Super User

Alfa Laval to support Californian recycled water program

Alfa Laval has won an order to supply decanters to a wastewater treatment plant in San Diego, USA. The decanters will treat municipal wastewater, ensuring it is suitable for irrigation and other non-potable uses. The project is part of San Diego’s Recycle Water program which will provide more than 40 percent of the city’s water supply locally by the end of 2035.

The Recycled Water program offers a cost-effective investment for San Diego’s water needs and will provide a reliable, sustainable water supply. It gives the city a dependable, year-round and locally controlled water resource. Alfa Laval’s decanters will be installed in one of the municipal water treatment plants where they will be used for thickening and dewatering of the sludge.

“I’m very pleased to announce this decanter order in the important area of municipal wastewater treatment that confirms our customer’s trust in our world leading products,” says Nish Patel, President of the Food & Water Division. “Alfa Laval’s products within water treatment can also be used in industrial processes where they enable zero liquid discharge – well in line with the view of circular economy.”

“I’m very pleased to announce this decanter order in the important area of municipal wastewater treatment that confirms our customer’s trust in our world leading products,” says Nish Patel, President of the Food & Water Division. “Alfa Laval’s products within water treatment can also be used in industrial processes where they enable zero liquid discharge – well in line with the view of circular economy.”

Did you know… The city of San Diego also has a plan to install proven water purification technology to clean recycled water and enable production of safe, high-quality drinking water.

This is Alfa Laval

Alfa Laval is a world leader in heat transfer, centrifugal separation and fluid handling, and is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq Stockholm.

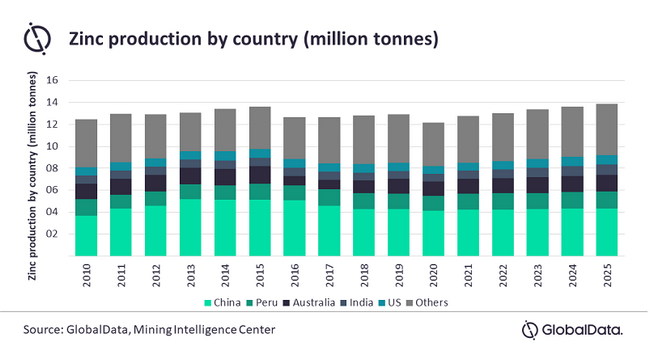

Global zinc production set to recover 5.2% in 2021 following ~6% decline in 2020, says GlobalData

Zinc mines are recovering from the impacts of COVID-19, according to GlobalData, with production expected to recover by 5.2% in 2021 to reach 12.8 million tonnes (Mt). The leading data and analytics company notes that production declined by approximately 5.9% to 12.1Mt in 2020, mainly due to COVID-19 related lockdowns and restrictions; however, looking ahead, zinc production over the forecast period (2021–2025) is expected to grow at a compound annual growth rate (CAGR) of 2.1% to reach 13.9Mt in 2025.

Vinneth Bajaj, Mining Analyst at GlobalData, comments: “Bolivia’s zinc was particularly affected by the pandemic in 2020, but production is now expected to recover. Mines in the region such as the Colquiri, Cerro Rico and San Cristobal sites are now reopening. Similarly, the re-opening of Peru’s Chungar Mining Unit, and El Porvenir and Cerro Lindo mines is expected to increase production in the country by 9.4%, to reach 1.5Mt in 2021.

“However, production is not recovering in all regions, as declines are expected in Canada (-5.8%) and Brazil (-19.2%) - mainly due to scheduled zinc mine closures and planned maintenance shutdowns.

“The US, India, Australia and Mexico will be the key contributors to zinc production growth in 2021-2025. Combined production in these countries is expected to increase from a forecasted 3.6Mt in 2021 to 4.2Mt in 2025.”

Bajaj highlights some key zinc mine products worldwide:

- One key upcoming project is the Aripuana Zinc mine in Brazil, which is jointly owned by Votorantim and Karmin Exploration and is currently under construction. By March 2021, 79% of the works were completed. During Q1 2021, the company invested $40m in the project, taking total investment to $353m since the beginning of construction. The project will have an annual zinc production capacity of 72.7 kilotonnes (kt), and is expected to commence operations in the third quarter of 2022.

- Another major development is the Pavlovskoye project in Russia, which is 99.5% owned by State Atomic Energy Corporation Rosatom and is currently undergoing a definitive feasibility study. The lead-zinc-silver project reported mineral resources of an estimated 55Mt, with an average zinc grade equivalent to 4%. The $400m project will have an annual zinc production capacity of 223kt and is expected to commence operations in 2023.

- Lastly, the Kudz Ze Kayah project in Canada, which is wholly owned by BMC Minerals Ltd (UK), is currently undergoing a definitive feasibility study (DFS) and awaiting regulatory approvals and permissions. In August 2020, the company announced that the assessment board had begun preparing its final screening report for the proposed mine development and in November 2020, the company issued an updated DFS for the project. The project will have an annual zinc production capacity of 106.6kt, and is expected to commence operations in 2023.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

High emission real estate set to depreciate in next five years

Commercial property without plans to slash carbon emissions will soon plummet in value.

That's the stark warning to their owners from new real estate stock exchange IPSX and sustainability data and consulting firm Carbon Intelligence, in a joint report on net-zero initiatives for UK commercial property market valuations.

Its findings factor in UK government commitments to a 78% reduction in greenhouse-gas emissions by 2035 and increasingly stringent energy-efficiency standards.

High emission real estate set to depreciate in next five years

High emission real estate set to depreciate in next five years

Carbon Intelligence's Real Estate Commercial Director Oliver Light, said: "By not investing CAPEX (Capital Expenditure) now into a long-term net-zero strategy, not only will you (building owners) miss out on the short-term advantages associated with a building that drives high tenant demand, due to minimal energy costs, prestige, and ESG credentials, but you will also have to invest the same or more to deal with obsolescence as a result of non-compliance, voids, and capital deprecation of the building."

Separate research from investment management services provider Fidelity International found that 97% of commercial real estate in Europe cannot currently support a net-zero transition.

"Today's liquidity conditions mean valuations do not yet reflect the stark difference between buildings that are ready to support the low-carbon transition and those that are not," says the Fidelity report.

"That won't last forever, and owners who delay investment in retrofitting could come to regret it."

Digital Twin market leader Cityzenith is helping building owners get to net-zero with its SmartWorldOS software platform. Digital Twins aggregate massive amounts of data, enabling powerful building analytics at unprecedented scale.

Cityzenith CEO Michael Jansen said: "The next decade is pivotal to the future of the built environment in cities. Using SmartWorldOS, our advanced Digital Twin platform, building owners can reduce emissions to zero while increasing real estate asset value. We plan to demonstrate this as part of our 'Clean Cities – Clean Future' (CCCF) campaign while decarbonising urban areas worldwide.

"We will use CCCF to sponsor urban Digital Twin implementations in 10-15 major cities, helping commercial building owners dramatically reduce carbon emissions. New York City's Brooklyn Navy Yard was the first to join the initiative. Phoenix (the fifth largest US city) is expected to follow next, along with many other cities.

"In each city, 5 to 10 major building owners will leverage Cityzenith's ground-breaking technology to determine an optimal smart building and financial strategy to achieve net-zero emissions. The projects will track cuts in energy costs and emissions, productivity gains, and property values."

Cityzenith aims to complete each project within nine months. Other project participants include city government agencies, universities, architects and planners.

Cityzenith is based in Chicago with offices in London and New Delhi. The company’s SmartWorldOS Digital Twin platform was created for anyone designing, constructing, and managing complex, large-scale building projects, properties, and real estate portfolios but has developed to cover infrastructure, energy projects, transport, health, people movements, and whole cities.

Husqvarna Group invests in Gamma Technologies

Husqvarna Group’s venture capital arm has recently invested €1 Million to take an equity stake in Gamma Technologies. Gamma is the fifth investment for Husqvarna Group’s venture capital fund where the aim is to collaborate and help grow start-ups in areas of digital disruption that impact the Group’s industries.

“Gamma is innovating in an area of high interest to us as we believe Augmented Reality (AR) is an important technology when delivering new technology-based services to our customers going forward. We look forward to a close collaboration with the Gamma team and to capture learnings to accelerate the evolvement of our Construction business”, says Mark Johnson, Vice President Corporate Venture Capital, Husqvarna Group.

Gamma Technologies

Gamma is disrupting the construction industry by bringing 3D Building Information Modeling (BIM) models with interactive features intuitively to the construction site. Gamma utilizes its augmented reality technology to overlay BIM models on contractors’ mobile handsets displaying the otherwise unseen infrastructure. Gamma’s BIM / AR software is used to guide operators on where to cut, drill, etc., therefore reducing both planning time and the risk of performing work in the wrong place, which is very costly to our customers.

Gamma Technologies Porr AG

Gamma Technologies Porr AG

“The investment from Husqvarna Group will accelerate the revolution of the construction industry and spread awareness about the benefits of using AR technologies on the jobsite. Husqvarna Group, with our current shareholders Formitas, are strategic investors and partners which will help us define the future of construction. We are excited to start working with Husqvarna Group on the implementation of innovative technology in the construction industry.”, says Caner Dolas, CEO & Co-founder, Gamma Technologies.

Husqvarna Group Ventures

Husqvarna Group Ventures is looking for startups to invest in and partner with, where Husqvarna Group’s industry knowledge and distribution network will deliver value, and help scale these companies to maturity. Gamma represents a great example of how Husqvarna Group likes to get involved at the early stages to help co-develop customer solutions.

Husqvarna Group

Husqvarna Group is a global leading producer of outdoor power products and innovative solutions for forest, park and garden care. Products include chainsaws, trimmers, robotic lawn mowers and ride-on lawn mowers. The Group is also the European leader in garden watering products and a global leader in cutting equipment and diamond tools for the construction and stone industries. The Group’s products and solutions are sold under brands including Husqvarna, Gardena, McCulloch, Flymo, Zenoah and Diamant Boart via dealers and retailers to consumers and professionals in more than 100 countries. Net sales in 2020 amounted to SEK 42bn and the Group has around 13,000 employees in 40 countries.

Metso Outotec’s sustainable screening technology to iron ore project – Unique solution eliminates water consumption in the screening process

Metso Outotec will supply unique sustainable screening technology for an iron ore project in the Southern Hemisphere. The order value, which is not disclosed, has been booked in Minerals segment’s Q3 2021 orders received. The start-up of the project is scheduled for the first half of 2024.

The order for the product screening and scalping application covers 12 Metso Outotec BSE Series™ (Banana Screen Elliptical) tandem screens and 4 MF Series™ screens, all equipped with 305PS screening media. In addition, the contract covers Metrics monitoring system for screens, expert support, and installation services.

The need to reduce water in iron ore production and other minerals processing is a critical global challenge. The innovative and patented BSE Series screens enable iron ore processing even with higher natural moisture content without adding water.

“We are pleased that the customer chose Metso Outotec for sustainable screening solutions for their process. The BSE screen is an outstanding option for their needs. The elimination of process water ultimately results in lower processing costs, increasing the customer’s competitiveness and profitability in the iron ore global markets,” says Jouni Mähönen, Vice President, Screening business line, Metso Outotec.

CNS BSE Screen

CNS BSE Screen

Results the customer can expect after implementation

- BSE Series™ screens enable elimination of process water in the screening process

- 93% reduction of the plant’s overall water consumption and eliminates the need for tailing dams

- Reduced energy consumption from the entire plant compared to the wet screening process: 18,000 MWh/year electricity saving

- 30% increase in screening capacity compared to traditional screening

- Increased safety during media change-outs using the unique Hammerless Attachment system

- Reduced CAPEX due to the adoption of high-performing BSE screens

Metso Outotec BSE™ screening technology is a Planet Positive solution. More information is available on https://www.mogroup.com/portfolio/bse-series/

Metso Outotec offers a wide range of screening solutions designed to meet the regional specifications and needs.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Metso Outotec is committed to limiting global warming to 1.5°C with Science Based Targets. We ranked 8th on the 2021 Global 100 list of the world’s most sustainable companies.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its sales for 2020 were about EUR 3.9 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

STATS Group complete six concurrent North Sea pipeline shutdown campaigns

Pipeline technology specialist, STATS Group, has successfully completed the largest number of simultaneous pipeline isolation projects in its 23 year history.

During the 2021 summer shutdown season, STATS supported six separate Tecno Plug isolation deployments in the UK North Sea, on pipelines ranging from 20” to 36” in diameter. The projects were on critical pipeline systems on behalf of multiple clients, with the isolation periods ranging from 10 to 45 days.

Isolation activities were carried out onshore and offshore at various locations and included the use of STATS Remote Monitoring System, which allowed Tecno Plug isolation tools to be monitored continuously via satellite from STATS Remote Monitoring Centre in Kintore, Aberdeenshire.

A range of STATS Group’s Remote Tecno Plug Leak Test Modules, which were deployed in the recent North Sea summer shutdown campaign.

A range of STATS Group’s Remote Tecno Plug Leak Test Modules, which were deployed in the recent North Sea summer shutdown campaign.

The satellite monitoring technology enables customers to reduce site Personnel on Board (POB) requirements on their oil and gas installations during breaking of containment activities, whilst still ensuring that the isolation status is continually monitored.

The majority of Tecno Plugs deployed as part of the shutdown campaigns incorporated Leak Test Modules, which allowed Operators to perform reinstatement testing of new valves and pipework without disturbing the integrity of line isolations.

Each isolation scope was carried out with design, manufacturing, testing and project support being provided locally from STATS Group’s Kintore headquarters. Factory Acceptance Testing was also live-streamed remotely to clients, ensuring the client had full participation and oversight during the testing phase, despite the logistical restrictions necessitated by the Covid-19 pandemic.

The summer shutdown period also saw a surge in demand for STATS Process Plant Solutions which supported both North Sea and international clients with the provision of vapour barrier and localised weld testing services, with many requirements being delivered in quick turnaround times, due to the inevitability of unforeseen scopes that appear.

In addition, STATS worked closely with multiple North Sea Operators in the manufacture and installation of its Topside Mechanical Pipe Connectors. These units were provided in sizes ranging from 2” to 20” as a safe and permanent cold-work solution, removing the associated risks of welding, and were installed on several key platform systems, including instrument air, diesel, and the larger of the units on flare systems.

STATS Group Sales Director, Ron James, said: “This has been our busiest period in terms of simultaneous isolation workscopes, but careful planning meant we were able to build and test in advance the necessary tools and equipment, so that everything was in place to be deployed during the optimum shutdown window.

“Our Remote Monitoring Centre means we are able to reduce the number of personnel on board an installation during the length of the shutdown - thereby offering cost savings to our clients, while maintaining the highest level of safety monitoring.”

STATS Group provides specialist engineering services for the maintenance, integrity and repair of oil, gas and petrochemical installations and infrastructure.

STATS have gained an excellent reputation for providing a responsive, client-centred approach combined with expertise and innovative products which enhance safety and environmental performance, reduce system or plant downtime, improve asset performance, and support decommissioning and abandonment.

The group operates from its headquarters in Kintore, Aberdeenshire in the UK; Edmonton, Canada; Houston, USA; Abu Dhabi, Oman and Qatar in the Middle East; and Kuala Lumpur in Malaysia.

Website: www.statsgroup.com

OILFIELD SERVICES SECTOR ALREADY COMMITTING TO ‘GREEN’ ENERGY, ACCORDING TO NEW PROTOLABS REPORT

The oilfield services sector is radically restructuring to survive in a world moving towards net-zero carbon emissions, according to a new industry report released today.

Almost three quarters (73%) of the UK respondents to ‘Decision Time’ – a Protolabs report that explores the challenges and opportunities for Europe’s oilfield services sector – are already redefining what their core business should be due to energy transition.

The majority of business leaders in the sector who took part in the research see sustainability as an opportunity, with 77% saying sustainability is a way to differentiate and grow their business, and with 80% saying that experience in sustainability gives European businesses an edge in global markets.

The research saw more than 180 senior leaders from oilfield services companies across Europe, including Welltec and Swire Energy Services, interviewed by digital manufacturer Protolabs which delivers a range of services to the sector.

The research found that most highlighted the need to innovate in order to survive. Within the next 12 months, 87% of UK respondents plan to implement robotics and automation and 83% plan to engage in Manufacturing-as-a-Service (MaaS) – 3D printing and on-demand manufacturing to streamline component production.

“Innovation and technology are hallmarks of oilfield services, which is encouraging given the extraordinary pressures on the sector,” explained Bjoern Klaas, Vice President and Managing Director of Protolabs Europe.

“The sector’s appetite to secure a long-term future means companies are branching out into other industries and extending their capabilities. With energy transition revolutionising the sector, combined with a much lower profit environment, it is imperative that companies continue to innovate and embrace renewable markets.”

Protolabs, the world-leading digital manufacturer of custom prototypes and low-volume production parts, completed the ‘Decision Time’ survey in summer 2021.

The results from the survey also indicate a clear departure from fossil fuels, with respondents expecting the majority of their portfolio to be non-oil and gas business. Klaas added: “The ‘Decision Time’ report shows that respondents expect to have shifted 64% of their projects to new energy or non-energy business within the next five years, compared with 56% of projects today. This, too, is testament to the willingness to meet the challenges faced by the sector.”

The opportunities for oilfield services

42% of respondents across Europe see new renewable energy technology as the greatest energy transition opportunity for their business over the next two to three years. And 22% consider CO2 management as the greatest energy transition opportunity over the same timeframe. But also, 31% consider innovation in enhanced oil recovery to be key to growth over the next 12 months.

Klaas concluded: “That the oilfield services sector, and the wider energy sector, will transition to renewable energy is well understood. But this report makes clear the transition already being undertaken along the supply chain.

“Companies in the sector appreciate the value of environmental credibility, not only to secure their own reputation and funding, but also in response to the legislative need to cut down on emissions and the competitive need to be sustainable within the global marketplace.

“And it’s the same for Europe’s battery industry: our ‘In Charge’ report earlier this year showed that 58% of respondents believe sustainability principles will give European battery makers an edge in the international market. Also mirroring our battery industry report, 83% of UK respondents to the ‘Decision Time’ report say they are planning to move their supply chain closer to their manufacturing base within the next 12 months.

“This is an important tactic when considering the need to rely on innovation, create a leaner business and turn to Manufacturing-as-a-Service to deliver an operation that will flourish in the new era.”

To view the full report, please visit https://get.protolabs.co.uk/oil-and-gas/decision-time/

Tendeka secures $30m worth of new wells contracts

Global completions specialist Tendeka has secured more than $30million USD worth of international contracts within the last quarter which will cover the next three years.

In addition to this unplanned revenue, the company has won long-term work with operators for its swellable packers and sand and inflow control technologies across key energy hubs, including the North Sea, Australasia and the Gulf Cooperation Council (GCC).

Brad Baker, CEO at TendekaTendeka is also delivering its first significant FloSure autonomous inflow control devices (AICDs) campaign in the United States, following a successful trial earlier this year.

Brad Baker, CEO at TendekaTendeka is also delivering its first significant FloSure autonomous inflow control devices (AICDs) campaign in the United States, following a successful trial earlier this year.

Brad Baker, CEO at Tendeka, said: “To secure a number of multi-year, international agreements is always satisfying, but even more so with what the industry has been going through over the last 18 months. It has been an uncertain time for the sector, but due to the hard work of our team and our investment in technology, we have forged even stronger relationships with our global customers to enhance their operations.

“These wins for our sand and inflow control technology cements our position in the market as the industry leader of inflow control technology.”

To support the inflow control of wells, Tendeka has installed more than 50,000 FloSure AICDs around the world. The field adjustable FloSure AICDs preferentially chokes unwanted produced fluids whilst promoting production of oil from the entire length of the well, leading to greater recovery, lower water cuts and less gas production.

Deployed as part of the lower completion using zonal isolation packers to divide the reservoir into compartments, the AICD can be integrated with sand control screens for soft formations.

Tendeka’s SwellRight Swellable Packers provide a permanent packer solution suitable for many applications where a pressure seal or zonal isolation is required. SwellRight packers help reduce well construction costs, extend well life and improve well integrity.

Tendeka is also the developer of the PulseEight dynamic downhole reservoir management system, which is the world’s first re-deployable wireless completion with control, power, monitoring and communications already on-board.

About Tendeka

Tendeka is a global specialist in advanced completions, production solutions and sand management for the oil and gas industry. From simple to complex well designs, the company has an extensive track record in enhancing productivity for clients’ reservoirs offshore and onshore. Tendeka invests in research and development, bringing to market disruptive technologies and offering solutions targeted to operators’ specific production challenges.

Established in 2009 and headquartered in Aberdeen, UK, Tendeka operates in strategically positioned bases, located at global energy hubs including the North Sea, Asia-Pacific, Middle East and North and South America.

To find out more, visit: www.tendeka.com

Hexagon announces agreement with Volvo Construction Equipment to provide autonomous safety systems for the mining industry

Hexagon’s Mining division has just announced an agreement with Volvo Construction Equipment (Volvo CE) that would allow Volvo CE off-road mining vehicles to be equipped with Hexagon Level-9 vehicle intervention technology.

The award-winning independent and interoperable HxGN MineProtect Vehicle Intervention System (VIS) provides brake and drive-by-wire technology, automatically taking control of the propulsion system of the truck in defined situations, if the operator fails to do so. VIS is now being deployed in three continents across 20 mines with trucks expected to be deployed by the end of 2022.

Today’s agreement empowers customers of both companies to accelerate their pursuit of zero harm. Visitors to MINExpo in Las Vegas this week can see VIS integrated and demo-ed at the Volvo CE booth (# 8127). Demonstrations of Hexagon’s latest autonomous capabilities are also scheduled today at Las Vegas Motor Speedway. These include a preview of Hexagon’s autonomous mission management system, which provides intelligent routing in the mining environment, and Hexagon-AutonomouStuff’s drive-by wire capabilities.

Today’s agreement empowers customers of both companies to accelerate their pursuit of zero harm. Visitors to MINExpo in Las Vegas this week can see VIS integrated and demo-ed at the Volvo CE booth (# 8127). Demonstrations of Hexagon’s latest autonomous capabilities are also scheduled today at Las Vegas Motor Speedway. These include a preview of Hexagon’s autonomous mission management system, which provides intelligent routing in the mining environment, and Hexagon-AutonomouStuff’s drive-by wire capabilities.

Hexagon is the market-leader in mining safety solutions, offering a holistic and integrated platform for proximity detection, collision avoidance and operator awareness as part of a broader sensor, software and autonomous portfolio.

“We are thrilled to have this agreement with Volvo Construction Equipment, who share Hexagon’s belief that the most important assets coming out of a mine are the people who make mining possible,” said Nick Hare, Hexagon’s Mining division President. “VIS is a key enabler of autonomy in our drive towards delivering a truly autonomous connected ecosystem, helping customers to improve efficiency and effectiveness safely and sustainably.”

Hexagon is a global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications.

Our technologies are shaping production and people-related ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon’s Mining division solves surface and underground mine challenges with proven technologies for planning, operations and safety.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 21,000 employees in 50 countries and net sales of approximately 4.6bn US. Learn more at hexagon.com and follow us @HexagonAB

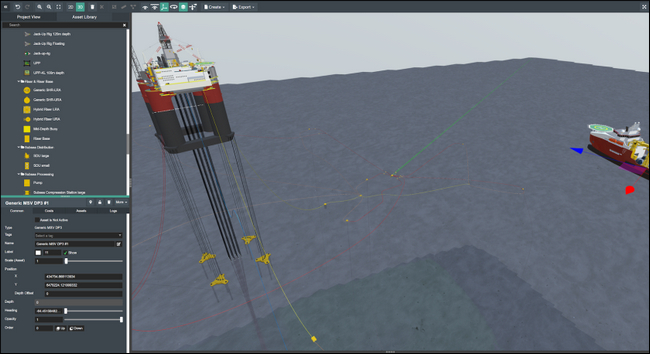

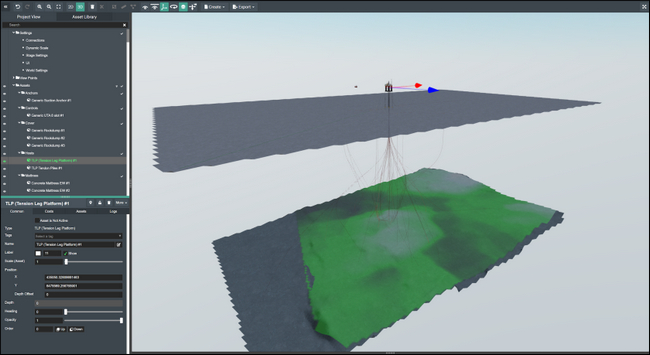

FutureOn’s next-generation digital twin technology shortlisted for an OGUK Award

FutureOn, the global energy software company and creator of the award-winning, SaaS field design applications, FieldTwin Design and its API-centric collaboration platform, FieldTwin, has been named as a finalist at the OGUK Awards 2021.

The company has been shortlisted in the Business Innovation category in recognition of its pioneering design and planning tools, which have been adopted by the world’s major asset operators to maximise project efficiencies from the earliest concept stage, through to construction and operations, and into decommissioning.

The shortlisted entry focuses on the company's innovative FieldTwin Design software (previously known as FieldAP) in particular, which has been honed at the cutting edge of oil and gas development by world-leading operators in the most challenging of conditions – both environmental and economic.

The digital twin technology can include well placement, field layouts and installation details, as well as crucial bathymetry data and costing tools, and facilitate accurate projections of both technical and investment requirements. Ultimately, the solution supports crucial time and money-saving decisions at the earliest possible stage based on actual project parameters.

Specifically, FutureOn's technology enables a reduced degree of variability, thereby maximising the impact of the capital deployed and speeding the time to first oil. The transfer of information can then be streamlined in real-time across a shared, traceable digital twin platform, where layouts and schematics are produced directly in FieldTwin rather than third-party systems. This cuts the timeline by 30%, and significantly reduces the period necessary to evaluate development options thanks to an iterative, responsive and user-friendly approach to 3D visualisation.

Typically, the tool delivers pre-FEED time savings of approximately 50% and allows asset operators to export the full range of information required to prepare ITT packages for the supply chain – another crucial step in an anticipated acceleration, from discovery to first oil, of between one and two years, which helps to optimise the economics of the project and meet policy demands such as emission reduction.

Organised by the leading trade body for the UK offshore oil and gas industry, Oil & Gas UK (OGUK), the winners will be announced at a physical black-tie awards ceremony to be held at the P&J Live on 8 December 2021.

Jostein Lien, Senior Vice President of Products at FutureOn, commented:

“The OGUK Awards are held in the highest regard in the energy events calendar each year, and it is an honour to have FutureOn and our game-changing digital twin technology recognised. FieldTwin Design demonstrates true digital twin capability, designed – crucially – to work with third party and in-house systems. It provides a direct route to the next generation of field development, offering the ability to make better and faster decisions, providing the shortest path to first oil and the best lifetime returns, with minimal impacts on the environment.

“Events such as these are crucial if we are to share new innovations and successes on a global stage which can bring significant improvements to the industry as a whole. It’s highly encouraging that the OGUK Awards ceremony will bring industry together to reward key achievements and talent during these challenges times. We are looking forward to the ceremony and building on this achievement in the future.”

About FutureOn

Experts in data visualization, FutureOn emerged from Xvision in 2016 to become a standalone provider of state-of-the-art visual engineering for the global energy sector. The company transforms the performance of complex capital projects with our cutting-edge visualization technology.

FutureOn is proud to offer its global customer base industry-leading software solutions to create digital twins that deliver a complete asset visualization and integrated data model that unlocks value through increased efficiency, improved safety, reduced costs, risk mitigation, lower emissions and increased uptime.

FutureOn technology includes:

FieldTwin Design, a cloud-based digital platform that provides rapid visual workflows for early-stage subsea engineering work. Multiple data streams from geography to bathymetry, topography, existing infrastructure and other physical constraints can be combined with proprietary information such as reservoirs, wells and drilling to create an information-rich 3D visualization of any potential project location.

FieldTwin provides a visual representation of the entire life cycle of a field by creating and maintaining a digital twin — an exact digital copy of an oil and gas company’s physical asset — which enables producers to maximize asset performance and value.