Displaying items by tag: abb

Tata Steel and ABB will jointly explore technologies to help reduce carbon footprint of steel production

Tata Steel Ltd and global technology leader ABB have signed a Memorandum of Understanding (MoU) and will work together to co-create innovative models and technologies to help reduce the carbon footprint of steel production. ABB will bring global experience in automation, electrification and digitalization for the mining and metals industries.

- The project will target improvements in energy efficiency, decarbonization and circularity in plants and production facilities

- Tata Steel is pursuing carbon neutrality by 2045 as one of its major sustainability goals

Tata Steel is among the top global steel companies with a crude steel capacity of 35 million tons per annum and is committed to major sustainability targets including achievement of carbon neutrality by 2045. In line with its aspirations, the steelmaker has a medium-term target to reduce carbon emissions to less than two tons of CO₂ per ton of crude steel in its Indian operations by 2025.

The two companies will focus on system-level assessments of Tata Steel’s manufacturing plants and production facilities for evaluation and co-development of short and long-term options for energy efficiency, decarbonization and circularity.

“Steel companies know there are opportunities to improve their processes, and Tata Steel is one of the leaders in this movement towards energy efficiency and reduction of carbon footprint,” said Vipul Gautam, Group Vice President, Global Account Executive for Tata Group, ABB. “World Economic Forum figures anticipate the energy transition will require as much as three billion tons of metals over the medium term; six times more mineral inputs by 2040 to reach net-zero emissions globally by 2050. ABB is confident in working with our customers and partners to evolve how steelmaking is powered to help reach production and environmental targets.”

Tata Steel is committed to sustainable development and growth as an integral part of its business philosophy. To ensure sustainable growth, the company is working on deployment of key enablers for deep decarbonization, including the use of more scrap in steelmaking, use of alternate fuels such as natural gas and green hydrogen, use of renewable energy and deployment of carbon capture and storage/utilization technologies. Tata Steel expects to increase capacity to 40 million tons by 2030 hence this collaboration with technology partner ABB is a key enabler to achieve that growth in a sustainable manner.

ABB and Tata Steel will explore energy optimization via hydrogen as an alternative fuel for upstream processes and energy reduction as well as substitution through fully integrated electrification and digital systems such as ABB Ability™ eMine and e-Mobility solutions and energy efficient motors.

The global steel industry contributes between 7 to 9 percent of global fossil fuel CO₂ emissions, according to various sources including the International Energy Agency (IEA).

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

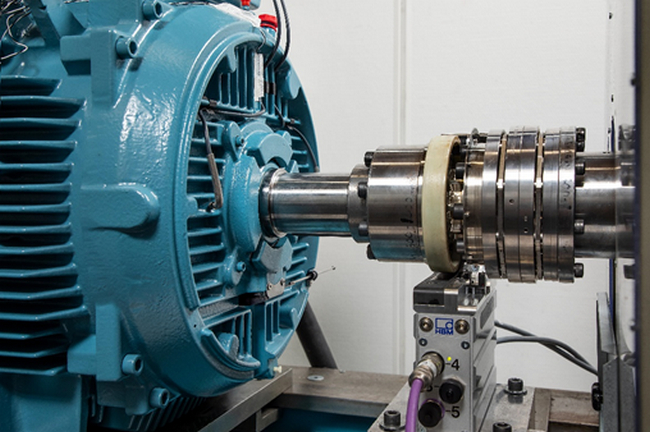

ABB is first in world to deliver IE5 ultra-premium motor efficiency in explosive environments

ABB has extended its award-winning IE5 SynRM (synchronous reluctance motor) series with a brand-new addition: the IE5 SynRM Increased Safety motor. In a world-first, customers operating in hazardous area industries can now ensure safety and boost their energy efficiency by deploying motors that offer up to 40 percent lower energy losses compared to commonly used IE3 motors.

- 40 percent lower energy losses in the most challenging of spaces: hazardous areas

- Cooler-running motor ensures a cost-efficient and competitive solution for increased reliability, lower maintenance needs and a longer life

The new version of the IE5 SynRM motor has been developed for use in potentially explosive atmospheres across a wide range of demanding variable speed industrial applications. It offers accurate control and high efficiency throughout the whole speed range, even at partial loads. This makes it the ideal upgrade choice for standard induction motors in pumps, fans and compressors for industries where explosive gas, vapor or dust might be present, such as oil and gas, chemicals, wood processing and flour milling.

In addition to energy savings, the new SynRM Increased Safety motors can help customers specify a more cost-effective installation. For example, in Zone 1, the cooler running design could allow the use of an increased safety motor where a flameproof motor with a special enclosure would be the traditional choice. While in Zone 2, the improved loadability of SynRM motors, that enables more power to be delivered from the same size as an induction motor, is important. This could enable a smaller, and therefore lower-cost, motor to fulfill the same duty.

Stefan Floeck, Division President IEC Low Voltage Motors, ABB, says: “We have achieved a significant world-first by bringing the benefits of IE5 ultra-premium efficiency to the hazardous area sector. Adopting best-in-class technology has made our IE5 SynRM motors a game-changer for operators in a wide range of industries. They see the capability to improve energy-efficiency as key to achieving their net zero ambitions while optimizing their business costs.”

A key benefit of IE5 SynRM Increased Safety motors is that they run cooler than standard designs. Bearing temperatures are reduced by up to 15°C and winding temperatures by up to 30°C. This provides increased reliability, prolongs the motor’s lifetime and reduces maintenance needs.

The SynRM design combines the performance advantages of permanent magnet technology, with the simplicity and service-friendliness of an induction platform. To ensure an environmentally friendly design, the motors don’t contain magnets or rare earth metals.

IE5 SynRM Increased Safety motors are available with output power of 5.5 to 315 kilowatt (kW) in frame sizes IEC 132-315.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Top aluminum producer and recycler Novelis to increase uptime following ABB modernization

Novelis Inc., a leading sustainable aluminum solutions provider and the world leader in aluminum rolling and recycling, is working with ABB to upgrade its third-party drives and controls system as part of a brownfield modernization project at its hot rolling mill in Oswego, New York, USA.

- ABB replacing outdated third-party installed base, including obsolete motor and generator sets at Oswego, New York, facility

- Retrofit will improve availability, reliability, energy efficiency, and productivity, while cutting downtime and maintenance

To futureproof the mill, ABB is replacing obsolete and outdated equipment with new switchgears, transformers, medium voltage drives, medium voltage synchronous motors, motor control centers and auxiliary controls, all integrated with the facility’s existing non-ABB control system. This will support Novelis’ ambitions for increased power capacity and reliability. Commissioning of the upgrade is expected by the end of 2023.

The Oswego mill was the company’s first US operation and is today the company’s largest, wholly owned fabrication facility in North America. It produces high-quality aluminum sheet for the automotive, beverage can, and building and construction markets. Novelis is also the world’s largest recycler of aluminum and seeks sustainability commitments from its supply chain as its customers look for environmentally friendly and circular aluminum products.

“In order to continue to provide our customers with the highest quality, sustainable aluminum sheet, and do so reliably, we are focused on increasingly optimizing our production output,” said Ganesh Panneer, Vice President of Operations, Novelis North America. “ABB is helping to ensure that we continue to have the highest levels of availability in our processes. The expertise of the ABB metals team, together with their commitments on providing the latest, most energy efficient products, will secure Oswego’s future as we maintain our leading position.”

“We’re proud to support Novelis in meeting their production targets, which promote efficient use of energy and other resources,” said Siraj Boudighar, Sales Manager North America for Metals, Process Industries, ABB. “By leveraging our long-term experience and in-depth knowledge of metals industry processes, including more than 400 references for modernization projects since the year 2000, we are able to tailor technology packages that meet the specific needs of each customer.”

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation

ABB awarded electrification and automation contract for ArcelorMittal Nippon Steel India’s new advanced cold rolling mill

ABB has been appointed to provide electrification and automation systems for ArcelorMittal Nippon Steel India’s (AM/NS India) advanced steel cold rolling mill (CRM) in Hazira, Gujarat. The contract at the flagship manufacturing plant comes through John Cockerill India Limited (JCIL), the original equipment manufacturer (OEM) for the project.

- Order placed through original equipment manufacturer John Cockerill India Limited (JCIL) for the new advanced steel processing lines at the client’s flagship Hazira plant in Gujarat

- ABB technology will support increased energy efficiency and optimized zinc consumption, leading to greater sustainability in the steel production process

- The electrification and automation contract is part of a large order placed with John Cockerill India Limited (JCIL)

AM/NS India – a joint venture between two of the world’s leading steel companies ArcelorMittal and Nippon Steel – is setting up the new CRM as part of its downstream expansion plan.

ABB is providing advanced electrification and automation systems, including the ABB Ability™ System 800xA distributed control system (DCS) and associated equipment and components, to support enhanced energy efficiency, optimized zinc consumption and high levels of corrosion resistance throughout the steel production process. This will support AM/NS India in its bid to reach greater levels of sustainability at Hazira.

“Our goal is to help create smarter steels for brighter futures, brighter futures for people and the planet. To do this, we place safety, innovation, and technology at the heart of our manufacturing operations and product development and ABB’s technology will support us in this,” said Mr. Dilip Oommen, Chief Executive Officer, ArcelorMittal Nippon Steel India (AM/NS India). “The new processing lines are designed to produce new-age value-added steel, embedding the most demanding quality standards. This expansion will help us meet the growing demand for high-end steel, while also enhancing our portfolio of value-added, sustainable steel.”

“We are proud of having been chosen by such a first-class steelmaker for the supply of two highly automated processing lines, combining cutting-edge equipment with integrated quality control and enhanced energy efficiency,” said Frédéric Midy, Project Director, John Cockerill Industry. “The fight against climate change is part of John Cockerill’s mission. This new contract will not only enable us to accompany AM/NS India on its journey towards sustainability but will also contribute to the country’s low-carbon economy ambitions.”

“The metals industry is essential for the transition to a net-zero world. Working with JCIL on this milestone project will support AM/NS India in developing one of the most sustainable, efficient, and modern steel operations,” said Vinod C, Local Division Manager, Process Industries, ABB.

The new CRM with advanced processing lines is due to be commissioned in 2024.

A leading integrated flat carbon steel producer in India, AM/NS India has a crude steel capacity of 9 million metric tons per annum with state-of-the-art downstream facilities. It produces a fully diversified range of flat steel products, including value-added steel, and has a pellet capacity of 20 million metric tons.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

ArcelorMittal Construction orders digital and control system technology for steel mill in France

ArcelorMittal Construction has awarded ABB a contract to deploy solutions specifically designed for metals processing at its cold rolling mill in Contrisson, France, as part of a modernization project. The solutions, which include ABB Ability™ Manufacturing Operations Management for metals (MOM4Metals), Roll-Gap (RGC) and Automatic Gauge Control (AGC), will help the world’s largest steel producer to bring productivity to a new level, improve quality and performance.

- ABB will install its Manufacturing Operations Management system (MOM4Metals) on cold rolling mill at Contrisson plant

- ABB will modernize technology for Roll-Gap Control (RGC) and Automatic Gauge Control (AGC) on the same mill

- ABB’s technology will help the steel producer to bring productivity to a new level, improve quality and performance

ABB MOM4Metals product, based on precise data analytics, improves information sharing, production planning, execution, reporting, asset monitoring and operational performance optimization. It is designed for and used in various metal production processes from rolling mills to processing lines delivering clear benefits over generic industry-agnostic MES platforms.

ABB is also modernizing advanced RGC and AGC technologies to reduce thickness deviations and off-gauge length. The project is expected be completed in the first quarter of 2024.

“ArcelorMittal Construction has placed its trust in ABB know-how and solutions for cold mill applications,” said Frederik Esterhuizen, Global Business Line Manager for Metals at ABB. “Through discussions with the customer we have been able to utilize our deep metals expertise to refine the ABB solution to meet their needs. ABB solutions enable cold rolling mills to improve and maintain performance and meet quality requirements in terms of thickness tolerances, flatness and surface characteristics via precise process control and equipment lifecycle management.”

“ABB will bring a combined MOM4Metals and RGC/AGC automation solution specific to metals processing to our modernization project at Contrisson,” said Frédéric Geoffroy in charge of process and automation department at ArcelorMittal Construction. “This stands out from standard automation and digital solutions and we are pleased that our needs can be met by one supplier with whom we have a long standing relationship at and beyond this site. ABB successfully revamped the drive of the cold rolling mill previously.”

“For ArcelorMittal Construction France, leader in the field of steel building envelopes, ABB supports us through its business solutions and allows us to offer our customers innovative solutions based on decarbonized and sustainable steel.”

Technology is a decisive factor in determining the quality of rolled products. ABB’s rolling mill solutions, including metals specific electrical, process automation and control technologies, leverage over 100 years of metals industry expertise to enable increased speed, reduced non-rolling time and threading problems while allowing for precise process control in terms of strip surface, flatness, thickness, off-gauge length and more to deliver improved strip quality, productivity and resource efficiency.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

New ABB SWIFTI™ industrial cobot delivers class-leading speed, accuracy and safety

ABB has launched the SWIFTI™ CRB 1300 industrial collaborative robot, bridging the gap between industrial and collaborative robots. Combining class-leading speed and accuracy with expanded load handling capability of up to 11kg, the SWIFTI CRB 1300 can be used in a wide variety of production and product handling applications – from machine tending and pelletizing to pick-and-place and screwdriving.

- SWIFTI™ CRB 1300 industrial collaborative robot is six times faster and five times more precise than other robots in its class

- Combination of high payload capability – up to 11kg - and speed improves production efficiency by up to 44%

- Features ensure safe deployment alongside workers and ease-of-use for non-robotics specialists

“Our customers are looking to robotic automation to make their processes more flexible, efficient and resilient, helping to counter labor shortages by enabling their employees to perform more value-added work,” said Andrea Cassoni, Managing Director for Global General Industry Robotics at ABB. “The latest addition to our SWIFTI family is a highly accurate, high payload cobot that’s up to six times faster than other robots in its class. This means it can be used by both SMEs and large manufacturers looking for collaborative automated solutions to achieve new levels of flexibility and productivity.”

Featuring a high-quality design, backed by expert support, the SWIFTI CRB 1300 incorporates several features that can improve production efficiency by up to 44 percent compared to other cobots in its class. In a typical palletizing application, SWIFTI’s speed and performance enable it to handle up to 13 boxes per minute compared to the nine boxes possible with other cobots in its class.

Powered by ABB’s OmniCore™ C30 and C90XT controller, the SWIFTI CRB 1300 is up to five times more precise than any cobot in its class, making it ideal for tasks requiring consistent accuracy and repeatability. This, combined with a top speed of 6.2m/s, and payload options from 7 kg to 11 kg and reaches from 0.9 to 1.4, enables the SWIFTI CRB 1300 to perform a range of higher payload tasks including screwdriving, assembly, pick-and-place, and palletizing. With protection against dust and moisture (up to IP67), it can also be used in demanding environments, making it ideal for machine tending applications.

If the laser scanner detects a worker within SWIFTI’s operating area, ABB’s SafeMove software will automatically slow the robot or stop it completely. As the worker moves away, movement will be restored, returning to full speed for full productivity only once the working area is completely clear. As a further protective measure, a built-in interaction status light provides a visual indication of the cobot’s status when a worker is within the workspace area. Integrating the scanner and software is simple, with SafeMove’s software add-ins enabling workers to quickly set up a safe working zone and other safety features using their handheld FlexPendant operating unit.

The same simplicity applies to programming the SWIFT CRB 1300. Users can set up the robot by either physically guiding it through a process (lead-through programming), or through ABB’s new Wizard Easy Programming software. Based on simple graphical blocks, Wizard Easy Programming makes programming accessible for non-specialists in robotics.

The SWIFTI CRB 1300 is part of a wider cobot portfolio covering payloads from 0.5 to 11kg, with options including the YuMi® single and dual-arm robots, the GoFa™ CRB 15000 and the SWIFTI CRB 1100 industrial collaborative robot for payloads up to 4kg. For more information, visit new.abb.com/products/robotics/collaborative-robots.

ABB (ABBN: SIX Swiss Ex) ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation.

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors - from automotive to electronics and logistics – become more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

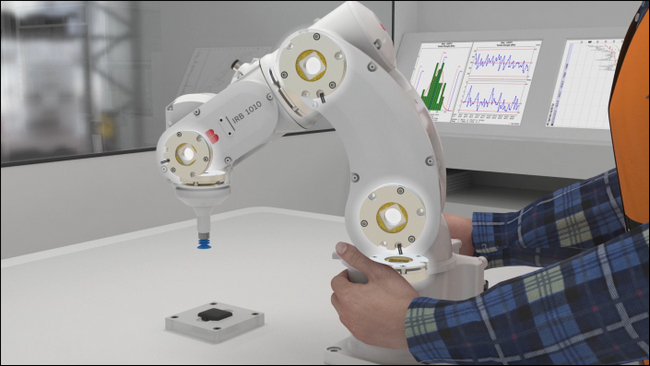

ABB unveils smallest industrial robot with class-leading payload and accuracy

ABB has launched its smallest ever industrial robot, offering new possibilities for faster, more flexible and high-quality production of wearable smart devices. With its compact size, class-leading payload and unrivaled accuracy, the new IRB 1010 offers electronics manufacturers the opportunity to increase their production of devices including smart watches, earphones, sensors, and health trackers through automation.

- New IRB 1010 designed to meet growing consumer demand for wearable smart devices

- Most accurate robot in class for 1.5 kg payloads for highest manufacturing quality, 50 percent higher payload than comparable robots on the market,

- Consumes 20 percent less energy using OmniCore E10 controller enabling manufacturers to improve energy efficiency, reduce costs

“The market for wearable smart devices is accelerating rapidly, with projections estimating double digit growth between 2022 and 2028,” said Rui Liang, Managing Director of ABB Robotics’ electronics business line. “To meet this growth, companies are demanding compact robotic solutions that are suited to narrow production spaces in electronics manufacturing lines and that can accurately handle the small components used in wearable devices. As the most accurate robot in its class for 1.5kg payloads, our IRB 1010 meets these demands, enabling companies to maximize output and productivity while maintaining the highest levels of product quality.”

The IRB 1010 is designed to suit the narrow spaces and special purpose machines typical of electronics production environments. With a reach of 370mm and a footprint of 135mm by 250mm, the IRB 1010 is 30 percent smaller than ABB’s current smallest robot, the IRB 120. These compact dimensions increase the number of cells that can be fitted into production spaces, enabling manufacturers to boost output through higher density factory layouts.

Capable of handling loads up to 1.5kg, the IRB 1010 has the highest payload in its class, with the ability to lift up to three times more weight than comparable robots. This increased payload capacity – coupled with a larger diameter air hose that provides added power for vacuum suction – enables simultaneous handling of multiple objects, allowing more objects to be processed per hour. It also opens opportunities for new applications including film peeling, material handling, assembly, gluing and inspection.

Capable of handling loads up to 1.5kg, the IRB 1010 has the highest payload in its class, with the ability to lift up to three times more weight than comparable robots. This increased payload capacity – coupled with a larger diameter air hose that provides added power for vacuum suction – enables simultaneous handling of multiple objects, allowing more objects to be processed per hour. It also opens opportunities for new applications including film peeling, material handling, assembly, gluing and inspection.

Productivity is further enhanced by the inclusion of six braking systems, which allow the robot arm to remain in its position even when stopped. By eliminating the time needed for the robot to recover its position after a stop or pause, production can be resumed more quickly, enabling the IRB 1010 to do more in less time than other robots in its class.

Key to the IRB 1010’s high accuracy is ABB’s OmniCore™ E10 controller, which offers class-leading position and path repeatability of 0.01mm. With its slimline design, the controller is well suited to small part assembly in applications where production cell sizes need to be minimized. The controller offers the flexibility to meet changing requirements, with built-in digital connectivity and over 1000 additional functions enabling easy scalability.

Consuming up to 20 percent less energy compared to ABB’s previous IRC5C controllers, the OmniCore E10 also enables manufacturers to cut their energy costs and improve energy efficiency.

Robot Control Mate makes programming simple

Programming the IRB 1010 is made simple with ABB’s Robot Control Mate. Available as an add-in to ABB’s RobotStudio® programming software, Robot Control Mate enables users to move, teach and calibrate the IRB 1010 from their computer or mobile tablets without the need for programming skills.

This simple programming, together with the small size of the IRB 1010, also opens new possibilities for educational applications. The IRB 1010’s compact design makes it suitable for installation on classroom desktops, while its ease-of-use enables both teachers and students to quickly master the skills needed for programming and operation.

The addition of the IRB 1010 complements ABB’s comprehensive range of articulated industrial robots, with includes a full range of small, medium, and large options, including a growing family of collaborative robots that can be safely deployed alongside workers.

For more information, visit www.abb.com/robotics.

ABB Robotics & Discrete Automation is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the world’s leading robotics and machine automation suppliers, we have shipped more than 500,000 robot solutions. We help our customers of all sizes to increase productivity, flexibility and simplicity and to improve output quality. We support their transition towards the connected and collaborative factory of the future. ABB Robotics & Discrete Automation employs more than 11,000 people at over 100 locations in more than 53 countries. go.abb/robotics

Brewing industry to benefit from new automation solution crafted by ABB’s brewmaster for brewmasters

ABB has launched its ABB Ability™ BeerMaker intelligent process control solution to further support breweries in their operational efficiency through digital transformation. ABB’s brewmaster, who has the notable achievement of qualifications from Technical University of Munich in Weihenstephan, devised the new package alongside a team with deep process know-how.

- Brewery-specific ABB Ability™ BeerMaker intelligent process control solution will support safety and quality improvements, boost productivity and raise operational efficiency

- Connectivity of plant processes will enable sustainable water and energy usage and drive effective digitalization in breweries

- Brewing teams will be empowered to take better decisions at the right time using modern interfaces and intuitive insights

It will benefit beermakers seeking to optimize their processes, reduce their impacts on water and energy resources and meet consumer demand for more sustainably crafted drinks. The new solution is based on the ABB Ability™ System 800xA® distributed control system and will help brewers improve process quality, achieve high engineering and operator efficiency, enhance safety and boost plant productivity. It has been made available to ABB’s end customers and channel partners.

As part of its launch, ABB Ability BeerMaker will be presented at this year’s drinktec, the world’s leading beverage and liquid food trade fair, held in Munich from September 12 to 16. The timing of the event coincides with the city’s Oktoberfest, which returns after a two-year break due to COVID-19 and runs from September 17 to October 3.

The process automation solution comprises a technological package including a control system with batch functionality following the worldwide S88 standard and a digital twin to simulate new recipes. Crafted and tested with brewing knowledge from ABB’s brewmaster, it can be adapted for each customer using a variety of parameters.

Ready-made and tested templates and objects bring a high level of automation and intelligence of plant functions into operators’ hands. There is a prepared inventory for queue handling, diagnostics and comprehensive cleaning in place (CIP) support.

Designed to meet the industry’s need for intuitive, visual solutions, BeerMaker will help to empower operators to manage their preferred operating procedures and have freedom to use the package on computers, tablet or mobile devices. Teams can gain greater process certainty by testing on a real-time digital twin, a complete and operational representation of the control system and a powerful tool for companies deciding on a new strategy to easily simulate new recipes.

Additional digital solutions based on ABB Ability™ Manufacturing Operations Management (MOM) have the capabilities to identify energy consumption, beer or extract losses and provide reporting functions and dashboard visualization. These include the ABB Ability™ BatchInsight concept, which can use big data analytics to identify process anomalies at the earliest stages. Operators and customer brewmasters will benefit from making decisions in real time to further improves processes, quality and productivity.

“Our new solution is from our own ABB brewmaster for brewmasters and truly has domain-specific knowledge embedded as well as ABB’s expertise from years in this field,” said Marcello Gulinelli, Global Head of Food and Beverage, Process Automation, ABB.

“We’re confident it is a technological package that is ready for advanced and digital solutions,” said Gernut van Laak, Brewmaster and Global Food and Beverage Solution Manager, ABB. “It can be applied within a customer’s installed base to enhance efficiencies and help reach sustainability targets.”

“We are using the full breadth of our automation and control system platform and connect the whole factory, including shop floor operations, simulation, digital and control room solutions, with less engineering and always with the possibility for expansion. We’re looking forward to further work with brewing customers to optimize to their plant specifics.”

Breweries will experience intuitive controls and high-performance human-machine interfacing, fast detection and resolution of process disturbances, consistent alarm messages, report management and standard operating procedures (SOPs), while engineers will benefit from a structured application design with process technology functions, and powerful pre-testing with built-in simulation.

ABB Ability System 800xA has helped the global technology leader to remain the #1 distributed control system market leader for 22 years as ranked by the ARC Advisory Group.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation

ABB launches five axis Delta robot fastest for lightweight product picking, packing & re-orientation

ABB is expanding its FlexPicker® Delta robot portfolio with the IRB 365. With five axis and 1.5kg payload, the IRB 365 is both flexible and the fastest in its class for reorientating packaged lightweight products such as cookies, chocolates, peppers, candies, small bottles, and parcels.

- New FlexPicker® IRB 365 picking robot fastest-in-class for picking and packing applications up to 1.5kg

- Flexibility to be used in a range of applications, from shelf ready packaging to parcel sorting and bottle handling

- Commissioning time reduced from days to hours with ABB PickMaster® Twin software

Responding to the rise in e-commerce and growing demand for shelf ready packaged goods, the IRB 365 has been developed for applications including food and beverage, pharmaceuticals and consumer goods, where production line speed and adaptability are essential.

“The IRB 365 can pick, reorientate and place 1kg products at 90 picks per minute,” said Roy Fraser, Global Product Manager for ABB Robotics. “Our customers saw that the growth in online shopping was driving the demand for shelf ready packaged goods, so we developed a new Delta robot that would rise to the challenge. By handling more products per minute, the IRB 365 robot increases productivity, while saving time and energy to make production more efficient.”

From product reorienting, top-loading and secondary packaging, to bottle handling, unscrambling, 3D picking, feeding and parcel sorting, the IRB 365 meets a wide variety of applications. Powered by the OmniCoreTM C30 controller - the smallest Delta robot controller on the market - the system offers best-in-class motion control, built-in digital connectivity, and 1000+ additional software hardware functions ready to meet future demands and requirements.

From product reorienting, top-loading and secondary packaging, to bottle handling, unscrambling, 3D picking, feeding and parcel sorting, the IRB 365 meets a wide variety of applications. Powered by the OmniCoreTM C30 controller - the smallest Delta robot controller on the market - the system offers best-in-class motion control, built-in digital connectivity, and 1000+ additional software hardware functions ready to meet future demands and requirements.

Through ABB’s PickMaster® Twin software, the IRB 365 can be integrated into packaging lines in a matter of hours rather than days, using digital twin technology, which also reduces changeover times from hours to just minutes.

As the latest member of ABB’s portfolio of robots for picking and packing, the IRB 365 can be paired with other robots including the IRB 390 to pick, handle and pack payloads weighing from a few grammes up to 15kg.

ABB Robotics & Discrete Automation is a pioneer in robotics, machine automation and digital services, providing innovative solutions for a diverse range of industries, from automotive to electronics to logistics. As one of the world’s leading robotics and machine automation suppliers, we have shipped more than 500,000 robot solutions. We help our customers of all sizes to increase productivity, flexibility and simplicity and to improve output quality. We support their transition towards the connected and collaborative factory of the future. ABB Robotics & Discrete Automation employs more than 11,000 people at over 100 locations in more than 53 countries. go.abb/robotics

ABB launches next-generation mine hoist control system drawing on 130 years of expertise

ABB announces the launch of ABB Ability™ NGX Hoist Control, a global control system enabling mining companies to achieve maximum performance and safety of hoist operations. Building on ABB’s reliable and proven past generations of hoist control systems, it brings new levels of reliability, flexibility and ease of use to smaller companies on greenfield projects or upgrades. It can also help larger companies reduce costs and improve efficiencies through standardization of control systems.

- Global technology company ABB is introducing a new standardized hoist control system for use by mining companies worldwide

- New ABB Ability™ NGX Hoist Control can adapt to any hoist and replace older and third-party systems, offering more flexibility than ever

- The launch comes 130 years after ABB’s first electrical motor for a mine hoist was commissioned in Sweden in 1891

ABB Ability NGX Hoist Control, which is set to be unveiled at Euro Mine Expo 2022 in Sweden next month, is adaptable to any type of hoist and can be used in upgrade projects replacing third-party control systems. The NGX Hoist Operating Station was designed with the latest ergonomic and human factors engineering guidelines and is based on the latest human machine interface (HMI) insights, offering the most modern and intuitive operator interface.

It can be easily integrated with other market leading ABB technologies including ABB Ability™ Safety Plus for hoists – the first fully SIL 3 certified hoist solutions which ensure the highest level of safety – which was first commissioned in 2019 on the world’s largest friction hoists. It is also compatible with advanced digital monitoring service ABB Ability™ Performance Optimization for hoists which continuously tracks the status of a mine hoist and improves uptime, availability, performance and productivity by providing actionable information on key performance indicators (KPIs) and provides remote access to ABB experts at all times.

“This exciting new launch follows the recent introduction of ABB Ability Safety Plus and is another milestone for greater levels of reliability, optimization and protection for mine hoists,” said Oswald Deuchar, Global Product Line Manager for Hoisting, ABB. “With ABB Ability™ NGX Hoist Control mine operators benefit from more flexibility and an improved user experience, including round-the-clock support and the ability to manage hoists for greater optimization. By implementing the same control system across plants OPEX can be further improved.”

“The health and safety of people working in mines, from our people to our customers’ employees, is of paramount importance at ABB,” said Max Luedtke, Head of Global Product Group, Mining Aluminium Cement and Vice President at ABB. “ABB Ability NGX Hoist Control is the latest example of this and follows the development of ABB Ability Safety Plus for hoists and of autonomous solutions including ventilation on demand and digital services. Together these improve the quality of the working environment, and enable remote supervision and autonomous operation, removing operators from hazardous areas.”

ABB will exhibit on Booth 188 in the Zink Hall at Euro Mine Expo 2022. The trade fair and conference is being held in Skellefteå Kraft Arena, Skellefteå, Sweden from Tuesday, June 14 to Thursday, June 16.

ABB draws on more than 130 years of experience in the mining industry and is a pioneer in the integration of electrification, automation and digitalization in mining. ABB is the sole supplier of complete mine hoist systems. ABB mine hoist solutions provide low life cycle cost, high reliability and system availability, short project execution time, and a single source of supply for complete systems, including service and spare parts.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation