Displaying items by tag: Matara UK Ltd

Ball Screws vs Lead Screws: horses for courses

By Japh Humphries, UK Sales & Commercial Manager, Matara UK Ltd.

When it comes to linear motion systems, one question that gets repeatedly asked is ‘which should I use – ball screw or lead screw?’ They both perform the same task, converting rotational motion into linear movement. However, assuming they are interchangeable because of this would be a mistake, and a potentially costly one at that. Their design and subsequent operation differ, providing each with its own set of advantages and disadvantages; weighing these up against the application at hand is essential to ensure your linear motion system performs to the specified criteria.

Design & operation compared

Both lead and ball screws feature a threaded shaft which acts as the screw element of the unit.

A lead screw - the simpler of the two options when it comes to design – has a threaded mating nut which is in direct contact with the screw. Rotational motion turns the screw, causing the nut to move along in a linear motion, thereby converting the motion from rotary to linear. Lead screws come in different formats with one of the most popular for industrial applications being trapezoidal lead screws. The screws are manufactured from steel and the nuts are available in a variety of materials from steel through to bronze, brass and plastic.

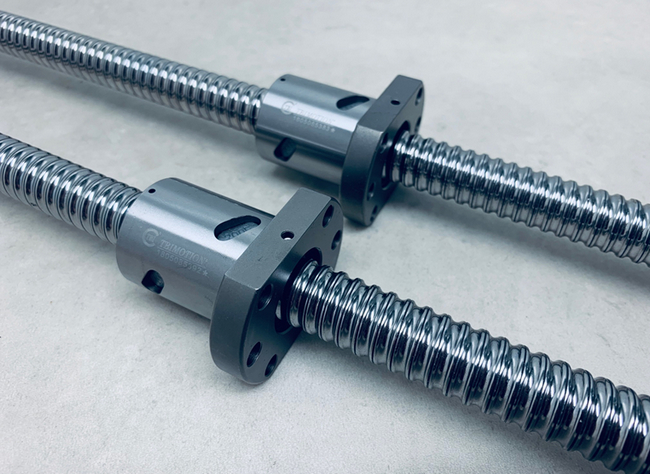

In the case of ball screws, a threaded shaft is also used, but it features a helical path around which ball bearings move. The ball assembly behaves as the nut. Ball screws are available in different formats, with rolled and ground types mostly favoured by manufacturers.

Lead screws: pros & cons

As mentioned above, lead screws are the more basic design of the two and that is reflected in the cost. Lead screws have a lower capital outlay than ball screws; ball screws can be two to three times the price of a comparable lead screw. They also do not require a braking system as they are self-locking, which is a further plus point when it comes to total cost.

This price differential often makes lead screws the first port of call, but this could be a false economy as it may not operate well in your specific application; it’s horses for courses, as the saying goes!

Apart from a lower purchase cost, lead screws have the advantage of generally being self-lubricating and they tend to be quieter in operation than ball screws. They are compact with minimal parts, and are easy to design into a system.

Where they don’t score so well is efficiency, which runs between 20% - 25%, as lead screws require greater torque and a larger motor and drive. They also have higher friction and therefore run at a hotter temperature.

Ball screws: pros & cons

With ball screws relying on point contact to support a load, as opposed to line contact, less friction is produced during use. This means that ball screws typically operate at a minimum of 90% efficiency, plus they run at cooler temperatures, and they produce a considerably smoother movement.

Due to recirculating balls supporting the load, ball screws have a higher load capacity than lead screws of a similar size.

Ball screws are also more versatile than lead screws. They are available in higher accuracy grades for greater positional accuracy, and they can be adjusted to increase/decrease preload.

But there are some drawbacks. Obviously cost is one, as outlined above, which is further increased by the need for braking mechanisms to eliminate the risk of back driving. Back driving occurs when the motor shuts off and the ball screw free-falls as a result. Brakes must be fitted as a safety precaution in this case. This is particularly pertinent if the load is to be carried vertically.

With moving balls within the mechanism, it is likely to be noisier than a lead screw, and will also require regular lubrication to ensure the balls move freely. Furthermore, the overall size of ball screw device is larger than a comparable lead screw due to the need for the balls to be recirculated.

What to use where: the rule of thumb

So, which should it be – ball screw or lead screw?

Whilst a definitive answer isn’t practical – each application will have other factors and trade-offs that may need to be taken into account – generally speaking, lead screws are more suitable for transfer applications for which speed, accuracy, precision and rigidity are not as critical. That’s because most lead screws are not well suited to high throughput, high speed applications or those with continuous or long cycle times. Typically, you will find lead screws in use in fluid handling, data storage applications and life science equipment.

Ball screws, on the other hand, are mostly better for high precision applications where accuracy and control are critical. They are also a good option for high load applications and for where thrust force is required to move those loads across a distance in a smooth motion, whilst maintaining speed. Examples of applications include 3D printers and automobile and aeroplane manufacturing.

So, when deciding on whether a ball screw or lead screw is right for your machine, whilst they both perform the same task of converting rotational motion into linear movement, the way in which they realise this and type of end result you achieve are markedly different.

Matara designs, manufactures and supplies pneumatic and linear automation products, including lead screws and ball screws.

www.matara.com

Matara supplies converting solutions provider with machine guarding

Matara UK Ltd, specialist in automation, pneumatics and linear motion products, has completed a substantial project for the manufacture and supply of machine guard frames for T S Converting Equipment Ltd. (Elite Cameron).

T S Converting provides solutions for slitting, coating and lamination of a wide range of substrates, tailored to suit customers’ requirements. To ensure people do not get too close to the machinery when in operation, and to comply with safety regulations, machines are supplied to customers with a protective guard frame. Until recently, this frame was produced in-house, which was very time-consuming, costly and did not allow for key accessories, such as screw-in feet or castors, be used.

With T S Converting’s latest project – a substantial order of mixed machines – the company turned to Matara, which has over two decade’s experience in this field.

Working from T S Converting’s CAD drawings, Matara cut the aluminium to the correct size and assembled the guarding panels to T S Converting’s exact specifications. Aluminium profile was selected for this order due to its adaptability and the speed in which it can be produced, and for its cost-effectiveness when compared to steel.

Matara machine guarding for TS Converting

Matara machine guarding for TS Converting

This latest order has required over 200m of 40x40mm aluminium profile, which has been powder coated safety yellow (RAL1003). All sections of this guarding have been supplied with UK stocked 25x25 black powder coated wire mesh or clear polycarbonate panels. A wide range of accessories has been included into the guard frames, including feet for mounting the sections to the floor for stability, connecting plates complete with fixings, door handles and hinges.

With T-slots pre formed into the aluminium profile, adding further accessories couldn’t be easier as they simply slide into these slots without the need for welding or drilling holes. This has enabled T S Converting to make further on-site adaptations, including adding switch panels to certain areas of the profile as well as safety switches on the doors of the guard frame.

Commenting on their decision to out-source the machine guard frame production to Matara, James Self, Director at TS Converting Equipment said: “One of the main reasons we chose Matara is the time it has saved us in production. We now have the guarding cut, powder coated and fully assembled, saving our engineers valuable time in our busy production schedule. The guarding has been a huge success not just for saving money but also how smart it looks.”

T S Converting has also been impressed with the service Matara has delivered: “The service provided from Matara has always been helpful and professional. Every member of staff at Matara have always been welcoming and more than happy to help. Because of the success on the guarding, we are now discussing other areas of the business that we can work together on. The partnership between T S Converting and Matara has a very bright future.”

Matara is part of Rubix, Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. For more information, please go to www.matara.com/

About Matara

Matara, established in 1995, is a specialist supplier of bespoke linear motion, automation, and pneumatic components. Based in Tewkesbury, Gloucestershire, Matara are a team of 27 employees, serving a wide range of industries, including printing & packaging, food & drink, pharmaceutical and metal processing. In the year ended 31 March 2020, Matara reported sales in excess of £5m.

About Rubix

Rubix is Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. It was created from the merger of IPH with Brammer in 2017, following the acquisition of Brammer by Advent International.

From around 750 + locations across 22 countries, 8,000 employees help to identify, install and provide a leading range of industrial products and services to more than 200,000 customers. The business had combined sales of €2.4bn in 2020 and is a leading distributor in bearings, transmission and automation, fluid power, machining, assembly, tools and protective equipment.

ARMOLOY TDC® COATED LINEAR RAIL AND BALLSCREWS FROM MATARA FOR HIGH WEAR RESISTANCE

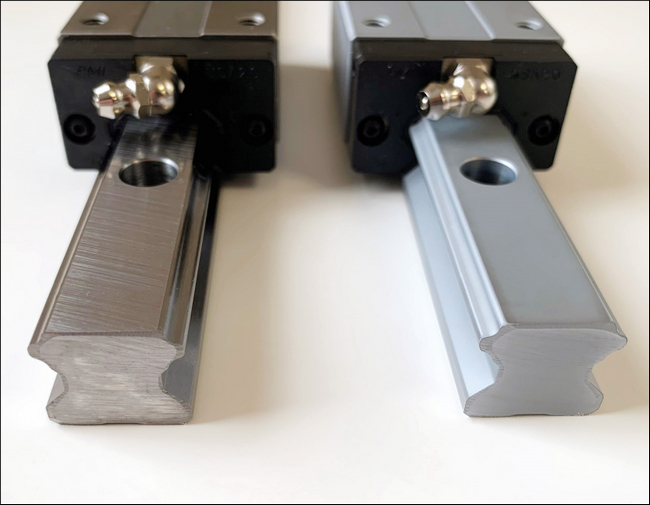

When motion equipment is being used in harsh environments, it needs to be of resilient design and manufactured from highly durable materials. Matara UK Ltd, specialist in automation, pneumatics and linear motion products, provides customers with Armoloy TDC® coated linear rail and ballscrews for maximum longevity in demanding applications and locations.

Matara linear rail and ballscrews use top grade materials and are subjected to extremely rigorous heat treatment and grinding processes, for high quality products. For added protection, and where the standard materials will not suffice, these products are now available with Armoloy TDC® coating, which is a hard (78Rc), thin, dense chromium coating with a micro-nodular surface texture. Using Armoloy® TDC coatings provides corrosion protection equal to 440 series stainless steel.

The nodular finish of the coating reduces the amount of the rail and ballscrews’ surface area exposed to surfaces in contact with it, thereby substantially reducing friction for smoother movement over rolling surfaces, as well as extending wear life by nearly 50% when compared with a typical hard chrome coating. The nodular finish also retains smaller amounts of industrial lubricants for longer periods, both further reducing friction and creating a cleaner work environment.

Matara linear rail without and with Armoloy TDC coating

Matara linear rail without and with Armoloy TDC coating

With the Armoloy TDC® coating, Matara linear rail and ballscrews have improved resistance to chemicals, detergents and weld spatter. They have anti-galling, spalling and fretting properties and are capable of withstanding very wide temperature ranges.

Application of this innovative coating is through a proprietary means at a precise 2.5 – 5 micron even deposit which will not affect the linear rail and ballscrews’ geometry, weight or balance and will not alter the metallurgical structure. 100% coverage is achieved with absolute adhesion, i.e. the coating will not chip, flake or peel, and a satin silver appearance free of rack marks is guaranteed.

Matara linear rail and ballscrews with Armoloy TDC® coating can be used in most industries, but are especially well suited to customers operating in corrosive environments, such as battery plants and marine applications, and for those who undertake regular wash down such as pharmaceutical manufacturing and food processing plants. The coating is USDA approved and FDA compliant, as well as compliant with EC 1935/2004 for food contact.

Matara has over 23 years’ experience in the linear motion industry. It has a large UK stock of linear motion control automation components, including precision ground and rolled ball screws, power lead screws and linear guides and rails, as well as providing cost-effective, bespoke linear motion control solutions. Matara is part of Rubix, Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. For more information, please go to www.matara.com/

About Matara

Matara, established in 1995, is a specialist supplier of bespoke linear motion, automation, and pneumatic components. Based in Tewkesbury, Gloucestershire, Matara are a team of 27 employees, serving a wide range of industries, including printing & packaging, food & drink, pharmaceutical and metal processing. In the year ended 31 March 2020, Matara reported sales in excess of £5m.

About Rubix

Rubix is Europe’s largest supplier of industrial maintenance, repair and overhaul products and services. It was created from the merger of IPH with Brammer in 2017, following the acquisition of Brammer by Advent International.

From around 750 + locations across 22 countries, 8,000 employees help to identify, install and provide a leading range of industrial products and services to more than 200,000 customers. The business had combined sales of €2.4bn in 2020 and is a leading distributor in bearings, transmission and automation, fluid power, machining, assembly, tools and protective equipment.