Ian Melin-Jones

Russian petrochemical producers are well-positioned for market recovery post-COVID-19, says GlobalData

The COVID-19 outbreak has led to an unprecedented decline in demand affecting all sections of the Russian economy, which has impacted the demand for petrochemicals in the short-term.

However, the pandemic triggered an increase in the demand for polymers in food packaging, and cleaning and hygiene products. With Russian petrochemical companies having the advantage of access to low-cost feedstock, and proximity to demand-rich Asian (primarily China) and European markets for the supply of petrochemical products, these companies appear to be well-positioned to derive full benefits from an improving market environment and global economy post-COVID-19, says GlobalData, a leading data and analytics company.

Dayanand Kharade, Oil and Gas Analyst at GlobalData, comments: “Oil and gas majors in the country are reducing spend in response to a substantial drop in crude prices and disruptions caused by the COVID-19 outbreak. Sibur Holding, one of the largest petrochemical producers in Russia, has lowered its capital expenditure (capex) outlook for 2020, which is approximately 30% lower in comparison to its initial budget. However, companies continue to evaluate their capital structure and focus on key projects ensuring sustainable growth.”

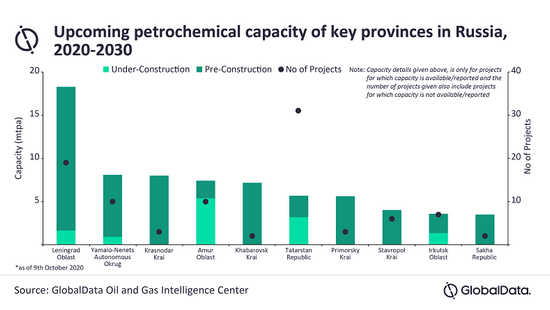

The majority of the upcoming projects in Russia are in the early stages of development, for example, pre-construction phase. Changes in supply/demand patterns, due to reduced economic activity across the globe, is likely to affect the pace of progress of these projects. Major announced projects such as Baltic Chemical project and EuroChem- Northwest Kingisepp project in Leningrad Oblast, and Gazprom and Novatek projects in Yamalo-Nenets Autonomous Okrug could face delays in startup. However, companies should continue to assess the impact based on prospective developments.

Kharade concludes: “With economic growth correlated to petrochemicals growth, the short-term outlook is expected to result in lowered petrochemical demand in the country. However, with an improving market environment, Russian producers are well-positioned to derive full benefit with the country’s access to low-cost feedstock.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make timelier and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors

AEG Power Solutions Launches its New Generation of Switch-Mode Power Supply Rectifier AC7000 N1

Extended lifetime and long-term spare part support for a highly reliable system

AEG Power Solutions, a global provider of power supply systems and solutions for industrial, critical infrastructure and innovative power electronic applications, have just announced the availability of its AC7000 N1 series - a new generation of its proven AC7000 industrial switch-mode power supply rectifier to ensure a future-proof and extended product lifecycle.

AC7000 N1 replaces both AC7000 and AC7000CAN series. Both have a long track record as reliable power supply for high output power applications in power generation and nuclear, Oil & Gas and petrochemical as well as transportation and signaling.

The new rectifier is very compact (19") and robust and ideal for all types of industrial applications. The output power of the system is 8000 W at 24, 110/120 and

220 VDC. Thanks to advanced protection (input, output, temperature, current, power) AC7000 N1 is highly reliable and benefits of a high MTBF (Mean Time Between Failure). The rectifier provides secured DC power in combination with a parallel battery, to supply all types of DC consumer loads including constant voltage and current sources such as central control rooms in nuclear and non-nuclear power plants as well as on-board power supplies for rail vehicles and ships.

AC7000 N1 benefits of AEG PS expertise in terms of robust design and is adapted to many types of batteries including vented lead acid, valve regulated lead-acid (VRLA) or nickel-cadmium batteries (NiCd).

AC7000 N1 has already met success and will be one of the key power supply system used in a major nuclear power plant project in Europe.

About AEG Power Solutions

AEG Power Solutions ensures continuous power availability and the safe operation of critical applications thanks to with a wide portfolio of power supply systems and services: AC and DC UPS, battery chargers, rectifier systems, service and maintenance on 24/7 basis, as well as fully customized UPS systems to customer specifications. AEG Power Solutions has developed a distinctive expertise and world-class engineering capacities that bridge both AC and DC power technologies and span conventional and renewable energy platforms. AEG Power Solutions has decades of experience with UPS and power electronics, and grid integration, and is leveraging its conversion expertise to engineer and deliver solutions for energy storage applications.

AEG Power Solutions is the sole subsidiary of the holding company 3W Power.

For more information, visit www.aegps.com

Vattenfall offers the state of Berlin complete takeover of the electricity grid

Vattenfall has offered the State of Berlin all shares in Stromnetz Berlin GmbH for sale. This will end years of dispute over the electricity concession and pave the way to continued development of the electricity grid - for the benefit of customers, employees and the citizens of Berlin.

The offer gives the State of Berlin the opportunity to take over the entire electricity network business and, together with Vattenfall, end the legal disputes that have been going on for many years.

“It was a difficult decision for Vattenfall to put Stromnetz Berlin up for sale. We are proud of this solid and well-managed company with its highly competent and committed staff. That is why we have been very committed to secure the electricity concession and to further develop the grid to meet the challenges of the “Energiewende” in Berlin,” says Magnus Hall, President and CEO of Vattenfall.

“It was a difficult decision for Vattenfall to put Stromnetz Berlin up for sale. We are proud of this solid and well-managed company with its highly competent and committed staff. That is why we have been very committed to secure the electricity concession and to further develop the grid to meet the challenges of the “Energiewende” in Berlin,” says Magnus Hall, President and CEO of Vattenfall.

“However, even after the recent success at the Berlin Court of Appeal, we cannot expect a timely concession decision in favor of Vattenfall. The prospect of further years of litigation not only places a burden on the company, but also makes it difficult to make decisions on the upcoming billion-euro investments. Such decisions can only be made with clarity on the framework conditions. That is why we would like to take a major step to finally settle the deadlock and seek cooperation with the State of Berlin on the way to a fossil free future," says Magnus Hall.

Vattenfall can now concentrate entirely on its business in Germany and devote all its attention and resources to fulfil its promise to make a fossil free living possible within one generation.

“Berlin will remain an important location for Vattenfall and we plan to invest heavily in the conversion to a fossil free heat supply in the city. This will contribute more than any other sector to the planned reduction of CO2 emissions in the German capital. In addition, we will enable over 1.3 million Berlin households to heat in a climate neutral way in the future. We will remain Berlin's largest electricity supplier and will continue to supply around 1.6 million electricity and gas customers in Berlin and 3.8 million nationwide. Now we want to pave the way for a good cooperation with the City of Berlin,” says Anna Borg, CFO and incoming CEO, Vattenfall.

The purchase offer to the State of Berlin is still subject to the approval of the Board of Directors at Vattenfall AB and the supervisory board at Vattenfall GmbH and the related antitrust authorities. If the State of Berlin decides to accept the offer, the transaction could be completed during the first half of 2021.

Valio’s researchers are the first to document the importance of ash-protein ratio in reduced sugar chocolate

Valio’s researchers discovered that '30% less sugar' chocolate made with milk-based protein is equal to regular chocolate in taste and texture. The optimal ash-protein ratio in the reduced sugar chocolate was linked to pleasant taste and texture. This solution allows manufacturers to make delicious ’30% less sugar’ chocolate without artificial sweeteners.

The current wellness trend means that consumers are looking for foods that support an active and healthy lifestyle. Yet, they want to enjoy eating and are reluctant to compromise on the taste, texture, or naturality of food. To reduce sugar consumption and the ill-effects of sugar, many countries have implemented sugar taxes.

“As a result of the wellness trend and sugar taxes, food and confectionery manufacturers are constantly looking for solutions to create tasty food products with reduced sugar content,” says Terhi Aaltonen, Development Manager and researcher at Valio.

The optimal ash-protein ratio gives '30% less sugar' chocolate the melt-in-your-mouth feel

Consumer acceptance is key in creating desirable and successful reduced sugar products. Both the reformulation and sensory properties of the products need to be acceptable. Valio’s researchers were able to produce an acceptable '30% less sugar' chocolate by replacing sugar with a milk-based protein.

“The control chocolate contained a standard sugar level and the trial chocolates had total sugar levels that were reduced by 30%. Consumers rated the chocolate samples according to their overall liking, liking of taste and texture and the attributes sweetness, saltiness and sandiness,” Aaltonen explains.

The ash-protein ratio, or the amount of salt and protein, proved critical in achieving the best possible consistency in ‘30% less sugar’ chocolate. The ash-protein ratio had the strongest positive correlation with the overall liking as well as the liking of texture and taste. The ash-protein ratio had the strongest negative correlation with sandiness.

Valio’s research findings were published in a peer reviewed article in the International Dairy Journal on February 7th, 2020.

Gut-friendly* sugar reduction with lactose free milk powder

Sugar in chocolate is commonly reduced by using either polyols, also known as sugar alcohols, or by adding fibre. Polyols can cause digestive discomfort if consumed in excess, and their use requires a warning label about laxative effects on product packaging.

“When the sugar reduction is achieved with Valio’s solution, that is lactose free milk powder, no such warning is necessary. It is possible to use the claim ‘reduced sugar’ as well as claim ‘protein source’ on these chocolates,” says Aaltonen.

Active research fuels Valio’s innovations

Active research is at the core of Valio’s innovativeness and has been throughout the company’s history. The strong R&D heritage has resulted in a Nobel prize as well as hundreds of published research papers. Thanks to active research, Valio can bring new ingredients and ways of implementing them to help food manufacturers gain new business and to support consumers in making healthy food choices.

*Contains calcium, which contributes to the normal function of digestive enzymes as a part of a healthy diet

Valio - The world’s most innovative dairy and food company

Valio’s mission is to create wellbeing and taste sensations in a responsible way. We make tasty products from milk and many other ingredients; we bring delightful tastes, variety and joy to the food table. We also carry out important roles in society: ensuring food security, enhancing public health and improving animal welfare are some examples of our impacts. In line with our mission, we are making life better. This is also the conclusion of the Finns who have chosen Valio as Finland’s most sustainable brand for seven consecutive years.

4,700 Finnish dairy farmers own Valio through cooperatives. We pay out all the profits to our milk producers through the milk price. We employ a total of 25,000 people at dairy farms. Valio has 4,000 professionals at work from different sectors and we listen to consumers with our more than 100 years of experience.

Nobel Laureate A.I. Virtanen’s legacy continues to live on with us. When he headed Valio’s laboratories, the concept of improving the wellbeing of people took root as our guiding principle. We turn science into products that make life better. Consumers in more than 60 countries enjoy Valio products, and we have 350 patents for our innovations around the world. We are Finland’s biggest food exporter and a trailblazer for the whole food industry. Valio’s sales in 2019 were EUR 1,787 million.

Celanese Launches blueridge™ Cellulosic Pellets as Home Compostable Alternative to Single-Use Plastics

Wood pulp and vinegar-based material works as potential replacement for hard-to-recycle, single-use plastic applications

Displaying a commitment to sustainable product developments and initiatives, Celanese Corporation (NYSE: CE), a global chemical and specialty materials company, has just launched a breakthrough cellulose-based material that aligns with ESG and circular economy objectives with a product that is both bio-based and broadly compostable.

To advance this effort, Celanese announces the commercial availability of its BlueRidge™ Cellulosic Pellets, a sustainability-inspired product intended to be an alternative to conventional plastics, both transparent and opaque, in difficult-to-recycle consumer applications. This material is both economically and technically viable, as well as rooted in sustainability from its raw materials to end-of-life compostability.

“We’ve studied how developments in sustainability impact the markets we serve and how we can better meet these growing demands; and we see the challenge of single-use plastic waste as one we are uniquely positioned to potentially tackle in a novel and significant way,” said Lori Ryerkerk, Celanese Chairman and Chief Executive Officer. “Today Celanese welcomes the launch of BlueRidge™ Cellulosic Pellets as the Company’s next leap forward with a sustainable and compostable alternative to plastic.”

Part of the BlueRidge™ material’s elegance is in the simple and sustainable chemistry that makes it work. It is based primarily on cellulose acetate, which is produced using cellulose from sustainably forested trees. The resulting BlueRidge™ material is recognized as being home and industrial compostable as well as broadly biodegradable in a range of environments, ultimately breaking down into glucose and vinegar, which are readily consumed in nature.

Production Capacity & Strength

Celanese is one of the world’s leading producers of cellulose acetate, with an annual production capacity of more than 300 kilotons globally. Celanese is also a leading global producer and supplier of engineered polymers with worldwide production capability providing local material supply to all regions of the world. This combined strength in cellulose acetate and polymer compounding capability enables Celanese to support the largest-scale demand for BlueRidge™ Cellulosic Pellets.

Consumer End Use Product Application Opportunities

Although its chemical composition is more that of paper than plastic, BlueRidge™ Cellulosic Pellets are designed to be processed on conventional plastics machinery to efficiently produce many of the products on which society depends. Additionally, the material can offer improved mechanical and temperature performance relative to other common bio-based and bio-degradable polymers, particularly as a fully transparent material. It is proving to be a material with potential value in many rigid single-use products, such as straws, cutlery, lids, containers and packaging, among many other uses. BlueRidge™ material provides new options for consumers to have more sustainable choices without having to sacrifice functionality and features.

Product Availability and Contacts

For additional information regarding BlueRidge™ Cellulosic Pellets, visit https://www.celanese.com/en/engineered-materials/products/blueridge to download the Company’s latest resource document on cellulosic pellet product development. To discuss end-use consumer product opportunities, contact a Celanese commercial representative at This email address is being protected from spambots. You need JavaScript enabled to view it..

About Celanese

Celanese Corporation is a global chemical leader in the production of differentiated chemistry solutions and specialty materials used in most major industries and consumer applications. Our businesses use the full breadth of Celanese's global chemistry, technology and commercial expertise to create value for our customers, employees, shareholders and the corporation. As we partner with our customers to solve their most critical business needs, we strive to make a positive impact on our communities and the world through The Celanese Foundation. Based in Dallas, Celanese employs approximately 7,700 employees worldwide and had 2019 net sales of $6.3 billion. For more information about Celanese Corporation and its product offerings, visit www.celanese.com or our blog at www.celaneseblog.com.

Emerson Launches Unique Heat Staking Technology to Meet Growing Demand for Complex Plastic Parts

Branson™ GPX platform provides greater design freedom by enabling high-quality joins and superior aesthetics in a range of challenging applications

Emerson has introduced new heat staking technology designed to give manufacturers greater design freedom by enabling them to join more complex, delicate and sensitive components to plastic moldings. Using a unique pulse staking technology that optimizes the heat staking process, the Branson™ GPX platform produces high-quality joins, superior product aesthetics and energy savings in increasingly challenging applications.

Electronics, automotive and medical device manufacturers must produce more creative designs to meet rapidly changing market demand. This has led to an increase in challenging heat staking applications involving parts with more complex 3D geometries, closely aligned features and fragile or heat-sensitive components, such as soldered components or sensors, and using a greater number of blended, glassreinforced, chromed and metallicized plastics.

The Branson™ GPX platform, with its unique heat-staking technology, provides greater design freedom by enabling high-quality joins and superior aesthetics in a range of challenging applications.

The Branson™ GPX platform, with its unique heat-staking technology, provides greater design freedom by enabling high-quality joins and superior aesthetics in a range of challenging applications.

The Branson GPX platform uses PulseStaker technology to provide instantaneous heating and cooling, with adjustable cycle times for optimized, low energy heat staking. The process creates no particulates or burn marks, and enables more delicate and sensitive parts, such as those with embedded electronics, to be joined with consistently high-performance finishes.

The advanced technology is suitable for all heat staking applications, including those with thermoplastic materials and metalized coated parts. A wide range of heat staking tip designs, which can be adapted to meet any stake welding requirement, and the ability to stake multiple points simultaneously provide manufacturers with greater design freedom.

“The automotive, electronics and medical industries require more complex, delicate and sensitive components to be joined to plastic moldings,” said Priyank Kishor, global product manager for Branson products at Emerson’s Automation Solutions business. “The unique heat staking process that the Branson GPX platform provides helps to meet this demand and offers manufacturers a broad range of benefits, such as superior product aesthetics and reduced energy use.”

For more information on the Branson GPX platform, visit www.Emerson.com/Branson.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximize production, protect personnel and the environment while optimizing their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com

German Startup makes decentral plastic waste recycling possible

Committed to finding solutions for some of the most challenging environmental problems, the community of Biofabrik has dedicated more than 7 years of researching and developing to present to the public a unique technology, which can convert plastic waste into energy. As one of the goals of the German start-up is to build hundreds of mini-recycling factories around the globe, the WASTX Plastic plant is also fully automatic and decentralized, which means it can be operated remotely.

This news comes in the wake of many recent initiatives and accomplishments of the Biofabrik company, including:

- Meeting all requirements for the transfer to serial production in 2019

- The successful endurance of long-term tests and multiple check-ups on the quality of the final product

- Implementing numerous improvements in the pilot plant, such as an optimized reactor technology and the highest safety standards.

Biofabrik Technologies GmbH

The Biofabrik team has successfully implemented two main technologies, which are currently on an international roll-out distribution: the WASTX Plastic and the WASTX Oil Plants. The WASTX Plastic technology is capable of processing plastic waste into energetically usable and tradable oil. Each plant can process up to 5,000 kg of plastic waste per day in a decentralized and fully automatic way.

The WASTX Oil technology transforms up to 3,000 litres of contaminated oil daily into a fresh base oil, which can be re-introduced into the cycle of materials. The WASTX Oil is currently the most compact system present in the world, that can solve the waste oil issue in every village and every city, regardless of location, bypassing the need to use large disposal companies.

Welltec asserts geothermal credentials with prestigious US initiative

Welltec® has been awarded a crucial role in an important project funded by the US Department of Energy (DOE) and led by the University of Oklahoma, to illustrate that near-field Enhanced Geothermal Systems (EGS) can be successfully deployed.

Welltec will be utilizing its extensive expertise from Completions and Interventions in the oil and gas sector to demonstrate that low permeability or unproductive Geothermal wells can also be turned into highly productive assets using EGS techniques. This will be achieved via the application of Welltec Annular Barrier (WAB®) technology.

The collaboration will see Welltec’s direct involvement in the Wells of Opportunity (WOO) project at the Coso Geothermal Field, further supporting FORGE objectives (Frontier Observation for Research in Geothermal Energy) to enable cutting-edge research, drilling, and technology testing to identify a replicable commercial pathway to EGS.

The collaboration will see Welltec’s direct involvement in the Wells of Opportunity (WOO) project at the Coso Geothermal Field, further supporting FORGE objectives (Frontier Observation for Research in Geothermal Energy) to enable cutting-edge research, drilling, and technology testing to identify a replicable commercial pathway to EGS.

“This is the second DOE project where a WAB has been selected as the preferred method for geothermal zonal isolation,” said Ricardo Vasques, VP Engineering, Welltec. “These awards will position the WAB as a ground-breaking technology for open-hole zonal isolation in geothermal environments and will ensure participation in additional DOE-funded projects,” Vasques added.

He went on to explain, “The all-metal WAB is being developed for the ongoing DOE-Welltec project where it will be applied as an integral part of the enhanced zonal isolation system for the EGS application in manmade reservoirs. The WABs will be deployed as part of the lower completion and will enable a precisely controlled hydro-thermo-chemical effective stimulation to enhance productivity from geothermal wells.”

Advanced technology to overcome geothermal challenges

In one of three projects totaling up to $10.4 million USD, the introduction of WAB technology will enable the controlled manipulation of hydraulic pressure, thermal stress, and geochemical dissolution, with the stimulated volume monitored via micro-seismic, tracer, and production data.

With FORGE having previously shown these considerations to be incredibly challenging, this will be a major step in well completions technology development and stimulation design, aided by utilizing advanced modelling to account for thermal stress factors, chemistry and fluid pressure.

According to the DOE, the research and development conducted through these selections will improve the tools, technologies, and methodologies used to explore, identify, access, create, and manage EGS resources, which are also critical to reducing development costs and risks.

Coso Geothermal Field

The Coso Geothermal Field is located in the eastern portion of central California where Welltec will also collaborate with the Coso Operating Company and Geologica – it is expected that activities will run at least until 2022.

Welltec® is a global technology company that develops and provides efficient hi-tech solutions for the energy industry.

The company’s cutting-edge products and services are designed to optimize the performance and integrity of a well in any environment. Through advanced engineering and lightweight design, Welltec’s solutions help clients reduce environmental emissions and carbon footprints in a safe and sustainable way.

With over 25 years of experience, Welltec is proud to collaborate with a growing number of international partners, providing technology to help further explore Enhanced Geothermal Systems (EGS).

About Frontier Observation for Research in Geothermal Energy

Middle East and Africa power industry contracts down 3% in Q3 2020

Middle East and Africa power industry contracts activity in Q3 2020 saw 84 contracts announced, marking a drop of 3% over the last four-quarter average of 87, according to GlobalData’s power database.

Middle East and Africa power industry contracts in Q3 2020: Iran leads activity

Looking at contracts by country, Iran led the activity in Q3 2020 with 13 contracts and a share of 15.5%, up 5.9% over the previous quarter and up 44% when compared with the last four-quarter average, followed by the United Arab Emirates with 13 contracts and a share of 15.5% and Saudi Arabia with 11 contracts and a share of 13.1% during the quarter.

Looking at contracts by country, Iran led the activity in Q3 2020 with 13 contracts and a share of 15.5%, up 5.9% over the previous quarter and up 44% when compared with the last four-quarter average, followed by the United Arab Emirates with 13 contracts and a share of 15.5% and Saudi Arabia with 11 contracts and a share of 13.1% during the quarter.

Looking at the last four-quarter average, Saudi Arabia held the top spot with ten contracts, followed by Iran with nine and Egypt with seven contracts.

Solar is top technology area for contracts in Q3 2020

Looking at contracts divided by the type of technology, solar accounted for the largest proportion with 22 contracts and a 42.3% share, followed by thermal with 15 contracts and a 28.8% share and wind with nine contracts and a 17.3% share.

Looking at power industry contracts divided by segment as tracked by GlobalData, T&D Project was the most popular segment in Middle East and Africa power contracts activity during Q3 2020, with 31 contracts, followed by Power Plant (24) and Generation Equipment (16).

The proportion of contracts by category tracked by GlobalData in the quarter was as follows:

- Project Implementation: 32 contracts and a 38.1% share

- Supply & Erection: 20 contracts and a 23.8% share

- Consulting & Similar Services: 17 contracts and a 20.2% share

- Power Purchase Agreement: 11 contracts and a 13.1% share

- Repair, Maintenance, Upgrade & Others: three contracts and a 3.6% share

- Electricity Supply: one contract and a 1.2% share.

Power contracts in Q3 2020: Top issuers by capacity

The top issuers of contracts for the quarter in terms of power capacity involved in Middle East and Africa were:

- Emirates Water and Electricity (United Arab Emirates): 2,000MW from one contract

- Societe Nationale d’Electricite (Democratic Republic of the Congo): 1,000MW from one contract

- ACWA Power International (Saudi Arabia): 900MW capacity from one contract.

Power contracts in Q3 2020: Top winners by capacity

The top winners of contracts for the quarter in terms of power capacity involved in Middle East and Africa were:

- EDF Renewables (France): 2,087.2MW from two contracts

- Jinko Power Technology (China), Abu Dhabi Future Energy (United Arab Emirates) and Abu Dhabi National Energy (United Arab Emirates): 2,000MW from one contract

- SkyPower (Canada): 1,000MW capacity from one contract.

All publicly-announced contracts are included in this analysis drawn from GlobalData’s Power database, which covers power plants, T&D projects, equipment markets, analysis reports, capacity and generation, and tracks tenders and contracts on a real-time basis.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

Metso Outotec and Boliden renew their service contract for the Aitik copper mine in Sweden

Metso Outotec and Boliden have signed an extension of their service contract for Boliden’s Aitik copper mine in Gällivare, Northern Sweden. The 3+2-year extension of the Life-Cycle Services agreement covers the supply of mill lining, chute lining solutions, preventive maintenance of the grinding circuit and recycling of used wear parts. The value of the order will not be disclosed. The first part of the contract has been booked in Metso Outotec’s orders received in Q3, 2020.

The contract is a performance-based cost-per-ton agreement, in which Metso Outotec gets paid according to the output of the customer’s process. The goal is to ensure the availability of the grinding circuit and to maximize valuable production time, striving for a common goal that benefits both parties.

Long partnership developing responsible mining business

Metso Outotec and Boliden have cooperated since the 1960s. Throughout the decades, the collaboration has evolved to meet new emerging needs, while continuing to improve uptime and annual production.

Safety is Boliden’s top priority and enhancing it is also embedded in the scope of the new contract. Metso Outotec will provide solutions that simultaneously cut maintenance time and increase the wear life of parts even further. The new contract also focuses more on the management of worn wear parts, because Metso Outotec will develop capabilities to recycle and dispose them more sustainably. The AG mills in Aitik will continue to use Metso Outotec’s innovative Megaliner(TM) mill lining.

Megaliner speeds up maintenance

Megaliner helps to maximize the availability of large mills by utilizing an innovative design that speeds up liner replacement. The larger-than-average liners mean that fewer individual pieces are needed. Megaliner also has fewer attachment points compared with conventional liners, further improving installation and removal time. It also improves worker safety during maintenance, because the liners are bolted into position from outside the mill.

The pebble mills and two regrind mills will be lined with rubber and Poly-Met mill linings.

Aitik is one of the largest copper mines in Europe. In 2019, the mine produced close to 41 kt of copper, employing nearly 800 people.

For further information, please contact:

Heikki Metsälä, Senior Vice President, Mill and Chute business line, Metso Outotec, tel. +358 20 484 100, email: heikki.metsala(at)mogroup.com

Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing, metals refining and recycling industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.

Headquartered in Helsinki, Finland, Metso Outotec employs over 15,000 people in more than 50 countries and its pro forma sales for 2019 were about EUR 4.1 billion. The company is listed on the Nasdaq Helsinki. mogroup.com, twitter.com/metsooutotec