Super User

PulPac, Nordic barrier coating and OrganoClick have been granted funding from BioInnovation for developing PFAS- and plastic-free barriers for food packages

The consortium of PulPac, Nordic Barrier Coating and OrganoClick has been granted financial support for continued development of 100% biobased, plastic- and PFAS-free barriers and materials for demanding food packaging applications. The development project is funded from the Swedish strategic innovation program BioInnovation financed by the Swedish innovation agency Vinnova.

Following breakthroughs made last 2021, the consortium will continue the project that focuses on integration of commercially scalable environmentally friendly water and/or grease resistant barriers specialized in Dry Molded Fiber.

Viktor Börjesson, Chief Partnership Officer at PulPac comments, “We are very proud about the breakthroughs achieved within BioInnovation with our partners. The combined performance in OrganoClick’s chemistry and scalability coupled with NBC’s dynamic ability to form specialized materials makes this a very important project. Dry Molded Fiber is disrupting fiber forming, making it possible to manufacture paper packaging without wasting valuable water resources or energy and significantly reducing CO2, at unit economics that are very competitive. These solutions are plastic-free, biodegradable and recyclable – very important qualities to our customers.”

Challenging packaging applications for Dry Molded Fiber is the target of the R&D consortium

Challenging packaging applications for Dry Molded Fiber is the target of the R&D consortium

Dan Blomstrand, VP Biocomposites at OrganoClick AB, comments “We are very eager to continue building on the breakthroughs reached in step one of this BioInnovation program. The potential markets being enabled in packaging and single-use products with our 100% biobased and home compostable coating and binder products for Dry Molded Fiber by PulPac are enormous.”

Urban Winberg, CEO at Nordic Barrier Coating AB, comments “The delicate art of designing materials and combining functions from OrganoClick’s chemistry adapted for Dry Molded Fiber has yielded very exciting opportunities as shown in last year’s breakthroughs. We can now invest in infrastructure and industrial capacity to commercially pilot the solutions discovered, and to cater to Dry Molded Fiber's global uptake.”

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About Nordic Barrier Coating

Nordic Barrier Coating AB manufactures and offers innovative barrier and packaging solutions for maximum functionality. Specialised on extrusion on paper, plastic and non-woven. With many years of experience from the paper, extrusion and conversion industries, we possess cutting-edge expertise in the field. www.nbcab.se

About OrganoClick

OrganoClick AB (publ) is a public Swedish cleantech company listed on Nasdaq First North Growth Market. The company develops, produces and markets functional materials based on environmentally friendly fiber chemistry. Examples of products that are marketed by OrganoClick are the durable water repellent technology for textiles OrganoTex®, the biocomposite material OrganoComp®, surface treatment and maintenance products for villa and property owners under the brand BIOkleen®, biobased binder under the trade name OC-BioBinder™ and the flame and rotresistant timber OrganoWood® (through the joint-venture OrganoWood AB). OrganoClick was founded in 2006 as a commercial spin-off company based on research performed at Stockholm University and the Swedish University of Agricultural Sciences within environmentally friendly fiber chemistry. www.organoclick.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.

COSEL announces 6W high isolation DC/DC converters for medical, industrial and ICT applications

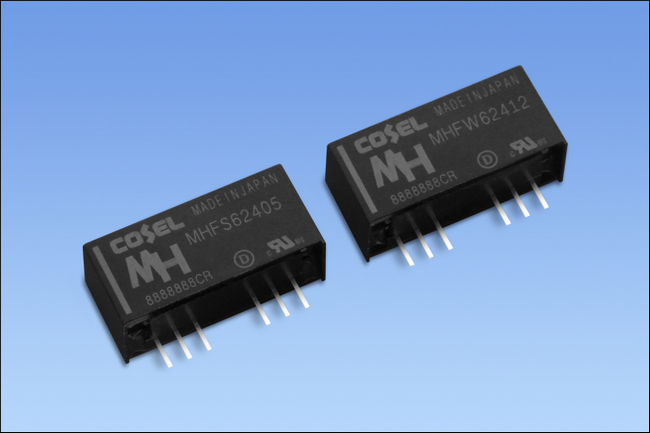

COSEL Co, Ltd has just announced the addition of a new series of high isolation 6W DC/DC converters for medical, industrial and ICT applications. Packaged in a Single In Line (SIP) type 8, the COSEL MH6 series has a reinforce isolation of 3kVAC, 4.2kVDC, complies with medical isolation standard (2MOOP (250VAC working voltage)) and ruggedized for industrial applications that might implies differential IN/OUT voltage. Three input voltages (4.5V-18V ; 9V – 36V and 18V -76V) and a large variety of single (MHFS6) and dual output (MHFW6) cover a large range of applications. Designed for performances, the MH6 has only 20pF max insulation capacitance reducing noise transfer. The COSEL MH is a unique design from COSEL, manufactured in Japan and covers by a 5 years warranty.

- High input/output isolation 3kVAC, 4.2kVDC

- Medical isolation 2MOOP - 250VAC working voltage

- Low input/output capacitance – 20 pF maximum

- Ultra-wide input voltage (4:1) - 4.5V to 18V ; 9V to 36V ; 18V to 76V

- Ruggedized pins connector

- Made in Japan - 5 years warranty

Designed with high reliability in mind, the COSEL MH6 series has a reinforced insulation, sustains 3kVAC and 4.2kVAC isolation test in accordance to safety standards and its transformer designed to sustain differential voltage that might happen in industrial applications. With long expertise in designing power supplies for equipment using IGBT drivers, COSEL designers applied high-power high-isolation best practice to the low power 6W MH6 series to reduce isolation fatigue resulting from differential high voltage happening in motor control or IGBT driver. COSEL conducted tests and verifications and provides, in the Application Manual, life expectancy curves helping system’s architects developing Gate Controllers for industrial equipment to apply proper design rules and cautions.

For medical applications, the MH6 series complies with the 2xMOOP (250VAC) (Means Of Operator Protection) isolation requirement, as specified in the IEC60601-1 3rd edition standard.

To reduce inventory but as well making their equipment easy to install and maintain, system’s designers require DC/DC converter able to accept a large range of input voltages. The COSEL MH6 series is available in three wide-input range voltage: 4.5V to 18V covering 12V battery applications, 9V to 36V combining 12V and 24V battery systems and 18V to 76V addressing 24V and 48V systems. The MH6 series is available in five single output 3.3V, 5V, 9V, 12V, 15V (MHFS6) and two dual outputs +/-12V and +/-15V (MHFW6). Output can be used in series, delivering 24V or 30V. Single output voltage MHFS6 can be adjusted by using the Vout Trim pin on the secondary side.

COSEL announces 6W high isolation DC/DC converters for medical and industrial applications

COSEL announces 6W high isolation DC/DC converters for medical and industrial applications

The MH6 series has built-in overcurrent protection circuit, with automatic recovery. A remote control pin operating as negative logic (L:ON, H:OFF) is available on standard.

The MH6 series can be operated within a temperature range of -40 to +85C ambient, 20 - 95%RH (Non condensing). Depending on cooling, a power derating may apply to not exceed +105C at specified measuring point.

To reduce transfer noise, COSEL designers reduced the isolation capacity to lowest possible level, reaching a maximum of 20 pF, which is a great benefit when powering motor control systems.

Industrial and in some case medical equipment can be subject to vibrations engendering possible damages on the pins of SIP products. COSEL MH6 series pins are molded in an epoxy holder, strengthening the connections between the application PCB and the module, making the unit even more reliable when used in demanding applications. The MH6 series has been qualified on vibrations testing: 10 - 55Hz 98.0m/s2 (10G), 3minute period, 60minutes each along X, Y and Z axis and shock: 490.3m/s2 (50G) 11ms, once each along X, Y and Z axis.

Addressing both, medical and industrial applications, the MH6 series received the agency approvals: UL62368-1, EN62368-1, c-UL (equivalent to CAN/CSA-C22.2 No.62368-1), ANSI/AAMI ES60601-1, EN60601-1 3rd, c-UL (equivalent to CAN/CSA-C22.2 No.60601-1).

To reduce user’s board space, the MH6 series is housed in a SIP8 packaging measuring 26.0X12.0X9.5mm [1.03X0.48X0.38 inches] (WXHXD) and with a weight of 8 grams maximum.

The power supply complies with the RoHS directive and is CE marked in accordance with the Low Voltage Directive.

Related URL:

Single output MHFS series

https://www.coseleurope.eu/Products/DC-DC/MHFS

Dual output MHFW series

https://www.coseleurope.eu/Products/DC-DC/MHFW

About Cosel:

Established in Japan 1969, COSEL is one of the world’s leading designers and manufacturers of high performance AC-DC Power Supplies, DC-DC Converters and EMI Filters. With quality, reliability & flexibility as our main focus, we pride ourselves on developing some of the highest quality and most reliable products seen anywhere in the world today. The Cosel Group is a $250m global company employing some 700 staff with sales offices throughout Japan, Asia, Europe and North America. Our product range is aimed mostly at demanding applications within the Industrial, Factory Automation, Medical, Telecoms, Lighting, Audio/Broadcast & Renewable Energy sectors. A flexible approach with full in-house design means we deliver products using the very latest technology meeting the growing demands of our customers.

Reference :

COSEL PR-22:002_MH6_EN

Filtration Solutions to Help Us Get Greener

The increasing use of renewable energy sources is helping with the urgent need to reduce carbon emissions. Compared with traditional power sources, however, these green resources place challenges on power grids because of their intermittent nature. To support their use, additional energy resource is needed to provide ‘grid firming’. This means when the sun doesn’t shine or the wind doesn’t blow, power is maintained to the grid. This additional power is often supplied by aeroderivative gas turbines, which provide rapid start and high cycling capability to support the intermittent nature of renewable energy.

Like any other power generation gas turbine, mobile aero derivative gas turbines, need protection from environmental elements, such as dust, sand and salt, to maintain their performance and reliability. However, to support the nature of the applications where these vital machines are used, inlet filter house packages need to be cleverly designed to provide a small, transportable, mobile solution that can be quickly implemented on site.

Aero derivative gas turbine inlet filter houses not only need to be light weight and compact but also cleverly designed to optimize air inlet flow and aerodynamic performance of the turbines. To overcome the complex design needs of these smaller packages, Parker uses advanced CFD modelling and simulations and careful material selection to optimise size and weight and ensure all installation needs are met. Designs are further based on modular, pre-factory assembled components to reduce the time needed to get the system up and running and power flowing.

Using clearcurrent™ PRO filtration technology, Parker’s small filter house packages are designed to handle anything that is thrown at them. Whether high levels of dust, moisture from fog or high humidity areas, airborne salt particulates in a coastal region, or combination of all of these, the filter ensures the turbine is protected from degradation or damage from these contaminants. The filters ensure there are no sudden pressure spikes that cause costly unexpected shutdowns.

As we strive to meet decarbonisation targets, the need for compact, more mobile solutions has become an essential component in supporting reliable, stable power grids. Parker’s small filter house solutions provide the same performance as those supplied for modern, heavy duty gas turbine systems and are available with many options, including static and self-cleaning configurations and evaporative cooler technology for power augmentation. They help optimise gas turbine efficiency and output power, further reducing emissions, and have become the filtration solution of choice in many of these smaller power generation applications.

About Gas Turbine Filtration Division

With more than 50 years of experience delivering innovative solutions for gas turbine inlet filtration and monitoring fleet-wide performance data, Parker’s Gas Turbine Filtration Division provides a full range of inlet systems and filters engineered to help customers meet their operating goals. Learn more at www.parker.com/gtf.

About Parker Hannifin

Parker Hannifin is a Fortune 250 global leader in motion and control technologies. For more than a century the company has been enabling engineering breakthroughs that lead to a better tomorrow. Learn more at www.parker.com or @parkerhannifin.com.

Waterproof IP69K stainless steel Panel PCs for Windows 11

Hardware specialist BRESSNER Technology now offers fanless panel PCs "ORCA PRO" with 11th Gen. Intel® Core™ processors and a corrosion-resistant full IP69K stainless steel housing for food processing applications.

The ORCA PRO models are available with 24-inch or 22-inch screen diagonals.

The ORCA PRO models are available with 24-inch or 22-inch screen diagonals.

System integrator and value-added hardware provider BRESSNER Technology expands its portfolio of touch panel solutions with the new ORCA PRO series. The model range consists of fanless Full IP69K panel PCs with stainless steel chassis, available in 22- or 24-inch screen diagonals. An Intel® Tigerlake Core™ i5-1145G7E processor is integrated to meet Windows 11 standard requirements. The units are designed specifically for industrial operations, chemical labs, and food processing industries.

A SUS316-standardized stainless steel enclosure is part of the ORCA PRO series' basic equipment and protects the devices from oxidation and corrosion caused by water or acidic/alkaline liquids. The brushed stainless steel makes it difficult for germs and bacteria to spread, which is especially beneficial for industries with high hygiene guidelines. All ORCA panel PC models are IP67 certified as standard and can even achieve up to IP69K through optional configuration and adjustments to the housing structure. This maximum upgrade even allows the operator terminals to withstand cleaning with high-pressure devices as well as steam jets.

A SUS316-standardized stainless steel enclosure protects the devices from oxidation and corrosion caused by water or acidic/alkaline liquids.

A SUS316-standardized stainless steel enclosure protects the devices from oxidation and corrosion caused by water or acidic/alkaline liquids.

The 22- and 24-inch panel PCs offer a resistive or PCAP multi-touch screen with a maximum resolution of 1920x1080 and can even be operated with latex gloves. An optional high-brightness display with a luminance of up to 1,000 nits can be installed. Furthermore, customers can configure additional interfaces to the already existing USB, Ethernet and serial ports (with IP67 circular connectors) on request. The devices meet all hardware requirements to manage a Windows 11 installation.

"There are strict requirements for enclosures and hardware equipment in the food and beverage industry, as well as for manufacturing and factory automation machines. The devices have to be sanitized under extreme conditions and still remain fully operable," explains Markus Schumacher, Senior Account Manager for panel PCs and touch displays at BRESSNER Technology. "The ORCA PRO panel PC models are up to these challenges while featuring a state-of-the-art tech build."

Metso Outotec completes the acquisition of Tesab Engineering Ltd

Metso Outotec has completed the acquisition of Tesab, a Northern Ireland based company specializing mostly on mobile crushing equipment for aggregates applications, including quarrying, recycling, asphalt and concrete.

Tesab’s offering will complement Metso Outotec’s offering in the mobile crushing and screening markets. Tesab continues as an independent product brand within Metso Outotec, with its more than 60 employees integrating to the Metso Outotec group.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Metso Outotec to deliver copper electrowinning technology to Africa

Metso Outotec has been awarded a contract for the delivery of advanced electrowinning equipment to a copper cathode production plant in Africa. The order value amounting to approximately EUR 11 million is booked in Minerals' Q2/2022 orders received.

Metso Outotec's scope of delivery includes the supply of basic engineering and equipment for the copper electrowinning plant expansion.

Metso Outotec’s offering for copper electrowinning tankhouses comprises pre-engineered solutions, key equipment, and services to ensure superior process performance, increased safety, and minimized environmental impact.

Discover more about our electrowinning technology on our website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change. Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2021 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com, twitter.com/metsooutotec

YesAsia partners with Geek+ for its first Smart Warehouse at Goodman Interlink, Hong Kong

Global online retailer YesAsia teams up with Geek+, a leading Autonomous Mobile Robots (AMRs) specialist, to build YesAsia’s first smart warehouse at Goodman Interlink, a best-in-class warehouse development and one of the world’s tallest warehouse facilities located in Tsing Yi, Hong Kong. This will be the largest number of AMRs deployed in any single Hong Kong E-commerce warehouse.

Logistics and supply chain management has proven to be the biggest challenge for E-commerce businesses since the COVID outbreak. As the forward-thinking owner and operator of retail websites YesAsia.com and YesStyle.com, YesAsia employs an ambitious strategy, using digitalization and automation for its business operations, especially its warehouses. This approach brings together three like-minded companies – global industrial property expert, Goodman Group, Geek+ and YesAsia – to pave the way for a future using smart logistics and automation.

The brand-new YesAsia smart fulfillment center will be located at Goodman Interlink in Tsing Yi, Hong Kong, and equipped with 145 innovative AMRs from Geek+. This is the first partnership between the three parties, and is the largest single warehouse deployment of AMRs in Hong Kong’s E-commerce industry. Goodman Interlink is awarded a Gold Standard Certificate from HK BEAM and a Silver Certificate from LEED. With its floor plate, Goodman Interlink provides spacious and high-quality spaces that are suitable for the newest advancements in automation and robotics.

Joshua Lau, CEO of YesAsia, said, “YesAsia understands the importance of staying ahead of the game in the face of ‘new norms.' This is why we are investing in and introducing 145 Geek+ AMR robots into our Hong Kong warehouse with our like-minded partners, Goodman Group and Geek+. This move reflects our commitment to reforming our supply chain in order to provide the best possible logistics services to our valuable customers.”

YesAsia’s smart warehouse is a revolutionary step that will impact the company’s operations and supply chain. The change is expected to be fully integrated by July 2022 in order to commence service for YesAsia’s global customer base in the second half of the year. To enable this smart fulfillment center, Goodman Group provides well-located warehouses that are designed to accommodate the latest robotics and technology, not only to ensure a more efficient supply chain, but also faster and more flexible delivery of goods. The smart warehouse is conveniently located in the logistics hotspot of Hong Kong which is adjacent to Container Terminal 9, Stonecutters Bridge, with easy access to Hong Kong International Airport.

The YesAsia smart fulfillment center will implement Geek+’s goods-to-persons solutions. After receiving orders, the AMRs will automatically pass the goods to warehouse operators for an overall fulfillment process that is more accurate and highly efficient. The center is expected to handle over one million orders within its first year of operation for both YesAsia.com and YesStyle.com customers around the world.

“Our commitment is to transform global logistics with smart technologies, said Lit Fung, VP and Managing Director of Overseas Business at Geek+. “We are excited to work with industry innovation pioneer YesAsia and empower them to meet the growing demand of their E-commerce customers. Geek+ will continue to partner with Goodman in providing a one-stop solution for quality, sustainable properties equipped with the latest smart warehousing solutions to strengthen customers’ supply chains.”

About Geek+

Geek+ is a global technology company leading the intelligent logistics revolution. We apply advanced robotics and AI technologies to realize flexible, reliable, and highly efficient solutions for warehouses and supply chain management. Geek+ is trusted by over 500 global industry leaders and has been recognized as the world leader in autonomous mobile robots. Founded in 2015, Geek+ has over 1500 employees, with offices in Germany, the United Kingdom, the United States, Japan, South Korea, Mainland China, Hong Kong SAR, and Singapore.

For more information, please visit: https://www.geekplus.com/

About YesAsia

Established in 1997, YesAsia is an online retailer headquartered in Hong Kong that engages in the procurement and sale of Asian fashion & lifestyle, beauty and entertainment products to customers around the world. YesAsia has developed proven E-commerce platforms operated by a team that has, since 1998, accumulated over 20 years of experience in operating E-commerce businesses, as well as cultivated regional and global online markets for Asian products.

For more information, please visit: www.yesasiaholdings.com

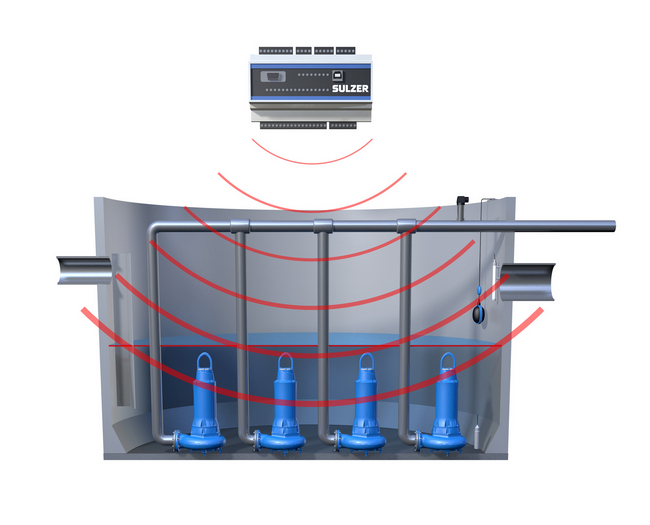

The internet of pumps

Smarter control of wastewater pump networks transforms performance, reliability and cost-efficiency

Data flows faster than water, providing a stream of optimization opportunities. The latest in control technology allows pumping stations and wastewater treatment facilities to talk to each other, providing a better picture of real-time conditions and enabling smarter, more proactive management of the whole network.

A modern municipal wastewater system will rely upon numerous pumping stations and typically each one in the network contains its own control logic. Wastewater levels are detected by ultrasonic, radar or pressure sensors, backed-up by float switches. To prevent flooding, or damaging and wasteful dry running, the controller in the station switches the pumps on or off, based on the data from those sensors.

This distributed approach is simple and robust, but what is best for one pumping station might not be optimal for the whole network. If multiple upstream stations all switch on at the same time, for example, their combined flows could overwhelm the capacity of the next station downstream. That situation is especially likely to happen if a blockage or mechanical problem temporarily reduces downstream pumping capacity.

Making the link

Today, larger pump networks are addressing this challenge by taking a smarter, more proactive approach to control systems. Sulzer pump controller technology, for example, allows every station to connect with the treatment works using secure, two-way communications. Stations can report real-time local levels, flow rates and operating conditions with the central controller issuing commands to adjust pump control parameters as required.

This interconnected approach gives operators a much more detailed picture of the real time status of the wastewater network. They can spot increasing flows earlier, allowing them to take preemptive action to prepare the treatment site for a spike in demand. They can also reduce the severity of these spikes by instructing pumping stations to delay their activation, taking advantage of the storage capacity within the network.

Intelligent pump control enables a network of pumping stations to work more efficiently

Intelligent pump control enables a network of pumping stations to work more efficiently

From reactive to proactive

Sulzer’s smart control approach even allows operators to take proactive steps to meet demand before it hits the network. Take the example of a large, but intermittently used facility such as a sports stadium. Around the time of a big match, that stadium might impose a significant additional load on the network, while for the rest of the time it produces relatively low flows.

With a smart control system in place, the pumping station closest to the stadium can detect the initial increase in flow that indicates a forthcoming spike in demand. That signal can automatically trigger a series of actions. Stations downstream of the stadium can switch to a lower “start” level, emptying the well and increasing their available storage capacity. Other stations in the network, meanwhile, can be instructed to store more wastewater temporarily, releasing it into the system when the local peak has passed.

The same approach can help operators handle other transient events, such as intense local rainfall, or regular demand peaks when many people use their showers at the beginning or end of the day. In addition, the system enables energy consumption and costs to be optimized. If storage capacity allows, for example, the activation of pumps can be delayed until times of the day when low-cost electricity is available. Alternatively, stations with multiple pumps can cut the number of units in operation to reduce flow rate and energy consumption as demand tapers off after a peak.

Same assets, more value

Best of all, smart control doesn’t require a mass of costly new hardware. Sulzer pump controllers generate their data from the standard sensors already installed in the pumping station. Outflow rates are a function of pump capacity and run time, while inflows can be calculated from the rate of level change reported by the level sensors, multiplied by the well’s cross-sectional area. If a pressure sensor is added to the outgoing mains, this reading can be used to further increase the pump capacity and forward flow calculation accuracy as well helping to determine problems such as partially clogged mains.

For these systems to operate effectively, the station’s sensors do need to provide reliable, consistent data, however. The experience of one major water utility in the UK suggests that radar sensors tend to be less dependent on optimal setup and maintenance than ultrasonic sensors, for example.

Whatever technology is used, built-in features of the Sulzer controllers can monitor sensor performance and alert operators if a sensor becomes faulty or poorly calibrated. This is achieved by comparing the level reported by the sensor to a known reference point, such as the activation of a float switch. The system can also warn of other problems in the station, such as a potential blockage, pipe breakage or pump fault. That allows operators to deploy field maintenance resources quickly and cost-effectively.

Sulzer’s smart pumping station controls can deliver truly significant savings and system performance improvements. At the UK water company mentioned earlier, for example, the introduction of this approach led to a 45% reduction in operating costs and a 75% reduction in potential environmental impact costs. The payback period for the entire new control and monitoring system was only two and half years.

Learn more about Sulzer’s control and monitoring equipment by watching the video below

About Sulzer:

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).www.sulzer.com. The Pumps Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

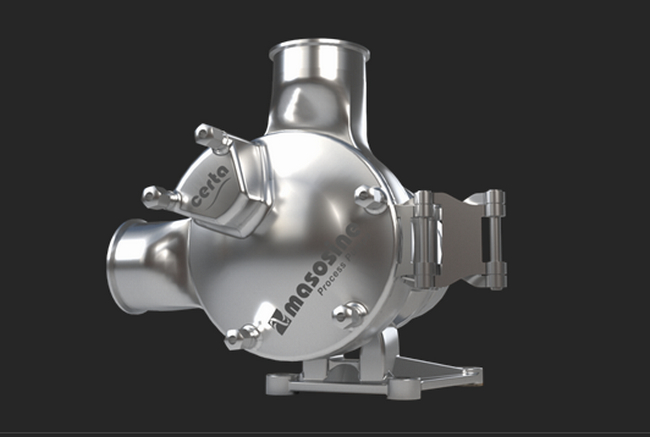

New parts provide even more ease-of-use, hygiene and safety for Watson-Marlow Certa pump users

Watson-Marlow Fluid Technology Solutions (WMFTS) is now fitting newly-designed components to its class-leading range of MasoSine Certa pumps, benefiting companies with COP (clean-out-of-place) or post-CIP (clean-in-place) inspection requirements. Already cleaner than any lobe or circumferential piston pump, Certa pumps featuring the new parts — which include a new O-ring seal system, hexagonal locking screw and weld-on hinge — elevate ease-of-use, hygiene and safety to even higher levels.

In combination with optimal process efficiency and minimal TCO (total cost of ownership), Certa pumps meet the highest standards in hygiene and cleanability. Designed primarily for CIP processes, Certa pumps do not require stripping down to component level for cleaning between batches or before use. However, some customer processes stipulate regular strip-downs regardless, either to clean the pump as part of a COP requirement, or to check for cleanliness after a CIP cycle. The new components for the Certa range have been designed with these processes in mind.

“The new O-Ring seal system is designed for applications that require frequent assembly/disassembly procedures,” explained Florian Walter, Product Manager for MasoSine. “It’s available for all MasoSine Certa pump sizes and can be retrofitted to existing pumps without the need of a pump modification. The O-Ring seal system is also less expensive than a mechanical seal,” Walter said.

“Another important ease-of-use improvement on the latest Certa pumps is the introduction of a hexagonal locking screw,” added Walter. “Now, users can easily release the new locking screw to remove the pump rotor, without special tools. Just like the new O-Ring seal, the locking screw is purpose-designed for frequent disassembly/re-assembly.

“With safety in mind, a new weld-on hinge option is now available for the Certa 400 and larger pump models. This new hinge option takes the weight of the front cover, thus allowing users to have their hands free for cleaning or inspection of the pump rotor or gate,” concluded Walter.

OccamSec Unveils Revolutionary Cybersecurity Platform Set to Change the Industry

Providing Continuous Penetration Testing with context, and a host of other features, the Incenter platform is built to give organizations what they need to effectively secure their environment

OccamSec, a leading cybersecurity provider, announced today the launch of their Incenter platform. Incenter identifies the security weaknesses an organization has in real-time, and helps teams develop insights and communicate business context from a security perspective.

For today’s organizations, the threat landscape is constantly evolving. Penetration testing and vulnerability scanning can help, but with new vulnerabilities and exploits found all the time, infrequent testing means risk data may be outdated. At the same time the industry is trending towards slicing the solution ever thinner, which means costs keep increasing.

Incenter combines the functionality of a range of security services in one single solution. The platform provides, in real time, where an organization is vulnerable, and just as critically, what the impact will be if an attack occurs.

Incenter combines the functionality of a range of security services in one single solution. The platform provides, in real time, where an organization is vulnerable, and just as critically, what the impact will be if an attack occurs.

Incenter utilizes a dual approach. It combines the best in technology with advanced automated testing, and the best in people with OccamSec’s security team. Supported by vulnerability research and a threat intelligence team, the burden on clients having to buy multiple services is eliminated.

Users have the ability to generate reports that compile real-time information with the touch of a button, rather than waiting for a timed report to be generated. Incenter also provides step-by-step guidance on how to mitigate any risks that are identified, with the tools an organization already has which means no hidden costs.

Incenter combines the functionality of a range of security services in one single solution:

- Manual Penetration Testing

- Penetration Testing as a Service (PTaaS)

- Automated Security Validation (ASV)

- Vulnerability Scanning

- External Attack Surface Management (EASM)

- Crowd Source Penetration Testing

- Threat Intelligence

This provides a single source of truth on the exposures an organization faces. Improving the effectiveness of any security team, regardless of size, and at the same time breaking organizations out of ever increasing cyber security expenditure.

The platform's focus on the unique business context of each organization means that security teams no longer have to trudge through 1000’s of scan findings or determine how relevant a penetration test finding is and how to fix it. At the same time from the dashboard, management can see a high level summary of their organization's exposure, the likelihood of a breach, and how much it’s going to cost them.

“Over the years we have seen what works, what doesn’t and where the gaps are,” says OccamSec founder Mark Stamford. “The biggest gap is organizations needing more and more tools and services to effectively secure themselves. The key to effective security is joining the dots, not having ever more dots scattered in ever more places. With Incenter we have combined the talents of our security team and their expert knowledge, with a technical solution that is unrivaled. The result is a win for our clients, regardless of size.”

Incenter is now available. For more information, visit: www.occamsec.com/incenter

About OccamSec

OccamSec is a leading provider in the world of cybersecurity. Its clients rely on them to provide information security services that exceed current industry standards. OccamSec provides accurate, actionable information to reduce risk and enable better informed decisions. Its unique end-to-end solutions detect, identify, respond, and protect in order to maximize the effectiveness of security programs.

OccamSec’s methodology is the result of years of experience in the field, providing real business outcomes. Its team has performed security assessments at some of the world’s largest companies, including financial services and technology. They bring this experience to each and every project, ensuring that their clients get the best service in the industry.