Super User

Unique in the world: Wachendorff encoder configurable via NFC

The new WDGN series of incremental encoders from Wachendorff Automation enables configuration of any pulse count from 1 I/U to 16,384 I/U via NFC.

Depending on the equipment, Basic or Advance, further parameters can be set via APP using NFC.

After downloading the Wachendorff WDGN app to the smartphone, the desired parameters and values can be configured without contact or voltage, if necessary also through the outer packaging.

Encoder configurations created can be saved under different names, reloaded at any time and transferred to another encoder. This means that saved configuration sets can be used for the encoder in different applications. The configuration set of an encoder can be read out, saved, shared and reused for other encoders at any time after entering the PIN. The PIN and PUK principle is used for security.

More detailed information: www.wachendorff-automation.com/wdgn

App download for Android, Google Play Store (Huawei and IOS app to follow soon):

Wachendorff Automation GmbH & Co. KG

Wachendorff Automation (Geisenheim/Germany) stands for the development and manufacture of encoders, motor feedback and complete measuring systems for use in a wide variety of series applications in mechanical and plant engineering. The focus is on an extensive standard program with numerous options as well as the efficient development of customer-specific solutions. Sales offices in the USA and China.

Contact worldwide: https://www.wachendorff-automation.com/contact/

The optimum combination of electronics, optics and mechanics make Wachendorff encoders the most robust and reliable devices on the market. High protection classes, wide temperature ranges and the very robust electronics enable use also in very demanding applications.

Unique worldwide: 5-year warranty!

www.wachendorff-automation.com

Chevron, Talos and Carbonvert Announce Proposed Joint Venture Expansion to Enhance the Bayou Bend CCS Project Offshore Jefferson County, Texas

Chevron U.S.A., Inc. (“Chevron”), through its Chevron New Energies division, Talos Energy Inc. (NYSE: TALO) (“Talos”), through its Talos Low Carbon Solutions division, and Carbonvert, Inc. (“Carbonvert”) announced today a memorandum of understanding (“MOU”) for an expanded joint venture to develop the Bayou Bend CCS offshore carbon capture and sequestration hub currently held by Talos and Carbonvert.

In 2021, a joint venture between Talos and Carbonvert (now known as Bayou Bend CCS) was the winning bidder for the Texas General Land Office’s (“GLO”) Jefferson County, Texas, carbon storage lease, located in state waters offshore Beaumont and Port Arthur, Texas. The Bayou Bend CCS project site encompasses over 40,000 gross acres and, based on Talos and Carbonvert’s preliminary estimates, could potentially sequester 225 to 275 million metric tons of carbon dioxide (CO2) from industrial sources in the area. The Bayou Bend CCS lease is the first and only offshore lease in the U.S. dedicated to CO2 sequestration.

Under the terms of the MOU, Talos and Carbonvert would contribute the Bayou Bend CCS lease to an expanded joint venture including Chevron in exchange for consideration of cash at closing and capital cost carry through project FID. Upon closing of the joint venture, equity interests in the joint venture would be 25 percent Talos, 25 percent Carbonvert and 50 percent Chevron, and Talos would remain the operator.

Under the terms of the MOU, Talos and Carbonvert would contribute the Bayou Bend CCS lease to an expanded joint venture including Chevron in exchange for consideration of cash at closing and capital cost carry through project FID. Upon closing of the joint venture, equity interests in the joint venture would be 25 percent Talos, 25 percent Carbonvert and 50 percent Chevron, and Talos would remain the operator.

“Since our establishment of Chevron New Energies, we have been consistent in our communication that partnership will be required to grow successful lower carbon businesses. This venture is an example of the potential that partnering can have in moving large-scale lower carbon projects forward,” said Chris Powers, vice president of Carbon Capture, Utilization, and Storage (CCUS) for Chevron New Energies. “Talos and Carbonvert have worked to rapidly advance this project, and as a priority project for Chevron in a key industrial area, we are excited to contribute our experience and capability to develop the leading offshore carbon sequestration hub for the region.”

“Chevron brings significant expertise and experience to this project, and we are excited about what this partnership can deliver,” said Timothy S. Duncan, president and CEO of Talos. “We share a collective interest and commitment to developing low carbon solutions, and the success of these solutions will depend greatly on collaborative partnerships throughout the value chain. We believe the addition of Chevron greatly enhances the execution of this hub-scale project and we hope this sends a clear signal to industrial partners in the Beaumont and Port Arthur region that we are focused on making Bayou Bend the premier CCS project in southeast Texas.”

“This project is a catalyst that enables dramatic regional carbon emissions reduction to the benefit of local industry, the global community, and future generations,” said Alex Tiller, president and CEO of Carbonvert. “We look forward to the opportunity to partner with Chevron on such a monumental project supporting decarbonization and partnering with customers on their paths to net zero.”

The creation of the proposed joint venture is subject to the negotiation of definitive agreements with customary closing conditions, including regulatory approval.

About Chevron

Chevron is one of the world’s leading integrated energy companies. We believe affordable, reliable and ever-cleaner energy is essential to achieving a more prosperous and sustainable world. Chevron produces crude oil and natural gas; manufactures transportation fuels, lubricants, petrochemicals and additives; and develops technologies that enhance our business and the industry. We are focused on lowering the carbon intensity in our operations and seeking to grow lower carbon businesses along with our traditional business lines. More information about Chevron is available at www.chevron.com.

About Talos Energy

Talos Energy (NYSE: TALO) is a technically driven independent exploration and production company focused on safely and efficiently maximizing long-term value through its operations, currently in the United States and offshore Mexico, both upstream through oil and gas exploration and production and downstream through the development of future carbon capture and storage opportunities. As one of the Gulf of Mexico's largest public independent producers, we leverage decades of technical and offshore operational expertise towards the acquisition, exploration and development of assets in key geological trends that are present in many offshore basins around the world. With a focus on environmental stewardship, we are also utilizing our expertise to explore opportunities to reduce industrial emissions through our carbon capture and sequestration initiatives along the U.S. Gulf Coast and Gulf of Mexico. For more information, visit www.talosenergy.com.

About Carbonvert

Carbonvert Inc. is a carbon capture and storage project development and finance company that simplifies decarbonization for industrial clients. Carbonvert was established in late 2020 by Alex Tiller and Jan Sherman, veterans of the renewable and conventional energy sectors to manage the financial and technical complexities of CCS project development. Our executives have decades of experience developing projects, financing tax advantaged projects, trading carbon offsets, and structuring over $4 billion in infrastructure investments, including equity, tax equity, and debt for large assets. Carbonvert’s senior team has extensive experience with large-scale CO2 projects and have designed, secured environmental and CO2 storage permits, and completed and operated large-scale carbon capture, transportation, and storage projects notably Petra Nova CCS in Thompsons, Texas, Quest CCS in Alberta, Canada, and In Salah in Algeria. For more information, visit www.carbonvert.com.

Electric heating equipment manufacturer to present at PRC Europe

~ Watlow to discuss decarbonizing with electric heaters ~

Industrial technology company, Watlow, will attend PRC Europe 2022 Congress at Wanha Satama exhibition center in Helsinki, Finland. Taking place on 30 and 31 May 2022, Watlow will present how the electrification of process heaters can avoid coking and fouling, working towards decarbonizing industrial processes.

Each year, PRC Europe gathers industry leaders from oil and gas companies, refineries and petrochemical plants, licensors and chemical companies to discuss the ongoing technology trends and energy transition challenges that downstream industry deals with. Common themes of the congress include energy transition, sustainability, renewable fuels production, intelligent operations in refining and petrochemical operations.

Watlow has manufactured thermal system components including heaters, sensors and controllers since 1922, and is the only manufacturer to develop an electric heat exchanger designed to reduce fouling.

At this year’s congress, Hammad Chowdhury, director of global sales energy and environmental technologies at Watlow, will present how the company’s thermal systems can reduce coking and fouling to decarbonize industrial processes, focusing on the shift from gas-fired heaters to electric ones. Chowdhury will also discuss Watlow’s latest solution — its medium voltage heating and control system, POWERSAFE™.

“It’s no secret that each and every industry must find alternative, environmentally friendly solutions of operating,” said Hammad Chowdhury. “And one of the most effective ways to embrace this is by switching process heater systems from fuel-burning to electric.

“Electrification of process heating is one of the key strategies for addressing climate change concerns in oil and gas, and electric heaters that do not burn fossil fuels and can be powered via renewable energy sources play an important role in solving industrial sustainability challenges.

“Besides reducing reliance on fossil fuels, other standout features of electric heaters include less thermal lag, more uniform distribution of heat and smaller overall footprint. Systems such as the POWERSAFE™ integrated medium voltage control and heating solution provides a safe, reliable and clean replacement for fossil fuel alternatives in process equipment,” said Chowdhury.

“Watlow is contributing to the decarbonization needs of many industries that, historically, have experienced the greatest challenges in controlling emissions. We look forward to meeting with the many companies at PRC Europe and demonstrating how we can help them to electrify their thermal processes and support decarbonization goals.”

Hammad’s speaker slot will take place on May 30 at 14:30-14:55 CET European time. For more information about Watlow’s thermal solutions, visit www.watlow.com

About Watlow:

Watlow is a global industrial technology company that uses its world-class engineering expertise, advanced thermal systems and manufacturing excellence to enrich everyday life. Many of the world’s leading companies leverage our technology in vital applications such as semiconductor processing, environmentally-friendly energy solutions and lifesaving medical and clinical equipment, to name a few. Founded in 1922, Watlow’s culture is driven by our purpose of “Enriching Lives Through Inspired Innovation,” enabling us to deliver high-impact solutions that improve our customers’ competitive advantage.

Ref: WAT066/04/22

How solving Central Asia's water-energy conflict can also boost renewable energy generation

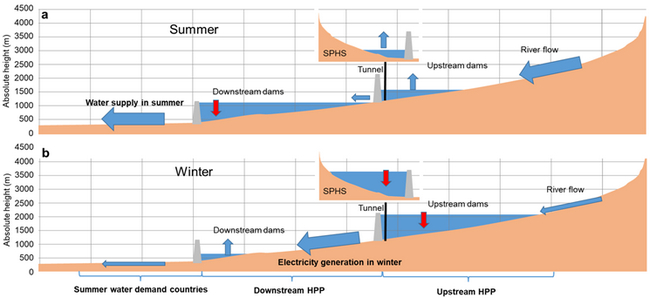

Researchers from the IIASA Energy, Climate, and Environment Program found that agricultural efforts in downstream countries in Central Asia, traditionally hampered by a lack of water for irrigation during the summer growing season, would be significantly boosted with a “Dual water and energy storage scheme”, which also paves the way for high shares of renewable energy generation in the region.

Behnam Zakeri, the lead author of the open-access paper published in the Journal of Energy Storage, explains the historical precedent to the current situation:

"The five countries we looked at in Central Asia were once part of the Soviet Union. When their infrastructure was developed during this period, there was no consideration that they would one day be five separate and independent countries. The separation has led to a mismatch between their interests and their available resources."

Zakeri further explains that the upstream countries of Tajikistan and Kyrgyzstan have control of more than 80% of freshwater resources of Central Asia. If they only used that water for their own needs, the water would mainly go to generating electricity in hydropower dams in winter, when the electricity demand is high. This water would flow down during cold seasons, when downstream countries don't need as much water, but leave them dry in summer when their peak agricultural season requires water for irrigation.

Julian Hunt, a coauthor of the paper, says that the key to the solution is the development of a so-called “Dual water-energy storage scheme”. The proposed scheme establishes two different hydrological cycles in up- and downstream areas throughout the year, which disentangles the seasonal demand of water for hydroelectricity and irrigation.

“This can be achieved by building hydro reservoirs in upstream areas backed with seasonal pumped hydropower storage (SPHS) to store water for hydropower generation and meet energy needs in upstream countries in winter. When this water reaches lower elevations, existing reservoirs downstream can be employed to store water until summertime to serve water demand for irrigation in downstream countries,” he notes.

Schematic of the proposed “dual water and energy storage scheme” that can resolve the mismatch between water availability for electricity generation and irrigation. The size of the arrows indicates the amount of water flow in each season. Red arrows show the discharge of water from dams. HPP: hydropower plant; SPHS: seasonal pumped hydro storage.

Schematic of the proposed “dual water and energy storage scheme” that can resolve the mismatch between water availability for electricity generation and irrigation. The size of the arrows indicates the amount of water flow in each season. Red arrows show the discharge of water from dams. HPP: hydropower plant; SPHS: seasonal pumped hydro storage.

The novel twist to the plan uses excess renewable energy generated in the lower reaches during summer, when wind and solar provisions are abundant and energy demand is low thanks to a mild climate, to pump water from lower elevations back to the top for re-use at less plentiful times of the year. This kind of potential energy storage is a long-duration solution far beyond the ability of batteries, for example. Exploiting that abundant clean energy would save hydroelectricity for winter when there is less solar generating potential, but more demand for electricity, heating, and lighting.

"In this paper, we propose integrated, cross-sectoral storage solutions that can resolve the temporal mismatch between the needs and availability of resources, which can potentially solve the transboundary water and energy conflicts in the region," says Zakeri. "Our proposal shows that, with political and economic cooperation, investments in infrastructure can be made in one or two countries upstream, while benefits flow throughout the entire region, including water and energy security as enablers of sustainable development.”

The researchers applied the IIASA open-source, systems optimization model, MESSAGEix, to create the most affordable scenario to reduce CO2 emissions from electricity generation, while guaranteeing water supply.

Hunt was also the lead author of a 2020 study published in Nature Communications that presented a detailed map showing a large number of locations that could benefit from similar seasonal pumped hydroelectric systems.

![Global potential for seasonal pumped storage. [https://www.google.com/maps/d/u/0/edit?mid=1O9aK_dTL3mDOgLgY2G0BSgmlHqRNSlHA]](/images/news/power_water/2022-05-03_171624.jpg) Global potential for seasonal pumped storage. [https://www.google.com/maps/d/u/0/edit?mid=1O9aK_dTL3mDOgLgY2G0BSgmlHqRNSlHA]

Global potential for seasonal pumped storage. [https://www.google.com/maps/d/u/0/edit?mid=1O9aK_dTL3mDOgLgY2G0BSgmlHqRNSlHA]

Reference

Zakeri, B., Hunt, J.D., Laldjebaev, M., Krey, V., Vinca, A., Parkinson, S., Riahi, K. (2022). Role of energy storage in energy and water security in Central Asia. Journal of Energy Storage, DOI: 10.1016/j.est.2022.104587

The International Institute for Applied Systems Analysis (IIASA) is an international scientific institute that conducts research into the critical issues of global environmental, economic, technological, and social change that we face in the twenty-first century. Our findings provide valuable options to policymakers to shape the future of our changing world. IIASA is independent and funded by prestigious research funding agencies in Africa, the Americas, Asia, and Europe. www.iiasa.ac.at

The key to more sustainable watchmaking

Polycrystalline diamond (PCD) veined CoroDrill® 862 micro drill offers way forward for manufacturers

Can luxury watchmaking go green? While there’s a growing onus on watchmakers to be more sustainable, they must also fashion masterpieces of micro engineering from some of the world’s toughest materials, like ceramics. But these materials can cause serious issues with regards to tool life. Here, James Thorpe, global product manager at the leader in metal cutting Sandvik Coromant, explains how advanced tools including its CoroDrill® 862 micro drills can give enhanced wear resistance for more sustainable production.

Perhaps the most extreme recent example of sustainable watchmaking is the so-called Garbage Watch by Vollebak, a radical design-led British clothing brand that makes clothes and accessories using emerging materials, with new technologies and processes. Vollebak says its products are “of the future” while also being sustainable. Despite its name, the Garbage Watch is a coveted made-to-order item that has featured in the world’s top design publications.

“I thought, you must be able to build a watch out of e-waste,” Vollebak co-founder Nick Tidball told Esquire magazine earlier this year. Esquire’s article mentions findings from the UN’s Global E-waste Monitor report that a record 54 million tonnes of electronic waste was generated by all industries globally in 2019, which was up 21% in five years. Precious metals with a value of $1.7 billion were recovered from this e-waste, but this was only 17% of the total recyclable amount. The overall value of the precious metals would have been closer to $10 billion.

Ceramics are tough to machine but increasingly used in all-black luxury watches.

Ceramics are tough to machine but increasingly used in all-black luxury watches.

This figure shows how far industry is falling behind in making full use of recyclable e-waste. But steps are being made to rectify this, including by watch manufacturers. Let’s look at another e-waste material, ceramics — solid compounds that consist largely of inorganic and non-metallic components bound by strong chemical bonds. They are fully-recyclable and are becoming more popular among watch designers. According to SwissWatchExpo, advantages of ceramics include their exceptional hardness, especially when compared to steel and gold, and they are a good material for all-black watches which continue to gain popularity.

But ceramics are often very difficult to machine. As confirmed by a study by the Department of Mechanical Engineering at the BMS College of Engineering in Karnataka, India: “Machining of ceramics is also plagued by surface damage, excessive tool wear, and edge chipping when machined using conventional techniques.” It continues: “Non-conventional techniques such as electric discharge machining (EDM) and abrasive water jet machining are characterized by poor surface finish and excessive occurrence of pits, respectively.”

BMS College’s report identifies achieving dimensional accuracy and minimizing collateral damage, such as surface cracks, as the main challenges of machining ceramics — and neither obstacle is conducive to sustainable manufacturing. How can watchmakers overcome these challenges?

Drilling ceramics

The answer lies in more wear-resistant tools. Sandvik Coromant has evolved its tool offering by introducing two new micro drill families to its product range, CoroDrill® 462 with -XM geometry and CoroDrill® 862 with -GM geometry, which each offer a wide range of cutting diameters and lengths. Both tools are designed to be ideal for precision machining in industries dealing with small parts, while also offering more sustainable performance.

In particular, each tool is designed to offer superior wear resistant properties that deliver outstanding performance with challenging materials within all ISO applications areas, including ISO P, M, K, N, S, O and H. This is further enhanced by the option of purchasing the micro dill with a polycrystalline diamond (PCD) vein cutting edge. Based on successful tests of PCD drills on micro parts made from platinum, Sandvik Coromant has found that PCD is up to 100 times more wear resistant than solid carbide and, in addition, is more accurate and can produce tighter tolerances than solid carbide tools.

The tools are also suitable for machining ceramics and semi-fired ceramics. In one test, a Sandvik Coromant CoroDrill® 862 tool with a veined PCD cutting edge was used in a horizontal machining centre to drill 8.38 mm (0.330 inch) deep blind holes in an alumina ceramic workpiece, a fine ceramic material well-known for its chemical and physical stability, with no pecking. The tool was run at a diameter (Dc) of 1.70 mm (0.067 inches), a cutting speed (vc) of 53 m/min (174 ft/min) and feed rate (fn) of 0.025 mm/z (00.001 in/z).

Sandvik Coromant’s CoroDrill® 862 with -GM geometry can be further enhanced with a PCD vein cutting edge.

Sandvik Coromant’s CoroDrill® 862 with -GM geometry can be further enhanced with a PCD vein cutting edge.

In the end, 933 holes were drilled and the hole quality and tool life were both excellent. Aside from these results, the key takeaway is the lifecycle advantages of CoroDrill® 862 micro drill. Customers can achieve longer-lasting, reliable and predictable performance that better-complements the plant’s sustainability strategy. Sandvik Coromant’s engineers also recommend PCD to those seeking to drill micro-sized holes in notoriously difficult-to-machine materials, such as titanium, aluminium, glass and also ceramics.

As with macroscale applications, the importance of coolant must also be considered in microscale applications like watchmaking. It’s critical to have quality coolant delivery to effectively evacuate chips when performing deep-hole drilling with micro tools.

The features and performance of veined PCD for extended tool life, are shown to overcome the machining challenges posed by tough materials like ceramics. Sandvik Coromant’s expanded CoroDrill® family of tools show that more productive and sustainable production processes are available, and can help contribute towards a greener future for watchmakers.

Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 1700 patents worldwide, employs over 7,700 staff, and is represented in 150 countries.

For more information visit www.sandvik.coromant.com

Xodus emissions project identifies $10 million cost saving for Middle East operator

Global energy consultancy Xodus has completed a major benchmarking emissions review for a leading Middle East oil operator’s full asset portfolio, demonstrating significant emissions and cost savings.

The team identified more than 100 emissions reduction opportunities as a result of the site studies, representing a minimum 20% reduction in total CO2 equivalent. A third of the improvements can be easily implemented with low or no capital expenditure required. The complete reduction potential would deliver overall savings of $10 - $15 million per year.

The six-month project reviewed scope 1, 2 and 3 emissions, establishing the foundations for a sustainable reduction action plan. Scope 1 covers direct emissions at the production stage, scope 2 covers indirect emissions from generation and scope 3 covers all other indirect emissions.

The six-month project reviewed scope 1, 2 and 3 emissions, establishing the foundations for a sustainable reduction action plan. Scope 1 covers direct emissions at the production stage, scope 2 covers indirect emissions from generation and scope 3 covers all other indirect emissions.

The Xodus team also reviewed national and international guidance, legislation and policy with existing internal processes, identifying best practices, peer benchmarking and recommendations for the development of an internal emissions and energy efficiency framework.

Natasha Howlett, emissions lead at Xodus said: “The comprehensive review of greenhouse gas emissions gives our client a clear understanding of their emissions baseline along with a robust hopper of improvement opportunities and how best to prioritise these for implementation in order to decarbonise a portfolio of assets.

“This exercise has demonstrated this client’s ambitions as a decarbonisation leader for the region. Oil and gas operators are looking to responsibly reduce emissions and ultimately achieve net zero. Benchmarking and opportunity identification are vital first steps in order to ensure that this complex journey to net zero is manageable and will deliver big impacts when it comes to cutting both emissions and costs.”

Xodus has built up a wealth of experience and learnings from developing emissions reductions strategies in the UK and other global regions, which can help Middle East operators as they strive to meet new country-level targets being set.

Saudi Arabia has pledged to bring its carbon emissions down to net zero by 2060 and the UAE by 2050. Bahrain and Israel have also made net zero pledges while Qatar has set out a plan to cut emissions by 25% by 2030. Given the scale of oil and gas production from the Middle East, sustained incremental emissions reductions from production assets can make a significant impact on global climate targets.

As a global energy consultancy, we unite our unique and diverse people to share knowledge, innovate and inspire change within the energy industry. We provide support across the energy spectrum, from advisory services to supply chain advice. Including all of the engineering and environmental expertise needed in between. Our people strive to ensure global energy supply as we all work together to realise a net zero world.

Kongsberg Digital has acquired software developer Interconsult Bulgaria Ltd

Interconsult Bulgaria Ltd (ICB), a software developer and supplier of process modeling, software architecture design, quality assurance and 3D modeling and design, has been acquired by Kongsberg Digital.

Kongsberg Digital is experiencing significant commercial traction across our three digital divisions Digital Energy, Digital Wells, and Digital Ocean. To support the roll-out of our leading digital positions in Energy and Maritime and to support the growth into Renewables, KDI is ramping-up the development capacity.

The acquisition agreements were signed 26th of April 2022. The full acquisition is completed after 2 years, with KDI effectively acquiring 65 per cent of the company now.

The acquisition agreements were signed 26th of April 2022. The full acquisition is completed after 2 years, with KDI effectively acquiring 65 per cent of the company now.

ICB will serve as KDI’s European development hub for software development to attract and develop key talent to deliver into existing projects and support KDI’s vision to accelerate the green shift by digitalizing the worlds industries. ICB has proven solid delivery and highly skilled developers through the long-lasting relationship with Kongsberg Group starting already in 2004 supporting on a range of products.

“ICB has delivered high value into a wide range of products for KDI, and they are an important and trusted partner. Their ability to solve problems and deliver efficiently with high quality will be crucial going forward. ICB has also shown that they can attract and retail real talent in a highly competitive market, which is key to establishing ICB as a European location for growth. Bringing ICB onboard as a KDI company will strengthen our team and support our journey ahead,” says Hege Skryseth, President Kongsberg Digital.

“Kongsberg Digital has been an important partner for ICB through many years and represents the natural way forward for our company. This will bring opportunities to continue innovation and together we will strengthen our product development for the future,” says Stoyan B. Boev, CEO of ICB

ICB offers highly innovative and skilled personnel complementary to KDI, with focus on IoT, visualization, AI and machine learning within the maritime and energy domain. ICB is also considered a good platform for future recruitments and ramp-up, with high standard office premises, a people-first culture. Bulgaria is considered attractive as it is close-to-home and offers access to highly talented people with a high ranking on Software Engineering Statistics.

Through the acquisition of ICB, we expand and strengthen our long-lasting partnership going back to 2004 for developing Kongsberg Digital SaaS products. ICB represents developers and technologists with deep software knowledge and extensive experience in industrial business domains. The company is technology and developer-driven, with a curious and dedicated mindset. The expertise in the latest technologies such as AI/ML, industrial IoT, Cloud, and VR/AR is a perfect fit with the Kongsberg Digital software culture. The acquisition enables us to expand and develop our Kongsberg Digital SaaS products such as the Kognitwin Energy digital twin product, the SiteCom drilling solutions, the maritime simulators, and the Vessel Insight ecosystem.

ICBs head quarter is located in Sofia, Bulgaria, with smaller offices in Plovdiv, Kyustendil and Blagoevgrad mainly to broaden recruitment footprint and increase attractiveness as an employer. ICB consists of about 150 employees serving mainly Scandinavian customers and will be a great extension to the growing KDI team now consisting of more than 760 employees globally. The company was founded in 1996 and owned by founder and CEO Stoyan B. Boevand Technical Director Atanas Golev.

The acquisition agreements were signed 26th of April 2022.

KONGSBERG DIGITAL

Kongsberg Digital is a provider of next-generation software and digital solutions to customers within maritime, oil and gas, and renewables and utilities. The company consists of more than 700 software experts with leading competence within the internet of things, smart data, artificial intelligence, maritime simulation, automation and autonomous operations.

INTERCONSULT BULGARIA Ltd

For more than 26 years ICB has been providing software development and consultancy services to market-leaders in Scandinavia, Western Europe, and North America. Our company’s client-centric and agile approach has helped us become one of the most successful companies in the Central and Eastern Europe (CEE) region. ICB has received the Information & Document Management Solution Provider for 2016 of the year award at IT Europa, the Innovation Hub of Bulgaria for 2013. ICB was recognized also as the Channel IT Company of 2010 at the prestigious IT Excellence award ceremony and has been awarded with the Seal of E-Excellence Award on the CeBIT Hanover Fair 2011. Find out more about our history and philosophy on the next pages.

Buckman and energy drive partner on sustainability efforts

In 2012, Buckman, a US-headquartered specialty chemical company, partnered with Energy Drive with a goal of reducing electricity usage and water consumption at Buckman’s Hammarsdale, South Africa facility. Energy Drive is a company that forges partnerships with organizations to reduce energy consumption in a sustainable manner, with minimal capital investment requirements. Together, the two saw an opportunity to monitor Buckman’s primary cooling tower to help the company achieve sustainable environmental benefits.

The cooling tower system comprises two fans and two pumps, which originally ran at maximum speed for 24 hours per day every week from Monday morning until Saturday morning, even when water temperatures were sufficient for process requirements.

Once Energy Drive’s energy-saving solution was installed on the four motors; sensors provided variable frequency drives with the information necessary to regulate the speed of the motors depending on the temperature required. Now, when the system reaches the desired temperature, the pumps and fans slow to the optimal speed to ensure that energy is not wasted.

As the systems have been in place for 10 years, Buckman has realized many benefits of this technology. “The low monthly service charge is completely offset by the energy savings we gain from the variable speed drives,” said Mukesh Ramatar, Plant Manager for Buckman South Africa. “But even more important are the positive environmental impacts we’ve seen from the solution - they are the real driver of the value we see.”

Energy Drive’s David Classens presents Buckman South Africa’s Mukesh Ramatar, Plant Manager, and Rolf Breidenbach, General Manager, with a milestone achievement certificate. The certificate was awarded in recognition of Buckman surpassing 4.0M kWh of energy saved. This equates to 4.16M kg of CO2 eliminated, 5.5M liters of water saved and 2.74M kg of coal and ash not used or generated.

Energy Drive’s David Classens presents Buckman South Africa’s Mukesh Ramatar, Plant Manager, and Rolf Breidenbach, General Manager, with a milestone achievement certificate. The certificate was awarded in recognition of Buckman surpassing 4.0M kWh of energy saved. This equates to 4.16M kg of CO2 eliminated, 5.5M liters of water saved and 2.74M kg of coal and ash not used or generated.

In 2022, Buckman received a milestone achievement certificate from Energy Drive. In collaboration with the company, Buckman has surpassed the milestone of 4.0M kWh hours in energy saved. This equates to 4.16M kg of CO2 eliminated, 5.5M liters of water saved and 2.74M kg of coal and ash not used or generated.

"It has been a privilege working with Buckman, actualizing sustainability on their behalf,” says Mark Milne, General Manager for Energy Drive South Africa. “The focus on ESG targets over recent years highlights the importance of these kinds of projects. The whole is greater than the sum of the parts. Together we have a greater impact."

The variable speed drives also add an extra layer of protection to motor and pump systems by allowing the pump to gradually ramp up to the speed required by the process, rather than starting and operating at 100% speed. Operating the motor and pump at less than full speed reduces the flow and pressure created by the pump meaning excess flow and pressure do not need to be dissipated in the system. When less strain is put on the pumps it not only protects the equipment, but also reduces the energy consumed by the system.

“One of the best things about variable speed drives is that they could be installed across all cooling tower systems and chiller systems globally,” said Ramatar. “Which could exponentially impact our energy savings and sustainability efforts. We look forward to continuing our close relationship with Energy Drive and are proud to continue reaching and surpassing sustainability milestones.”

About Buckman

Buckman is completely committed to helping our customers succeed, regardless of the challenges facing them, the industry they operate in or their location in the world. To fulfill that commitment, we surround our rigorously trained industry experts with the highest-quality chemicals, the latest smart technology and advanced data analysis. All focused on helping our customers’ operations improve productivity, increase profitability and ensure safety, compliance and sustainability. That’s more than chemistry. That’s Chemistry, connected.

About Energy Drive

Energy Drive partners with companies from a range of major industries to actualize their energy-related sustainability goals. Using variable speed drives to reduce our clients’ energy consumption and achieve more efficient operations, we also lower energy-related business costs. We achieve this by removing the barriers to energy optimization by taking on the risk and staying invested with our clients for the long term. By purchasing the required equipment, installing it, and ensuring that it runs effectively for as long as it’s on a client’s site, we have founded an innovative, fully-engineered, turnkey sustainability solution executed via a zero-capex service contract. It’s our way of providing sustainability as a service.

A.W. Jenkinson Forest Products ackknowledge the work of FISA

A.W. Jenkinson Forest Products and A. W. Jenkinson Transport Ltd are pleased to acknowledge the work of the Forest Industry Safety Accord (FISA) being founder members since 2012 when representatives of the Forest industries leading organisations came together to set out the Accord which underlines a commitment from the sector to raise the standard of health and safety in the forestry workplace: www.ukfisa.com

FISA have just produced a great new online resource for the sector – a Forest Haulage Induction Video which can be viewed here. As the haulage industry currently works through some well documented driver challenges, this is aimed at new entrants who have HGV experience – but who have may not have previously driven in Forest conditions. As well as the obvious timber trucks and walking-floors, this also covers drivers of fuel tankers, low loaders and other materials deliveries. A.W. Jenkinson Transport will use this easily accessed online tool to create a meaningful impact on new entrants and use it as part of their induction process and driver apprentice training.

Moxa Launches E1 Mark and EN 50121-4 Compliant Robust Computers for Intelligent Transportation Applications

For modern transportation systems, maintenance is always crucial if you want to bring a safer overall transport experience to passengers. To save on maintenance efforts, Moxa, an IRIS-certified railway communication solution provider, has launched the V2403C Series, a new series of robust industrial computers that comply with the E1 Mark, ISO 7637-2, and EN 50121-4 standards for vehicular and wayside applications.

Versatile Design to Strengthen Reliability in Transportation Infrastructure

Drawing on Moxa’s extensive expertise in building robust computing platforms, the V2403C Series operates in a wide range of operating temperatures for deployments in harsh environments, which require high computing power and reliable wireless connectivity. As a field-ready solution, the V2403C computers are built around an Intel® Core™ i7/i5/i3 or Intel® Celeron® high-performance processor and come with up to 32 GB RAM, one mSATA slot, and two hot-swappable 2.5-inch SSDs for storage expansion. Embedded with two mPCIe slots for I/O expansion, the ultra-compact fanless computers support multiple displays in the control room for local monitoring of status and real-time control.

Robust Industrial Computers for Rugged Operating Conditions

Wayside and vehicular applications require robust computers with expansion capabilities to connect sensors, cameras, and devices that use Wi-Fi and cellular technology. Furthermore, the design must handle “dirty power” during engine starts and shutdowns with a graceful shutdown mechanism in place to preserve system stability and lifespan of batteries. Compliance with E1 Mark, ISO 7637-2, and MIL-STD-810G requirements protects the V2403C computers from shocks and vibrations that are common in transportation applications.

The V2403C computers are also compliant with the EN 50121-4 standard for wayside applications. To provide reliable transportation and ensure passenger safety, the V2403C computers come with power ignition control that protects equipment against unstable power. The combination of high performance, rugged design, compact size, wireless connectivity, and enhanced security makes the V2403C Series a perfect fit for mission-critical, heavy-duty wayside and vehicular applications.

V2403C Series Highlights

• 7th Gen Intel® Core™ i7/i5/i3 or Intel® Celeron® high-performance processor

• Configurable power ignition delay to protect equipment

• Higher cybersecurity awareness with optional TPM module

• Compact yet robust design with sufficient interfaces for wireless expansion

• MIL-STD-810G compliant for protection against shocks and vibrations

• E1 Mark* compliant for vehicular applications

• Compliant with ISO 7637-2 requirements

• Compliant with EN 50121-4 for wayside applications

• -40 to 70°C (-40 to 158°F) wide-temperature models available

• Microsoft Azure and AWS certified for IoT applications

For product information and technical specifications of the V2043C Series, visit the product pages.

* Certification process is expected to be completed in Q3, 2022.