Super User

Nature’s vault launches novel blockchain-powered platform to monetize in-ground mineral assets, avoid environmental destruction

Team Headed by Global Leaders in ESG, Mining, FinTech, Finance Secure Seed Funding Targets First Tokenization Project, “Avoided Mining” of Gold Deposits

Nature’s Vault, a GreenTech platform designed to accelerate the funding of impact investments combating climate change and ecosystem damage, today announced its seed funding round, Board and Advisors, and an expected first tokenization project to monetize the preservation of in-ground gold deposits avoiding the environmental impact of physical mining.

“Building a first-of-its kind platform that allows anyone to fund impact investing projects around the world is a legacy everyone at Nature’s Vault is proud to be part of,” said Founder and CEO Phil Rickard. “We are bringing our breakthrough approach to tokenizing ESG projects and Natural Capital assets to help mitigate climate change in a transparent manner via distributed ledger technology and a platform that can be replicated and scaled up for future growth.”

Nature’s Vault is creating a platform built on the blockchain to tokenize projects focused on preserving Natural Capital – the planet’s natural resources. Its initial project avoids the environmental impact and carbon emissions related to gold mining by utilising tokenization to monetize the value of in-ground gold deposits by preserving quantified proven gold reserves in a secured mine. The world’s first zero carbon gold preservation linked investment.

Nature’s Vault is creating a platform built on the blockchain to tokenize projects focused on preserving Natural Capital – the planet’s natural resources. Its initial project avoids the environmental impact and carbon emissions related to gold mining by utilising tokenization to monetize the value of in-ground gold deposits by preserving quantified proven gold reserves in a secured mine. The world’s first zero carbon gold preservation linked investment.

Its “Legacy Token”, expected to launch in the first half of 2022, will unlock the value of gold assets, without the negative environmental impact associated with mining in some of the world’s most pristine locations. The Legacy Token is designed to achieve a net-zero future and to ensure that fractional asset ownership is transparent and irrefutable by recording all transactions on a secure blockchain.

Secures Seed Funding From CDI

Nature’s Vault also announced that it has secured seed funding from a consortium of international technology investors led by CDI, an Asian-based biometrics and data-analytics platform provider, with serial entrepreneur Irawan Mulyadi joining as an independent director.

“Nature’s Vault has a proven leadership that combines FinTech and natural resources prowess to offer all investors a platform that leverages the power of digital assets to mitigate climate change, preserve biodiversity, and invest back into the local communities affected,” said Mr. Mulyadi.

Experienced Team Leadership

Building Nature’s Vault is a global, highly experienced team of entrepreneurs, investors, and executives across ESG, mining, FinTech, and finance including:

- Phil Rickard, CEO and Founder. Phil is a global entrepreneur who has founded and developed enterprises focused on natural resources, renewable energy, FinTech, and artificial intelligence. He was CEO and owner of one of the largest mobile payment companies in Southeast Asia and was founder and executive vice president of the NASDAQ-listed ActiveIQ Technologies. Phil also was chairman and CEO of a Singapore Exchange-listed energy company and founding president of the Singapore Stock Exchange Association.

- Michael Harrison, Chairman. Michael is an entrepreneur and investor who has built resource, energy, and biotech companies around the world focusing on a sustainable future. He has 35 years of investment banking experience and has served as CEO of two Indonesian mining companies that developed major resources, resulting in successful exits totalling more than $1 billion.

- Paul Matysek, Director. Paul is one of Canada’s leading natural resources developers, with a recent focus on metals that are essential to a sustainable future through the greater utilization of electric battery storage. A serial entrepreneur, geochemist and geologist with over 40 years of experience in the mining industry, Paul has focused on the exploration, development and sale of five public companies, in aggregate worth of almost $3 billion. He was awarded EY Entrepreneur of the Year for Mining & Resources in 2018.

- Dr. John Wiebe, Director. John is an early leader in business and sustainability, bringing business and government together to ensure the health of the planet through economic development. He established the GLOBE Foundation in 1993 and was recognized in 2011 as one of Canada’s Clean16, one of 16 individuals who have done the most to advance sustainability and clean capitalism in Canada.

- Irawan Mulyadi, Director. Irawan is a serial IT entrepreneur with extensive experience in the strategic use of information technology in a diverse range of areas, including payment systems, social media, e-commerce, eHealth and mobile applications. Irawan’s international experience includes a broad range of assignments from analysis to implementation.

- Willie Chang, FinTech Advisor. Willie is the CEO of Hg Exchange, a private exchange formed by an alliance of leading financial intermediaries, individually licensed and regulated by the Monetary Authority of Singapore. He has 20 years of experience spanning FinTech, investment banking, and management consulting.

- Jason Wagner, Senior Advisor. Jason has 30 years international experience in financial services, strategy consulting and senior executive talent. He is advising on Web 3.0/Blockchain technologies, talent, and corporate development.

Nature’s Vault LLC is developing a GreenTech platform to accelerate the funding of impact investments aimed at combating climate change and ecosystem damage. Launched in 2022, Nature’s Vault expects to be the one of the first to create a blockchain powered platform to tokenize projects focused on preserving natural capital – the planet’s natural resources. The Company’s first project involves avoiding the environmental impact and carbon emissions related to gold mining while utilising tokenization to preserve the value of in-ground gold deposits. Nature’s Vault has operations and a presence in North America and Asia.

BASF and REEF Technology sign strategic cooperation agreement to improve the quality of plastic recyclate materials

BASF has signed a strategic cooperation agreement with Zhejiang REEF Technology Co., Ltd. to develop state-of-the-art recyclate formulations for applications used in the automotive, packaging and consumer industries.

- BASF to supply its new IrgaCycle™ additive solutions to REEF Technology

- Builds on extensive know-how in the plastics industry

Under the agreement, BASF will provide its recently launched IrgaCycle™ additive solutions along with technical consultancy and support for recycled polymer formulations conducted at BASF’s test facilities.

“Our goal is to help deliver higher quality, safer and more effective products while supporting the plastic circular economy and helping reduce the use of virgin plastic material,” says Hermann Althoff, Senior Vice President, Performance Chemicals Asia Pacific. “In this way, we support our customers and partners to achieve their sustainability targets and create sustainable innovations together.”

“We wanted to partner with a world-class manufacturer of plastic additives like BASF to improve the quality of our recyclates,” says Shirley Wu, General Manager, REEF. “With its in-depth expertise in plastic additives, BASF supports us in this core area by improving the processing and long-term stability of highly contaminated recycled plastic fractions.”

The new IrgaCycle™ solutions improve the processing and long-term stability of recycled plastics fractions strongly contaminated with paint, ink or adhesive residues, e.g. exterior automotive parts (bumpers).

The new IrgaCycle™ solutions improve the processing and long-term stability of recycled plastics fractions strongly contaminated with paint, ink or adhesive residues, e.g. exterior automotive parts (bumpers).

IrgaCycle™ additive solutions help to increase the percentage of mechanically recycled content in several end-use applications such as packaging, automotive & mobility, and building and construction. These solutions address specific quality issues associated with recycled resins, such as limited processability, poor long-term thermal stability and insufficient protection from outdoor weathering.

The IrgaCycle range is offered as part of the VALERAS™ portfolio. In addition to enabling plastics circularity with IrgaCycle, VALERAS solutions bring significant sustainability value to plastic applications by improving durability, reducing waste, saving energy, reducing emissions, and promoting biodiversity.

Zhejiang REEF Technology Co., Ltd. is a subsidiary of Veolia Huafei Polymer Technology (Zhejiang) Co., Ltd., a joint venture company of the French Veolia Group in China. It focuses on the R&D and production of high-end engineering plastic modified materials. REEF’s core products include recycled polypropylene, high density polyethylene, ABS, and polyamide.

About BASF Plastic Additives

BASF is a leading supplier, manufacturer, and innovation partner of plastic additives. Its comprehensive and innovative product portfolio includes additives which provide ease in processing, heat and light resistance to a variety of polymers and applications including molded articles, films, fibers, sheets and extruded profiles. The portfolio is constantly analyzed, assessed and actively improved towards solutions which make a larger contribution to sustainability. More information about plastic additives: www.plasticadditives.basf.com.

BASF plastic additives is part of BASF’s Performance Chemicals division. The division’s portfolio also includes fuel and lubricant solutions, kaolin minerals, as well as oilfield chemicals and mining solutions. Customers from a variety of industries including Chemicals, Plastics, Consumer Goods, Energy & Resources and Automotive & Transportation benefit from our innovative solutions. To learn more, visit www.performancechemicals.basf.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. Around 111,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio comprises six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €78.6 billion in 2021. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

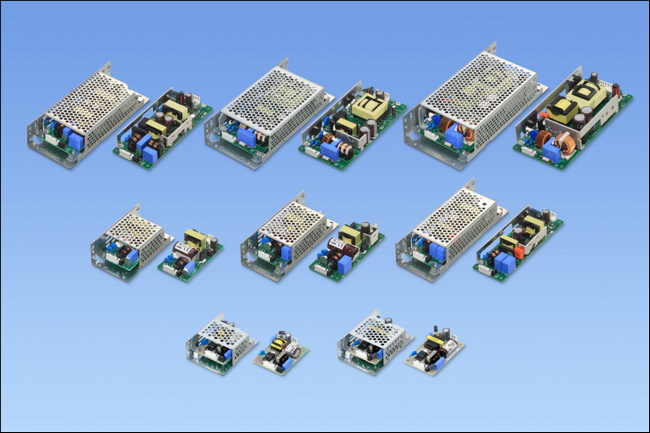

COSEL announces the addition of 10W and 15W units to its low profile open frame power supplies for demanding industrial applications

Cosel Co, Ltd (6905: Tokyo) have just announced the addition of two open frame compact power supplies for demanding industrial applications to its LHA series. Benefiting from the latest power switching technologies, the LHA10F and LHA15F are 15% smaller and offer a leakage current 50% lower than conventional products on the market. Designed for use in a wide range of applications, the LHA10F and LHA15F are able to operate in a wide temperature range from -10 to +70 degrees C. The power supplies are UL/EN62368-1 certified.

- Low profile open frame (21.5 mm)

- Safety approvals UL62368-1, c-UL (equivalent to CAN/CSA-22.2 No.62368-1), EN62368-1

- Low leakage current

- Wide temperature range -10 to +70 degrees C

- High reliability – 5-year warranty

With the increased levels of systems integration, factory automation requires more compact power supplies able to work with the highest levels of safety in a variety of environments. The LHA10F and LHA15F have been designed to provide robust isolation levels and very low leakage currents.

Designed for worldwide applications, the LHA10F and LHA15F have an input voltage range of 85VAC to 264VAC single phase, and conform to the safety standards input voltage range of 100-240VAC (50/60Hz).

The power supplies are available in five output voltages, 3.3V, 5V, 12V, 15V, 24V with respective currents. On both versions, the 3.3V output voltage can be adjusted in the range of 2.85V to 3.63V, all other voltages being factory fixed.

The LHA10F and LHA15F benefit from an optimized switching topology developed for higher power LHA series, and have an efficiency up to 84.5% at 230VAC and rated load.

The power supplies include inrush current limitation, over-current protection with automatic recovery when the default is removed, and over-voltage protection.

The units are designed to operate from -10 to +70 degrees C and they can be mounted in any orientation, though depending on the ambient temperature and environment, a derating may apply.

Embracing eight models, the Cosel’s LHA series offers a wide range of products from 10W to 300W for demanding applications

Embracing eight models, the Cosel’s LHA series offers a wide range of products from 10W to 300W for demanding applications

In conducted noise tests, the LHA10F and LHA15F comply with FCC-B, VCCI-B, CISPR11-B, CISPR32-B, EN55011-B, and EN55032-B.

The units have a 3,000VAC input to output isolation voltage, 2,000VAC input to ground and 500VAC output to ground. They offer low leakage currents, the LHA10F has 150 microampere max and the LHA15F has 100 microampere max at 240VAC/60Hz.

Designed for use in demanding applications where space is often limited, the LHA10F measures just 50 X 21.5 X 62.5mm (1.97 X 0.85 X 2.46 inches) and weighs 45g max. The LHA15F measures 50 X 21.5 X 73.5mm (1.97 X 0.85 X 2.89 inches) and weighs 60g max.

Additional options are available for specific applications, option-C for a conformal coating for improved moisture resistance, option-J4 for input and output EP connectors, option -S with chassis, option -SN with chassis and cover, and option -Y for an output voltage potentiometer.

The LHA10F and LHA15F complement the Cosel’s extensive range of products for high demanding industrial applications requiring efficient power from 10W all the way up to 300W. The power supplies offer an ideal solution for the maintenance of equipment using the previous COSEL LDA series.

The LHA10F and LHA15F are suitable for a wide range of applications including measurement and analysis equipment, machine tools and industrial robots, display equipment, and semiconductor manufacturing equipment. They comply with the RoHS and Low Voltage directives and carry the CE mark and UKCA.

About Cosel:

Established in Japan 1969, COSEL is one of the world’s leading designers and manufacturers of high performance AC-DC Power Supplies, DC-DC Converters and EMI Filters. With quality, reliability & flexibility as our main focus, we pride ourselves on developing some of the highest quality and most reliable products seen anywhere in the world today. The Cosel Group is a $250m global company employing some 700 staff with sales offices throughout Japan, Asia, Europe and North America. Our product range is aimed mostly at demanding applications within the Industrial, Factory Automation, Medical, Telecoms, Lighting, Audio/Broadcast & Renewable Energy sectors. A flexible approach with full in-house design means we deliver products using the very latest technology meeting the growing demands of our customers.

Related links:

Lesters boss predicts a triple whammy of spiralling fuel, energy and material costs for the packaging sector

The boss of one of the UK’s large packaging specialists is urging Government to step in to help with spiralling energy and materials costs.

Billy Hutchinson, Managing Director of Lesters, believes his sector is often overlooked when it comes to support, yet finds itself faced with a potential 30% increase in paper prices in the next month.

A number of European mills have already shut their doors, and this is going to magnify the focus on those that are left, causing inflation in charges and the possibility of instability of supply.

Billy Hutchinson, Managing Director of Lesters

Billy Hutchinson, Managing Director of Lesters

It comes after the Burntwood company has boosted its sales by 120% and taken on another 15 staff to cope with the rise in demand.

“There’s a perfect storm about to hit and there’s no way our sector can avoid it,” explained Billy, who has worked in the packaging industry for more than 18 years.

“It’s a triple whammy of energy, fuel and material prices all rocketing at the same time and, just the prospect of this, is enough to make people think twice about spending and this is translating into a freeze in the economy.”

He continued: “We’re already looking at how we can mitigate some of the challenges in our control and have invested heavily in new technology (which uses less energy) and switching to more solar power. This isn’t going to be a quick fix, more a long-term strategy.

“The packaging sector is taken for granted. People just see boxes, but it’s how everything is transported and crucial to everyday life. We’re going to need support and Government has a role to play in providing subsidies or tax cuts around energy usage.”

Lesters, which has become a certified CarbonNeutral® company, has become one of the major disruptors to the packaging sector.

More than £6m has been invested or in the process of being spent to ensure the firm can supply corrugated boxes, large format, heavy-duty cases and bespoke packaging to clients in the automotive, aerospace, bike manufacturing, mail order and third-party logistics space.

The business is also exploring a way of creating its own eco-system where it has full control over the whole of the packaging production process, from print ink and design, right through to distribution through Lesters Logistics in Nuneaton.

This was the first acquisition by the current management team, with plans in place to look at other complementary businesses that give it greater market share, access to new customers and wider geographic reach.

Billy concluded: “Our fuel bills have gone up from £3k to £5k per week, material prices could hit a 30% increase and our fixed term electricity contract is up at the end of the year. There will be companies in our market where those agreements finish earlier, and they will be contending with the new prices very soon - that’s going to cause major distortion.

“We’re not asking for something special, just to receive the same Government support which other sectors receive, such as aerospace and automotive. After all, without our boxes many industries would fail to operate.”

For further information, please visit www.lesterspackaging.co.uk

Forged Solutions Group adds its weight to CBM’s call for Government support on energy prices and steel quotas

One of the UK’s leading specialists in high integrity forgings is adding its voice to industry’s call for greater support to offset escalating energy costs.

Matlock-headquartered Forged Solutions Group, which works with high profile clients in the aerospace, energy production, underground mining and off-highway vehicle sectors, is calling on Government to address rocketing gas and electricity prices by exploring potential subsidies or removing some of the tax burdens.

The company has decided to increase its membership of the Confederation of British Metalforming (CBM) to include all its five manufacturing sites in England and Wales and to ensure it has the strongest possible voice and access to MPs and Business Ministers.

President Ben McIvor is also keen to address the issue of steel quotas and the negative impact they are having on production flexibility and capacity to match increasing customer demand, with his own company securing more than $200m dollars of revenue since it became an independent group in 2019.

The manufacturer is keen to build on this growth and has already invested over £3m in new CNC machining capabilities and testing facilities, with a recruitment push also underway to take on 25 new staff.

“We are operating in a really strange environment at the moment, where opportunities are significant, but challenges – through no fault of our own – are equally as big,” explained Ben, who oversaw the formation of Forged Solutions Group after the purchase of several sites from Doncasters and Arconic.

“The single biggest challenge for our business is energy. You simply could not have predicted what we are seeing at the moment and there are very few, if any, businesses who can sustain the meteoritic rises we’re having to endure.

“Our consumption is very intensive, and we are facing a significant increase in our energy cost rates compared to recent years. You can’t pass all of this on to the end customer, so you are then found looking at alternative solutions and this is where I feel the Government really need to step up and offer possible solutions.”

He went on to add: “Our Welsh site has always been part of the CBM and we have seen first-hand the difference the trade organisation can make. We wanted to give it our full support and will now be working with it to lobby the powers that be on all the critical issues for manufacturing.”

Forged Solutions Group has enjoyed a new lease of life under the new ownership structure and being able to shape its own future has led to an increase in turnover despite the challenges of the pandemic.

A large part of the company’s work is in aerospace, with its forgings used as shafts, rings and discs for engine parts, as well as finding their way into landing gear and structural components for the main body of aircraft.

“The nature of our business means we use a lot of different grades of steel and the quota system the Government has in place is also causing operational challenges, with the UK’s allowed amount used up quickly, leading to us or our customer potentially having to pay tariffs,” continued Ben.

“In some instances, you simply can’t buy the material domestically, so you have to import it. and this approach to regulation makes it a difficult trading environment.”

The Confederation of British Metalforming, which represents more than 200 members producing fasteners, forgings and pressings, cold rolled and sheet metal products, has been in discussions with the Government for some time on the issue of energy and steel quotas.

It has been able to capture feedback from the shopfloor and galvanise industry support to provide a collective train of thought on these issues and is in regular contact with senior people from the Department for Business, Enterprise and Industrial Strategy (BEIS).

Geraldine Bolton, Chief Executive of the CBM, picked up the story: “Now is the time for our specific part of industry to stand up and start shouting about the challenges we are facing and having the entire Forged Solutions Group on board is great news for our efforts.

“Ben has significant experience of our sector and is well respected, so it will be vital to make sure his voice and first-hand thoughts are heard by people making decisions on new business support measures.

“The forgings it makes are used in some critical applications across the world, so we have to ensure we have a UK supply chain in place to deliver the products and components we desperately need.”

In addition to lobbying, Forging Solutions Group will look to use experts at the CBM to help it access the Climate Change Agreement scheme across all its five sites, which could deliver significant cost savings in the future.

For further information, please visit www.forgedsolutionsgroup.com or www.thecbm.co.uk

Seamless engineering for turnkey wastewater treatment plants: DMT and MUTAG combine competences

The age of "survival of the fittest" is over - the future will be won by companies that cooperate with each other, according to the trend monitor of the German Future Institute. The international engineering and consulting company DMT GmbH und Co. KG has been working on this since 1737, enabling joint progress in complex engineering assignments across the world. A new milestone is the recently signed strategic cooperation with MUTAG, the leading specialist in the field of biological wastewater treatment from Chemnitz, by signing a cooperation agreement. The aim of the cooperation is to jointly implement turnkey wastewater treatment projects for the industrial sector worldwide. To this end, both companies offer individual, customised solutions that are particularly suitable for technologically demanding applications.

Creating more efficient processes and saving costs, pooling resources to position themselves sustainably in the market for large orders: Corporate cooperation offers many advantages. Especially when companies complement each other's skills so seamlessly, as is the case with DMT GmbH und Co. KG and MUTAG. "Thanks to the cooperation with MUTAG, we can jointly offer turnkey wastewater treatment plants worldwide. And that from the initial planning to turnkey construction and commissioning," says Christian Heiermann, who is responsible for EPC and EPCM in plant construction at DMT. This offer is particularly relevant for companies from the steel industry, the chemical and petrochemical industries, as well as the paper and food industries.

Christian Heiermann explains: "The treatment of wastewater consists of several individual steps in engineering, so it makes sense to combine the synergies of the two companies in order to map all the steps". While MUTAG specialises mainly in the area of design and basic engineering, DMT can complement its competencies to implement turnkey projects and plants for wastewater treatment. "We have many years of experience in process engineering, in the planning and construction of plants for a wide range of industries. MUTAG brings us the special expertise in the field of wastewater treatment," Christian Heiermann sums up. In addition, MUTAG contributes its own developments, such as the Mutag BioChip™ MBBR carrier media, which enables savings in investment and operating costs. “We are proud of contributing with our unique product and proven technology. Our sustainable vision and purpose align with the DNA and foundation of DMT. Therefore, we see great possibilities in combining our competencies in future projects” says Jesper Brix, CEO of MUTAG.

Christian Heiermann is not the only one who is looking forward to the closer cooperation with his colleagues at MUTAG. His DMT colleague Umalan Gogilan is also enthusiastic; he has known the Chemnitz-based company well for a long time: "Gas processing is one of DMT's strengths. For example, we have currently developed a process to make the purification of coke-oven gas even more resource-conserving and energy-friendly. As soon as ancillary recovery plants are operated, there is always the task of treating the wastewater. Our clients have often brought MUTAG on board for this," he recalls of the first joint orders and describes the cooperation as a partnership of equals. "We maintain good communication with each other. Our customers also benefit from this. In order to be able to offer them solutions from a single source with a central contact partner in the future, transparency, trust and commitment form the foundation of the high-quality cooperation".

The advantages and synergy effects of this agile, dynamic cooperation have long since been recognised by the customers of both companies, who are already actively using them: "Although the foundation stone for the cooperation was not laid until November 2021, we are already working on a feasibility study for a company in Canada and a proposal for a major project in Turkey," says Christian Heiermann, who is already looking forward to further joint projects.

India to lead Asia liquids storage capacity growth through 2026, forecasts GlobalData

India is expected to lead the liquids storage capacity growth in Asia, contributing about 23% of the total capacity growth between 2022-26. The country is likely to add 23.9 million cubic meters (mmcm) of liquids storage capacity by 2026, forecasts GlobalData, a leading data and analytics company.

GlobalData’s report, ‘Global Liquids Storage Industry Outlook to 2026 – Capacity and Capital Expenditure Outlook with Details of All Operating and Planned Terminals’, reveals that Asia’s liquids storage capacity is expected to increase by 103.6 mmcm during 2022-2026. Out of the total capacity additions, 67.5 mmcm is likely to come from new build projects, and expansions of active projects contribute to the rest with 36.1 mmcm.

Teja Pappoppula, Oil and Gas Analyst at GlobalData, comments: “India is expected to account for the total liquids storage capacity additions of 23.9 mmcm by 2026. Of these, 19.5 mmcm is likely to come from new build projects and the rest 4.4 mmcm would be from expansion projects. Most of these capacity additions are being planned to meet ever growing demand for crude and petroleum products in the country.”

Teja Pappoppula, Oil and Gas Analyst at GlobalData, comments: “India is expected to account for the total liquids storage capacity additions of 23.9 mmcm by 2026. Of these, 19.5 mmcm is likely to come from new build projects and the rest 4.4 mmcm would be from expansion projects. Most of these capacity additions are being planned to meet ever growing demand for crude and petroleum products in the country.”

Among the new build projects, the planned Chandikhol liquids storage terminal will be the largest with a capacity of 4.8 mmcm and is expected to become operational in 2025.

The announced Bikaner liquids storage terminal stands next in India with capacity of 4.4 mmcm and is expected to be added in 2025.

The third highest contributor in the country is the planned Padur II terminal, which is likely to add a capacity of 2.9 mmcm in 2025. Indian Strategic Petroleum Reserves Ltd will be the operator of this liquids storage terminal.

- Comments provided by Teja Pappoppula – Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s report: Global Liquids Storage Industry Outlook to 2026 – Capacity and Capital Expenditure Outlook with Details of All Operating and Planned Terminals

- This report was built using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

AGE Industries, Ltd Now Offers KN95 Masks

AGE Industries provides cost effective KN95 masks that are comfortable and protective

AGE Industries, Ltd, a leading supplier of innovative and custom packaging and shipping solutions for industry and government agencies, offers highly protective KN95 masks that are comfortable and cost effective.

KN95 masks feature 4-layer protection, a step above most masks on the market, which are 1 to 3 layers thick. Further, KN95 masks provide a striking 95% protection against all particles that are greater than 0.3 µm in diameter. This includes bacteria, viruses, pollution particles, fine particles, dust, smog, pollen, and more.

KN95s offer even more protection than cloth masks, confirms the CDC on their website. The CDC also provided an update on January 14th, 2022 removing concerns related to supply shortages for these masks, clarifying that people can in fact choose masks such as N95s and KN95s. Currently approved by the WHO as a safety measure from COVID-19, these masks’ superior protection is the reason why they are used by healthcare providers, patients, and citizens across the globe. KN95 respiratory masks are also regulated by the Chinese government under GB2626-2006, GB262-2019, and GB19083-2010.

KN95 masks offer considerable comfort. They are skin-friendly and do not cause rashes or irritation. KN95 masks also have a 3D foldable design, ear loops, and a nose bridge, allowing them to provide excellent fitting and sealing. The ability for these masks to fit the form of your face leads to better protection and also reduces fogging in glasses. Most other masks on the market do not fit well, leaving gaps near the side of the face and the nose uncovered.

Providing packages at 20 masks per box and 50 boxes per case, AGE Industries can ship anywhere in the US, Mexico, and Canada and can also deliver globally via AGE Industries or one of its partners. AGE Industries is committed to providing these protective and comfortable masks at affordable prices to people around the world who need them.

For more information about the AGE Industries, Ltd, visit www.ageindustries.com.

About AGE Industries, Ltd.

Founded by Arthur G. Eltzroth in 1974, AGE offers innovative custom packaging and shipping solutions for private industry and governmental agencies. AGE designs and manufactures corrugated boxes, fiber tubes, and wood crating for Texas, Arkansas, Oklahoma, Louisiana, and New Mexico in the United States. AGE Box de Mexico, based out of Reynosa, Tamps. Mexico, provides custom corrugated packaging and overall packaging solutions for Mexico. AGE meets WBENC, Tx HUB, and CMBL certifications.

Moxa Unveils Its Next-generation Industrial Networking Solutions to Help Futureproof Industrial Automation

Moxa Inc., a leader in industrial communications and networking, announced the launch of its next-generation industrial Ethernet switches, the EDS-4000/G4000 Series. The EDS-4000/G4000 Series includes 68 models that will help Moxa’s customers build futureproof industrial networks to strengthen operational resilience in industrial spaces such as power, transportation, maritime, and factory automation.

According to IDC’s Worldwide IT/OT Convergence 2022 Predictions1, by 2024, 75% of new operational applications deployed at the edge will leverage containerization to enable a more open and composable architecture that is necessary for resilient operations. As industrial automation applications continue to evolve, OT architectures require enhanced networking capabilities and network security.

‘Recently, we have observed that our customers find it more challenging to connect their devices while fulfilling a variety of requirements for critical infrastructure,’ said Gary Chang, Product Manager at Moxa Networking Co. Ltd. ‘Critical infrastructure requires advanced networking solutions that strengthen operational resilience and futureproof networks. Our EDS-4000/G4000 Series portfolio of switches transforms the networking-evolved concept into tangible networking capabilities in order to empower our customers to build secure, reliable, and high-bandwidth industrial networks with ease.’

Evolved Networking Solutions That Strengthen Operational Resilience

While OT/IT convergence is accelerating, enhanced network security, high performance, strong reliability, and advanced usability become paramount to building next-generation industrial networks that strengthen operational resilience.

• Industry-leading Network Security: The EDS-4000/G4000 Series was the world's first IEC 62443-4-2 certified Ethernet switches to be certified by IECEE due to the built-in hardened security that was developed by following the stringent software development lifecycle described in the standard. Along with Moxa’s extensive network security portfolio, Moxa helps create a secure network foundation to safeguard and futureproof industrial operations.

• Unprecedented Performance for Mass Deployments: As the number of connected devices in industrial operations grows exponentially, the EDS-4000/G4000 Series provides multiple interface combinations with up to 14 ports and a range of options including fast Ethernet, Gigabit, 2.5GbE uplinks, SFP, and IEEE 802.3bt PoE connectivity. This enables customers to connect more devices especially in applications such as intelligent transportation systems that require high-power and high-bandwidth networking.

• Multiple Industrial Certifications: The EDS-4000/G4000 Series is certified for NEMA TS2, EN 50121-4, IEC 61850-3/IEEE 16132, DNV2, ATEX Zone 23, Class I Division 23, to fulfill the needs of a wide variety of industrial applications. The EDS-4000/G4000 Series also features Turbo Ring and Turbo Chain fast network recovery to ensure smooth operations.

• Advanced Usability: The improved web GUI provides a more intuitive way for users to perform configurations and network management. The rotatable power module offers flexibility to field engineers when they are installing devices and maintaining the network. In addition, the LED indicators on two sides of the device help engineers easily identify the status of networking devices, making their job easier.

Customer Testimonial

‘We particularly appreciated the intuitive user interface, the innovative mechanical design with the rotatable power supply module, and the robust DIN-rail mounting kit. The EDS-4000/G4000 Series gives us more confidence to provide futureproof, robust, and secure industrial automation and navigation solutions to our customers on their digital transformation journeys,’ said Christian M. Skytte, Head of Product Management, Automation, at Wärtsilä Lyngsø Marine A/S.

EDS-4000/G4000 Series Industrial Ethernet Switch Highlights

To learn more about the EDS-4000/G4000 Series, please refer to the following materials:

• EDS-4000/G4000 Series Microsite

• Futureproof Networking and EDS-4000/G4000 Launch Video

• EDS-4000/G4000 Series Product Introduction Video

1 IDC FutureScape: Worldwide IT/OT Convergence 2022 Predictions, Doc #US47131521, October 2021.

2 Certification is expected in Q2, 2022.

3 Certification is expected in Q3, 2022.

4 If the port link speed is 1 Gigabit or higher, the recovery time is < 50 ms.

About Moxa

Moxa is a leading provider of edge connectivity, industrial computing, and network infrastructure solutions for enabling connectivity for the Industrial Internet of Things. With over 30 years of industry experience, Moxa has connected more than 71 million devices worldwide and has a distribution and service network that reaches customers in more than 80 countries. Moxa delivers lasting business value by empowering industry with reliable networks and sincere service for industrial communications infrastructures. Information about Moxa’s solutions is available at www.moxa.com.

The MOXA logo is a registered trademark of Moxa Inc. All other trademarks herein are the property of their respective owners.

High power density motors create new opportunities for machine builders

ABB has upgraded its extensive range of High Dynamic Performance (HDP) induction motors. This creates new opportunities for machine-building OEMs seeking motor and drive solutions with excellent dynamic response and high power density. The motors are typically used in plastic and rubber extrusion, injection molding, winders, lifting, conveyors, test benches and machine tools.

- High Dynamic Performance (HDP) motors have been upgraded to offer even higher power density and a broader scope for machinery applications

- Motors are offered as part of a complete package with variable speed drives (VSDs) for precise control and maneuvering capabilities

The upgraded HDP motor range enables ABB to offer machine builders frame sizes between 80 and 400, and output capacities up to 2 megawatts (MW) – as well as alternative variants such as high-speed and water-cooled motors. The motors are designed for use with a VSD and ABB can provide matching motor and VSD packages across the frame-size range.

“ABB is well known for its optimized motor and VSD packages that provide precise motor control and maneuvering capabilities in a wide variety of general industrial applications,” said Marcus Westerlund, Product Manager, Special Motors at ABB. “The HDP motors now bring the same advantages to machine builders who need the extra boost in power provided by a high-torque design and exceptional power density.”

High power density benefits both retrofits and new build machinery

Machine builders can capitalize on the high power density of HDP motors in two ways. They can retrofit an existing machine with a more powerful replacement motor to boost performance; or they could select a more compact, yet equally powerful motor when designing a new machine to reduce its footprint.

Low inertia and high overload capacity

HDP motors are designed to enable fast motion control and high maneuvering precision due to their low inertia and high overload capacity. Low-inertia motors are ideal for applications requiring fast changes in rotational direction to enable, for example, faster back-and-forth machine motion.

Easy installation

ABB has prioritized ease of installation as an integral element of the HDP design. That makes it easy to install a replacement HDP motor into an existing machine without excessive engineering work. Furthermore, ABB has considered simplicity in everything from accessible connection points to installation of accessories, such as cooling fans, encoders and brakes, whether from ABB or a third party.

Customization

The upgraded HDP motor range includes all the commonly-requested frame sizes and technology variants such as water-cooled, high-speed and megawatt-class alternatives to allow ABB to meet most machine-building requirements without extended delivery times. Should the standard design not meet a machine builder’s specific needs then it can be customized.

HDP motors are compliant with the IEC 60034 standard and suitable for unrestricted global use. Worldwide technical support is provided to OEMs and end users through ABB’s global services organization.

To learn more about ABB’s high dynamic performance motors: https://new.abb.com/motors-generators/iec-low-voltage-motors/high-dynamic-performance-motors

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB Motion keeps the world turning - while saving energy every day. We innovate and push the boundaries of technology to enable the low-carbon future for customers, industries and societies. With our digitally enabled drives, motors and services our customers and partners achieve better performance, safety and reliability. We offer a combination of domain expertise and technology to deliver the optimum drive and motor solution for a wide range of applications in all industrial segments. Through our global presence we are always close to serve our customers. Building on over 130 years of cumulative experience in electric powertrains, we learn and improve every day.