Super User

ESE set for official UK launch of new Split-Bin at Letsrecycle Live

ESE World Ltd – European manufacturer of temporary storage systems for waste and recyclables – will officially launch its latest waste container, the Split-Bin, at Letsrecycle Live on 15-16 September.

The 80-year-old firm will be using one of the waste and recycling industry’s biggest events to introduce its newest product to the UK market – a 240-litre-capacity, single container with a dual-stream capability, aimed at councils and waste management companies that run municipal contracts for kerbside collection containers.

The product has already been successfully applied in Denmark and is designed to reduce the contamination of recyclates.

Commenting on the new technology, ESE’s managing director, Peter Vernon, said: “With this kind of bin, the quality of the recyclate yield is higher, which not only attracts a greater return on investment, but only one collection vehicle is needed with one bin tip, meaning companies don’t have to buy – or replace – multiple caddies.

“Material contamination is a big bone of contention within the industry – and we need to innovate to bring new solutions which help to tackle this issue.

“Our Split-Bin allows larger volumes of different materials to be easily stored and separated – when compared to their individual box counterparts – and also reduces the collection rate, lowering CO2 emissions and fuel costs.”

The bin’s lid is designed to fan out when tipped – ensuring waste doesn’t get trapped when being emptied.

Peter continued: “While this type of waste storage equipment is widely used across Europe – especially in Scandinavia – there aren’t any like this model in the UK at the moment.”

Peter also believes that the country’s recycling rates would also be more likely to increase if UK councils were to adopt a one-system approach.

“Many local authorities use boxes or caddies instead of bins for recyclables – which can be lost or damaged more easily, when compared to a wheeled bin. There’s also no manual handling of the waste or lifting of separate containers, so truck operatives are at less risk of injury,” he concluded.

As well as launching the Split-Bin at the Letsrecycle Live exhibition in Stoneleigh, ESE will also be hosting a ‘guess the bin weight’ competition for attendees to take part in – the firm can be found at stand O2.

The news of ESE’s upcoming Split-Bin launch follows the recent announcement that the company has been shortlisted in Letsrecycle’s ‘Excellence in Innovation Awards 2021’.

ESE is also an organisation that possesses The Blue Angel ecolabel – meaning all its recycled solutions can have a minimum of 80% post-consumer resin – and it employs a closed-loop model for its products, collecting end-of-life containers for reprocessing into more units.

Iraq: TotalEnergies signs major agreements for the sustainable development of the Basra region natural resources

TotalEnergies, the Iraqi Ministries for oil and electricity, and the country's National Investment Commission have signed, in the presence of the Prime Minister of Iraq, major agreements covering several projects in the Basra region, designed to enhance the development of Iraq's natural resources to improve the country’s electricity supply. Iraq, a country rich in natural resources, is indeed experiencing electricity shortages while it faces a sharp increase in demand from the population.

TotalEnergies, with the support of the Iraqi authorities, on the one hand will invest in installations to recover gas that is being flared on three oil fields and as such supply gas to 1,5 GW of power generation capacity in a first phase growing to 3 GW in a second phase, and, on the other hand, will also develop 1 GWac of solar electricity generation capacity to supply the Basra regional grid.

TotalEnergies, with the support of the Iraqi authorities, on the one hand will invest in installations to recover gas that is being flared on three oil fields and as such supply gas to 1,5 GW of power generation capacity in a first phase growing to 3 GW in a second phase, and, on the other hand, will also develop 1 GWac of solar electricity generation capacity to supply the Basra regional grid.

These agreements include:

- The construction of a new gas gathering network and treatment units to supply the local power stations, with TotalEnergies also bringing its expertise to optimize the oil and gas production of the Ratawi field, by building and operating new capacities.

- The construction of a large-scale seawater treatment unit to increase water injection capacities in southern Iraq fields without increasing water withdrawals as the country is currently facing a water-stress situation. This water injection is required to maintain pressure in several fields and as such will help optimizing the production of the natural resources in the Basra region.

- The construction and operation of a photovoltaic power plant with a capacity of 1 GWp to supply electricity to the grid in the Basra region.

These projects represent a total investment of approximately $10 billion (100% share).

“These agreements signal our return through the front door to Iraq, the country where our Company was born in 1924. Our ambition is to assist Iraq in building a more sustainable future by developing access to electricity for its people through a more sustainable use of the country’s natural resources such as: reduction of gas flaring that generates air pollution and greenhouse gas emissions, water resource management and development of solar energy,” said Patrick Pouyanné, TotalEnergies' Chairman and CEO. “This project perfectly illustrates the new sustainable development model of TotalEnergies, a multi-energy Company which supports producing countries in their energy transition by combining the production of natural gas and solar energy to meet the growing demand for electricity. It also demonstrates how TotalEnergies can leverage its unique position in the Middle East, a region where the lowestcost hydrocarbons are produced, to gain access to large-scale renewable projects”, he added.

TotalEnergies in Iraq

In Iraq, TotalEnergies started its activities in the 1920s with the discovery of Kirkuk field. In the 1970s, TotalEnergies brought the Buzurgan and Abu Ghirab fields on stream. The company currently has a 22.5% interest in the Halfaya oil field producing approximately 20,000 barrels per day (TotalEnergies’ share) in 2020.

TotalEnergies sells lubricants in Iraq through distributors on the local retail market. Our affiliate Saft takes part in calls for tender as a subcontractor.

About TotalEnergies

TotalEnergies is a broad energy company that produces and markets energies on a global scale: oil and biofuels, natural gas and green gases, renewables and electricity. Our 105,000 employees are committed to energy that is ever more affordable, clean, reliable and accessible to as many people as possible. Active in more than 130 countries, TotalEnergies puts sustainable development in all its dimensions at the heart of its projects and operations to contribute to the well-being of people.

ANDRITZ to supply 10th high-efficiency PowerFluid circulating fluidized bed boiler to Japan

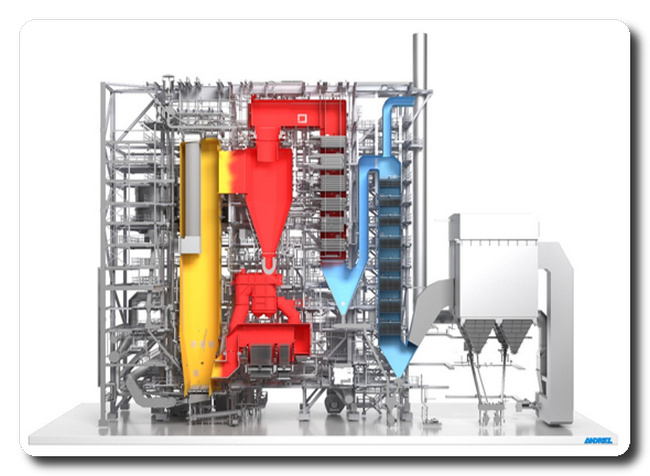

International technology group ANDRITZ has received an order from Toyo Engineering Corporation, Japan, to deliver a PowerFluid circulating fluidized bed boiler with a flue gas cleaning system. The boiler will be part of a new biomass power plant to be built in Niigata East Port in Niigata Prefecture, Honshu Island, some 300 km north of Tokyo, Japan. Commercial operations are scheduled to begin in September 2024.

The ANDRITZ PowerFluid (CFB) boiler with reheating system to be supplied features low emissions, high efficiency and availability, as well as high fuel flexibility. It forms an essential part of a high-efficiency biomass power plant for supply of green energy to the national grid. The biomass power plant fired with wood pellets and palm kernel shells will generate around 50 MWel of power.

ANDRITZ PowerFluid circulating fluidized bed boiler “Photo: ANDRITZ”.

ANDRITZ PowerFluid circulating fluidized bed boiler “Photo: ANDRITZ”.

ANDRITZ is proud to be part of this remarkable project with Toyo Engineering Corporation and to make an important contribution towards the Japanese power industry in the transition from fossil fuel to renewable energy resources.

This ANDRITZ power boiler to be supplied to Japan confirms ANDRITZ’s strong market position as one of the leading global suppliers of power boiler technologies and systems for generating steam and electricity from renewable and fossil fuels, with a large number of very successful references worldwide.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

First Floating LNG project for BASF's Gas Treatment technology

The latest Floating Liquefied Natural Gas (FLNG) project of the Malaysian oil and gas company PETRONAS (PFLNG DUA) has selected BASF’s OASE® purple for its Acid Gas Removal Unit process. This is the first FLNG reference worldwide for BASF’s OASE Gas Treatment technology. Together with PETRONAS and the Japanese engineering partner JGC Corporation, PFLNG DUA has been successfully started up in February 2021 and completed its Performance Test Run in May 2021. The floating LNG facility opens a new source of supply for cleaner energy as it is designed to extract natural gas from deepwater gas reservoirs in depths up to 1,500 meters.

OASE purple is an amine-based solution that is utilized for the removal of acid gases such as carbon dioxide (CO2) and hydrogen sulfide (H2S) from natural gas. The removal of acid gases is necessary to prepare the gas for the liquefaction and subsequent pipeline transportation. The highly efficient and environmentally friendly BASF-technology provides flexibility and low capital expenditure (CAPEX) for its customers. Additionally, the low energy demand of the process combined with the non-corrosive nature of the solvent keeps operating and maintenance costs (OPEX) low. The process also provides a high level of gas purity and product gas recovery while keeping solvent losses to a minimum.

Our photo shows the latest Floating Liquefied Natural Gas (FLNG) project of the Malaysian oil and gas company PETRONAS (PFLNG DUA). The project has selected BASF’s OASE® purple for its Acid Gas Removal Unit process. This is the first FLNG reference worldwide for BASF’s OASE Gas Treatment technology. The FLNG project opens a new source of supply for cleaner energy as it is designed to extract natural gas from deepwater gas reservoirs in depths up to 1,500 meters. The FLNG facility will be moored over the Rotan Gas Field at a water depth of 1,300 meters, located 140 kilometers offshore Kota Kinabalu, Sabah, Malaysia in the South China Sea with a capacity to produce 1.5 million tons of LNG annually.

Our photo shows the latest Floating Liquefied Natural Gas (FLNG) project of the Malaysian oil and gas company PETRONAS (PFLNG DUA). The project has selected BASF’s OASE® purple for its Acid Gas Removal Unit process. This is the first FLNG reference worldwide for BASF’s OASE Gas Treatment technology. The FLNG project opens a new source of supply for cleaner energy as it is designed to extract natural gas from deepwater gas reservoirs in depths up to 1,500 meters. The FLNG facility will be moored over the Rotan Gas Field at a water depth of 1,300 meters, located 140 kilometers offshore Kota Kinabalu, Sabah, Malaysia in the South China Sea with a capacity to produce 1.5 million tons of LNG annually.

Andreas Northemann, Head of BASF’s Gas Treatment business, says: “We are proud to now have our first FLNG reference in operation and running at 100 percent capacity, which is the fruit of many years of research. We applied our on-shore LNG expertise and conducted motion studies and Computational Fluid Dynamics (CFD) to ensure a high reliability, low maintenance design which meets our customer’s stringent off-shore specifications and challenges.”

With PFLNG DUA, PETRONAS owns and operates two floating LNG facilities, following the success of PFLNG SATU which has been in operation since 2017. Construction of PETRONAS’ latest – second – floating LNG facility started in 2015 and will be moored over the Rotan Gas Field at a water depth of 1,300 meters, located 140 kilometers offshore Kota Kinabalu, Sabah, Malaysia in the South China Sea with the capacity to produce 1.5 million tons of LNG annually.

ABB signs memorandum with Stäubli to develop solutions for the transition to all-electric mines

ABB has signed a Memorandum of Understanding (MoU) with Stäubli Electrical Connectors to collaborate in bringing solutions to market to reduce the greenhouse gas (GHG) emissions associated with heavy machinery in mining.

- Global industrial electrical connectors provider Stäubli and ABB to explore technologies to support the decarbonization of mining operations

- The two companies will focus on mine infrastructure solutions for battery electric vehicles (BEVs)

Stäubli, a leading manufacturer of connector solutions, and global technology company ABB, will explore the development of electrification solutions that will meet the demands of industrial applications. These include high power requirements, automated and safe operations, adaptation to harsh environmental conditions and meeting approved standards. The focus will be on mine infrastructure solutions for battery electric vehicles (BEVs).

“As a global provider of reliable connectors with a strong commitment to drive innovation, we have many key applications across various industries,” said Winnijar Kauz, Stäubli Electrical Connectors’ Global Head of E-Mobility. “Every industry demands unique technological solutions, with mining now developing for a more sustainable future in the long-term. Today’s mining environments need industrial leaders to collaborate and support the transition to all-electric operations. We look forward to teaming up with ABB to explore and develop technology solutions that will lead the way for emission free mining operations.”

“Mining and heavy industry customers seeking to decarbonize their operations are looking for innovative solutions to support the electrification of their fleets,” said Max Luedtke, ABB’s Global Head of Mining. “These solutions are needed to facilitate the transition to net zero emission transport and to fast-track the development of new emissions-reducing systems. The goal is for electrification and automation of the whole mining operation.”

“This MoU is another cornerstone of our dedication towards sustainability in mining and to reach a platform which is able to provide new solutions to the market out of collaboration between companies,” said Mehrzad Ashnagaran, ABB’s Global Product Line Manager Electrification & Composite Plant. “Partnering and joining forces amongst domain experts and complementing the offering for the best possible customer experience in terms of productivity and safety while focusing on environmental aspects is what drives us at ABB. We are really looking forward to this joint approach with Stäubli.”

The agreement between ABB and Stäubli was signed by Mehrzad Ashnagaran, ABB’s Global Product Line Manager Electrification & Composite Plant, and Philippe Grunenberger, Stäubli’s Director Global General Industries.

ABB is celebrating 130 years of experience in the mining industry in 2021. The company delivers complete electrification, automation and digital solutions, industry-specific products and lifecycle services across every stage of the mining cycle. ABB’s digital applications draw on advanced libraries and software solutions to reduce process complexity and can integrate with existing equipment and technology. ABB Ability™ MineOptimize is a digitalized portfolio of connected solutions that is already improving the energy efficiency as well as productivity and optimization of CAPEX and OPEX of open pit and underground mines worldwide.

Stäubli Electrical Connectors stands for advanced contact technologies and elaborate solutions developed with a methodical and qualified approach. Close conceptual and geographical collaboration with customers, even for the most uniquely demanding tasks, has kept Stäubli Electrical Connectors at the pulse of events for more than 50 years and this proximity is one of the keys to successful innovative solutions.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries.

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

Metso Outotec and PT Trakindo Utama to agree on aggregates distribution in Indonesia

Metso Outotec has appointed PT Trakindo Utama as a distributor for aggregates solutions in Indonesia as of September 2021 onwards. PT Trakindo Utama will provide Metso Outotec’s track-mounted, wheel-mounted, and stationary crushers and vibrating equipment, crusher wear parts and screening media, as well as commissioning and aftermarket services including technical support and service contracts for aggregate quarries and contractors in Indonesia.

“When selecting the new aggregates distributor for this territory, we emphasized the ability, capacity and expertise to take care of the existing Metso Outotec crushing and screening customers as well as to grow the customer base,” comments Shaun Fanning, Vice President, Distribution Asia Pacific at Metso Outotec. “We are very excited to start the cooperation, as PT Trakindo Utama is well-recognized and one of the biggest construction heavy equipment dealers in the world. We believe that the partnership will enhance the availability of our solutions and elevate our service level for aggregate processing quarries and contractors in Indonesia, one of the most active construction markets in the region.” “The partnership with Metso Outotec, a prominent player in aggregate crushing and screening solutions, strengthens our position as a complete solution provider in Indonesia’s quarry and aggregate market,” says Ali R. Alhabsyi, Managing Director, PT Trakindo Utama. “Their aggregate crushing and screening solutions complements our existing heavy equipment portfolio, and helps us to expand our business, as well as become the preferred one-stop-shop for the construction industry.”

From left: Unggul Aribowo, Metso Outotec, Immawan Priyambudi and Arif Prawira, PT Trakindo Utama

From left: Unggul Aribowo, Metso Outotec, Immawan Priyambudi and Arif Prawira, PT Trakindo Utama

The scope of the contract includes for example the following Metso Outotec aggregate crushing and screening solutions; Lokotrack® and Nordtrack™ mobile crushers and screens, Nordberg© C-Series jaw crushers and Nordberg® HP™ Series cone crushers, Premier™ and Compact™ Series screens, Metso Outotec Truck Body™ and Trellex® screening media.

PT Trakindo Utama is a world-class provider of construction heavy equipment solutions in Indonesia with 50 years of experience. They have an extensive network of more than 60 branches and more than 6,000 employees throughout the country. Read more on their website at: www.trakindo.co.id

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Linxon announces Stefan Reisacher as CEO

The Linxon Board of Directors is pleased to announce the appointment of Stefan Reisacher as CEO of Linxon to lead the company in a new phase of growth.

“Stefan has successfully led the company as interim CEO since March 2021. After conducting a comprehensive search of internal and external candidates, the Board has selected Stefan because of his values, leadership style, experience, passion for Linxon and his performance as interim CEO since March 2021. We have confidence in his abilities and collaborative approach to see the company into the future”, said Steve Morriss, Chairman of the Board of Directors. “Stefan brings in-depth knowledge of Linxon, its clients and opportunities for growth and the Board looks forward to supporting him in unlocking the company’s full potential.”

Stefan ReisacherLinxon has a bright future and continues building its reputation in the electric power industry with a unique company in the EPC substation market. Within the 3 years since its inception, the company has made great strides and is confident in its journey ahead. The energy market has been, and will continue to, evolve as the world deals with the critical issue of climate change. Linxon has a key role to play in this space and is proud to be part of a sustainable solution, bringing a carbon-neutral offering and technical expertise to its clients and do its part in helping the world deals with the critical issue of climate change.

Stefan ReisacherLinxon has a bright future and continues building its reputation in the electric power industry with a unique company in the EPC substation market. Within the 3 years since its inception, the company has made great strides and is confident in its journey ahead. The energy market has been, and will continue to, evolve as the world deals with the critical issue of climate change. Linxon has a key role to play in this space and is proud to be part of a sustainable solution, bringing a carbon-neutral offering and technical expertise to its clients and do its part in helping the world deals with the critical issue of climate change.

“It is an honor to accept the CEO position as Linxon celebrates its third birthday. As a team, we have made great strides in a short period of time and are completely focused on growing the business and positioning Linxon as an outstanding partner in our key segments,” said Stefan Reisacher, CEO, Linxon. I look forward to leading Linxon in its journey and am committed to our mission and strategy, serving our clients, nurturing our culture and creating value for our shareholders.”

Stefan brings a background in engineering and broad experience across the power industry, including senior roles at Alstom, ABB and since 2018 at Linxon on the senior management team leading the company’s EMEA operations and then as interim CEO. He is a graduate of the Technical University of Munich and holds an MBA from the University of Reading’s Henley Business School.

About Linxon

We combine Hitachi ABB Power Grids deep technological knowledge and SNC-Lavalin’s project management expertise to create a company dedicated to substations. As one of the leading engineering companies, we help our customers with turnkey solutions in the field of substations for power transmission, renewable energy and transportation. As a single point of contact we combine the accumulated knowhow of key-suppliers and contractors so that customers benefit from efficient solutions, increased industrial productivity and a lower environmental impact. We work to shape energy solutions to empower sustainable connectivity. linxon.com

LANXESS increases prices for inorganic pigments

Specialty chemical company LANXESS is raising its prices for its inorganic pigment products worldwide with immediate effect. Prices for iron oxide pigments will increase by a minimum of EUR 200 per metric ton, for chromium oxide pigments by a minimum of EUR 300 per metric ton and for ferrites by a minimum of EUR 250 per metric ton, or their equivalent in local currency. In addition, depending on the destination, LANXESS will charge a fee to cover increasing transportation costs. Customers will be informed individually as to how it applies to their products.

The fields of application for synthetic iron and chromium oxide pigments from specialty chemicals company LANXESS are broad. Bayferrox and Colortherm are the main product groups used for coloration in the construction, paints and coatings and plastics industry. These high-tinting-strength inorganic pigments are produced according to strict sustainability criteria. Photo: LANXESS AG

The fields of application for synthetic iron and chromium oxide pigments from specialty chemicals company LANXESS are broad. Bayferrox and Colortherm are the main product groups used for coloration in the construction, paints and coatings and plastics industry. These high-tinting-strength inorganic pigments are produced according to strict sustainability criteria. Photo: LANXESS AG

The LANXESS Inorganic Pigments business unit is the world's largest manufacturer of synthetic iron oxides and a leading producer of inorganic chrome oxides. These products have a track record going back many decades as colorants for building materials, paints and coatings, plastics, paper and other applications. These high-tinting-strength inorganic pigments are produced according to strict sustainability criteria.

Detailed information on the product range can be found on the internet at www.bayferrox.com

LANXESS is a leading specialty chemicals company with sales of EUR 6.1 billion in 2020. The company currently has about 14,800 employees in 33 countries. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

Innovative corrugated face mask bin wins a ScanStar 2021

An innovative corrugated bin for face masks by Metsä Board, part of Metsä Group, has been awarded a ScanStar in a Nordic packaging design competition organised by the Scandinavian Packaging Association. The mask bin, made of lightweight and durable corrugated board, helps to collect and dispose of used face masks easily and safely. Metsä Board developed the concept together with packaging design agency Futupack and corrugated board converter Capertum.

The competition jury commented: “A simple but clever solution for a new problem – mask littering. The bin is made from corrugated material, and is easy to assemble even without the instructions which have been printed on the bin itself. The lid makes the light packaging more rigid and, if you turn the lid, it closes the package when it is full. Good printing supports the product. The bin is also accessible to those who have disabilities.”

“The Covid-19 pandemic has brought its own challenges to waste management and together with Futupack and Capertum we wanted to develop a solution to this. In our design, we paid special attention to the lightness of the material, its durability and the ease of use and consumer guidance,” said Ilkka Harju, Packaging Services Director EMEA and APAC at Metsä Board.

MetsäBoard Pro WKL 160 g/m2 coated white kraftliner was used as the top liner of the mask bin. The Finnish corrugated board converter Capertum printed the E-flute corrugated board in silk screen. Thanks to fresh fibre board the waste bin is strong but light, which reduces the carbon footprint.

Metsä Board

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

University of Konstanz successfully takes legal action against patent infringements in the field of solar cell production and wins initial case

The University of Konstanz has reached an agreement with a German equipment manufacturing company on the protection of patent rights relating to their patents on LID regeneration of solar cells. With the support of TLB GmbH from Karlsruhe, Germany, a mutually beneficial agreement was reached. The foundation for this was laid by a successful lawsuit for patent infringement. As a patent exploitation agency, TLB will continue to step up enforcement of the University of Konstanz's property rights and take legal action against further infringements. The basic intellectual property rights for LID regeneration held by the University of Konstanz have already been granted for years in the most important industrial nations and regions such as the USA, Europe and China.

"The protected method has been and is being used for the treatment of probably all boron-doped monocrystalline PERC solar cells. Therefore, it is a billion-dollar market in global terms," explains Dr.-Ing. Hubert Siller, Managing Director of TLB GmbH. It is a method that supports increase the efficiency of monocrystalline solar cells, which are mainly produced on the basis of the Czochralski (Cz) technique. Under operating conditions, however, the boron-doped CZ solar cells suffer from so-called light-induced degradation (LID), due to which the efficiency of a CZ-silicon solar cell is considerably reduced after only a short period of exposure to solar radiation. Depending on the material and production process, this can lead to a loss in efficiency of more than one percent absolute.

Scientists at the Photovoltaics Department of the University of Konstanz introduced as early as in 2006 a method to neutralize this type of degradation. The process developed and optimized over years by Axel Herguth, Svenja Wilking and Professor Giso Hahn can easily be integrated into the production process. The scientists made use of the fact that the degraded solar cells can be regenerated by exposing them to light energy greater than 100 degrees Celsius. Alternatively, regeneration can also be achieved using electrical current instead of lighting.

The economic potential of regeneration is enormous: If the degradation-caused loss in efficiency of one percent absolute is nearly completely offset, this yields additional efficiency of approx. five percent. With a 1 GWp production line, we are looking at over ten million euros per year. Another major advantage is the resource conservation that can be realized by regeneration. A higher level of efficiency means that less raw materials and energy are consumed, which in turn leads to a more environmentally friendly production. Operators of solar plants thus benefit from higher yields and end consumers from lower energy costs.