Displaying items by tag: Konecranes

Konecranes to modernize two cranes for Fortum Power & Heat at Finland’s largest hydropower plant

Konecranes will modernize the industrial cranes at Fortum Power & Heat’s turbine hall in Imatra, Finland to ensure a continued steady supply of electricity for over 50,000 households annually. The order was booked in November 2023, with deliveries and installation scheduled for October 2024.

The modernization of the two aging cranes at the Imatra Hydropower Plant, which started operations in 1929, will enhance performance and extend the cranes' service life. The project involves working within the confines of a protected historical building, adding an extra layer of complexity to the task.

"We leveraged advanced technologies such as our Crane Reliability Study and RailQ to assess the cranes' condition, providing Fortum Power & Heat with a comprehensive solution tailored to their needs," said Jari A. Koskinen, Sales Manager, Konecranes Industrial Service & Equipment, Finland.

Photo: Fortum Power & Heat

Photo: Fortum Power & Heat

"The heritage protection status of our facility meant there were significant restrictions on how to carry out the project. Konecranes played an active role in planning the modernization so the historical integrity of the power plant was preserved," said Petra Väisänen, Project Manager, Fortum Power & Heat.

Konecranes used a variety of advanced Consultation Services, such as a Crane Reliability Study and RailQ, coupled with a steel structure analysis to take a deeper look at the crane and its components. This analysis formed the basis for the modernization plan, addressing specific challenges posed by the aging cranes. The modernization includes the installation of two 87-ton hoists (SMT1925) and two 10-ton (CXT6022) auxiliary hoists, along with the replacement of electrical cubicles, cables and wiring.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

For a concise overview of Konecranes’ business, please click here. Konecranes’ leading solutions for the power industry can be found here. For a useful glossary of crane and lifting terms, please click here.

Konecranes is a global leader in material handling solutions, serving a broad range of customers across multiple industries. We consistently set the industry benchmark, from everyday improvements to the breakthroughs at moments that matter most, because we know we can always find a safer, more productive and sustainable way. That's why, with around 16,500 professionals in over 50 countries, Konecranes is trusted every day to lift, handle and move what the world needs. In 2022, Group sales totalled EUR 3.4 billion. Konecranes shares are listed on Nasdaq Helsinki (symbol: KCR).

Konecranes secures 16-crane order to support environmentally sustainable scrap metal recycling rebar mill in Arkansas

Konecranes will provide 16 cranes to Hybar, an environmentally sustainable scrap metal recycling and steel production company in the United States. These cranes, including ladle, charge, rolling mill, and shipping bay cranes, will be instrumental in supporting Hybar's steel rebar production. The order was won in September 2023, with deliveries scheduled in 2024 and early 2025.

A Konecranes ladle crane in action.Hybar’s first mill is currently being built to produce a full complement of high-yielding rebar for large industrial projects. Once operational, Hybar expects its greenhouse gas emissions to be the lowest among all North American steel producers, and likely the lowest in the world’s steel making community. Furthermore, it will be directly connected to an adjacent solar panel field to tap renewable energy. For this transformative initiative, Konecranes will deliver a diverse array of heavy-duty cranes that are engineered to withstand challenging conditions including high temperatures and dust.

A Konecranes ladle crane in action.Hybar’s first mill is currently being built to produce a full complement of high-yielding rebar for large industrial projects. Once operational, Hybar expects its greenhouse gas emissions to be the lowest among all North American steel producers, and likely the lowest in the world’s steel making community. Furthermore, it will be directly connected to an adjacent solar panel field to tap renewable energy. For this transformative initiative, Konecranes will deliver a diverse array of heavy-duty cranes that are engineered to withstand challenging conditions including high temperatures and dust.

The cranes offer unique features and technology tailored to Hybar's specific needs. For example, two Shipping Cranes are equipped with specialized magnets for the efficient handling of spooled rebar coils and long flat bundles, and two ladle/charge cranes come equipped with operator cabins designed for optimal visibility, ensuring safe and precise handling of molten metal.

“The team at Konecranes understands the complexities of moving steel,” said Ari Levy, Hybar’s Chief Financial Officer. “They also share our dedication to operational efficiency, environmental stewardship and, above all else, safety.”

"Hybar’s commitment to reducing carbon emissions aligns very well with our sustainability approach, which makes this order for high-quality steel mill cranes that support Hybar's financial and environmental initiatives a perfect fit for both companies,” said Juergen Gieske, VP of Process Cranes Sales, AME, Konecranes.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

For a concise overview of Konecranes’ business, please click here. Konecranes’ leading solutions for the metals production industry can be found here. For a useful glossary of crane and lifting terms, please click here.

Konecranes is a global leader in material handling solutions, serving a broad range of customers across multiple industries. We consistently set the industry benchmark, from everyday improvements to the breakthroughs at moments that matter most, because we know we can always find a safer, more productive and sustainable way. That's why, with around 16,500 professionals in over 50 countries, Konecranes is trusted every day to lift, handle and move what the world needs. In 2022, Group sales totalled EUR 3.4 billion. Konecranes shares are listed on Nasdaq Helsinki (symbol: KCR).

Port Houston orders 5 more Konecranes RTGs, continuing its hybridization drive

Port Houston in Texas has ordered 5 Konecranes hybrid RTGs for its Barbours Cut Container Terminal to support its long-term improvement program covering channel development and land infrastructure investment. The order was booked in Q3 2023, with the cranes to be delivered at the beginning of 2025.

Port Houston is continuing to hybridize RTG container handling in its Barbours Cut and Bayport operations to meet growing container traffic in an eco-efficient way. Houston’s current RTG fleet consists of 116 Konecranes RTGs, of which 26 are hybrid RTGs. By early 2025, the hybrid RTG fleet will grow to 57 following this order and another one announced last October.

“Konecranes RTGs are very popular in North America and it’s good to see the hybrid version populating the RTG fleet of Port Houston, which is always forward-looking, especially when it comes to eco-efficiency,” said Jussi Suhonen, VP Regional Sales, Port Solutions, Konecranes.

Photo from Port Houston

Photo from Port Houston

The hybrid Konecranes RTGs on order have advanced Li-ion battery technology and a battery management system that monitors the charge level and general health of the batteries. Konecranes can monitor the status of this system via TRUCONNECT® remote connection. The hybrid power system is completely modular and retrofittable. It includes an eco-efficient Tier 4f diesel engine that charges the batteries when necessary.

This repeat order is part of EcoliftingTM, Konecranes’ continuous work to decrease the carbon footprint of our customers. From eco-optimizing diesel drives, to hybridization and fully electric fleets, we will continue to do more with less.

A strong focus on customers and a commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

For a concise overview of Konecranes’ business, please click here. More on Konecranes RTGs can be found here, while more on Konecranes RTG power options, including the hybrid option, can be found here.

Konecranes is a global leader in material handling solutions, serving a broad range of customers across multiple industries. We consistently set the industry benchmark, from everyday improvements to the breakthroughs at moments that matter most, because we know we can always find a safer, more productive and sustainable way. That's why, with around 16,300 professionals in over 50 countries, Konecranes is trusted every day to lift, handle and move what the world needs. In 2022, Group sales totalled EUR 3.4 billion. Konecranes shares are listed on Nasdaq Helsinki (symbol: KCR).

Guinea’s Winning Logistics bolsters its bauxite handling fleet with two more Konecranes barge cranes

In Q1 2023, Konecranes won an order for two Konecranes Gottwald Cranes on Barge from Winning Logistics in Guinea. After on-site commissioning in Q3 2024, Winning will operate a total of ten Konecranes Gottwald Cranes on Barge, loading ships with bauxite off the West African coast.

Konecranes Gottwald Cranes on Barge are specially designed and built to ensure uninterrupted material flow on water, even under demanding marine conditions. They can operate in winds of up to 24 m/s and at maximum wave heights of 2.5 m, and are built according to Lloyd’s Register Code for Lifting Appliances in a Marine Environment.

“Winning International Group takes Environmental, Social, Governance compliance seriously in terms of sourcing products and services that are safe, reliable and efficient. We know that Konecranes Gottwald mobile harbor cranes are reliable products for harsh environments. Their high productivity backed by quality service consistently creates added value for us. These cranes play a critical role in our unique offshore transshipment operation that has proven to be efficient, cost-effective and environmentally friendly. We are happy to be able to partner with suppliers, like Konecranes, who share our belief in sustainability beyond shipping and mining,” says Mr. Sun Zhijun, Vice President of Winning International Group.

“Winning International Group takes Environmental, Social, Governance compliance seriously in terms of sourcing products and services that are safe, reliable and efficient. We know that Konecranes Gottwald mobile harbor cranes are reliable products for harsh environments. Their high productivity backed by quality service consistently creates added value for us. These cranes play a critical role in our unique offshore transshipment operation that has proven to be efficient, cost-effective and environmentally friendly. We are happy to be able to partner with suppliers, like Konecranes, who share our belief in sustainability beyond shipping and mining,” says Mr. Sun Zhijun, Vice President of Winning International Group.

“Our barge cranes are thoroughly modern cargo handling machines that can operate mid-stream and on the open sea. Winning’s continuing trust in our expertise in this area, which reaches back over 20 years, confirms our leadership in this market,” says Holger Wagner, Regional Sales Manager, Port Solutions, Konecranes.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

For a concise overview of Konecranes’ business, please click here. More on Konecranes Gottwald cranes on barge can be found here. For a useful glossary of crane and lifting terms, please click here.

Further information:

Robert Vennemann, Marketing Manager, Mobile Harbor Cranes, Port Solutions, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +49 211 7102 3119

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2022, Group sales totaled EUR 3.4 billion. The Group has approximately 16,500 employees in around 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

North Italian terminal orders Generation 6 Konecranes Gottwald Mobile Harbor Crane to lift productivity and eco-efficiency

TDG, Terminal Del Golfo, part of Tarros Group, has ordered an eco-efficient Generation 6 Konecranes Gottwald Mobile Harbor Crane for their operation in La Spezia, in northwestern Italy. The crane represents the latest in mobile harbor crane technology: it will be equipped with an external power supply that lowers operating costs while reducing noise and exhaust emissions. The order was booked in July 2022 and the crane will be delivered in the first quarter of 2023.

The new Generation 6 crane will increase capacity and improve flexibility at the terminal. It can handle containers, general cargo and heavy project cargo, and its external power supply will raise both operational performance and reduce local carbon emissions. When unplugged the crane uses a hybrid drive, consisting of an EU Stage V diesel engine paired with ultracapacitors refilled by lowering and braking energy.

The crane will work at Terminal del Golfo (TDG), a container and multipurpose terminal in La Spezia. TDG is operated by Tarros Group, a port operator with a network of depots and terminals across the Mediterranean region.

The crane will work at Terminal del Golfo (TDG), a container and multipurpose terminal in La Spezia. TDG is operated by Tarros Group, a port operator with a network of depots and terminals across the Mediterranean region.

“We are excited to utilize the latest eco-efficient mobile harbor crane technology to support our terminal enlargement project in La Spezia. We were convinced by the combination of productivity, flexibility and eco-efficiency that the Generation 6 offers,” says Andrea Natale, Terminal Manager at TDG.

The crane is TDG’s first Generation 6 mobile harbor crane. The decision to purchase one was supported by Konecranes’ MHC Product Advisor, a virtual tool that helps operators find the right mobile harbor crane. The crane will have smart features such as automatic lubrication to reduce maintenance work, an emergency ladder on the tower wall for added safety, and digital services that streamline operation in line with Italy’s National Industry 4.0 Plan, a state strategy that encourages industrial innovation.

“This order underlines the strengths of the Generation 6 crane, with its high productivity, reliability and eco-efficiency, and we are proud to support TDG in their terminal expansion” says Gino Gherri, Regional Sales Manager, Port Solutions, Konecranes.

This order is part of Ecolifting™, Konecranes’ continuous work to decrease the carbon footprints of our customers. From eco-optimizing diesel drives to hybridization and fully-electrified fleets, we will continue to do more with less.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totaled EUR 3.2 billion. The Group has approximately 16,600 employees in around 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Kemi Shipping orders eight Konecranes E-VER electric forklifts to its fleet in northern Finland

Kemi Shipping Oy, owned by Finnish Metsä Group, has ordered eight award-winning Konecranes E-VER fully electric forklifts including full service contracts for their operations in the Port of Kemi. Highly impressed with an E-VER delivered early in 2022, the Finnish logistics company is strengthening operations with an additional order. The order was received in June 2022 and will be delivered in the first half of 2023.

Kemi Shipping provides a range of harbor services for customers in the region. With Metsä opening a new mill for bioproducts in the north, Kemi Shipping is taking the step to invest in new lift trucks for their new warehouse operations. The port facility is big and will benefit from the eight Konecranes E-VER electric forklifts that will serve the mill with their product handling as it reaches full production capacity.

“Sustainability is at the core of our business, so the first thing that attracted us to the Konecranes E-VER was the fact that it is fully electric,” says Kari Lundell, CEO of Kemi Shipping. “We had one Konecranes E-VER delivered earlier this year for paper board handling, and we could see its advantages immediately. Besides eliminating tailpipe emissions, it offers outstanding efficiency, and our drivers love it. Once all eight E-VER electric forklifts are on-site, they will mark another big step on our journey to greater productivity and lower emissions.”

“Kemi Shipping has been a loyal Konecranes customer for over two decades, sharing our mutual commitment to the environment” says Klaus Kaukovalta, Product Manager, Lift Trucks for Konecranes Finland. “Konecranes E-VER, that won the sawmill industry Product Novelty Competition for improving the environmental performance, gives us the perfect opportunity to provide Kemi Shipping equipment that meets their specific requirements in a demanding industry.”

The eight additional lift trucks are Konecranes E-VER 16-1200C forklifts, with a fully-electric driveline and a capacity of 16 tons. Lithium-ion batteries manufactured with clean energy power each truck, taking just 45 minutes to fully recharge and re-generating brake energy back to its battery. With less heat, oil and fewer moving parts, the electric forklift requires less maintenance, and produces less chemical waste. The trucks will be supplied with special bale clamps to securely handle wood pulp.

These Konecranes E-VER electric forklifts are also Smart Connected Lift Trucks, in which TRUCONNECT® Remote Monitoring follows each truck’s performance and maximizes battery life through analytics such as charge optimization and energy consumption.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totaled EUR 3.2 billion. The Group has around 16,600 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Konecranes to supply nuclear fuel handling machines to Sweden’s largest nuclear power plant

Konecranes will supply replacement fuel handling machines for three reactor units to the Forsmark nuclear power plant, the largest electricity producer in Sweden. The order is part of the plant modernization work. The new machines are equipped with the latest Konecranes technology and operator interfaces to improve the productivity and safety of the plant operations. The order was booked in April 2022.

Forsmark nuclear power plant in Sweden, mainly owned by Vattenfall, is currently modernizing its facilities to meet increased safety and environmental requirements, prolong the service life of the reactor and increase the output. They chose Konecranes to renew their fuel handling machines to support continued safe and productive operations.

The new Konecranes fuel handling machines comply with all major international nuclear standards and utilize single failure proof technology. This technology is designed to prevent load drop during the occurrence of any single failure of the lifting system. The Konecranes safety and diagnostic systems continuously monitor equipment operation which improves the safety of the fuel handling and the productivity of the nuclear power plant.

The equipment will be used to move the fuel assemblies between the reactor locations and fuel racks at each of the three units. The contract covers the replacement of all three fuel handling machines within five years to ensure they are ready for the scheduled refuelling outages.

“This contract showcases Konecrane's role in our customers’ work for securing critical societal functions, such as energy production. Forsmark nuclear power plant is a forerunner in their environmental work and imposes strict requirements on suppliers concerning quality and environmental issues, and we are proud to support them in their sustainability efforts,” says Steve Waisanen, Vice President and Head of BU Nuclear from Konecranes.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Further information:

Steve Waisanen, Vice President and Head of BU Nuclear, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity-enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totalled EUR 3.2 billion. The Group has approximately 16,600 employees in around 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Konecranes named best Finnish Large Cap company on furthering diversity

At its annual gala, the Finnish Foundation for Share Promotion (Pörssisäätiö), a foundation promoting securities investment and the securities market, rewarded Konecranes as the best Finnish Large Cap company on furthering diversity. Diversity and inclusion are cornerstones of Konecranes’ culture and business, propelling its performance and organization.

With the award, Konecranes was praised for its all-company diversity trainings, set targets, activities and processes. Konecranes has placed special focus on key topics such as inclusive recruitment and accountability.

“Diversity and inclusion are key for our culture and performance as a company. We are humbled to receive this award, with big thanks to our people who made our progress a reality through their participation and commitment”, Konecranes Interim CEO Teo Ottola says.

Konecranes has made diversity and inclusion a top priority, with an ambition to reshape both the company and industry. In 2019, the company established the position of Chief Diversity & Inclusion Officer and embarked on a multi-year roadmap. Diversity brings a wide range of benefits: improving innovation and performance, enabling employees to have equal opportunities and being close to customers by representing the societies the company operates in.

Progress is monitored through a set of key metrics, including gender balance as well as representation of nationalities and geographies. To ensure everyone’s involvement, trainings on diversity and inclusion are mandatory for the entire company.

“I’m proud of our progress. Inclusion is underpinning our culture and we have made improvements in our gender representation and diversity is being advanced on all levels and sectors of the company. Still, there is much to achieve for both us and the industry and we are determined to be pioneers in that work”, Konecranes Chief Diversity & Inclusion Officer Mara Zavagno says.

For more information on Konecranes work on diversity and inclusion, please see the 2021 Sustainability Report.

Further information:

Mara Zavagno, Chief Diversity & Inclusion Officer, Konecranes

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. or phone: +491722030543

Konecranes is a world-leading group of Lifting Businesses, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2021, Group sales totaled EUR 3.2 billion. The Group has around 16,600 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

Konecranes provides 17 Automated Rubber-Tired Gantry Cranes in fully integrated solution for Port of Felixstowe

The Port of Felixstowe (Felixstowe), operated by Hutchison Ports, has ordered 17 Automated Rubber-Tired Gantry Cranes (ARTGs) from Konecranes. The order was booked in Q4 2021. The ARTGs will be delivered and commissioned in a project covering 3 phases starting in Q2 2023. Completion and go-live is scheduled for Q4 2025. The new ARTGs will be fully electric, powered by busbars, and delivered as carbon neutral.

This order marks the first Konecranes ARTGs to be delivered to the United Kingdom, and the first Konecranes ARTGs ordered by Hutchison Ports. To date, it is the largest order of Konecranes ARTGs for a single terminal or project.

The project consists of three phases. The first phase will start in the second quarter of 2023 with the delivery of 6 ARTGs. The remaining ARTGs will be delivered in two batches. By the fourth quarter of 2025, all 17 ARTGs will be handed over. Electrified and automated container movements will help to make Felixstowe’s large container throughput more efficient. They are also part of a major decarbonization investment by Felixstowe, which plays a key role in the British economy and international trade. Felixstowe’s eight existing ARTGs will be integrated with the new Konecranes ARTGs and Remote Operating Stations as part of a single automated system.

The fully electric ARTGs will give a big boost to productivity and decarbonization efforts at Felixstowe, the busiest container port in Britain. Konecranes ARTG technology, introduced in 2013, has been successfully implemented around the world. This case also brings our integration expertise to the fore. “Konecranes will integrate Felixstowe’s existing ARTGs with the Konecranes ARTGs in a harmonized automation platform” says Darryn Scheepers, Sales Manager EMEA, Port Solutions, Konecranes.

The Port of Felixstowe

The Port of Felixstowe

The automation harmonization will be accomplished by integrating the existing ARTGs with the Konecranes Remote Operating Stations (ROSs) and the Konecranes Crane Task Management System. A Konecranes Crane Adapter Module will adapt the controls to the Konecranes ROS and give the work orders to the existing cranes. A single operator at a Konecranes ROS will be able to remotely handle up to five ARTGs simultaneously across the yard. The Konecranes’ “street bogie” solution will enable fully automated gantry travel, using proven safety technologies for obstacle detection. Konecranes TRUCONNECT® remote monitoring is included, providing remote crane diagnostics.

Hutchison Ports has a network of 48 container ports around the world, including the Port of Felixstowe, on the east coast of England. With many shipping routes to Europe and beyond, it's the busiest container port in Britain, handling more than 4 million twenty-foot equivalent units (TEU) per year.

This project with Felixstowe is an excellent example of Konecranes’ path to port automation, where container terminals improve productivity and safety in manageable steps. From smart features up to full automation, the path can include supervised operation and remote operation to smoothly introduce the power of automation.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).

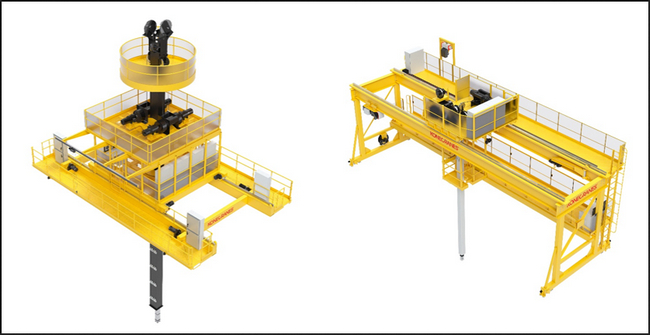

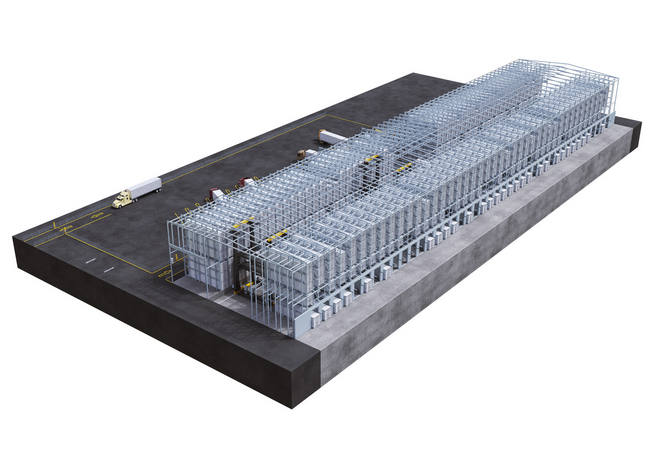

Konecranes partners with Pesmel to supply automated warehouse container handling systems

Konecranes is partnering with Pesmel to supply automated warehouse container handling technology that revolutionizes material handling in logistics hubs and distribution centers. Konecranes and Pesmel signed a Memorandum of Understanding on 25th November 2021, to provide the globally available new solution under the Konecranes brand.

The solution will handle containers fully automatically in a high-bay warehouse, where they are stacked up to 14 high. This reduces the space needed for containers by up to 80%. Automated container tracking is part of a management system that can be integrated easily with the facility’s overall logistics management system.

Tero Vallas, Business Development Manager, Konecranes Port Solutions, said: “Many logistics operations and distribution centers are faced with handling a large number of incoming and outgoing containers, with great operational complexity and an increasing scarcity of land. Now, from Konecranes and Pesmel, warehouse container handling solutions are available that will impose order on the container chaos while eliminating the complexity, improving throughput, and also greatly reducing the space needed for containers in logistics hubs and distribution centers.”

Container shipping is expected to grow in the future, both in volume and speed. The better containers are handled at logistics hubs and distribution centers, the better their customers will be served, in ways that give decisive competitive advantage. Konecranes and Pesmel are here to give that advantage.

“Partnering with Konecranes is a great opportunity for Pesmel to bring our high-bay warehouse technology into a new business area,” said Tony Leikas, CEO, Pesmel.

About Pesmel

Pesmel is the Material Flow How® company. Founded in 1978 and headquartered in Finland, Pesmel has more than 40 years of experience in delivering solutions that improve material flows and logistics at different types of warehousing and manufacturing facilities. Pesmel focuses on serving customers around the world in the pulp and paper, metals and tire manufacturing industries.

A strong focus on customers and commitment to business growth and continuous improvement make Konecranes a lifting industry leader. This is underpinned by investments in digitalization and technology, plus our work to make material flows more efficient with solutions that decarbonize the economy and advance circularity and safety.

About Konecranes

Konecranes is a world-leading group of Lifting Businesses™, serving a broad range of customers, including manufacturing and process industries, shipyards, ports and terminals. Konecranes provides productivity enhancing lifting solutions as well as services for lifting equipment of all makes. In 2020, Group sales totaled EUR 3.2 billion. The Group has around 16,500 employees in 50 countries. Konecranes shares are listed on the Nasdaq Helsinki (symbol: KCR).