Ian Melin-Jones

TOOLING - Roll-Kraft begins lean processes for tube and pipe and roll forming tooling production

Recently implemented methods initiated by Roll-Kraft’s Lean Manager, Kevin Hartman, have resulted in an immediate reduction of waste material in the tube and pipe and roll forming tooling production process by 43%. This is the first of several improvements expected to be realized over the coming months, as various processes are reviewed and modifications identified.

Recently implemented methods initiated by Roll-Kraft’s Lean Manager, Kevin Hartman, have resulted in an immediate reduction of waste material in the tube and pipe and roll forming tooling production process by 43%. This is the first of several improvements expected to be realized over the coming months, as various processes are reviewed and modifications identified.

“We are taking significant measures in our industry to practice Lean,” said Roll-Kraft president Chuck Gehrisch. “These waste reduction improvements that Kevin and his team have achieved will directly benefit our customers by helping us improve our industry-leading 98% on-time delivery and 97% first-time performance rates.

“We look forward to further improvements in the near future and are committed to keeping our customers and the industry informed of our continued progress on these Lean initiatives.”

Roll-Kraft is consistent in its on-going search for ways to go beyond the expectancy of the customer. This constant focus has made Roll-Kraft a leading provider of roll tooling to tube and pipe and roll form producers around the world, as companies identify Roll-Kraft as a single-source supplier, from initial roll tooling design, to training, to first-time performance when the tooling is installed on their mill.

Roll-Kraft has its headquarters in Mentor, Ohio, and maintains other facilities in Frankfort, Illinois (Roll-Kraft Northern), and Ontario, Canada (Roll-Kraft Ltd.). Calls to the company‘s main line, (888) 953-9400 or (440) 205-3100, are greeted by a live operator who can assist callers in quickly reaching a technician, engineer, or sales staff, who can provide immediate assistance. The fax number is (440) 205-3110. Please also visit the website at roll-kraft.com. For easy and immediate contact with Roll-Kraft that transcends time zones and working hours, the website features Dr. Resolve. Simply complete and submit an on-line form and Roll-Kraft will respond.

EuroBLECH 2014: Sheet metal working industry keeps focus on international business

Sheet Metal Working Industry Keeps Focus on International Business

From 21-25 October 2014 the international sheet metal working industry will meet again for its leading industry fair EuroBLECH 2014 in Hanover, Germany. A total of 1,411 exhibitors from 41 countries have to-date booked their stands, covering 86,500 m2 of net floor space across eight halls of the Hanover Exhibition Centre. This represents a 3% increase in exhibition space compared to the previous show.

Major exhibitor countries next to Germany are Italy, China, Turkey, the Netherlands, Spain, Switzerland, Austria and the USA. Half of all exhibiting companies come from outside Germany. This high percentage of international exhibitors once again confirms EuroBLECH’s position as the world’s No 1 exhibition for the sheet metal working industry. It also demonstrates that the industry sector continues to focus on international business contacts in order to be successful with their products in the long run.

“The sheet metal working industry is currently facing an economic environment of diverse regional market situations within our globalised world. In addition, there is a demand for an ever-growing choice of products which needs to be met by using innovative and flexible fabrication processes. In this challenging but highly promising environment, it is essential for companies in the sheet metal working industry to invest in innovative technologies and tailor-made machines and systems. Intelligent process chains and efficient networks are indispensable,” explains Nicola Hamann, Exhibition Director EuroBLECH on behalf of the organisers, Mack Brooks Exhibitions.

Smart solutions for modern production

“As the technological showcase and business barometer of the sheet metal working industry, EuroBLECH offers its audience a comprehensive overview of the prevailing technological trends. For companies in sheet metal working looking to find suitable machinery and smart solutions for modern production, the exhibition is the key global event. Visitors can find an extensive product range, from conventional systems through to advanced, high-tech processes and also gain an overview of what is available worldwide,” says Nicola Hamann.

The show profile of the 23rd International Sheet Metal Working Technology Exhibition represents the entire sheet metal working technology chain: sheet metal, semi-finished and finished products, handling, separation, forming, flexible sheet metal working, joining, welding, tube / section processing, surface treatment, processing of hybrid structures, tools, quality control, CAD/CAM systems, factory equipment and R&D. EuroBLECH 2014 will once again be held in halls 11, 12, 13, 14, 15, 16, 17 and 27 at the Hanover Exhibition Grounds.

With its dedicated exhibition profile, EuroBLECH targets all sheet metal working specialists at every management level in small and medium-sized companies as well as large enterprises. Visitors include engineers, production managers, quality managers, buyers, manufacturers, technical directors and experts in associations and R&D.

Visitor information

A visitor brochure including important information for trade visitors to EuroBLECH 2014 can now be ordered in twelve separate language versions at www.euroblech.com. The show website also offers detailed information about the exhibition as well as photos and videos, an up-to-date exhibitor list and useful tips on travel and accommodation.

Interested visitors can also subscribe to the EuroBLECH Bulletin, a regular online newsletter offering the latest updates on the exhibition as well as industry news and articles about the products being showcased in October in Hanover.

The show website also features the EuroBLECH Job Board. Specialists in sheet metal working looking for a new challenge in their career can reach employers worldwide. Job vacancies and candidate profiles are advertised on the EuroBLECH website, through the exhibition app which will be live two weeks before the show, as well as on-site at the exhibition. Taking part as a candidate is free of charge and further details are available within the visitor section of the website.

EuroBLECH 2014 is open from Tuesday, 21st October to Friday, 24th October 2014, from 09.00 – 18.00 and on Saturday, 25th October 2014, from 09.00 – 15.00.

SERVICES - Metso wins a contract to supply services solutions to Codelco's Chuquicamata mine in Chile

Metso's services solutions will improve the operational reliability and process efficiency of Codelco's grinding process.

Metso has signed an 18-month services contract with Codelco's Chuquicamata mine. Codelco is the biggest state-owned enterprise in Chile and the world's largest producer of copper.

Metso has signed an 18-month services contract with Codelco's Chuquicamata mine. Codelco is the biggest state-owned enterprise in Chile and the world's largest producer of copper.

The contract covers changing the components to 33 ball mills currently operating in the A0 and A1 plants in the Codelco Chuquicamata mine. The work will involve changing the pinion-gear assembly as well as repairs to the shell. Metso will repair two mills per month and also take care of the continuous monitoring of the status of the equipment. The value of the new contract will not be disclosed.

"Codelco chose Metso due to our expertise in similar type of projects. Metso's specialized, high-quality services are focused on optimization and improved reliability of the mills. As a result, the customer will gain the desired return on their investment", states Eduardo Nilo, Services Director for Metso's Mining and Construction in Chile.

The agreement, which covers gear disassembly, new gear assembly, pinion assembly, gear alignment (slow rotation) and mantle repair, will take effect in April 2014. The contract will create 30 new Metso services jobs in the Northern part of Chile. The order has been included in Metso Mining and Construction's Q1 2014 orders received.

Proven track record in safety

A services supplier's safety performance is highly important for the global mining industry and an important factor behind Codelco's decision to choose Metso as a services supplier for Chuquicamata.

Metso's commitment to Health, Safety and Environment is framed through its global policy and the high standards implemented locally. As a consequence, Metso has been able to reduce the lost time incidents significantly. Our 750 employees in Chile have operated more than two years without any lost time incidents. The Association of Major Suppliers for Mining in Chile awarded Metso for its safety results in 2013.

Experience in field services

Metso has a long history of offering specialized engineering services, maintenance and emergency repairs for the mining industry through its technical team of field engineers. Metso has provided millions of solutions during its more than 40 years in Chile. Metso's solid track record in providing and optimizing customer assets as well as its deep knowledge of user technology and processes makes it one of the leading providers of integrated solutions with experience in highly complex tasks.

In 2012, Metso supplied three large MP1250 cone crushers and an automatic control system to the Chuquicamata mine.

Codelco is the largest mining company in Chile. The Chuquicamata Division operates two copper and molybdenum producing mines: Chuquicamata and Mina Sur. By excavation volume, Chuquicamata is world's largest open-pit copper mine.

Metso's mining and construction professionals specialize in always bringing the right technology, processes, machinery and services to our customers in aggregates production, construction, mining and minerals processing and in metal and waste recycling. Expect results

Metso is a leading process performance provider, with customers in the mining, construction, and oil & gas industries. Our focus is on the continuous development of intelligent solutions that improve sustainability and profitability. Metso's shares are listed on the NASDAQ OMX Helsinki Ltd. Metso employs around 16,000 professionals in 50 countries. Expect results.

For further information, please contact:

Eduardo Nilo, Services Director, Chile, Mining and Construction, Metso, tel: +56 2 2370 2000, This email address is being protected from spambots. You need JavaScript enabled to view it.

STEEL - Outokumpu delivers 4,000 tonnes of stainless steel to the Husab mine in Namibia

Outokumpu delivers about 4,000 tonnes of LDX 2404 duplex stainless steel for the Husab uranium mine project in Namibia, Africa. Outokumpu stainless steel will be used in tanks, pressure vessels, clarifiers and columns. The deliveries have started and they will continue until September 2014.

Outokumpu delivers about 4,000 tonnes of LDX 2404 duplex stainless steel for the Husab uranium mine project in Namibia, Africa. Outokumpu stainless steel will be used in tanks, pressure vessels, clarifiers and columns. The deliveries have started and they will continue until September 2014.

The Husab Mine project is owned by Swakop Uranium and the project is led by Husab Project Joint Venture. Once completed, Husab will be one of the three largest uranium mines in the world.

Chris Tsai from Swakop’s majority shareholder China General Nuclear Power Corporation comments: “Leaching and counter current decantation processes as well as tanks fabricated at the site are one of the critical parts of the Husab project. Based on the excellent corrosion resistance, LDX 2404 has been chosen as the main construction material for the main body of tanks.”

“The Outokumpu LDX 2404 is the most suitable grade for this project due to its superior combination of corrosion and wear resistance and excellent mechanical properties. The wear resistance in particular is important, as the processed slurry contains high amounts of solid material. For the customer, LDX 2404 also gives clear benefits, such as lower overall cost. The grade enables thinner tank walls, requiring less material. Outokumpu delivers 2 meter wide stainless steel which results in less welding and fewer plates to manage. Furthermore, the expected lifecycle cost is low, since stainless steel requires very little maintenance,” says Johan Karlsson, General Manager of Outokumpu in South Africa.

“The Outokumpu LDX 2404 is the most suitable grade for this project due to its superior combination of corrosion and wear resistance and excellent mechanical properties. The wear resistance in particular is important, as the processed slurry contains high amounts of solid material. For the customer, LDX 2404 also gives clear benefits, such as lower overall cost. The grade enables thinner tank walls, requiring less material. Outokumpu delivers 2 meter wide stainless steel which results in less welding and fewer plates to manage. Furthermore, the expected lifecycle cost is low, since stainless steel requires very little maintenance,” says Johan Karlsson, General Manager of Outokumpu in South Africa.

FLSmidth is the engineering company that designed the first tanks for the Husab project. Pedro Miguel Teixeira from FLSmidth comments: “The cooperation with Outokumpu has worked well. Delivery was done on time and the quality of the product and service has been extremely professional.”

Michael van Kan from Husab Project Joint Venture says: “It was crucial for the project to select the right grade to ensure the optimal mix of strength and corrosion resistance for the process requirements. Outokumpu provided the Husab project with world class service from grade selection advice to technical support for the products. Husab Project Joint Venture will recommend Outokumpu for the supply of stainless steel because they offer a quality product with excellent service backup.”

Outokumpu is dedicated to good delivery accuracy which is very important in mining projects. In the Husab project, door-to-door deliveries from the mill to the fabricators were required. Outokumpu has this as a standard service in South Africa.

Outokumpu is a global leader in stainless steel. We create advanced materials that are efficient, long lasting and recyclable – thus building a world that lasts forever. Stainless steel, invented a century ago, is an ideal material to create lasting solutions in demanding applications from cutlery to bridges, energy and medical equipment: it is 100% recyclable, corrosion-resistant, maintenance-free, durable and hygienic. Outokumpu employs more than 12 000 professionals in more than 30 countries, with headquarters in Espoo, Finland and shares listed in the NASDAQ OMX Helsinki. www.outokumpu.com

For more information:

Saara Tahvanainen, tel. +358 40 589 0223

AUCTION - Liquidity Services Conducting Auction for Bottling Equipment from PepsiCo

Bidding open at Liquidity Services’ online marketplace www.Go-Dove.com for array of surplus bottle filling and packaging equipment from across Europe

Liquidity Services, Inc., a global solutions provider in the reverse supply chain with the leading online marketplace for business surplus, is conducting an online auction for PET bottle blowing, filling, and packaging equipment no longer needed by PepsiCo in Europe. This sale features a diverse array of lots available as a whole or as individual machines. This includes: complete AVE ultra-clean bottling filling line with dosing systems (line capacity from 8,000 to 12,000 bph, bottle range capacity from 250ml - 1ltr bottles), as well as a PET bottling filling and packing line (capacity of up to 8,000 bph). These surplus assets will be sold via Liquidity Services’ online marketplace, www.Go-Dove.com.

Liquidity Services, Inc., a global solutions provider in the reverse supply chain with the leading online marketplace for business surplus, is conducting an online auction for PET bottle blowing, filling, and packaging equipment no longer needed by PepsiCo in Europe. This sale features a diverse array of lots available as a whole or as individual machines. This includes: complete AVE ultra-clean bottling filling line with dosing systems (line capacity from 8,000 to 12,000 bph, bottle range capacity from 250ml - 1ltr bottles), as well as a PET bottling filling and packing line (capacity of up to 8,000 bph). These surplus assets will be sold via Liquidity Services’ online marketplace, www.Go-Dove.com.

“Liquidity Services is pleased to partner with PepsiCo to streamline surplus asset sales processes, enhancing its environmental sustainability by extending the life of surplus assets and increasing recovery on otherwise idle equipment.”

Bidding is open and closes May 22nd at 12 pm BST (4 am PDT). Potential bidders can register for the auction event and place bids at https://international.go-dove.com/en/event-18625.

“This sale is a tremendous opportunity for businesses to acquire surplus bottling equipment ready for operation from a Global 500 company,” said Nick Taylor, Vice President of Global Valuations and Sales for Liquidity Services’ Capital Assets Group. “Liquidity Services is pleased to partner with PepsiCo to streamline surplus asset sales processes, enhancing its environmental sustainability by extending the life of surplus assets and increasing recovery on otherwise idle equipment.”

Below is a partial list of items available for sale from locations in the UK, Greece, and Poland:

- Complete AVE ultra-clean bottling filling line including dosing systems (2005)

- AVE 'NH-EFS 30/30/40/8' Ultra-clean liquid filling line (2007)

- Krones 'Autocol' Self-adhesive labeller (2001)

- Krones 'Vario-Pac TF30' Tray film shrink wrapper (2005)

- Dimac 'Star T 30' Wrap-around case bottle packer (2006)

- Dawson 'BHP048' de-palletiser (2002)

- Nate Chotebor 'VSN18' Skid mounted syrup mixing & dosing system (1998)

- AVE 'RAHNOX RAI 28SX' Inline bottle rinsing machine (1990)

To view a complete list of all upcoming equipment sales, please visit: www.Go-Dove.com

Liquidity Services allows professional buyers to acquire quality used capital assets from any location around the globe. Bidders can evaluate available equipment from an online platform and easily purchase assets via a transparent auction process. The GoIndustry DoveBid marketplace www.Go-Dove.com provides buyers a safe, easy and secure purchasing experience, which includes buyer support services, logistics, and multiple payment methods.

About Liquidity Services, Inc.

Liquidity Services, Inc. (NASDAQ: LQDT) provides leading corporations, public sector agencies, and buying customers the world's most transparent, innovative, and effective online marketplaces and integrated services for surplus assets. On behalf of its clients, Liquidity Services has completed the sale of over $4.7 billion of surplus assets in over 500 product categories, including consumer goods, capital assets, and industrial equipment. The company is based in Washington, D.C. and has more than 1,300 employees. Additional information can be found at: http://www.liquidityservices.com.

Liquidity Services, Inc.

Sultana F. Ali, APR, 202-467-5723

This email address is being protected from spambots. You need JavaScript enabled to view it.

IRON ORE - Outotec awarded two 3-year contracts by Samarco for shut-down services

Outotec has been awarded two contracts for the management and execution of shut-down services of Samarco's four iron ore pellet plants in Brazil. These contracts, to be carried out together with Samarco's own personnel, will last until the end of 2016. The first year's services have been booked in Outotec's 2014 first quarter order intake.

Outotec has been awarded two contracts for the management and execution of shut-down services of Samarco's four iron ore pellet plants in Brazil. These contracts, to be carried out together with Samarco's own personnel, will last until the end of 2016. The first year's services have been booked in Outotec's 2014 first quarter order intake.

Samarco has, in total, four pellet plants at its manufacturing facility in Ubú, in the state of Espírito Santo. Outotec has designed, supplied and installed the two newest indurating furnaces at the facility, both of which incorporate the use of Outotec core technology. The fourth indurating furnace, in the largest plant of its type in the world, was successfully commissioned in March 2014 and it is currently undergoing ramp-up of production with Outotec's operational support.

Outotec has already performed several big shut-down campaigns for Samarco. Over 250 workers have been involved in the last repair, which was finalized ahead of schedule with a zero accident rate.

"Samarco is a major producer of iron ore pellets and our long-term partner. The new service contracts are a further step towards a real life-cycle partnership between our companies. Acquired in 2012, Demil Manutenção Industrial in Guarapari played a significant role in this case. With the purchase, Outotec took over two on-going long-term maintenance contracts for Samarco's pelletizing and filtration areas. By combining our resources we can provide the full range of maintenance, shut-down and technical services for our customers", comments Kimmo Kontola, head of Outotec's Americas region."

Outotec provides leading technologies and services for the Sustainable use of Earth’s natural resources. As the global leader in minerals and metals processing technology, we have developed many breakthrough technologies over the decades for our customers in metals and mining industry. We also provide innovative solutions for industrial water treatment, the utilization of alternative energy sources and the chemical industry. Outotec shares are listed on NASDAQ OMX Helsinki. www.outotec.com

Kimmo Kontola, President - Americas region

Tel. +1 905 3196 111

Robin Lindahl, President - Metals, Energy & Water business area

Tel. +49 6171 9693 100

VALVES - Metso wins a significant repeat order for its innovative noise attenuating valve technology in North America

The results for the customer include a safer working environment and improved process efficiency, leading to significant savings. Metso has won a significant repeat order for Neles® ball valves with Neles® Q-Trim noise attenuating technology from a North American pipeline owner that brings crude oil from Canada to US refineries.

The results for the customer include a safer working environment and improved process efficiency, leading to significant savings. Metso has won a significant repeat order for Neles® ball valves with Neles® Q-Trim noise attenuating technology from a North American pipeline owner that brings crude oil from Canada to US refineries.

By reducing cavitation, noise and related vibration to acceptable levels, Q-Trim technology protects process equipment, thus lowering the operating costs and minimizing the need for valve spare parts and other accessories. This, in turn, means lower total costs of ownership.

"The savings achieved for this customer with Metso's solution are estimated to amount to millions of dollars per year thanks to the higher efficiencies from our technology," says Kyle Rayhill, Global Business Manager, Neles & Mapag, Automation, Metso.

"It really pays off to deal with the noise problem even before it is created. Elevated control valve noise in the throttling process can be harmful not only to employees and surrounding communities, but it can also seriously damage process equipment. Once noise is created, it is hard to eliminate," Rayhill points out.

Based on the excellent achievements, this customer is increasing its installed base of Metso technology. The company has placed another order for more valves with Q-Trim in April 2014. Value of the order is not disclosed.

Leading valve technologies

Metso has a long track record of delivering engineered performance and reliability to the oil & gas industry through its leading product brands Neles®, Jamesbury® and Mapag®. The company has delivered millions of valves, control valves, and on-off valves globally more than 90 years, and has become one of the leading suppliers of intelligent valve controllers. Metso's valve technology centers and production facilities are in Finland, the United States, Germany, China, South Korea, India and Brazil. The company has over 55 automation service hubs, 36 valve and field device Service Centers and over 1,000 service professionals serving automation customers around the world.

Patented Q-Trim technology

For more than 30 years, Metso's patented Q-Trim technology has been the industry benchmark for rotary noise attenuation solutions in challenging applications. Recently, Metso added a new level of performance by introducing Neles Q-Trim that solves aerodynamic noise problems and reduces noise up to 30 decibels compared with a typical control valve.

This front-running technology is a combination of various techniques, including pressure staging, flow division, peak frequency shifting and velocity control. Metso has recently added the new Neles Q2-Trim, thereby extending the family of Q-Trim product capability up to 30 dbA. The full range of Neles Q-Trim is available for pressure classes ANSI 150 through 900 in sizes up to 36".

Metso's automation solutions are designed to maximize the profitability of our customers' businesses by improving their production performance and their cost, material and energy efficiency. Our extensive range of flow control and process automation solutions and services is supported by a worldwide network of automation experts. The Automation business' biggest customer industries are oil & gas, and pulp and paper. We also have a strong growth focus in mining and construction and power generation. www.metso.com, www.twitter.com/metsoautomation

Metso is a leading process performance provider, with customers in the mining, construction, and oil & gas industries. Our focus is on the continuous development of intelligent solutions that improve sustainability and profitability. Metso's shares are listed on the NASDAQ OMX Helsinki Ltd. Metso employs around 16,000 professionals in 50 countries. Expect results. www.metso.com, www.twitter.com/metsogroup

.

For more information:

Kyle Rayhill, Global Business Manager, Neles & Mapag, Automation, Metso,

tel. +1 (508) 852 - 0215 ext. 2941 or mobile +1(401) 486 - 2244,

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

WATER - Swagelok Analytical Instrumentation Article – Water Hammer

CALCULATING AND MITIGATING THE EFFECTS OF WATER HAMMER IN A LIQUID SAMPLING SYSTEM

By Dean Slejko, Product Manager, Analytical Products, Swagelok Company

In a liquid analytical sampling system, a common problem has the potential to destroy pressure gauges, flowmeters, pumps, and other sensitive components. It’s known as water hammer, and it occurs when a valve abruptly closes and liquid flow is suddenly stopped.

Water hammer strikes as a sudden pressure pulse that is in addition to the working pressure in a system. This pulse of additional pressure can be enough to damage every pressure gauge or flowmeter upstream of the closed valve. It can even burst lines or end connections if the pulse is too great.

Yet operators often don’t realize what caused the damage. They know the maximum process pressure won’t exceed the system’s design. So they have trouble understanding where the extra pressure originates.

Let’s take a closer look at why the phenomenon of water hammer occurs and how to estimate its effect in your sampling system. In addition, we’ll review a few methods for mitigating the water hammer effect, including using needle valves for shutoff, diverting flow instead of shutting it down, and using pressure snubbers to protect gauges.

Estimating Water Hammer

When the operation of a valve suddenly interrupts the flow of a liquid, something has to absorb the momentum of that liquid and bring it to a standstill. The liquid is heavy, and it’s travelling fast. Therefore, the force required to decelerate the liquid creates a rapid increase in pressure. This pressure surge originates in the compression of the liquid and from deformation of the tube walls. The resulting pressure wave travels upstream in the tube and, unfortunately, the pressure rises too quickly for a typical proportional relief valve to open and release it. Without a means of escape, the pressure spike can be severe enough to damage components anywhere in the line.

A variety of mitigation methods can help to avoid the sudden pressure spikes of water hammer. We’ll cover those methods in a moment.

But first, let’s review how to determine if water hammer may impact your sampling system. You’ll need to know a few specific details, including the density (ρ) and velocity (u) of your sample fluid. These parameters can be entered into an equation known as Joukowski’s Law, which estimates the magnitude of the water hammer pressure pulse (ΔP) experienced in a line when the liquid velocity (u) suddenly changes by Δu. The equation for Joukowski’s Law reads:

ΔP = c · ρ · Δu

The parameter c is the speed of sound in the liquid under actual operating conditions. For example, the speed of sound in water at 20°C is about 1400 m/s. Therefore, when the operation of a valve suddenly stops a water flow with a velocity of 1 m/s, the calculated pressure pulse is:

ΔP = 1400 m/s × 1000 kg/m3 × 1 m/s

ΔP = 1400 kPa

That’s 14 bar of additional pressure that you have likely not planned for in your sampling system. This extra pressure spike may not be tolerable for this particular system. And the pressure pulse will be even higher if the liquid sampling system flows at a higher velocity than 1 m/s.

In practice, the pulse pressure may not be as high as that calculated by the Joukowski’s Law equation. The full force of the pulse develops only when the change in velocity is sudden, specifically when Δu occurs within a given time period (t), as determined by the following equation (in which L is the length of the liquid line):

|

t ≥ |

2L c |

If the water line in the example above is 100 m long, then:

|

t ≥ |

200 1400 |

s |

t ≥ 142 ms

The time period (t) is the time the pressure wave takes to spread along the upstream line and reflect back to the valve. The full pressure pulse develops only when the reflected pressure wave returns to find a closed valve. The above result indicates that the pulse will be less than the calculated pressure if the valve takes longer than 142 ms to shut off. In other words, you can minimize the water hammer pulse by closing the valve in more than 142 ms.

Mitigating Water Hammer

In domestic water systems, it’s common to mitigate water hammer by installing vertical pipes containing trapped air in water lines near each faucet. The air in the capped pipes absorbs the water hammer pulses. This design could work in sampling systems, too, but it would create an unacceptable dead leg that could lead to sample contamination. Instead, you’ll need to use other remedies to avoid water hammer.

First and foremost, don’t use ball valves to shut off the flow in a liquid sampling system. Ball valves shut off flow instantaneously, which can cause large pressure surges in the sample transport and conditioning systems.

Instead, you may opt to manage flow via one of two methods that help to mitigate water hammer issues, including:

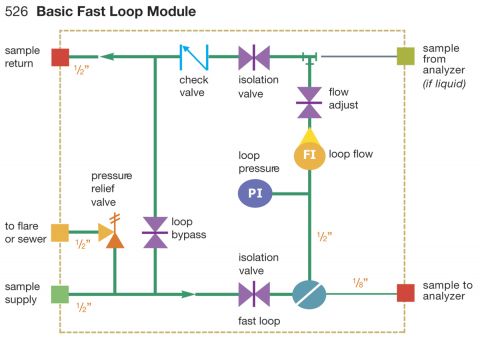

- Using multi-turn needle valves with tight shutoff seats to stop the flow, as shown in the fast-loop module in Figure 1. The needle valves isolate and bypass the fast-loop flow. They close the flow slowly, which dissipates the momentum over a longer duration and minimizes the water hammer pulse. Rising plug valves may also be effective.

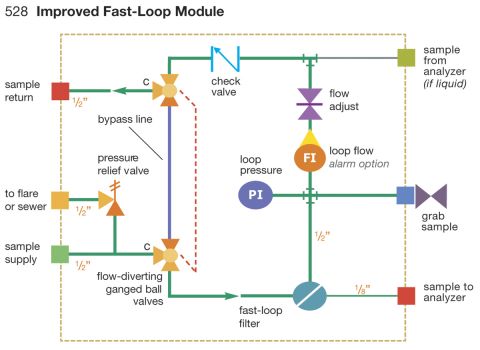

- Diverting the flow instead of stopping it. In Figure 2, a common handle operates two bypass valves, so they can’t move separately. The three-way ball valves have special porting that opens a bypass flow path before closing the main flow path. The valves are never off, so water hammer never occurs.

As noted earlier, pressure spikes due to water hammer are too fast for a pressure relief valve to open and relieve the excess pressure. The rupture disc in the pressure relief valve might burst, but it will do so too late to avert severe damage to an upstream flowmeter or pressure sensor. Those components will receive the full force of the water hammer spike before the relief valve opens.

Figure 1.

Figure 2.

Snubbing Pressure Pulses

Even by following the precautions noted above, valve operation in a liquid sampling system is likely to cause water hammer pressure pulses that may be large enough to damage pressure gauges. Your best defense is to use pressure snubbers to protect all gauges potentially exposed to the pressure pulses. A pressure snubber slows the response of a pressure gauge so it doesn’t respond to the transient pressure pulse in the line.

Protecting Your System

In summary, suddenly stopping flow in a sampling system can create a pressure surge that’s large enough to damage multiple components in the line. Known as water hammer, this surge is a system performance and maintenance issue, and could even be a safety issue if toxic system media were to escape due to a burst line or component. To mitigate water hammer, use needle valves to shut off sample lines, or divert the flow rather than shutting it down. In addition, consider pressure snubbers to protect pressure gauges in your system. These practices will help to minimize the effects of water hammer, reducing maintenance costs and system downtime, as well as enhancing safety.

REFERENCE

This article was adapted from “Industrial Sampling Systems: Reliable Design and Maintenance for Process Analyzers” (2013), a process sampling textbook authored by Tony Waters and published by Swagelok Company. For more information, visit www.industrial-sampling-systems.com.

ABOUT THE AUTHOR

Dean Slejko, Product Manager, Analytical Products

Dean Slejko is product manager, analytical products, for Swagelok Company. He is responsible for product development and marketing of sample handling system solutions that provide process analyzers with timely, representative samples. His previous experience includes a variety of product and market management positions for companies specializing in process control and power management systems. Slejko holds a bachelor's degree in environmental engineering and an MBA from Case Western Reserve University. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..

KEY SEARCH TERMS

- Analytical instrumentation

- Analytical sampling system

- Water hammer

- Pressure spikes

- Needle valves

- Bypass valves

GEOTHERMAL - Leading Tenerife Wind Energy Specialist Guillermo Galvan Speaks at London Sustainability Conference

One of the island of Tenerife’s leading experts on wind energy has delivered a speech at a sustainable energy conference at the RAC Club in Pall Mall on Friday May 2 2014.

The event, hosted by scientific field trip organisers GeoTenerife, brought a number of Tenerife’s leading scientists to London to share their efforts on making the island 100 percent renewable.

Guillermo Galvan, the Director of Wind Energy at the Tenerife Renewable Energy Institute (ITER), spoke about the science being learned from their neighbourhood of 24 fully bioclimatic houses.

Mr Galvan spoke of the challenges faced during the construction of the houses, and what lessons have been learned for use in future developments, particularly for sustainable tourism.

Speaking at the conference, Mr Galvan said “Sometimes you have to be innovative to integrate the bioclimatic design with an appealing house.

Our students and professors that visit Tenerife with us from architecture or sustainable backgrounds love to visit these houses

“This is of particular relevance to the type of sustainable tourism we are looking to develop in Tenerife.”

The ITER director was at the conference to highlight how these houses can help to advance Tenerife’s booming tourist trade in a sustainable fashion, as they have proved to be a runaway success with visitors to the island looking for chic and original properties.

Mr Galvan was just one of the scientists who attended the conference to demonstrate their work to potential British partners.

His speech was well-received by an attentive audience made up of representatives from UK-based renewable energy firms, delegates from African embassies and educationalists.

Sharon Backhouse, Director of GeoTenerife, says that the houses are extraordinary. Built in one of the most challenging environments on the island, beaten by strong winds and sun, the architects had to work hard to use only local elements to build houses that provided comfortable living conditions.

"Our students and professors that visit Tenerife with us from architecture or sustainable backgrounds love to visit these houses and see the various solutions proposed by architects from all over the world. Some of the houses are stunning, but not as effective bioclimatically. Some are semi buried, or use local stone to build series of walls and columns. One house even has plants on the roof, another has sea shells. And all of them are controlled electronically to see which performs best and why. It's the perfect bioclimatic laboratory."

Academic institutions interested in these houses and incorporating them into a detailed sustainable architecture field trip programme should contact GeoTenerife.

About GeoTenerife:

GeoTenerife is a British company that coordinates scientific bespoke trips to the island of Tenerife for UK Universities. It also organizes conferences and webinars on the island, bringing experts from Tenerife to the UK.

Our desire to promote the potential of the island is backed by over fifteen years of experience in the field of renewable energy. We work with investors interested in projects in Tenerife and schools of all levels in the UK.

Our events are specifically coordinated to the requirements of each group responding with activities tailored to their courses and levels of study.

Our goal is to redefine the island of Tenerife: not just a sun and beach destination, the island has resources and potential to be a key destination for global travel and scientific study of the highest level.

For further information about GeoTenerife please contact the event organiser, Director Sharon Backhouse on 07793 063232 or email enquiries@geotenerife.com

POWER GRID - Tieto to help in power grid maintenance in Central Finland

Tieto is to facilitate the management of power grid maintenance in Central Finland by delivering the mobile PGField system to JE-Siirto Oy (JE-Transmission Ltd), a power grid company based in Jyväskylä. The mobile solution helps in tasks related to the inspection and maintenance of a power grid, and it is integrated into Tieto's grid management system PowerGrid used by JE-Transmission.

Tieto is to facilitate the management of power grid maintenance in Central Finland by delivering the mobile PGField system to JE-Siirto Oy (JE-Transmission Ltd), a power grid company based in Jyväskylä. The mobile solution helps in tasks related to the inspection and maintenance of a power grid, and it is integrated into Tieto's grid management system PowerGrid used by JE-Transmission.

Tieto's mobile solution serves both the company and its stakeholders in managing the condition of a power grid, related inspections and documentation. The system also includes a usage map functionality that replaces the traditional hard-copy network maps with digital maps used on mobile devices. A usage map contains functions related to navigation on a map as well as displaying and searching for information, and it supports electronic location finding by means of GPS devices.

"The system has been primarily acquired to enhance the process of managing the condition of a power grid and the property management process. The system enables the contractor to record condition-related observations at the inspection site. The information is then integrated into our network information system and is thus made available to anyone who needs it. With the possibility to report condition-related information, faults in grid components requiring repairs can be included in the work programme in a timely manner. Based on the observations on the grid's condition, we also define any large-scale renovations required in the grid and schedules for such renovations to keep the supply reliability of our power grid at the current good level," saysplanning engineer Jari Helin at JE-Transmission Ltd.

"Tieto's mobile solution enables the provision of real time information over a LAN or WiFi connection. With the system, the user can update and retrieve information as needed and without delays, for example, in connection with a fault repair. This enhances business processes and makes, for example, handling disruptions considerably quicker," says Ari Oksanen, Business Development Director for Tieto's Energy Industry.

Tieto is the largest Nordic IT services company providing full life-cycle services for both the private and public sectors and product development services in the field of communications and embedded technologies. The company has global presence through its product development business and global delivery centres. Tieto is committed to developing enterprises and society through IT by realizing new opportunities in customers' business transformation. At Tieto, we believe in professional development and results.

Founded 1968, headquartered in Helsinki, Finland and with approximately 14 000 experts, the company operates in over 20 countries with net sales of approximately EUR 1.6 billion. Tieto's shares are listed on NASDAQ OMX in Helsinki and Stockholm. Please visit www.tieto.com for more information.

JE-Transmission Ltd is a wholly owned subsidiary of Jyväskylä Energy Ltd, and operates as the power grid system operator in Jyväskylä's inner city. The object of Jyväskylä Energy Group is the production, sales and distribution of district heating, electricity and water and business supporting these.

For further information, please contact:

Ari Oksanen, Business Development Director, Energy Utilities, Tieto, mobile. +358 (0)50 594 6207, This email address is being protected from spambots. You need JavaScript enabled to view it.

Jari Helin, Planning Engineer, JE-Transmission Ltd, tel.+358 (0)50 546 7802, This email address is being protected from spambots. You need JavaScript enabled to view it.