Super User

Ball Screws vs Lead Screws: horses for courses

By Japh Humphries, UK Sales & Commercial Manager, Matara UK Ltd.

When it comes to linear motion systems, one question that gets repeatedly asked is ‘which should I use – ball screw or lead screw?’ They both perform the same task, converting rotational motion into linear movement. However, assuming they are interchangeable because of this would be a mistake, and a potentially costly one at that. Their design and subsequent operation differ, providing each with its own set of advantages and disadvantages; weighing these up against the application at hand is essential to ensure your linear motion system performs to the specified criteria.

Design & operation compared

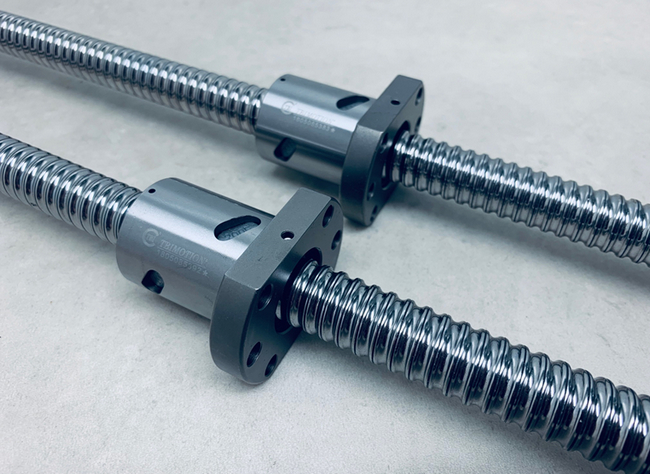

Both lead and ball screws feature a threaded shaft which acts as the screw element of the unit.

A lead screw - the simpler of the two options when it comes to design – has a threaded mating nut which is in direct contact with the screw. Rotational motion turns the screw, causing the nut to move along in a linear motion, thereby converting the motion from rotary to linear. Lead screws come in different formats with one of the most popular for industrial applications being trapezoidal lead screws. The screws are manufactured from steel and the nuts are available in a variety of materials from steel through to bronze, brass and plastic.

In the case of ball screws, a threaded shaft is also used, but it features a helical path around which ball bearings move. The ball assembly behaves as the nut. Ball screws are available in different formats, with rolled and ground types mostly favoured by manufacturers.

Lead screws: pros & cons

As mentioned above, lead screws are the more basic design of the two and that is reflected in the cost. Lead screws have a lower capital outlay than ball screws; ball screws can be two to three times the price of a comparable lead screw. They also do not require a braking system as they are self-locking, which is a further plus point when it comes to total cost.

This price differential often makes lead screws the first port of call, but this could be a false economy as it may not operate well in your specific application; it’s horses for courses, as the saying goes!

Apart from a lower purchase cost, lead screws have the advantage of generally being self-lubricating and they tend to be quieter in operation than ball screws. They are compact with minimal parts, and are easy to design into a system.

Where they don’t score so well is efficiency, which runs between 20% - 25%, as lead screws require greater torque and a larger motor and drive. They also have higher friction and therefore run at a hotter temperature.

Ball screws: pros & cons

With ball screws relying on point contact to support a load, as opposed to line contact, less friction is produced during use. This means that ball screws typically operate at a minimum of 90% efficiency, plus they run at cooler temperatures, and they produce a considerably smoother movement.

Due to recirculating balls supporting the load, ball screws have a higher load capacity than lead screws of a similar size.

Ball screws are also more versatile than lead screws. They are available in higher accuracy grades for greater positional accuracy, and they can be adjusted to increase/decrease preload.

But there are some drawbacks. Obviously cost is one, as outlined above, which is further increased by the need for braking mechanisms to eliminate the risk of back driving. Back driving occurs when the motor shuts off and the ball screw free-falls as a result. Brakes must be fitted as a safety precaution in this case. This is particularly pertinent if the load is to be carried vertically.

With moving balls within the mechanism, it is likely to be noisier than a lead screw, and will also require regular lubrication to ensure the balls move freely. Furthermore, the overall size of ball screw device is larger than a comparable lead screw due to the need for the balls to be recirculated.

What to use where: the rule of thumb

So, which should it be – ball screw or lead screw?

Whilst a definitive answer isn’t practical – each application will have other factors and trade-offs that may need to be taken into account – generally speaking, lead screws are more suitable for transfer applications for which speed, accuracy, precision and rigidity are not as critical. That’s because most lead screws are not well suited to high throughput, high speed applications or those with continuous or long cycle times. Typically, you will find lead screws in use in fluid handling, data storage applications and life science equipment.

Ball screws, on the other hand, are mostly better for high precision applications where accuracy and control are critical. They are also a good option for high load applications and for where thrust force is required to move those loads across a distance in a smooth motion, whilst maintaining speed. Examples of applications include 3D printers and automobile and aeroplane manufacturing.

So, when deciding on whether a ball screw or lead screw is right for your machine, whilst they both perform the same task of converting rotational motion into linear movement, the way in which they realise this and type of end result you achieve are markedly different.

Matara designs, manufactures and supplies pneumatic and linear automation products, including lead screws and ball screws.

www.matara.com

Emerson’s New Engineering Software Accelerates Plant Modernisation Using Artificial Intelligence

REVAMP simplifies and speeds transition to a modern automation architecture, reducing capital costs by up to 15%

Global technology and software leader Emerson (NYSE: EMR) is helping customers more quickly and efficiently transition legacy technology to modern DeltaV™ automation architecture that modernises and digitises operations. Emerson’s REVAMP advanced software solution uses cloud computing and artificial intelligence (AI) to automate up to 70% of system configuration, reduce errors and manual conversion work, and slash capital costs by up to 15%.

“Modernisation projects too often surprise teams late in the process with cumbersome, unanticipated work and errors from manual conversion,” said Claudio Fayad, vice president of technology for Emerson’s process systems and solutions business. “Emerson’s REVAMP helps project engineering teams modernise their systems more easily, on time and within budget, while also minimising errors and disruptions to production.”

Organisations seeking to modernise control and safety systems often start with decades-old code that must be transitioned to current software. Manually converting and documenting this code is an arduous process that dramatically increases the time and capital requirements for these projects.

REVAMP is a groundbreaking, cloud-based, advanced software solution that manages the transition of legacy applications to optimal control.

REVAMP is a groundbreaking, cloud-based, advanced software solution that manages the transition of legacy applications to optimal control.

Emerson’s REVAMP advanced software combines an extensive knowledge base from similar modernisation projects with Emerson’s experience library to develop continuously updating AI models. Each modernised control system feeds back into the REVAMP software, creating learning algorithms that perpetually get smarter and faster at converting legacy code.

The applied AI in REVAMP informs project teams of the engineering requirements before migration projects even begin, making planning easy. The AI engine analyses native files from the existing distributed control systems, safety instrumented systems or programmable logic controller back-ups while using a global library of thousands of successful projects to sort, select and automate engineering tasks. The modernisation project is automatically fully documented, and significant portions can be generated in the DeltaV control system, enabling the latest capabilities and using modern standards.

Emerson project teams around the world have access to the most recent functionalities and libraries of this secure, cloud-native tool. And with embedded machine learning, the libraries grow and improve as projects become more efficient over time.

Learn more at Emerson.com/revamp.

About Emerson

Emerson (NYSE: EMR) is a global technology and software company providing innovative solutions for the world’s essential industries. Through its leading automation portfolio, including its majority stake in AspenTech, Emerson helps hybrid, process and discrete manufacturers optimise operations, protect personnel, reduce emissions and achieve their sustainability goals. For more information, visit Emerson.com.

Circular separators versus linear separators

~ Appropriate separators crucial for effective grading and quality control ~

In industrial material processing applications, the selection of appropriate separators plays a crucial role in achieving efficient and effective production processes. Two commonly used types of separators are circular separators and linear separators. Here, Stephen Harding, managing director at the materials handling specialist Gough Engineering, explores the features, benefits, and differences between these two technologies, as well as their applications in various industries.

Balancing high throughput and process effectiveness in material handling applications is a common challenge for manufacturers, especially when diverse materials are being handled. Diverse means the materials can vary in size, density, shape and composition. In addition, they can entail a range of ingredients, herbs or spices and nutraceuticals in the food industry or various chemicals and plastics in their respective sectors.

More complex factors include moisture content, contamination, inconsistent particle size and variability in product properties also pose significant hurdles. Fortunately, this is where advanced technologies, including specialised screening and sorting equipment, come into play. With automated quality control systems and stringent quality assurance protocols, manufacturers can overcome these challenges and deliver high-quality products that meet industry standards and customer satisfaction.

Linear separators

Linear separators are commonly used in the recycling industry, such as to process rubber or copper metals, for handling small-volume and small particle-sized aggregates.

They offer high throughput rates and the ability to separate materials into multiple fractions. Linear separators can handle irregularly shaped product materials that may require more aggressive vibration for efficient separation. They can also accommodate larger volumes of product due to their larger screen surface areas and vibrational amplitude compared to circular machines.

They can also provide multi-deck separation. Similar to circular separators, linear separators can be configured with multiple screening decks. This allows for the separation of materials into two, three, or four fractions, condensing multiple processes into a single unit.

To optimise the performance of circular and linear separators on production lines, it is crucial to integrate them with complementary and co-harmonious equipment. This integration ensures a smooth material flow and maximises overall process efficiency.

Circular separators

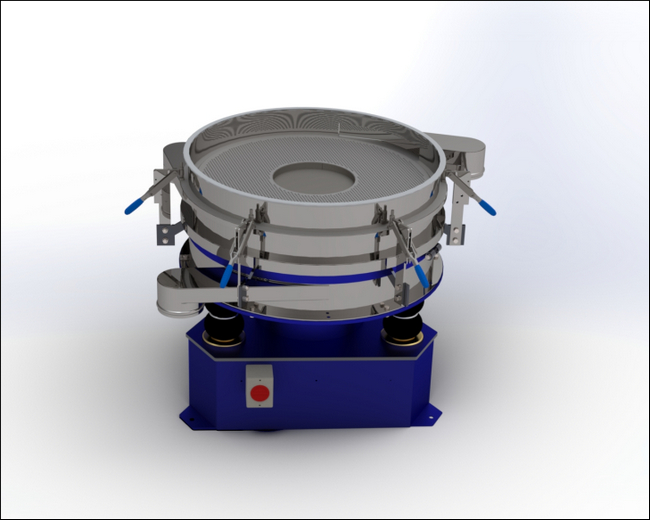

Circular separators are suitable for fine powders, granular materials, and pellet products. They utilise controlled spiral vibration flow during separation, designed for differing particle sizes and ensuring precise grading and accurate separation. They are particularly effective in fine classification, ensuring product quality before packaging or forming machines.

Circular separators, such as the Vibrecon® Vibratory Separator (GVC) by Gough Engineering, offer a rotary action separating and sifting system. These separators excel at processing materials on an industrial scale, providing accurate particle separation based on size.

The GVC system, with the correct mesh(es) or perforated plate(s), can handle multiple fractions and can be configured with single or multiple screening decks. This allows for the separation of materials into specific grades or fractions based on particle size, increasing process effectiveness for superb classification. Gough Engineering's circular separators are designed to be robust and easily maintained, resulting in minimal spares over the machine’s operational lifetime and reduced full cleaning downtimes, respectively.

Areas for growth

Gough Engineering stands out from its competitors in the vibratory separator market due to its fit-for-purpose solutions and extensive knowledge and experience. The company offers trials and utilises a comprehensive database of previous applications to provide tailored solutions to various industries. Moreover, Gough Engineering provides full parts and service backup, ensuring reliable support throughout the equipment's lifecycle.

Several Gough Engineering customers use circular and linear separators. Molecular Products, a world leader in the design and manufacture of life critical devices for the treatment of breathable gases, utilises circular separators for fine classification, removing oversize materials and fines from breathable gas treatment products. GA Pet Food Partners, a dry pet food manufacturer, uses a linear vibrating screen to remove fine from dry kibble products before packaging. Each solution designed specifically for the customer’s product materials and operational requirements.

In the coming years, Gough Engineering envisions expanding its vibratory separators and linear screens into new markets and applications. Promising areas for growth include proteins and nutraceutical production lines, and entomophagy — the use of insects for protein and minerals in certain food production.

Circular separators and linear separators are essential tools in industrial material processing applications. Their individual features and benefits make them suitable for different industries and production challenges. Gough Engineering's vibratory separators, with their fit-for-purpose solutions, dedicated customer support, and extensive knowledge base, provide efficient and reliable solutions for a wide range of industrial applications.

To learn more about Gough Engineering’s vibratory separators and linear screens, visit its website.

Top aluminum producer and recycler Novelis to increase uptime following ABB modernization

Novelis Inc., a leading sustainable aluminum solutions provider and the world leader in aluminum rolling and recycling, is working with ABB to upgrade its third-party drives and controls system as part of a brownfield modernization project at its hot rolling mill in Oswego, New York, USA.

- ABB replacing outdated third-party installed base, including obsolete motor and generator sets at Oswego, New York, facility

- Retrofit will improve availability, reliability, energy efficiency, and productivity, while cutting downtime and maintenance

To futureproof the mill, ABB is replacing obsolete and outdated equipment with new switchgears, transformers, medium voltage drives, medium voltage synchronous motors, motor control centers and auxiliary controls, all integrated with the facility’s existing non-ABB control system. This will support Novelis’ ambitions for increased power capacity and reliability. Commissioning of the upgrade is expected by the end of 2023.

The Oswego mill was the company’s first US operation and is today the company’s largest, wholly owned fabrication facility in North America. It produces high-quality aluminum sheet for the automotive, beverage can, and building and construction markets. Novelis is also the world’s largest recycler of aluminum and seeks sustainability commitments from its supply chain as its customers look for environmentally friendly and circular aluminum products.

“In order to continue to provide our customers with the highest quality, sustainable aluminum sheet, and do so reliably, we are focused on increasingly optimizing our production output,” said Ganesh Panneer, Vice President of Operations, Novelis North America. “ABB is helping to ensure that we continue to have the highest levels of availability in our processes. The expertise of the ABB metals team, together with their commitments on providing the latest, most energy efficient products, will secure Oswego’s future as we maintain our leading position.”

“We’re proud to support Novelis in meeting their production targets, which promote efficient use of energy and other resources,” said Siraj Boudighar, Sales Manager North America for Metals, Process Industries, ABB. “By leveraging our long-term experience and in-depth knowledge of metals industry processes, including more than 400 references for modernization projects since the year 2000, we are able to tailor technology packages that meet the specific needs of each customer.”

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 130 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation

Overcoming rising energy prices

~ Material handling systems help food and beverage manufacturers offset rising energy costs ~

Given that energy accounts for 15 per cent of food and drink manufacturers’ costs, according research by Centrica Business Solutions, the continued rise of energy prices is a major concern for these companies. Indeed, the same study found that 56 per cent of manufacturers believe investing in energy efficiency technologies is “very important” for their business. But where should they invest? Here, Stephen Harding, managing director of Gough Engineering, looks at how improved material handling processes can help manufacturers overcome rising energy costs.

Energy costs were a significant worry for businesses across the UK, last year. In April 2022, 21 per cent of businesses surveyed by the UK’s Office for National Statistics (ONS) said that energy prices were their main concern, up from 15 per cent in February. These figures have remained consistent ever since.

So, how can food processors better offset these costs, and how can they do this while benefiting production and yielding a return on investment (ROI)? It all boils down to how businesses optimise their production processes — and that includes material handling.

Equipment schemes

Proper material handling is about optimising the mechanical and physical relationship between products and ingredient flows, versus machinery and processes.

Equipment schemes describe bespoke systems that ensure a plant’s production line runs according to the manufacturer’s key performance indicators (KPIs). KPIs would generally include the time, quality and quantity of production, and the manufacturer’s core value adding process to manufacture end products.

An equipment scheme can rely on equipment to automate the weighing, mixing, cooking, heating and cooling operations during a process. This equipment may have built-in quality assurance systems for sieving or screening processes to ensure products are transferred, or conveyed, from one process to another without them being damaged.

Weigher systems, for instance, check the quantity of produce or ingredients at certain stages of production. Industry 4.0 sensors can capture this data, relaying it to Supervisory Control and Data Acquisition (SCADA) systems to control, monitor and visualise the information. Scheme controls can be integrated into existing systems, and controlled from a central SCADA location through easy-to-use Human Machine Interfaces (HMIs).

But how can manufacturers achieve costs savings and an improved ROI through control schemes? This is where the partnership of a trusted materials handling expert is essential. A partner can review the sequential and functional needs of materials management on the customer’s production line, and plan how to optimise these processes in order to best serve the plant’s KPIs.

The right calculations

Let’s look at food conveying systems as an example. Conveyors, whether they are floor-mounted or overhead, must transport produce safely, carefully and efficiently between the various machines on a production line — from the weighers and processing machinery, all the way to the packing line.

The first questions that Gough Engineering asks its customers at the start of a project are: “What type of material are you transporting?” and “What product throughput rate do you need to achieve with this conveying system?” For the latter, the customer will respond with a figure of tonnes or kilograms per hour. Gough Engineering’s specialists then establish further clarification of volume rates, bulk densities, transfer lengths and orientations, feed points, distribution points, and can then prescribe a suitable solution.

Bucket elevators are often overlooked when considering material transportation, but they can be a more suitable option than linear conveyors. This is particularly important for transporting dry bulk materials, ingredients and part-completed products. A materials handling expert can provide you with guidance on what’s best for you, based on your specific material.

To determine the best elevator design to convey a product, we must consider three factors. First, bucket capacity, which refers to the volume of product that can be held in each bucket. Every bucket is filled to a specific per cent of its overall capacity, to ensure that all of the product is retained — doesn’t spill over the edges — during transport.

The second factor is bucket pitch. For instance, when the bucket elevator system is mounted between two parallel chains, correct buck pitch means determining the correct distance between the centres of each bucket. This determines how much product can be transported. Third is bucket speed, or the rate at which the buckets are travelling.

These factors combined give us the total volumetric capacity moving through a specific conveying design. This allows the product to be transported correctly and carefully to suit the required distance of travel, while also integrating the process into the overall feed, distribution and production line requirements.

In some cases, a belt and bucket elevator, where buckets are fixed to a belt running at high speeds, might be the best choice. These systems allow high throughput rates of cubic metres per hour. However, they also involve a lot of kinetic energy due to the centrifugal forces created, which can lead to product degradation and damage.

As an alternative, a pendulum bucket elevator system, mounted between two parallel chains, might be more suitable. As the name suggests, the buckets hang like in a pendulum, travelling in all elevator positions in a horizontal position, and are eventually tipped using a cam to discharge the product at the desired location. While this system can be slower than other solutions, it offers gentler product handling with less spillage than high-speed alternatives. A pendulum bucket elevator can convey buckets in many shape configurations, with multiple inlets (feeds) and controlled discharge positions.

Reducing waste

Let’s imagine an instance where 25 kg bags are emptied into the necessary production processes. In this scenario, waste can accumulate in terms of lost produce during de-bagging, as well as packaging materials. Not only is this process wasteful, but the manual approach also creates safety concerns for human workers. There’s the repetitiveness of the material handling task itself, and the need to perform multiple operations in order to move pallets of product bags around for de-bagging — these factors can cause bottlenecks in the flow of production.

As a solution, Gough Engineering recommends the customer install FIBC Big Bag Dischargers. This technology provides lifting support to make emptying large bags easy and efficient. FIBC Big Bag Dischargers can eliminate product loss, capture any dust and prevent contamination thanks to their enclosed design. By automating the debagging process, the customer increases throughout and minimises waste.

Equipment schemes and automated material handling give manufacturers new ways to offset rising energy costs, while boosting production and ROI. Moreover, these systems can also empower manufacturers to tackle the rising prices head-on.

To learn more about Gough Engineering’s material handling solutions, including custom bucket elevators and FIBC Big Bag Dischargers, visit its website

Start your engines with next-level data processing

Ratingen, Germany 15th August 2023 Companies in the Automotive industry have always been at the forefront of innovative manufacturing practices. To remain at the cutting-edge, they rapidly adapt and adopt the latest developments in technology. This approach equips them to face evolving market demands as well as supply chain challenges. The next step to driving the competitiveness and profitability of manufacturers even further is integrating real-time data generation and management within all aspects of car and part production. This is what Lucas Majewski, Global Director of Automotive/EV Industry, Factory Automation, at Mitsubishi Electric, outlines in the videocast “Trends in Automotive – Data means Energy”.

The combined effects of a shifting regulatory landscape, evolving customer requirements as well as ongoing supply chain issues are testing conventional automotive manufacturing. However, the industry has proven itself to be agile and as a result, resilient. For example, it is one of the most automated sectors, having invested heavily in digital technologies over the past decades. Thanks to this forward-looking approach and its existing infrastructures, the automotive value chain can benefit from a privileged position when it comes to upgrading its capabilities to support a changing marketplace.

About Mitsubishi Electric Corporation

With more than 100 years of experience in providing reliable, high-quality products, Mitsubishi Electric Corporation (TOKYO: 6503) is a recognized world leader in the manufacture, marketing and sales of electrical and electronic equipment used in information processing and communications, space development and satellite communications, consumer electronics, industrial technology, energy, transportation and building equipment. Mitsubishi Electric enriches society with technology in the spirit of its “Changes for the Better.” The company recorded a revenue of 5,003.6 billion yen (U.S.$ 37,3 billion*) in the fiscal year ended March 31, 2023. For more information please visit http://www.MitsubishiElectric.com.

About Mitsubishi Electric Factory Automation Business Group

Offering a vast range of automation and processing technologies, including controllers, drive products, power distribution and control products, electrical discharge machines, laser processing machines, computerized numerical controllers, and industrial robots, Mitsubishi Electric helps bring higher productivity – and quality – to the factory floor. In addition, its extensive service networks around the globe provide direct communication and comprehensive support to customers. The global slogan “Automating the World” shows the company’s approach to leverage automation for the betterment of society, through the application of advanced technology, sharing know-how and supporting customers as a trusted partner.

About Factory Automation EMEA

Mitsubishi Electric Europe B.V., Factory Automation EMEA has its European headquarters in Ratingen near Dusseldorf, Germany. It is a part of Mitsubishi Electric Europe B.V. that has been represented in Germany since 1978, a wholly owned subsidiary of Mitsubishi Electric Corporation, Japan.

The role of Factory Automation EMEA is to manage sales, service and support across its network of local branches and distributors throughout the EMEA region. For more information, please visit: emea.mistubishielectric.com/fa

About e-F@ctory>

e-F@ctory is Mitsubishi Electric’s integrated concept to build reliable and flexible manufacturing systems that enable users to achieve many of their high speed, information driven manufacturing aspirations. Through its partner solution activity, the e-F@ctory Alliance, and its work with open network associations such as The CC-Link Partners Association (CLPA), users can build comprehensive solutions based on a wide ranging “best in class” principle.

In summary, e-F@ctory and the e-F@ctory Alliance enable customers to achieve integrated manufacturing but still retain the ability to choose the most optimal suppliers and solutions.

Further Information:

https://emea.mitsubishielectric.com/fa

Automated Real-Time Liquid Natural Gas Custody Transfer System Provides Product Quality and Quantity Transparency

Eliminates disputes and reduces maintenance costs

By John de Viet, Solutions Development & Sales Support Manager at KROHNE Marine,

With the skyrocketing cost of fuel, the value of any mistakes made while loading and unloading liquid natural gas (LNG) carriers is increasing. This makes it even more important for plant and instrumentation managers to have access to the most accurate measurement tools. New automated systems provide transparency in measuring fuel quantity and quality, improving trust between buyer and seller. These new tools can reduce maintenance costs by as much as 25-50 percent annually and can also avoid costly disputes at terminals, estimated at between $1-10 million per year.

Determining quality and quantity while loading and unloading of LNG carriers

Loading and unloading of liquid natural gas (LNG) carriers requires documentation of both the quantity and quality of the LNG transferred. As per gas sales purchase agreement (GSPA) this information, recorded in a quality certificate, and a bill of lading, is usually derived from multiple instruments and independently operated systems. Plant managers have typically used manual data collection, calculation, and verification systems to obtain the required information.

Quantity is typically determined with level measurements taken on the LNG vessel; these measurements are the input for the bill of lading. Quality is determined in a laboratory using samples collected during the (un)loading operation, with the results used to prepare the quality certificate. Data is manually processed primarily in Excel-based worksheets, without traceable references to instrument uncertainties and standards and with no dynamic validation.

Accurate calculations have been made even more complicated by the fact that LNG is a mixture of gas and liquid. Unlike transfer standards for oil or gas, which are well-defined and well-known, those for LNG are less advanced. Many operators have had to rely on collecting information from independent systems doing just a portion of the measurements, with no one fully integrated measurement system. The existing manual quantity and quality data collection systems have led to a variety of potential problems:

- Introduction of human error during data collection.

- Certificates of quality are produced using distributed control system (DCS) historians or external plant information systems, including the PI real-time data management software and MS Excel. None of these systems are designed and dedicated for custody transfer applications.

- Data is transferred through multiple interfaces with the possible loss of resolution or loss of data due to filtering (ISO demands up to 6th decimal point).

- Calculations have not been validated or certified by an independent body such as NMi.

- Quality data is not traceable, and measurements are often not in compliance with ISO/GPA standards.

- There is no dynamic validation of data while LNG loading is in progress.

- Validation of data is often done after the shipload, with no way of reconciling if equipment had developed faults during the loading.

- Contractual clauses differ, which could lead to incorrect interpretations and calculations.

- Overall loading system is difficult for authorities to audit.

New automated systems eliminate uncertainty disputes

New automated systems are now available that eliminate uncertainty disputes, reduce maintenance costs, and make loading and unloading of LNG carriers at terminals easier and more efficient. Among these is the KROHNE LNG-Quality Release System (L-QRS), a software offering that collects all relevant information needed to determine the amount of energy transferred during LNG vessel loading and unloading operations. See Figure 1 for a graphic overview of typical loading/unloading points in the LNG value chain.

This automated system processes information in an NMi-certified SUMMIT 8800 flow computer to allow the operator real time monitoring of batch quantity and quality. It uses on-line measurements and certified statistical calculations, including quality and outlier calculations, energy calculations, loading mass balance and billing reports on vapor returns. A gas chromatograph analyzes samples in real-time while the ship is being loaded. See Figure 2.

The applied flow computer software provides the quality release certificate and the bill of lading instantaneously once the batch is completed. Instant availability of bill of lading and quality certificates avoids costly retrospective corrections of the bill of lading and quality certificates once the vessel has departed. The system incorporates an analyzer management and data acquisition system, which ensures full traceability of the instrumentation and optimizes maintenance cycles. Estimates suggest that maintenance costs can be reduced by 25-50 percent. Data is securely stored and, together with the certified calculation, fully auditable.

The fully automated information flows eliminate human errors in the data processing that can arise when copying measurement data among different systems. Simply avoiding LNG quality disputes has the potential to save terminals from $1-10 million per year. Because the automated system is certified by NMi and compliant with such international standards as ISO 8943, GPA 2172, ASTM 4784, GIIGNL, it also avoids discussions over the amount of energy transferred. Increased availability of critical instruments ensures constant and reliable quality measurements, resulting in less product give-away due to a lower system uncertainty.

Designed for mid-size and large liquefaction and regasification LNG terminals, it can be installed in both new and existing LNG terminals and can be sized to the available infrastructure.

Once the automated system is installed and operational, plant managers experience improvements in maintenance costs, a reduction in the number of disputes, and improved availability, resulting in less product give-away.

Basic L-QRS functionality is available using only the Summit 8800 flow computer in combination with existing instrumentation. Depending on the level of existing automation, this provides automated calculations, outlier detection, standard reporting and time stamped measurement registration. The system can be further enhanced with a user-friendly HMI, customized reports and an integrated analyzer/instrument management system. The latter enables the operator to optimize its maintenance program and reduces costs, provides detailed information about instrument availability and full traceability of the calibration records.

A further level of performance is achievable by adding custody transfer LNG flowmeters like the OPTIMASS 6400 Coriolis mass flowmeter, which features advanced entrained gas management (EGM). For larger line sizes the ALTOSONIC 5 ultrasonic flowmeter can be used. Ultimately, and even higher level of overall system performance can be reached by adding an on-line LNG sampling and analyzer system. This way all the relevant parameters related to quantity and quality are available in real-time and the full benefits of L-QRS are realized.

Given the increasing expense of fuel and the transitioning of fuel types, LNG operators need more robust and reliable metering and measuring systems. New systems like the L-QRS can go a long way to meet traceable custody transfer data standards while avoiding costly disputes, retroactive corrections, and product give-away.

About KROHNE Marine:

The KROHNE Marine team, based in Norway, is a dedicated expert division with over 60 years of experience in the marine industry. Since 1957, our highly qualified team of Engineers has provided the Global Marine Industry with certified systems, products, measurement solutions, and services. We have gained extensive knowledge of what it takes to deliver high-quality products and solutions to ship owners, managers, and yards through long-term and close collaboration with our customers. Our systems are installed on a wide range of vessels, from small inland vessels to large seagoing ships. https://krohne.com/en/industries/marine-industry

About KROHNE:

KROHNE is a world-leading manufacturer and supplier of solutions in industrial process instrumentation. The North American subsidiary, KROHNE Inc., is headquartered in Beverly, MA (USA) and provides service and sales throughout the region.

About the Author

John De Viet works at KROHNE Solution in Breda, The Netherlands where KROHNE’s measurement system solutions are developed for all industries.

Rohde & Schwarz sponsors HORYZN and LEVITUM student initiatives with test equipment for drone development

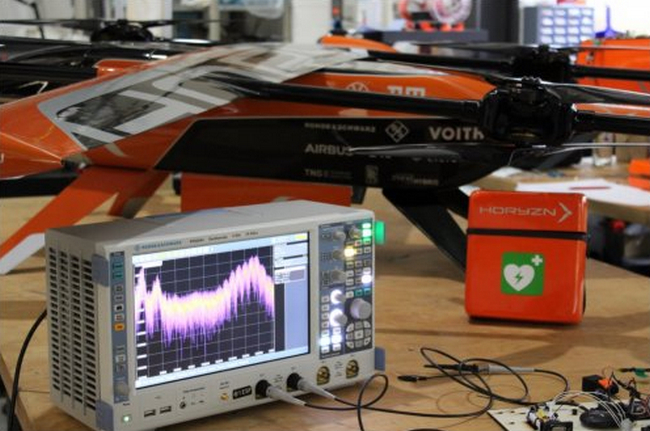

As a gold sponsor, Rohde & Schwarz provides test equipment to the HORYZN and LEVITUM student initiatives of the Technical University of Munich (TUM) to help with drone development. The students at TUM are working hard to develop, build and test vertical takeoff and landing drones for various applications.

The drones will be used in rescue operations or to complete long-distance journeys with the help of fuel cells. Rohde & Schwarz provides its latest generation of R&S MXO 4 oscilloscopes for control electronics testing, plus accessories and training.

HORYZN seeks to apply the theoretical knowledge gained during degree studies to the development of unmanned aerial vehicles capable of electric vertical takeoff and landing (eVTOL). As an international and interdisciplinary team, the students work on innovative solutions to real-world problems. During their first project, they developed and designed the largest eVTOL UAV in the history of TU Munich. In their next project, they will trial UAVs in a medical use case – the transportation of defibrillators. This will also stimulate public debate about the deployment of civilian UAVs.

The R&S RTO is a key component in the test environment for developing the HORYZN power electronics.

The R&S RTO is a key component in the test environment for developing the HORYZN power electronics.

The LEVITUM initiative is working on a hydrogen-powered eVTOL drone capable of traveling over 300 km without refueling. The team uses ultramodern fuel cell systems and state-of-the-art type IV pressurized tanks to develop the "Mercurius" prototype – the world's longest-range UAV with less than a 25 kg takeoff weight that outperforms any commercially available drone. Minimal refueling and lower overall costs are other factors here.

The TUM initiatives are proving instrumental in helping students to translate scientific methods into practical applications.

Rohde & Schwarz offers an extensive product range for testing radar, electronic warfare, satellite, navigation, guidance, military radiocommunications and radio monitoring systems in all relevant frequency bands. Outstanding performance and application-tailored measurement functions address the specific needs of the A&D sector in R&D, validation, production and in the field. This includes RF and microwave T&M instruments for lab and field measurements, turn-key systems, a full range of EMC measuring equipment as well as antennas and RF accessories. Sustainable product strategies ensure that Rohde & Schwarz products keep up with advances in technology throughout the long lifecycles customary.

R&S® is a registered trademark of Rohde & Schwarz GmbH & Co. KG.

New Mobile Supervisory System Launched for Global Mining Autonomy

Leading vehicle automation provider, ABD Solutions, has developed a new Mobile Supervisory System for its vehicle automation solution, Indigo Drive. It allows mining vehicles to be automated anywhere in the world without the need for existing infrastructure.

"Indigo Drive automates existing vehicle fleets, accelerating autonomy at a fraction of the cost of replacing the fleet with autonomous equivalents,” said Matthew Price, Managing Director of ABD Solutions. “Autonomous vehicles are revolutionising the mining industry by increasing efficiency, improving safety and reducing costs. Our new mobile solution is enabling these benefits to be extended across the entire mining operation, wherever it is in the world.”

The compact Mobile Supervisory System consists of the servers and operator stations that enable a site to manage its fleet of automated vehicles. It can be fitted into various configurations including a vehicle, such as a van, or a mobile container and can be placed in the most remote and hostile environments.

ABD Solutions has developed a new Mobile Supervisory System for its vehicle automation solution, Indigo Drive

ABD Solutions has developed a new Mobile Supervisory System for its vehicle automation solution, Indigo Drive

It acts as the operations centre for Indigo Drive, a technology ecosystem that enables a limitless number of mining vehicles to be quickly and cost-effectively automated. The secure system is IEC61508: 2010 and ISO17757: 2019 certified and includes a user-friendly software interface for route-planning, the hardware to move the vehicles (such as drive-by-wire and driving robots), communication (radio, V2X, GPS/GNSS), obstacle detection (LiDAR, camera, radar) and vehicle health and diagnostics (OBD2, telemetry, sensors). The system is completely modular and can be tailored around the specific vehicles and environments.

As a fully redundant high-availability system, the new Mobile Supervisory System ensures there is no single point of failure, providing a high level of reliability and continuous operation. The level of redundancy is scalable to meet the desired application.

Designed to operate in the most hostile of environments the mobile system is powered by hot-swappable lithium-ion battery packs providing 24 hours of operating life, or they can be recharged using solar power or hydrogen generators. The components are IP67 rated to prevent the ingress of dust and moisture making them highly ruggedised and spray washable.

ABD Solutions has developed a Mobile Supervisory System demonstrator van that contains everything needed for operators to supervise a fleet of Indigo Drive automated vehicles. It will be used to demonstrate the technology to prospective customers at their sites around Europe or at ABD Solutions’ test track in the UK.

ABD Solutions has developed a Mobile Supervisory System demonstrator vehicle to prove the technology.

ABD Solutions has developed a Mobile Supervisory System demonstrator vehicle to prove the technology.

About ABD Solutions

ABD Solutions create safer and smarter work environments by delivering vehicle autonomy solutions.

With expertise in actuation, perception, localisation and safety systems, existing machinery and vehicles can be transformed to benefit from autonomous capabilities faster and more cost-effectively than ever before.

As part of the global AB Dynamics plc Group, ABD Solutions has a heritage of driving vehicle safety and with offices around the world, its innovations solve global challenges.

Find out more at: www.abdsolutions.com

Press Contact

Richard Doherty at Automotive Technology PR

This email address is being protected from spambots. You need JavaScript enabled to view it.

+44 (0)7814 961855

From efficiency to eco-friendliness

~ Exploring the synergy of automation and sustainability ~

The pursuit towards sustainability continues to be an urgent priority shared by individuals, businesses and governments alike. The intersection of automation and sustainability holds tremendous potential for driving positive change, enabling all industries to streamline processes, reduce waste and optimise resource utilisation. Here Stephen Hayes, managing director at Beckhoff UK explores how connecting automation to sustainability goals can revolutionise businesses and help them contribute to a more sustainable planet.

The integration of automation and sustainability is a pivotal step towards creating a more resilient and eco-friendlier world. Despite companies understanding the importance of sustainability, the majority still have a long way to go as only 60 per cent of companies incorporate sustainability in their strategy, and just 25 per cent have sustainability fully integrated into their business model, according to a study by BCG/MIT. However, the integration of automation technologies can serve as a catalyst for progress, as they have the potential to go hand in hand with sustainable goals.

Numerous companies across various industries have embraced automation to advance their sustainability goals. For example, in the automotive industry, Tesla's Gigafactory employs automation extensively to streamline production and reduce energy consumption. By automating material handling and using energy-efficient equipment, Tesla has significantly minimised its environmental impact while increasing productivity.

Another example can be found in the food and beverage industry, where Coca-Cola implemented automation in its bottling plants. With the use of robotics, the company has achieved higher accuracy and consistency in its production processes, resulting in reduced waste and improved energy efficiency.

Several tools and technologies support the integration of automation in the pursuit of sustainability. Internet of Things (IoT) devices enable real-time data collection to facilitate better monitoring and optimisation of manufacturing processes. Advanced analytics and machine learning algorithms help identify energy-intensive activities and suggest energy-saving measures. Additionally, digital twins — virtual replicas of physical assets — allow manufacturers to simulate and optimise processes before implementing changes in the real world.

Automation also plays a crucial role in energy efficiency. Completing a power measurement chain from sensors to the cloud can simplify energy management approaches and improve the availability of machines and production facilities. Until now, continuous power monitoring involved a lot of effort, and external sensors would have to have been installed at great cost.

In such scenarios, power measurement terminals — such as Beckhoff's EtherCAT power measurement terminals — play a crucial role in helping achieve sustainability goals in the long term. By replacing external sensors and utilising standard components, these terminals can be easily integrated into existing machines and systems, including retrofitting projects. This seamless integration enables manufacturers to perform continuous, real-time power measurements, providing valuable insights for sustainable operations.

With permanent, system-integrated power measurement, manufacturers gain the ability to conduct extensive inline analyses. By monitoring power consumption trends, they can quickly detect deviations from normal patterns. For example, a steadily rising power consumption in a machine may indicate potential excessive wear on its bearings. Identifying such issues early on allows for timely maintenance or repair, preventing further damage and extending the machine's lifespan.

Conversely, a decrease in power consumption can be an indication of quality issues in the production process. By promptly rectifying these issues, manufacturers can improve product quality and minimise energy consumption. This proactive approach ensures that sustainability goals are met by optimising resource usage and minimising environmental impact.

Moreover, sudden drops in power usage can also trigger the need for urgent action within the production facility. It could signify a malfunction or breakdown that requires immediate attention to avoid costly downtime. By having real-time visibility into power consumption, manufacturers can swiftly respond to such situations — minimising production disruptions and maximising operational efficiency.

The data provided by power measurement terminals not only facilitates prompt corrective actions but also empowers manufacturers to make data-driven decisions towards long-term sustainability. By analysing the collected power data, manufacturers can identify areas of improvement, optimise energy usage and in turn, reduce carbon emissions. This comprehensive understanding of power consumption patterns enables manufacturers to make informed decisions that align with their sustainability objectives.

The integration of automation and sustainability represents a crucial milestone in the journey towards a resilient and environmentally conscious world. While businesses have yet to fully embrace sustainability in their strategies, automation technologies offer a promising pathway to progress. By leveraging tools such as IoT devices, advanced analytics and power measurement terminals, manufacturers can monitor and optimise their operations in real-time. This data-driven approach empowers businesses to make informed decisions that support long-term sustainability objectives. With automation as a catalyst for change, industries can revolutionise their practices and contribute to a more sustainable planet.