise shredder productivity in real-time.

- And the full range of services from the UNTHA Service Competence Centre.

Outside in the VDMA live shows, the UNTHA XR mobil-e will also prove what it’s capable of in the biomass market. And for IFAT visitors keen to see UNTHA’s shredding technology handling the most challenging of materials – that you won’t see at the expo – a private shuttle bus will transfer VIP guests to a customer’s site in the greater Munich area. This registration-only experience will shine the spotlight on a number of different UNTHA machines, tackling multiple tricky applications – even those typically deemed uneconomical to shred.

“IFAT is without doubt, the place where the industry’s leading decision makers gather, from across the world,” commented UNTHA Polska’s sales manager Pawel Pietowski. “But excitement for IFAT 2022 is particularly high, not least because of the international trade fair hiatus caused by the pandemic.

“So, we’re coming to make an especially big impact this time. Think ground-breaking engineering innovations, digital technologies that make shredders work harder than ever before, and service packages that mean customers can continue to optimise their machines long into the future. This all equates to unrivalled return on investment, which is one of the reasons we’ve been busier than ever since the start of the pandemic.

“UNTHA will not disappoint at IFAT 2022.”

Earlier this year, UNTHA unveiled global turnover had reached a record €70m. The company has more than 10,000 shredders in operation worldwide.

For up-to-date information about UNTHA's presence at IFAT, or to register for the off-site shredding demonstration, please visit: https://www.untha.com/en/fairs/ifat2022.

UNTHA unveils new ZR two shaft shredder

UNTHA UK has revealed a new two shaft shredder – the ZR. And, following 24 months of rigorous industry research and development – including prototype trials on the continent – the dual shaft machine now promises the lowest lifecycle costing (LCC) for waste, wood and metal shredding in its class.

The high-performance ZR has been specifically engineered for multi-shift, continuous pre-shredding – even when handling difficult materials some would consider economically unshreddable. And it will make its UK debut, when it is unveiled at the UNTHA showcase in the North of England, in October.

The machine’s low speed, high torque drive means it can process severe duty applications with ease, for a high level of plant availability. And the modular, quick-change cutting table design presents versatility at the core.

The ZR2400H, for example, has been engineered for the high throughput, rough shredding of bulky waste, C&I waste, waste wood, MSW, mattresses, carpets, railway sleepers, bales and rolled goods. Available as a static or mobile machine with crawler tracks, the goal for this model is volume reduction (90% <300mm), material breakdown for further treatment, and alternative fuel production. This cutting system is therefore perfect for cement plants, operators in the biomass and energy recovery industries, MRFs, sorting and waste disposal firms.

The ZR2400W is the perfect metal scrap shredder, and excels also in the processing of WEEE and large domestic appliances. Again, the goal is to achieve a rough material breakdown (90% <300mm) for downstream sorting, making this the ideal machine for metal processors, recyclers, and aluminium and metal manufacturers.

The ZR2400W is the perfect metal scrap shredder, and excels also in the processing of WEEE and large domestic appliances. Again, the goal is to achieve a rough material breakdown (90% <300mm) for downstream sorting, making this the ideal machine for metal processors, recyclers, and aluminium and metal manufacturers.

The ZR’s independent, bi-directional shaft rotation means the aggressive cutters grab, shear and liberate material in forward and reverse, for a machine action that always shreds.

Both pre-shredders are also supplied with the UNTHA Eco Power Drive with water-cooled synchronous motors – an energy-efficient concept which has become globally renowned for its ability to reduce energy consumption by up to 75%.

“With the ZR, we’re talking a reliable powerhouse that pays for itself!” commented sales director Peter Streinik. “Like all our shredders, the innovation is engineered for long service intervals, easy maintenance, safe operations and high uptime. But what will really make it stand out in its class, is the ability to tackle difficult materials, at low cost.

“We believe this will open up a whole new world of shredding possibilities.”

Strong in performing, smart in saving, the ZR will be supplied with UNTHA GENIUS – the condition monitoring system which provides operators with access to their shredder’s performance data, in real-time, from any device.

Commenting on his 12-month trial of the ZR prototype during the machine’s R&D phase, Hubert A. Schwarz, head of processing and process development at Schaufler said: “The most important advantages of the ZR are versatility – the unit can shred both large, coarse NF metals and composites; fast, easy and efficient cleaning and maintenance; low energy consumption – compared to other manufacturers, we’re saving €70,000 in energy costs a year as a result of using the ZR!”

ZR trials are currently being offered throughout Europe. The UNTHA UK showcase will take place in Lancashire on 13, 14 and 19 October. For further information, please visit untha.co.uk/events.

Hazardous waste specialist Malary bolsters UNTHA shredding fleet

Industrial waste management specialist Malary has bolstered its hazardous material recycling capabilities with an investment in a second RS100 UNTHA shredder.

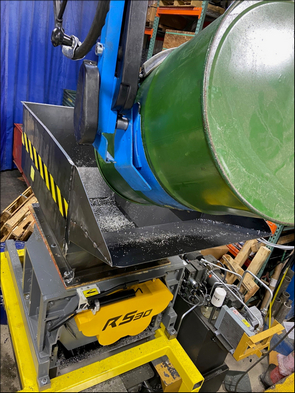

The heavy duty four shaft UNTHA RS100 is the latest addition to the fleet, with another existing RS100 already in operation.

Capable of processing the materials many operators shy away from, Malary will use the new equipment to shred contaminated waste such as IBCs, and plastic/steel drum shredding for re-use, recycling, and energy recovery. Currently configured to handle up to 150 tonnes pr/week the new RS100 machine doubles Malary’s total capacity, with the ability to transform difficult wastes into a homogenous particle size as small as 50mm.

The fraction is then further separated so that ferrous and non-ferrous material can also be salvaged for remanufacturing. Commenting on the latest shredder investment, Malary’s managing director Lewis Walker said: “With sophisticated in-house processing facilities that include seven different recycling routes – together with UKAS-approved laboratories to ensure the quality of all recycled product – we’ve built a solid reputation for complex waste handling and are trusted by some of the UK’s leading waste contractors.

“To continually offer the best possible solution for our customers – while boosting the environmental and commercial efficiencies of our facility – we are constantly investing in new and better technologies, and UNTHA’s four shredders now lie at the heart of our operation. The capabilities of these globally-proven machines – known for their ability to tackle difficult materials economically, safely and compliantly – is crucial to us.”

UNTHA’s four shaft shredder technology was the first to be introduced into the range, when the Austrian-headquartered manufacturer was founded back in the 1970s. The series began with the launch of the compact RS40 but has continually evolved as UNTHA’s engineering innovation has progressed over the decades.

UNTHA shredder transforms manufacturing site in heart of Brooklyn

An UNTHA shredder is now in operation in the heart of Brooklyn, New York, as precision manufacturer Linda Tool gears up for further growth.

The firm has been producing components and assemblies for industries including aerospace, and oil and gas, since it was founded in 1952. But nestled away in the bustling Brooklyn streets – where real estate is at a premium – the facility has found it harder to store chips and turnings as its production capacity has continued to rise.

The firm has been producing components and assemblies for industries including aerospace, and oil and gas, since it was founded in 1952. But nestled away in the bustling Brooklyn streets – where real estate is at a premium – the facility has found it harder to store chips and turnings as its production capacity has continued to rise.

Metallic machining chips – primarily aluminum, titanium, and various brass and stainless steel alloys – were previously stored in 55 gallon drums, to be collected for resale and recycling. But with the drums soon stacking up despite weekly pick-ups, this still represented an undesirable use of the site’s precious space.

Linda Tool therefore explored both the metal shredding and briquetting technology available in the marketplace, to make smarter use of space while bolstering its environmental performance. They first installed a briquetter, which handled their chips well, but was unable to process their longer, stringier material. Further research therefore brought president Mike DiMarino to UNTHA America, and the four shaft RS30 shredder – a compact yet robust machine capable of shredding this tough metallic ‘waste’ into free flowing material that the briquetter could better handle.

“It’s difficult to operate a manufacturing facility in Brooklyn – the second most densely populated county in the United States,” commented Mike. “We produced briquettes to get our chips off-site as efficiently as possible, but it was labor intensive as we had to hand load the machinery and stay close by to monitor the process and rake material around. This approach was also maintenance-heavy.

“We would easily need a recycling collection once or twice a week, which was a real logistical struggle too, when trying to get the trucks to site.”

Having researched the solutions available, Linda Tool quickly decided on an UNTHA shredder.

Having researched the solutions available, Linda Tool quickly decided on an UNTHA shredder.

Now, by producing a homogenous 1 inch output thanks to the RS30’s in-built screen, they can simply feed all of their material into the shredder, allowing the briquetter to do its job unattended. Adding the shredder also increased the density of the briquettes, allowing them to increase their loads to 1.8 tons of briquettes – 50% more than previously.

The machine is currently handling 1 ton of material per week but has capacity to process far more. The recycling contractor’s visits have fallen to once every 4-6 weeks, for further cost and environmental efficiencies, meaning the net financial yield from the recycling process has improved by 50%. The HVAC system is also more efficient as the overhead garage door does not have to open for as long, or as many times, due to the infrequency of scrap pickups.

Residual oils and lubricants are more easily recovered too, allowing the team to enhance its environmentally safe footprint – not least because it is easier to recycle and reuse the machine tool coolant.

“What many people perhaps don’t realize about smarter ‘waste’ handling, is that not only can they improve their environmental performance, but shredding makes good business sense too,” concluded Mike. “Our site is tidier, we’ve reduced material collection costs, and overall we’re more efficient – which is particularly important because our colleagues can spend time on more value-added tasks, rather than manual labor. This is especially applicable because the UNTHA RS30 is so easy to maintain.”

Lighthouse Security bolsters data destruction services with UNTHA collaboration

A global specialist in protective security, surveillance, intelligence, cyber security, due diligence, training and dog handling, has further strengthened its portfolio of services in collaboration with UNTHA UK.

The business has bolstered the capabilities of its secure destruction division with the investment in a confidential waste shredder, certified to DIN-66399 standards.

The four shaft RS30 shredder with in-feed and discharge conveyor will handle a range of materials including hard drives, sensitive documentation, uniforms, and seized products which cannot get onto the black market.

Capable of processing up to 1.5 tonnes of these materials per hour, the robust machine can produce a range of outputs from 10mm–100mm so that classified materials are completely destroyed. The cutting chamber also pre-shreds and re-shreds in a single pass, with a ‘mixing’ action for added peace of mind.

However, the low speed nature of Lighthouse Security’s new solution, means the materials can be shredded without damaging their fibres, which protects output quality and increases reuse or recycling potential. The zero-waste-to-landfill process therefore upholds high environmental standards, as well as compliance.

Plastic arisings are sent for recycling into plant pots and other products, for example, and textiles are shredded for reuse in the equestrian, surfacing and energy recovery markets.

Commenting on the investment, Lighthouse Security’s founding director Tim Jensen said: “Core to our security services, is a promise to safeguard our clients’ duty of care and accountability, in an increasingly high-risk world.

“Because we are an end-to-end security specialist, we can collect clients’ ‘items’, unload them into our secure CCTV manned and monitored facility, and apply a dedicated tracking number. Our secure storage facility also has an AI-driven security layer which proactively detects anything entering the area. Everything about this rigorously audited service is robust, so we set high standards for the shredder.”

The shredding process is recorded, with the option for the customer to remotely watch the destruction, in real-time.

“We take our business reputation very seriously, so in choosing a shredding partner, we looked for an organisation with equally high standards,” concluded Tim. “The UNTHA RS30 is a high performance, industry proven machine, and the changeable screen makes it highly configurable as our company continues to evolve.”

M&K Plastik invests in UNTHA shredder for remanufacturing operation

M&K Plastik has invested in an UNTHA RS40 four shaft shredder to transform its recycling operation.

The plastic remanufacturing specialist processes pre-sorted HDPE and PP material collected from municipal waste sorting plants, to support the circular economy and the regranulating of valuable plastics.

UNTHA RS40 four shaft shredder And now an UNTHA plastic shredder with pusher technology, lies at the heart of the recycling facility.

UNTHA RS40 four shaft shredder And now an UNTHA plastic shredder with pusher technology, lies at the heart of the recycling facility.

An UNTHA customer since 2016, M&K Plastik handles approximately 500 kg per hour and shreds the waste down to a homogenous 40mm particle. Further downstream equipment then refines the fraction for regranulation.

Commenting on the investment in an UNTHA machine, M&K Plastik’s co-owner Marek Kurkowski said: “We thoroughly researched the market before selecting the RS40. It sits at the beginning of our processing line, so the shredder’s output quality influences the success of our whole recycling operation.

“This shredder was by far the best choice. It is a robust and reliable unit, with high performance – especially in terms of uptime. We spend minimal time on ongoing maintenance and the cutters are long-lasting. This means we’re far more efficient in terms of human resources, and we’ve reduced operating costs by an estimated 20%.”

The first shredder ever to be designed and patented by UNTHA, the globally-acclaimed RS40 remains one of the most tried-and-tested pieces of equipment manufactured by this 50-year-old brand. Suitable for shredding plastic bottles, barrels, packaging, production waste, car bumpers, tetra paks and more, this 3.6 tonne machine is renowned for its high torque cutting system and defined fraction sizing.

“I think this UNTHA machine deserves particular praise for its durability, reliability, throughputs, energy efficiency and operator safety,” continued Marek Kurkowski “I would definitely recommend the RS40 plastic shredder.”

Mobile shredder to take centre stage at IFAT 2016

Visitors to IFAT 2016 will have an unrivalled opportunity to see the world’s first electrically-driven mobile shredder in action.

The pioneering new UNTHA XR mobil-e hit the headlines in February when it was launched by the Austrian-owned shredding specialists. With the same design features as the internationally acclaimed static XR, which will also be on display at the show (hall C2, stand 127/226), this mobile solution provides customers with identical benefits – high throughputs, low operating costs, energy efficiency, low noise, foreign object protection and ease of maintenance. Yet the XR mobil-e is the first machine of its kind to shred with a low power electric drive and, thanks to its on-board auxiliary power pack, it can be easily moved around a production facility and plugged back in.

The shredder has already been extensively trialled across Europe, to prove its flexibility when shredding MSW, C&I, C&D, wood and other bulky wastes to produce alternative fuels. Yet IFAT will be the first time the machine is demonstrated to the general public.

The shredder has already been extensively trialled across Europe, to prove its flexibility when shredding MSW, C&I, C&D, wood and other bulky wastes to produce alternative fuels. Yet IFAT will be the first time the machine is demonstrated to the general public.

An XR mobil-e will be on display on UNTHA’s open air site (12C, stand 9). But a free shuttle service will also transport IFAT attendees from Messe München to a nearby operational site, several times each day. Anyone making this short 20 minute journey will be able to see the XR shredding technology in action, shredding a variety of waste materials. UNTHA’s client will also be on hand, in addition to a team of UNTHA’s engineers, to answer any questions that visitors may have.

Commenting on the reasons to visit UNTHA at the 2016 show, product manager Christoph Lahnsteiner said: “We regularly invite existing and potential clients to our Austrian headquarters, so that they can speak to our team about their projects and see our machines being manufactured. However, the opportunity to get up close to one of our shredders under real operational conditions proves that our technology achieves what we say it does. I therefore encourage anyone with an interest in low cost, energy efficient and reliable alternative fuel production, to come along and see our XR shredder for themselves – whether they’re interested in a static or mobile machine.

“We’ve been delighted to read all the positive reports about our latest innovation, but seeing the shredder in action will tell so much more of the story than a write up ever could.”

Designed to provide customers with maximum flexibility, both the XR and the XR mobil-e can manufacture a wide range of high quality fuels for the WtE, cement, gasifier and biomass markets. A series of interchangeable screens and cutters enable these shredders to be configured according to the output specification, with homogenous particles of 30-400mm achievable.

To pre-register to attend one of these free site visits, please e-mail This email address is being protected from spambots. You need JavaScript enabled to view it..

IFAT will take place on May 30 – June 3, at Messe München, Messegelände, 81823 München (Munich). Discounted tickets are available to purchase in advance at http://www.ifat.de/trade-fair/visitors/purchase-ticket/.