Ian Melin-Jones

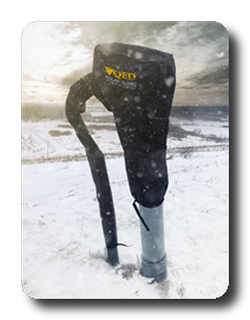

Q.E.D. Highlights PolarGuard Insulating Wellhead Cover for Protecting Wellheads and Gas Collection Hoses from Subzero Temperatures

Wellhead cover that prevents freezing condensation and wind damage on wellheads and gas collection hoses

Q.E.D. Environmental Systems, Inc., a leading manufacturer of innovative environmental products, announces the PolarGuard Insulating Wellhead Cover, an insulative cover which protects and prevents frozen condensation on wellheads and gas collection hoses.

Winter weather can cause many problems for landfill operators and landfill gas technicians.

Sub-zero temperatures and heavy winds can lead to freezing condensation in wellheads and landfill gas hoses, affecting gas extraction levels and causing unnecessary delays and expense. The PolarGuard cover protects against these harsh conditions by tightly wrapping wellheads and gas collection hoses.

Sub-zero temperatures and heavy winds can lead to freezing condensation in wellheads and landfill gas hoses, affecting gas extraction levels and causing unnecessary delays and expense. The PolarGuard cover protects against these harsh conditions by tightly wrapping wellheads and gas collection hoses.

QED’s PolarGuard cover allows for quick and easy installation using Velcro® closures and web buckle straps. The covers are able to come on and off with ease, allowing for convenient monitoring and maintenance. The PolarGuard Insulating covers are available for both Precision Control and Accu-Flo Wellheads and can accommodate wellheads of up to three inches.

By investing in PolarGuard Insulating Wellhead covers, landfill operators and gas technicians are granted the peace of mind that their wellheads and gas collection hoses are kept warm and blocked from the wind. Using this smart technology, operators may be able to avoid unnecessary maintenance costs or operation delays, increasing the efficiency of the landfill.

For more information, visit QED online at www.qedenv.com.

About Q.E.D. Environmental Systems, Inc.

Q.E.D. Environmental Systems, Inc., a subsidiary of Graco Inc., is a leading manufacturer of innovative environmental pumping systems, landfill products, landfill gas products, and air strippers for use at landfills, mines, oil refineries and other industrial sites, as well as hazardous waste cleanup sites. Our products are used around the world for a wide range of environmental applications, including groundwater sampling, groundwater remediation pumping, landfill leachate and condensate pumping, landfill gas collection and control, landfill and biogas analysis, air stripping and VOC removal, and wireless data acquisition. Based in Dexter, MI, QED serves customers from support centers in Michigan and California. For more information, call 734-995-2547 or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Rockwell Automation Expands Kinetix 5100 Servo Drive and TLP Motor Pairing to 480V

The Rockwell Automation Kinetix 5100 servo drive and Kinetix TLP servo motor standalone motion solution is now available in 480V for use in a wider range of OEM applications for packaging, converting, print and web, machine and assembly, and life sciences.

The Kinetix 5100 servo system meets growing consumer demand for more product variety by providing a market-competitive motion-control offering for flexible, standalone machines. Using the Kinetix 5100 servo drive, OEMs can create a motorized or automated system that can help speed up changeovers.

Additionally, with built-in safe torque off, users can remove motor torque without removing power from an entire machine. This allows a machine to restart faster after it has reached a safe state. Dual-port EtherNet/IP also supports device-level ring (DLR) topologies.

AFRY acquires ITE Østerhus in Kristiansand, Norway

With the acquisition of ITE Østerhus AS, AFRY establishes itself in an important industrial area in Norway and strengthens its position within process industry.

ITE Østerhus specialises in electrical engineering, automation and digitalisation for industrial customers. The company's largest market areas are smelting plants and process- and food industries.

ITE Østerhus focus on a wide range of projects of various sizes and complexities. The company delivers integrated solutions including the entire hierarchy of hardware equipment, panel production, automation, system integrations and digital solutions.

The acquisition adds a new location in the south of Norway with access to a new important regional market. ITE Østerhus complements AFRY’s service offering and increases the company’s capacity within electrical engineering, automation and digitalisation.

“Digitalisation is an important strategic focus area for AFRY. With this acquisition, we increase our competitiveness in digitalisation towards the industrial market,” says Jon Julsen, Director of Process Industries, AFRY.

“By joining AFRY we strengthen our position as a strategic partner for our customers through increased capacity, competence and services. This will create new business opportunities and access to a larger market,” says Jarle Windegaard, CEO of ITE Østerhus.

The company has 22 employees and the estimated revenue for 2020 is approximately MSEK 40. The company will be consolidated into AFRY as from January 2021.

In Norway, AFRY has more than 900 employees with offices in Oslo, Stavanger, Trondheim, Molde, Ålesund, Lillestrøm, Sarpsborg, Sandefjord and now also Kristiansand.

AFRY is an international engineering, design and advisory company. We support our clients to progress in sustainability and digitalisation. We are 17,000 devoted experts within the fields of infrastructure, industry and energy, operating across the world to create sustainable solutions for future generations.

Making Future.

Scallog, the French logistics robotics specialist, sets sail to conquer the USA in agreement with Bastian Solutions.

Scallog, one of the leading suppliers of logistics robots in France, has signed an integrator agreement with Bastian Solutions, a Toyota Advanced Logistics company, and a long-established intralogistics expert in the USA. The purpose of the agreement is to launch and market Scallog’s goods-to-person robotics solutions in the US. These solutions are designed to meet logistics challenges in a wide range of industries including food, cosmetics, pharmaceuticals, textiles, publishing and spare parts.

The American warehouse in the age of agility and flexibility!

The acceleration of eCommerce (up by over 32% according to eMarketer) and the impact of the Covid-19 crisis on the supply chain mean that warehouses in the USA are speeding up the automation of their operations to gain agility, shorten delivery times and increase service quality. The North American market has great potential for Scallog as only 5% of warehouses are fully automated and 15%, semi-automated (according to DHL). The Scallog robotic solutions - which compete with Amazon’s Kiva robotic solutions - meet the challenges currently facing logistics operators of automating their order picking process rapidly and flexibly at the lowest possible cost and without affecting their current systems.

Under its strategy of international development, Scallog has signed a major commercial agreement with Bastian Solutions, an integrator and one of the world’s top 20 logistics automation solutions providers, to market the Scallog goods-to-person robots for warehouses on the other side of the Atlantic.

Under its strategy of international development, Scallog has signed a major commercial agreement with Bastian Solutions, an integrator and one of the world’s top 20 logistics automation solutions providers, to market the Scallog goods-to-person robots for warehouses on the other side of the Atlantic.

The French innovation backed by a recognized intralogistics expert in the USA.

Bastian Solutions has added Scallog’s robotized order picking solutions to its offering in order to meet the growing need for agility and resilience among its logistics operator customers. The benefits of the Scallog solution include an ROI of under two years and flexibility, scalability and upgradability. These were determining factors in Bastian Solutions’ choice of Scallog as its collaborator in the supply of robots to transport shelf units to operators. With Scallog, American logistics operators can now embark on, and grow, their warehouse automation to meet their evolving requirements, spreading their investment and continuing their operations and/or production uninterrupted.

The agreement with Bastian Solutions is part of Scallog’s strategy of phased international development. Joining forces with a well-respected local player such as Bastian Solutions gives Scallog more rapid access to the US market due to its partner’s understanding of local conditions and ability to provide local support and high-quality services. Bastian Solutions, an integrator ranked among the world’s top 20 suppliers of logistics automation solutions, employs 1,000 people in 20 national offices and its subsidiaries in Canada, Brazil, Mexico and India. Over 30 of Bastian Solutions’ employees have already been trained in Scallog solutions as part of a skills transfer, and co-marketing activities will begin in the first quarter of 2021.

“This collaboration illustrates a change in scale in our strategy of international expansion, in line with our ambitions for deployment and commercial presence in key markets. The United States represents a new Eldorado for logistics robotics, where our value proposition for the automation of order picking has everything required to meet the growing demand for efficiency, agility and resilience in American warehouses”, says Olivier Rochet, CEO of Scallog.

Olivier adds: “We are delighted to be associated with a recognized intralogistics expert such as Bastian Solutions, which represents the ideal American partner inasmuch as our offerings, expertise, services and values complement each other so well. Bastian Solutions’ position, experience and in-depth knowledge of automation will accelerate the bringing to market, adoption and development of our vertical robotics solutions for the warehouses of the future in the USA - connected, digitalized and robotized”.

“We must continuously add technologies that address the growing demand and changing landscape order fulfillment providers face. Scallog’s technology will help us continue providing our customers with the competitive advantage they need to stay ahead in today’s market. We’re looking forward to introducing Scallog to our global network of clients”, enthuses Marvin Logan, Vice President of Consulting and Integration at Bastian Solutions

The companies anticipate the first installations of Scallog solutions in the first half of 2021.

About Scallog :

Founded in 2013, Scallog is a French company that designs, manufactures and markets robotics solutions for the logistics sector to boost warehouse agility and productivity for 3PL, e-commerce, distribution and manufacturing companies. In light of changes in B2C and B2B consumer demand patterns, particularly in terms of product availability and delivery, the Scallog solution helps companies accelerate order picking and absorb peaks in activity, whilst reducing arduous working conditions for employees and helping to phase investment. Its goods-to-person range includes the best “intelligent” decision-making and execution software and mobile robotics, meeting the need of logistics operators to increase order picking flexibility and integrate automation more widely in their warehouses. With over 30 different customers to its name and substantial funds raised, Scallog - the pioneer of scalable, flexible logistics robotics - is now aiming to boost its growth across Europe. www.scallog.com

Uptick in LNG demand this winter, but forecast dependent on several risks

Winter maybe a few weeks away, but it was front and centre at the latest GECF Monthly Gas Lecture, as a panel of experts from leading information provider, Refinitiv, uncovered what the 2020-21 winter might hold for the LNG industry reeling from the double whammy of coronavirus pandemic and economic downturn.

Held via videoconference on 6 Oct. and entitled ‘Winter Outlook for Global LNG – Cautiously Optimistic’, company analysts, Ms Anne Kat Brevik, Director - LNG Research & Forecasts, Ms Laura Page, Lead LNG Analyst, and Mr Hengky, Senior Analyst (LNG), sifted through the demand and supply outlook and their relationship with market’s balance and pricing dynamics.

“We expect LNG demand to increase by 4 billion cubic metres (bcm) this winter and that’s led by growth in China, Japan, and South Asia. LNG supply is expected to grow by 3 bcm led by the United States. And when we put together demand and supply forecast, we expect the LNG market to be slightly tighter than last winter by 1 bcm,” noted the Refinitiv representatives.

However, there remained several risks to the forecasts, foremost of which are winter temperatures and coronavirus pandemic. The former was unusually warm last winter for the northern hemisphere, dampening LNG demand. In the case of the latter, the full-blown effect of COVID-19 is unclear particularly as it is currently worsening in many countries and levelling off in others.

Recognising the importance of scientifically drawn forecasts – a hallmark of the GECF and epitomised in its annual Global Gas Outlook 20050 – HE Secretary General Yury Sentyurin said: “In many ways, COVID-19 has highlighted the importance of data so we can map and understand the economic and social effects of pandemic-related measures. This belief in the supremacy of data to generate valuable insights can be found in the DNA of both the Forum and Refinitiv.”

“The GECF data is distinguished, for it is based on our Member Countries’ primary sources of information. This is why we regularly share our data externally, such as in the OPEC World Oil Outlook, at the IEA-IEF-OPEC Symposiums on Energy Outlooks, and through our participation in JODI-Gas World Database, so the gas industry can grow and thrive.”

The audience at the lecture series further heard that accurate planning for the period ahead depends on not just weather but myriad factors such as government policies that can often change the course of LNG demand and pricing.

For instance, the team of lecturers shared that the story of LNG played out vastly differently last winter in Japan and South Korea, the world’s largest and third largest LNG buyers, respectively. In Japan, LNG import declined by about 4% due to the mildest winter on record in addition to an industrial demand that was hit by COVID-19 in Q1 of 2020. In contrast, South Korea saw an uptick of about 7% in LNG import due to the government policy of turning off coal-fired power plants between December and March to improve air quality; March alone witnessed the shuttering of 28 coal-fired power plants, stimulating gas for power demand.

“That said, while the economic recovery is still very slow in Japan, we do see the La Nina weather pattern emerging for this winter and that will mean colder temperatures than last winter, boosting demand for heating,” the experts noted.

South Korea, meanwhile, may witness a 10% decline in LNG import due to higher availability of nuclear power plant and the assumption that government-mandated coal-fired plant closures may not be as aggressive as last year.

“In terms of pricing dynamics, as the markets move into a period of oversupply due to the growing convergence of global gas prices, it is important to keep an eye on the direction of gas hubs like the Henry Hub, TTF (Title Transfer Facility) and Asian spot price,” concluded the speakers.

The GECF lectures and workshops feature policymakers and experts, who are invited to share their knowledge and insights on contemporary issues related to the gas industry and its interconnected influencers of geopolitics and economy. These activities form part of the GECF long-term strategy to promote natural gas as the fuel of choice for sustainable development.

More information about the GECF Events can be found on www.gecf.org.

About Gas Exporting Countries Forum:

Gas Exporting Countries Forum is an international governmental organisation of 20 Member Countries – Algeria, Bolivia, Egypt, Equatorial Guinea, Iran, Libya, Nigeria, Qatar, Russia, Trinidad and Tobago, Venezuela, Angola, Azerbaijan, Iraq, Kazakhstan, Malaysia, Norway, Oman, Peru, and the United Arab Emirates, which jointly control 72% of the proven gas reserves, 46% of its marketed production, 55% of pipeline, and 61% of LNG exports across the globe. It is headquartered in Doha, Qatar.

Being a foremost energy association, officially established in 2008, the GECF has recorded notable milestones in its evolution and remains committed to supporting its Member Countries in the pursuit of global energy security and meeting the world’s growing energy demand, while proving to be reliable suppliers of natural gas – a prominent contributor in the global pursuit towards net-zero emissions energy systems and attainment of the 2030 Sustainable Development Goals.

The Forum provides granular, scientifically based insights into the state of natural gas based on the diverse variety of the instruments and deliverables such as the Gas Research Institute, the GECF Global Gas Model – now with elements of artificial intelligence and digital technologies, Global Gas Outlook 2050, Annual Short-Term Gas Market Report, Special Envoys on Data and Statistics, Data Exchange Mechanism, the Short-, Medium- and Long-Term Gas Market Reviews, Monthly, Quarterly and Annual Statistical Bulletins.

GECF increasingly engages with UN agencies, the G20 Ministerial Meeting on Energy Transitions and Global Environment for Sustainable growth, ASEAN, EEC, OPEC, OAPEC, APPO, IEF, IEA, IRENA, OLADE, IGU, other peers, and regional entities, as well as maintains strategic multifaceted dialogue amongst natural gas producers and consumers.

Hyundai’s acquisition of Boston Dynamics can reinforce its position in smart mobility, says GlobalData

Hyundai Motor Group has agreed to acquire approximately 80% stake in American engineering and robotics design company Boston Dynamics from SoftBank Group for US$1.1bn. The move can fuel Hyundai’s long-term goal to become a smart mobility solutions provider by leveraging Boston Dynamics’ robots such as bipedal and quadruped equipped with 3D vision, navigation and advanced intelligence, says GlobalData, a leading data and analytics company.

Venkata Naveen, Senior Disruptive Tech Analyst at GlobalData, says: “Hyundai’s move to acquire major stake in Boston Dynamics polarizes with many automakers competing to add their name to the me-too stack of autonomous carmakers by purchasing self-driving tech startups. Moreover, the strategic location of Boston Dynamics in the Silicon Valley gives an advantage to Hyundai to collaborate with tech startups as well as pool the right talent.”

‘In 2013, Google purchased Boston Dynamics to power its core robotic division and eventually create new robotics technologies for commercial applications. But the startup did not meet any commercial success and began losing talent after Google’s restructuring into Alphabet.

In 2017, SoftBank acquired Boston Dynamics to push its smart robotics capabilities. Apart from a few interesting videos of its humanoid and dog-like robots, there was no direct visible benefit to SoftBank.

Naveen continues: “Integrating Boston Dynamics’ robotic technologies with the automotive expertise can strengthen Hyundai’s position in smart mobility, especially in areas such as robo-taxis, personal air vehicles and last-mile mobility.”

The last two years saw both automakers and tech giants ramp up their bets on autonomous vehicles by acquiring startups into self-driving technology. Apple acquired Drive.ai, Amazon purchased Zoox and Daimler snapped Torc Robotics.

Naveen concludes: “In contrast, Hyundai’s acquisition of Boston Dynamics is the first in line of such strategies in the automotive industry to build a smart mobility ecosystem for faster, cheaper and sustainable transportation.”

- Quotes are provided by Venkata Naveen, Senior Disruptive Tech Analyst at GlobalData

- The information is based on GlobalData’s Disruptor Database

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData’s Disruptor Database

Disruptor Database decodes emerging tech-enabled opportunities with must-have information on promising start-ups, technology led innovations, latest sector trends, consumer insights, and venture capital portfolio investments. It helps monitor competitor strategies, predict emerging trends, monetize disruptive innovation, decode smart money, mine thought leadership, and capture digital consumers.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Metso Outotec to modernize Norilsk Nickel’s smelting line in Russia

Metso Outotec has been awarded a landmark contract by PJSC MMC Norilsk Nickel to modernize one of the company’s two existing smelting lines at their Nadezhda Metallurgical Plant in Norilsk, Russia. The contract value is approximately EUR 90 million, and the order has been booked in Metso Outotec’s fourth-quarter 2020 order intake.Metso Outotec’s contract includes engineering and delivery of a nickel flash smelting furnace and a heat recovery boiler with related automation and advanced digital products. Replacing the existing smelting line with the latest process technology and furnace structures will significantly increase the line’s capacity and availability, reduce metal losses and ease maintenance. The new line will also allow for the easy connection and efficient operation with potential future sulfuric acid production and neutralization projects. The delivery of the equipment will take place during the first half of 2022.

“Metso Outotec is a long-term partner of Norilsk Nickel, supplying state-of-the-art equipment and technologies. Our cooperation allows us to solve the most important production and technological issues, such as increasing the reliability and efficiency of production,” says Sergey Dubovitsky, Senior Vice President, Strategy, Strategic Projects, Logistics & Procurement at Norilsk Nickel.

Metso Outotec Smelting furnaces

Metso Outotec Smelting furnaces

“Norilsk Nickel operates the world’s largest nickel and palladium deposit in Russia. We are very committed to our long partnership with Norilsk Nickel, and we are pleased to have been awarded the contract to modernize their smelting line at Nadezhda. Our unique process expertise and sustainable technologies enable the design and delivery of a world-class smelting process that meets today’s and future production requirements,” says Jari Ålgars, President of Metso Outotec’s Metals business area.

Metso Outotec is a leading supplier of smelting technology, with about 40 operational smelting lines around the world. Metso Outotec’s Flash Smelting Process is the cleanest smelting method available, giving high recovery of metals with low investment and operating costs.

More information on Metso Outotec’s smelting technologies is available on the website.

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its illustrative combined sales for 2019 were about EUR 4.2 billion. The company is listed on the Nasdaq Helsinki. mogroup.com

Glacier Energy secures significant PBS contract

Glacier Energy, a leading international provider of specialist products, services and engineering solutions for energy infrastructure, has been awarded a contract worth circa £1 million by PBS for the provision of export gas coolers for Total Exploration and Production UK’s (TEPUK) North Alwyn Platform, in the North Sea.

The scope of work includes the design, fabrication, assembly, inspection, testing and supply of four shell and tube heat exchangers which will be carried out by Glacier Energy’s heat transfer solutions division, based in Aberdeen, UK. Work has already commenced on the units with four heat exchangers due for delivery in January 2021.

PBS is a new organisation based in Aberdeen which consists of three separate companies – Ponticelli UK Ltd, Brand UK Ltd and Semco Maritime Ltd. As of 1st May 2020, PBS has been awarded a five-year contract to provide general operations & maintenance services to all TEPUK assets in the North Sea.

Andy Scott at Glacier Energy's Heat Transfer Facility in Aberdeen

Andy Scott at Glacier Energy's Heat Transfer Facility in Aberdeen

Commenting on the award, Andy Scott, Director of Glacier Energy’s Heat Transfer division, said: “This is a significant award for the team that reinforces the strength of our design and manufacturing expertise, as well as our market-leading status in the heat transfer solutions field across the oil & gas, chemical and alternative energy industries.

“A key factor in securing this award was our close collaboration with the client and ability to provide a custom-engineered solution to eliminate potential and substantial modifications to the platform.

“We look forward to developing our relationship further with PBS and successfully completing the safe and efficient delivery of this project.”

At the core of the Glacier Energy brand, is the company’s deep-rooted capability amassed through the acquisition of some of the most technical and reputable brands in the industry. Formed in 2011, the company’s mission was to create a fresh alternative in energy services, providing customers with world-class technologies, exceptional service and enhanced value, all from one integrated provider.

In 2013, Glacier Energy acquired Ross Offshore, renowned specialists with decades of experience in the installation, repair, refurbishment and replacement of heat exchangers. This acquisition, a natural strategic fit for Glacier Energy’s offshore business, was then swiftly followed by the acquisition of MSL Heat Transfer in 2014, which strengthened the company’s capability in the design, manufacture and repair of radiators and coolers.

Today, Glacier Energy is made up of four divisions – heat transfer solutions, welding solutions, onsite machining solutions and inspection & NDT services. Operating throughout the UK, the company has a growing international presence with strategic partners operating in the Middle East, Caspian and USA.

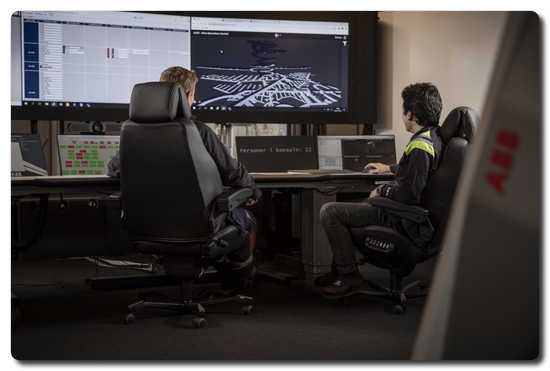

ABB leads electrification and automation innovation as part of Sustainable Underground Mining future mine project

ABB electrification and automation knowledge and solutions have been employed in a pioneering mine of the future project, which has ultimate ambitions to demonstrate zero carbon dioxide emissions and productivity increases of 50 percent.

ABB has provided electrification, connected control and operations management systems, high-visualization and mobile operator workplaces as part of a global mining partnership to visualize a once-in-a-generation technology shift and reduce climate impact.

Devised by LKAB, the Sustainable Underground Mining (SUM) project has the goal of setting a new world standard for sustainable mining at great depths in partnership with ABB, Combitech, Epiroc and Sandvik. The framework outlines ambitions for zero carbon dioxide emissions, completely safe mines for humans, productivity increases of 50 per cent and deeper mining.

ABB leads electrification and automation as part of the SUM project, image courtesy of LKAB and photographer Frederic Alm

ABB leads electrification and automation as part of the SUM project, image courtesy of LKAB and photographer Frederic Alm

ABB will continue to contribute its deep knowledge in electrification, automation and workplaces together with other suppliers to the mining industry. The collaboration aims to find new methods and smarter solutions for mining operations in the future. Test work in LKAB’s Kiruna mine, northern Sweden, as well as a virtual test mine will study the best way to build a carbon dioxide free and autonomous production system.

Within the mine, the Konsuln orebody is used to demonstrate future workplaces in a decentralized environment with efficient use of an autonomous electrical mobile transport system in a mixed environment. Real time process information is available to all organizations involved. When combined with the wider efforts of the SUM partnership, this shows a way of bringing completely new technology solutions to market for safer, more sustainable and more efficient mining production processes.

“We are taking significant strides towards a vision of the future operator environment through smarter working and demonstrable results,” said Jan Nyqvist, Global Product Manager for Underground Mining Automation at ABB, and one of the leaders in the project. “Electrification and automation are two important factors for the mining industry to continue its rapid, but effective, modernization. Sharing of information and data is crucial to reach substantial end goals.

“It is becoming increasingly common for suppliers to create dedicated collaboration groups to reach the best possible solutions for their customers. Collective successes and progress and the meeting of key targets for SUM, are initial evidence of the mutual benefits of collaboration.”

Overview of Kiruna mine location, image courtesy of LKAB and photographer Frederic Alm

Overview of Kiruna mine location, image courtesy of LKAB and photographer Frederic Alm

ABB has a relatively large team committing time to the project, with experts in digitalization and research, as well as electrification and automation.

“ABB is integral to the next step, which is to build a demonstration workshop to connect electrical and automation systems that have so far been developed for this challenging project,” said Jan Nyqvist. “We will, through various developed scenarios, be able to show how the systems work together.”

By 2022, the ABB electrification and automation solutions will be fully installed, and the aim is that a new standard for mining production will be set globally by 2030.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

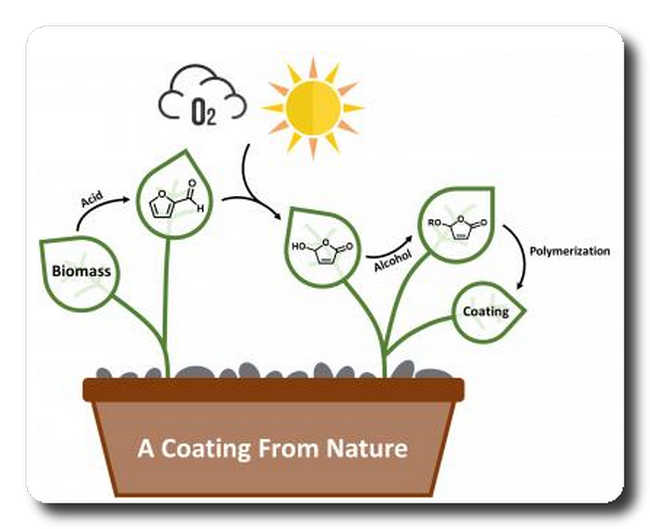

AkzoNobel unlocks more sustainable future for coatings after biomass breakthrough

A world of possibilities for paints and coatings has been unlocked by research being conducted by AkzoNobel, in collaboration with the Dutch Advanced Research Center Chemical Building Blocks Consortium (ARC CBBC).

The breakthrough innovation involves the development of a more sustainable way of making resins, which could pave the way for the introduction of futuristic functionality – such as intelligent paint that uses controlled release of active ingredients, or the ability to add new functionality during the lifetime of a coating.

The new process uses bio-based monomers to make the resins, rather than the traditional oil-based. Requiring just UV light, oxygen and renewable raw materials, patent applications have already been filed for resins and coatings made with monomers derived from sugar derivatives isolated from biomass.

“There’s no doubt we’re on the verge of progressing to the next level of coatings technology, thanks to this fantastic example of collaborative innovation in action,” explains Klaas Kruithof, AkzoNobel’s Chief Technology Officer. “We’re opening up a new future for paints and coatings by using sustainable building blocks that will enable us to explore and develop some really exciting functionalities for our customers.”

The process uses bio-based monomers to make the resins. Biomass is cracked by using acid to produce the sugar derivative (furfural). Using light and oxygen and adding different alcohols produces monomers that can be polymerized into polymers which are used in coatings; the monomers can also be used in coating formulations which are cured by UV-A light. CREDIT: GEORGE HERMENS AND PACO VISSER, UNIVERSITY OF GRONINGEN

AkzoNobel already produces many of its own resins, but in a bid to make the process more sustainable, the company has been working with the ARC CBBC, with most of this research taking place at the University of Groningen – where the team is led by professor in organic chemistry and Nobel Prize winner, Ben Feringa, and PhD student, George Hermens.

“Faced with the challenge of developing the sustainable chemistry of the future – a major goal of the ARC CBBC – I’m extremely pleased with these game-changing results,” adds Feringa. “They show that a material for coatings can be produced from biomass using a sustainable chemical process.”

Having started in 2018, the research project is still at a relatively early stage and a lot of work still lies ahead in order to optimize the monomers so they can be made in a more efficient way and on a larger scale. Estimates suggest it could be around five years before the first products start to emerge.”

“We’ve still got a long way to go in terms of exploring the scope of the technology, but it will almost certainly define the future of our products,” continues Kruithof. “By 2040 or 2050, there’s also a good chance we might only be using bio-based monomers in our resin production, which will help us to reduce the overall carbon footprint of our products.”

The biomass breakthrough is the latest example of the progress AkzoNobel is making in its search for sustainable solutions, having adopted a People. Planet. Paint. approach to sustainability. A detailed explanation of the science behind the development of the new process can be found in a research article which has just been published in the journal Science Advances.

About AkzoNobel

AkzoNobel has a passion for paint. We’re experts in the proud craft of making paints and coatings, setting the standard in color and protection since 1792. Our world class portfolio of brands – including Dulux, International, Sikkens and Interpon – is trusted by customers around the globe. Headquartered in the Netherlands, we are active in over 150 countries and employ around 32,000 talented people who are passionate about delivering the high-performance products and services our customers expect.