Super User

Vianode signs Antwerp Declaration to elevate industrialisation on the European Strategic Agenda

Vianode, an advanced battery materials company providing sustainable anode graphite solutions, has signed the Antwerp Declaration to support revitalisation and strengthening of Europe's industrial landscape.

The Antwerp Declaration is a visionary call to action for embedding industrialisation at the heart of the European Strategic Agenda for 2024-2029. This declaration seeks to establish a European Industrial Deal based on ten concrete initiatives to support industrial innovation and production as key drivers for future growth and sustainability.

Vianode's CEO, Burkhard Straube, expressed great support for the initiative: “The Antwerp Declaration resonates with our mission to support decarbonising transportation through our advanced battery materials. Our strategic roadmap is clear: to supply on a large industrial scale low-emission, high-performance anode graphite solutions that are essential for sustainable batteries and EVs. This commitment not only highlights our dedication to innovation but also our role in driving a competitive, sustainable, and resilient future for the European industry."

Vianode's CEO, Burkhard Straube, expressed great support for the initiative: “The Antwerp Declaration resonates with our mission to support decarbonising transportation through our advanced battery materials. Our strategic roadmap is clear: to supply on a large industrial scale low-emission, high-performance anode graphite solutions that are essential for sustainable batteries and EVs. This commitment not only highlights our dedication to innovation but also our role in driving a competitive, sustainable, and resilient future for the European industry."

Vianode has produced anode graphite solutions at its industrial pilot plant in Kristiansand, Norway since 2021. In 2022, the company opened its technology center at the same site and the company is now preparing start-up of the first full scale production plant at Herøya, Norway.

“We will deliver our first large-scale made-in-Europe customer samples later this year and have ambitions to contribute to shaping Europe's sustainable industrialisation”, Chief Commercial Officer Stefan Bergold added.

Echoing the importance of this initiative, Belgian Prime Minister Alexander De Croo, host of the Antwerp industry summit, emphasised: "We need our industry for their innovation capacity. To come up with tomorrow’s climate solutions. That is why Europe should not only be a continent of industrial innovation but should remain a continent of industrial production."

Vianode is dedicated to spearheading industrial innovation and was last year selected to lead a USD 7 million project supported by the Norwegian Research Council. The initiative targets to develop cutting-edge technologies for data capture and advanced process control, thereby reinforcing its commitment to the Antwerp Declaration's vision of a sustainable and innovative European industrial landscape.

Vianode is also awarded a EUR 30 million IPCEI EUBatIn grant designed to expedite green transition innovations to market at scale and a EUR 90 million grant from the EU Innovation Fund to support the preparation of large-scale innovative production of battery materials.

Launched earlier this year, the Antwerp Declaration had more than 800 signatories of which close to 600 are companies as of March 25 2024.

About Vianode

Vianode is an advanced battery materials company providing sustainable anode graphite solutions for the battery and EV value chains in North America and Europe. Vianode’s breakthrough solution enables tailored high-performance synthetic anode graphite and a holistic sustainability offering including a 90% reduction in CO2 footprint. The company is currently preparing to start its full scale plant at Herøya, Norway, before executing its multi-billion dollar phased investment program for large-scale plants in North America and Europe. The long-term ambition is to supply advanced battery materials to 3 million EVs per year by 2030. Vianode is owned by the world-leading industrial and financial companies Hydro and Altor.

Valmet to invest in filter fabric manufacturing in South America

Valmet has decided to invest in filter fabric manufacturing in Belo Horizonte, Brazil, in order to better respond to the growing demand of high-performing filter fabrics in both the mining and pulp and paper industries in South America. The value of the new investment will not be disclosed.

“The investment includes the relocation of the current office and manufacturing facility in Belo Horizonte, new machinery, and improvements in the operations’ energy efficiency and emission reduction. It gives us the necessary assets to further develop sustainable services close to customers,” says Jarkko Syrjälä, Director, Filtration at Valmet.

The new facility will be in operation during the first half of 2025.

The new facility will be in operation during the first half of 2025.

“Improved delivery times will strengthen our position in the South American market. The investment will also ensure our capacity for the coming years to deliver filter fabrics that respond to customer needs and provide maximized reliability and optimized performance for their filtration process,” says Felipe Floriani, Services Director, South America, Valmet.

Valmet is one of the leading suppliers of filter fabrics and industrial textiles globally. Valmet’s filtration offering covers filter fabrics and felts for the mining and chemical, pulp and paper, and laundry industries, as well as for the variety of dry filtration applications.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2023 were approximately EUR 5.5 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

AMADA WELD TECH EUROPE Offers Universal Spot Welding Heads

Provide a narrow footprint enabling high-density mounting in confined areas.

AMADA WELD TECH EUROPE highlights its Universal Spot Welding Heads, a modular weld head system that offers flexibility, simplicity, and high performance for micro joining applications. The precision ultra-low inertia weld head modules can be used either as a standalone system mounted on a third party product or as bench mounted units with fixed or variable height back supports.

The Universal Spot Welding Heads feature very low inertia, which delivers fast process response and rapid settling. They are suitable for motor, pneumatic, and manual drive systems. With a proven, rugged design ideal for automation, the Universal Spot Welding Heads provide a narrow footprint that enables high-density mounting in confined areas.

Available in a wide range of custom and standard electrode holders, the precision modules combine an integral force adjustment control with options to fit built-in force and displacement sensing monitoring transducers for use with process feedback based power supplies.

The Spot Welding Heads are ideal to use for micro joining applications, like coin cell tabs or engine components and many more.

About AMADA WELD TECH:

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We design and manufacture industry-leading product families for the global market and customize our products around specific micro-joining applications for all our customers. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. AMADA WELD TECH Europe is headquartered in Germany and has additional production facilities in The Netherlands and UK, as well as sales offices in France, Hungary and Italy. And is part of the worldwide AMADA Group, with about 8.500 employees worldwide. More about our products and services: www.amadaweldtech.eu

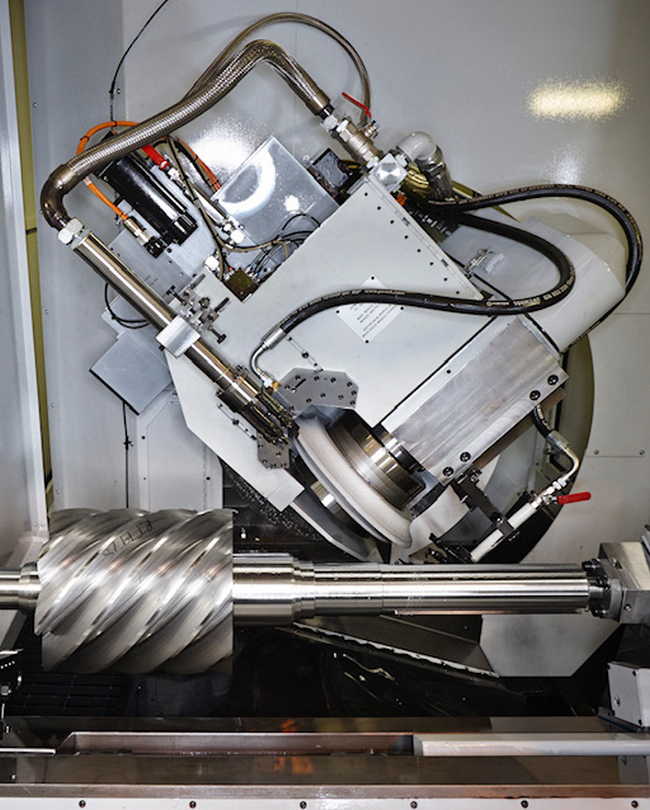

Next level control for PTG Holroyd helical rotor grinding machines

UK-based PTG Holroyd has announced that, going forward, all models in its TG Series of ultra-precise helical rotor and thread grinding machines will be equipped with the Siemens digitally native SINUMERIK ONE CNC as standard.

PTG Holroyd was the first UK machine tool manufacturer to embrace the benefits of the SINUMERIK ONE CNC, incorporating the control system into its recently launched HG350 range of worm and gear grinding centres. The decision to also use the CNC in its latest generation TG Series machines is a clear indication of PTG Holroyd’s commitment to futureproof its technologies.

“The SINUMERIK ONE CNC has brought significant user benefits to our HG350 machines, including class-leading integrated safety and failsafe features, enhanced reporting of machine health and performance data, and uncompromising levels of encrypted security. Factor in the high levels of support we receive from Siemens, and it seemed only sensible to migrate to SINUMERIK ONE for our TG Series of rotor and thread grinding machines,” comments PTG Holroyd Sales Director, Mark Curran.

PTG Holroyd’s TG Series is widely regarded as setting the industry standard for high speed, high accuracy, efficient stock removal. With the inclusion of the SINUMERIK ONE CNC, the machine tool manufacturer believes its TG range of helical rotor and thread grinding machines will be even more appropriate to its global customer base. Enhanced connectivity is provided via additional PROFINET interfaces, OPC/UA interfaces and increased performance – all made possible thanks to a PLC that is 10x faster than earlier Siemens controls. While from a machine tool manufacturing perspective, using the CNC’s Create MyVirtual Machine capabilities, in tandem with its own internal design packages, willenable PTG Holroyd’s design teams to develop all software and PLC controls on the desktop. “Just as with our HG range, this will reduce lead times significantly,” adds Mark Curran, “avoiding the need to have the physical machine on the shop floor before commencing software development.”

PTG Holroyd TG350E helical rotor and thread grinding machine.

PTG Holroyd TG350E helical rotor and thread grinding machine.

Equally suited to prototyping, batch and volume production, PTG Holroyd’s TG Series machines are designed primarily for the finish grinding of helical screw components such as worm screws and rotors after they have been milled to a rough or semi-finished state. The TG range starts with the TG50E, a machine designed to precision grind components of up to 50 mm in diameter and 610 mm in length, with models offering stepped increases in capability up to the production of helical components measuring 450 mm in diameter and 2020 mm in length. Each machine’s advanced automation means reduced setup time, while a significant amount of production time can be saved due to the fact that diamond dressing discs are continuously dressed during the semi-finish grinding cycles.

TG models offer production rates and accuracies to suit precise manufacturing strategies. Fully automated on-machine probing provides closed loop feedback of corrections to the dresser wheel and does not require a high level of operator skill.

PTG. The first name in precision

Incorporating the brands of PTG Holroyd, PTG PowerstirÒ Friction Stir Welding and Holroyd Precision Rotors, PTG has established itself at the forefront of high-precision machine tool design, build and supply for specialised applications. The range includes advanced machine tools for the production of complex helical components such as compressor rotors, pump screws and high-accuracy gears, and PowerstirÒ machine tools for friction stir welding advanced alloys used in transport applications. With production facilities in the UK, USA and China, Holroyd Precision Rotors manufactures the special purpose, ultra-precision helical components used in a wide range of industries, including refrigeration, air-conditioning, gas and vacuum pumping, industrial air handling, aerospace, medical equipment, motion control, power transmission, power generation, oil & gas, fluid transfer and high-end automotive. PTG also provides advanced technical consulting services.

www.holroyd.com

Movu Robotics and Reesink Logistic Solutions: A Powerful Alliance Transforming Warehouse Logistics with Innovative Solutions

Movu Robotics, the innovative leader in revolutionary warehouse automation technologies, and Reesink Logistic Solutions, the early adaptor integrating next-level technologies into future-proof automated warehouse solutions, are proud to spotlight their enduring partnership's success through groundbreaking projects across Europe. Highlighting their successful long-term collaboration, two flagship projects for the Weinig Group in Germany and B&S in The Netherlands showcase the partnership's innovative approach to logistics challenges, including a first-of-its-kind venture into next-level cold store logistics.

Tailored Solutions for the Weinig Group

In Germany, the Weinig Group, renowned for its wood processing technologies, will benefit from a compact and high-performance automated pallet & item storage and retrieval system designed by Reesink Logistic Solutions. This cutting-edge system streamlines the flow of parts, semi-finished and finished products, significantly enhancing efficiency and reducing manual handling using a Movu atlas pallet shuttle system. The solution underscores the beauty of a unique fit-for-purpose solution in the manufacturing and processing industry.

Innovative Cold Store Logistics for B&S

The B&S project in The Netherlands takes automation a step further with its unique concept for a pallet-based Goods-to-Person Solution in a cold store environment. Within this project, the Movu atlas pallet ASRS, the Movu ifollow AMRs, the pallet conveying system and the FAST PICK STATIONS are combined into this unique, state-of-the-art and scalable pallet-based Goods-to-Person solution. Both the Movu atlas shuttles and the ifollow AMR's can operate in temperatures ranging from -25 to +40°C. The B&S solution exemplifies how Reesink and Movu's innovative technologies can be utilized to meet the stringent requirements of temperature-controlled warehousing while ensuring operational excellence.

The Power of Collaboration

Machiel van den Hazelkamp, Commercial Director at Reesink Logistic Solutions, states, "Our enduring partnership with Movu Robotics is instrumental in our mission to provide our customers with future-proof, next-level warehousing solutions maximizing their competitive position. The projects for the Weinig Group and B&S not only demonstrate our joint capability to tailor our standard products into unique solutions in response to our client's specific needs but also highlight our commitment to advancing logistics technology in both standard and challenging environments like cold stores."

Future-Focused

Movu Robotics and Reesink Logistic Solutions are pioneering the future of logistics by focusing on high-density storage, scalability, flexibility, sustainability, and the integration of advanced technologies. They're leading the shift towards eco-efficient operations, ensuring their solutions can adapt to changing market demands using minimal space. By integrating advanced technologies, they're setting new efficiency standards, making warehousing smarter and more responsive. This strategic emphasis positions them at the forefront of sustainable and flexible logistics innovations, ready to meet tomorrow's challenges today.

Leaving no warehouse behind with next-level solutions

Movu Robotics, known for its innovative warehouse automation solutions, brings to this partnership its expertise in robotics and automation technology. The Movu atlas and ifollow solutions represent a significant advancement in pallet handling.

With more than 50 years of experience in warehouse automation, Reesink Logistic Solutions brings a wealth of knowledge and a track record of integrating over 850 warehouse automation projects.

Together, Movu Robotics and Reesink Logistic Solutions are set to redefine the standards of warehouse automation, delivering solutions that are not just efficient and cost-effective, but also tailored to the unique needs of each warehouse.

About Movu Robotics

Movu Robotics, part of stow Group, is a warehouse automation brand that stands out by bringing easier logistics automation solutions to the world’s warehouses. Employing more than 300 employees across Europe and the US, Movu Robotics offers a complete portfolio of automated technologies for efficient warehouses. This includes the pallet shuttle “Movu atlas” for multiple deep storage, the AMR solution “Movu ifollow” for collaborative picking or transport of pallets, the robotised 3D storage and fulfilment system “Movu escala” and the integrated picking robot arm “Movu eligo”. All Movu systems are controlled and managed via their own warehouse execution software. Movu Robotics’ headquarters in Lokeren, Belgium, combines a 5,000 square metre large office area with a 10,000 square metre surface for logistics and manufacturing operations under a single roof, next to a state-of-the-art experience centre - one of the biggest in Europe - where the latest technologies are showcased live to customers and partners.

For more information: www.movu-robotics.com

About Reesink Logistic Solutions

Reesink Logistic Solutions (RLS) is a top provider of automated, integrated logistics solutions ranging from robust, automated pallet storage to fully automated goods-to-person systems using advanced AutoStore (robots), Geek+ (AMR), and Movu atlas pallet shuttle technology. RLS consists of the companies AM Logistic Solutions (Offenau, Germany), Lalesse Logistic Solutions (Duiven, Netherlands), and two local subsidiaries in Poland and Austria. RLS is the Logistic Solutions division within the Royal Reesink group of companies. Royal Reesink is an international distributor and service provider with 2,600 employees and a yearly turnover of €1.6B, headquartered in the Netherlands.

As an integrated logistic solutions provider, RLS designs and delivers future-proof warehouse solutions combining a unique mix of innovative and state-of-the-art subsystems controlled by their in-house developed Warehouse Control System. The long-lasting and strategic partnerships with leading OEMs in this business, combined with the in-house developed software, ensure the best-in-class solution to almost every logistic challenge!

For more information: www.reesinkls.com

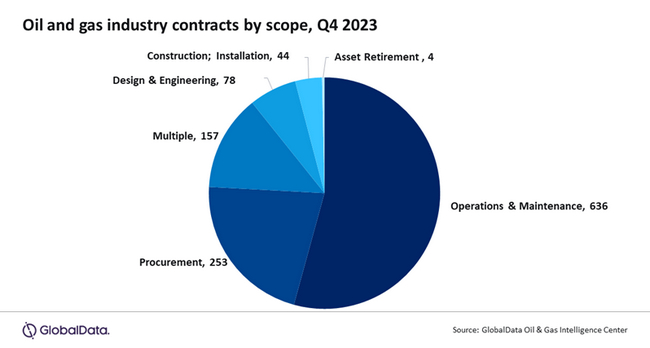

Oil and gas industry shows resilience amid 16% QoQ decline in overall contract volume during Q4 2023, reveals GlobalData

Amidst shifting market dynamics, the oil and gas industry faced a significant quarter-on-quarter (QoQ) decline of 16% in disclosed contract volume from 1,401 in Q3 2023 to 1,172 in Q4 2023. However, despite this downturn, a marginal uptick in overall contract value hints at resilience during the challenging times, reveals GlobalData, a leading data and analytics company.

GlobalData’s latest report, "Oil and Gas Industry Contracts Review by Sector, Region, Terrain, Planned and Awarded Contracts and Top Contractors and Issuers, Q4 2023,” reveals that the overall contract value marginally increased from $46 billion in Q3 2023 to $48 billion in Q4 2023.

Pritam Kad, Oil and Gas Analyst at GlobalData, comments: “The significant contract value in the quarter was largely driven by Tecnimont, Saipem, and NPCC's significant contracts with ADNOC totaling $8.7 billion and $8.2 billion, respectively, for the Hail and Ghasha Development Project in Abu Dhabi, the UAE. These contracts were pivotal in elevating the oil and gas contracts landscape, potentially boosting opportunities for further growth and collaboration in the region.”

Operation and Maintenance (O&M) represented 54% of the total contracts in Q4 2023, followed by procurement scope with 22%, and contracts with multiple scopes, such as construction, design and engineering, installation, O&M, and procurement, which accounted for 13%

ADNOC's contracts with Tecnimont, Saipem, and NPCC involve significant responsibilities. Tecnimont will oversee the construction of an onshore processing plant, including gas processing units, sulphur recovery sections, utilities, offsites, and export pipelines. Saipem and NPCC, on the other hand, will handle the Engineering, Procurement, and Construction (EPC) of drilling centers, processing plants, and various offshore structures on artificial islands for the Hail and Ghasha Development Project.

Additionally, in the petrochemical sector, notable contract being SGC eTEC E&C’s EPC contract from Sipchem and Tasnee for the expansion of an ethylene cracker plant in Al-Jubail, Saudi Arabia.

Kad concludes: “Despite facing challenges in the market environment, the oil and gas industry has demonstrated resilience. This is evident from the slight increase in total contract value, despite a significant drop in disclosed contract volume. Looking ahead, it is imperative for the industry to prioritize strategic investments and forge partnerships to navigate uncertainties and foster sustainable growth.”

- Quotes provided by Pritam Kad, Oil & Gas Analyst at GlobalData

- Data taken from GlobalData’s latest report: Oil and Gas Industry Contracts Review by Sector, Region, Terrain, Planned and Awarded Contracts and Top Contractors and Issuers, Q4 2023

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

Metso to deliver key crushing and grinding technology to the Hemi Gold Project in Australia

Australian mining company De Grey Mining Limited has awarded Metso orders for a Superior™ MKIII 50-65 primary gyratory crusher and two 14MW Premier™ ball mills. The equipment will be installed at De Grey Mining’s Hemi Gold Project located in the Pilbara region of Western Australia. The combined order value of over EUR 20 million is booked in the Minerals segment’s first-quarter 2024 orders received.

“Our aim with the Hemi Gold Project is to deliver a Tier 1 gold project and make a future top 5 Australian Gold Mine from a production perspective. The 10+ Mtpa process circuit will be equipped with state-of-the-art equipment and proven technologies contributing to responsible ore processing. We’ve just partnered with Metso in delivering the first key items for the process circuit, namely the primary gyratory and ball mills, and we’re looking to make the rest of the process equipment decisions soon. De Grey will make a series of payments according to milestones achieved over the manufacturing period and final commissioning, typical for contracts of this nature, commencing in March 2024,” says Glenn Jardine, Managing Director of De Grey Mining.

“Metso’s third generation Superior™ MKIII primary gyratory crusher, renowned for its safe and efficient operation, will be the driving force for Hemi Gold’s entire processing circuit, and the two Premier™ ball mills will provide optimized grinding performance and the highest availability for the concentrator. Both mills are equipped with failsafe Metso Polymer Hydrostatic Shoe Bearing (HSB) systems, significantly increasing reliability and reducing maintenance costs,” says Kai Rönnberg, Vice President, Minerals, Asia Pacific at Metso.

“We look forward to working on this project and future ones with De Grey Mining. In terms of servicing our customers when plants are operational, Metso also has an extensive footprint in Australia. Our state-of-the-art Karratha Service Centre in the Pilbara, which will be Metso’s largest Service Centre globally, opens this March. The Karratha Service Centre will be able to support our customers, as well as the Hemi plant, with the latest technologies and sustainable aftermarket solutions,” concludes Rönnberg.

About the products

The Metso Superior™ MKIII primary gyratory crushers provide high throughput and less downtime, enabling maximum efficiency for the operation. The product family has been developed especially to meet the needs of customers with changing ore grades and conditions in mining operations. Metso also provides a comprehensive scope of spare and wear parts and services to optimize the crushing circuit operation throughout the lifecycle. Since the product family’s launch in 2018, Metso has sold more than 50 Superior™ MKIII primary gyratory crushers around the world.

For horizontal grinding mills, Metso offers the industry’s widest selection, including the Planet Positive Metso Premier™ and Select™ mills. The energy-efficient mills can be easily integrated with Metso mill relining equipment and are supported by an extensive services network to ensure optimization during the mills’ lifetime. Metso also offers the market’s most comprehensive mill linings range and relining services, with materials and designs optimized for each application.

Learn more about Metso’s primary gyratory crushers and grinding mills on our website.

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. We improve our customers’ energy and water efficiency, increase their productivity, and reduce environmental risks with our product and process expertise. We are the partner for positive change.

Headquartered in Espoo, Finland, Metso employs over 17,000 people in close to 50 countries and sales for 2023 were about EUR 5.4 billion. The company is listed on the Nasdaq Helsinki. metso.com

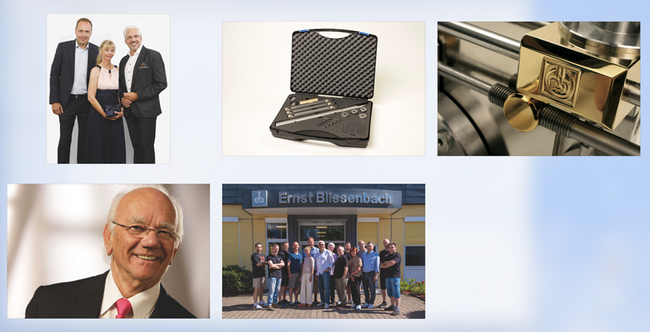

THE BLISSENBACH COMPANY AND THEIR SPECIAL FORCES

Internal weld flash removal is particularly important in the manufacture of cylindrical tubes where drawing is required to improve shape tolerances, e.g. B. in silencer pipes for the automotive industry, as they are subject to severe deformation. Reason: Deburring helps reduce nicks. Therefore, the formation of an appropriately small, flat burr is crucial in order to limit the cutting forces on the inner tube scarfing device to an absolute minimum. In conjunction with state-of-the-art high-frequency generators, our impeder meets this requirement through high efficiency. The resulting improvement in service life in turn leads to cost savings through a significant reduction in downtime for tool changes. In addition, high impeder efficiency allows the welding speed to be increased, which has a positive effect on the deburring process.

CORPORATE CULTURE AS ITS BEST

As an international developer and manufacturer of internal pipe scarfing tools for longitudinally welded pipes, we have gradually achieved the world market leadership position through constant improvements and exceptional developments.Confirmation at the national level This has been confirmed several times by relevant rankings such as TOP 100, the Mannesmann Innovation Prize, the Industry Prize and the Innovator of the Year award - all of which unanimously rank Blissenbach GmbH as one of the most innovative companies in Germany.

The pioneering spirit and innovations

have made the company the most future-oriented pioneer in the field of inner tube deburring systems and the industry leader over the last 30 years. The high-end tools, some of which are patented, were developed from the customer's perspective in order to offer pipe and system manufacturers the highest level of robustness, sustainability and cost-effectiveness for their complex production processes. Pipe producers and plant engineers around the world rely on our products, process technologies and services. They develop Ideas for their clients and the innovations are sending a clear message: Ernst Blissenbach has been at the forefront of competition for years so the customers remain viable in future. With the BLISSart® Systems any production of longitundinally welded tubes becomes safer, easier, more environmentally compatible and more economical.

HIGHLY SKILLED WORKFORCE ON ITS WAY

Benchmarking for the BLISSart® products focuses on the special type of people who work at the Blissenbach company. These are employees who go out of their way every single day to achieve the exceptional and thus guarantee the success of the company. They develop and produce precision internal pipe scarfing systems of the highest quality and increase the efficiency of pipe production.

Who are these people whose ideas have made Ernst Blissenbach GmbH one of the world market leaders? They are people who literally move mountains. They belong to the elite group and are the company's most valuable asset due to their high level of qualifications and know what needs to be done. They want pipe production to be sustainably successful and these experts know what is important. You understand the requirements of the market, recognize industry trends and keep customers up to date.

Added value through support in process solutions

What good does the best ID scarfing product do if it is not perfectly integrated into the existing Tube production? With the right know-how and support for process solutions on site at the customer’s site, Ernst Blissenbach GmbH ensures that BLISSart tools can be smoothly integrated into future production processes. To do this, the specialists work with their customer contacts to create a needs analysis and adapt existing processes individually to the requirements. On this ideal basis, the innovations offer maximum quality assurance and ensure risk and cost reduction through efficient systems.

REAL INNOVATION NEVER SLEEPS

State-of-the-art technology “made in Germany” shapes the ideas and helps to derive economic benefit from environmental advantages. The aim is to provide robust and sustainable ID scarfing solutions for effective production of longitudinally welded pipes. Through close collaboration with customers, these solutions are tailored to their individual needs and specific requirements.

Blissenbach innovations do not remain in the idea phase, but conquer the market and set standards worldwide. Constantly new technologies ensure an enormous competitive advantage and long-term success for our clients. The mission: to offer robust, sustainable internal scarfing solutions and shape the future of pipe production.

Advancing new technologies

ID scarfing systems from Blissenbach stand for robustness, longevity and functionality. Their perfect design and construction reduce tool-related machine downtimes, avoid rising costs and significantly increase the quality of internal pipe scarfing.

At the same time, the company is actively involved in research to improve material and production technology. Through systematic and intensive collaboration with technology centers and technical universities, we are always able to provide new impetus. Ernst Blissenbach GmbH stands for a culture of innovation that transcends boundaries.

How does innovation actually come about at Blissenbach?

In order to be able to develop efficient ID peeling systems, the latest trends in industry, research and the environment are used. This is where the inspiration for the company's innovation and technology agenda lies. But that's not all: the innovative ability of new BLISSart products, BLISSart further developments and innovation processes as well as the impact on the market with regard to customers and the international ecological balance are also regularly evaluated. This requires the willingness to change and the courage to consistently implement the changes deemed necessary.

MEDIA (only regarding awards and similar content)

03/2023 | Source: DDW

Innovator of the Year 2023

Ernst Blissenbach GmbH nominated for the biggest audience award of the German economy.

09/2022 | Source: Bergische Wirtschaft

Presentation of the Ernst Blissenbach GmbH in the Official Publication of the Chamber of Commerce (IHK)

Report on the Career of Company Founder Ernst Blissenbach as an Entrepreneur as well as the Development of His Tools and the Associated Founding of a New Company.

03/2022 | Source: RGA

Award collector celebrates milestone birthday

Ernst Blissenbach GmbH from Remscheid is 25 years old.

06/2020 | Source: RGA

Remscheid Placed Twice in the Top Ten

Ernst Blissenbach GmbH is one of the two companies which received the coveted seal awarded to the most innovative SMEs – an honor bestowed on them for the fourth time already.

June 2020 | Source: Compamedia

Ernst Blissenbach Was Crowned Innovation Champion

Letting go of the old and trying new ways: As an innovative SME you cannot be afraid of change — you have to embrace it.

July 2018 | Source: Die Wirtschaft

TOP 100: Ernst Blissenbach ranks among the 3rd Time to the Innovative Elite

Mentor Ranga Yogeshwar honours Ernst Blissenbach as TOP 100-Innovator 2018

July 2018 | Source: Pressebox

TOP 100: Ernst Blissenbach GmbH is among the Leading Innovators of 2018

For Ernst Blissenbach GmbH it is already the third time that they have made it into this elite group of innovators.

May 2018 | Source: Die Wirtschaft

Interview with Ernst Blissenbach

A very good example of the generation Free Ager

July 2017 | Source: Huber Verlag

“Best of 2017” For the Third Time

Huber Verlag für Neue Medien GmbH again recognizes Ernst Blissenbach GmbH.

June 2017 | Source: Remscheider General-Anzeiger

Ernst Blissenbach Receives TOP 100 Award For the Second Time

Blissenbach is part of the innovation elite of German KMU and impresses the Vienna University of Economics and Business with its Top Management and its climate of innovation.

May 2017 | Source: RGA Bergische Wirtschaft

Products In Demand Worldwide

Ernst Blissenbach GmbH manufactures specialty tools in Remscheid with great success.

Watson-Marlow to Showcase Award-Winning Fluid Management Technology at the 2024 Wine & Grape Symposium

Watson-Marlow Fluid Technology Solutions (WMFTS) will be exhibiting its award-winning fluid management technology at the Wine & Grape Symposium from January 23rd to 25th at the SAFE Credit Union Convention Center in Sacramento, California. At this leading event for enology, viticulture, and winegrape growing, WMFTS will showcase its technology at Booth 808 alongside Crush Fabricators, a custom stainless steel fabrication shop that uses WMFTS’s Certa Compact pump in their wine production.

Vintners at the show can experience first hand how WMFTS’s MasoSine Certa Sine® and Bredel line of pump solutions expand productivity and increase efficiency levels while maintaining pump quality. These pumps allow vintners to tackle complex challenges in the winemaking process, such as the handling of sensitive fluids and slurries with different viscosity levels and particulate sizes.

Certa Sine pumps deliver a gentle pumping action that is ideal for highly viscous fluids via its sophisticated sinusoidal design. Built to the EHEDG Type EL Aseptic Class I standard with 3A and FDA certifications, these pumps are an ideal solution for winemaking, eliminating the risk of aeration and unwanted oxygenation. With a max flow rate of 1124 GPM under 217 psi max operating pressures, Certa Sine® ensures a smooth product flow.

Certa Sine pumps deliver a gentle pumping action that is ideal for highly viscous fluids via its sophisticated sinusoidal design. Built to the EHEDG Type EL Aseptic Class I standard with 3A and FDA certifications, these pumps are an ideal solution for winemaking, eliminating the risk of aeration and unwanted oxygenation. With a max flow rate of 1124 GPM under 217 psi max operating pressures, Certa Sine® ensures a smooth product flow.

The Certa Compact pump is the latest member of WMFTS’s family of Certa Sine pumps. With an innovative space-saving model, the Certa Compact enables 20% footprint reduction while maintaining the integrity of a premium pump. This unique pump is ideal for applications up to 87 PSI, and its novel design empowers vintners to maximize space without compromising pump quality.

WMFTS’s Bredel line of peristaltic hose pumps offers many benefits to wineries and bottling centers, with large-capacity pumps designed to handle heavy slurries with a high density of suspended particles. Peristaltic pumps ensure safe transfer of grape and berry must by pumping the must through a secure hose without seals or contact with moving parts. In addition to the transfer of must, Bredel pumps can successfully transfer wines between storage tanks and barrels by offering accurate and repeatable metering capabilities.

Visit WMFTS at the Wine & Grape symposium to see for yourself how cutting-edge fluid transfer technology can transform your business, while also providing high energy efficiency and low maintenance that leads to substantial cost savings.

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions is an award-winning, global leader in fluid management technology and for over 60 years has engineered components and systems for customers in the food processing and handling, pharmaceutical and industrial markets. The company is part of Spirax-Sarco Engineering plc, a FTSE 100 company. Learn more at www.wmfts.com

Volvo Cars to go fully electric with European Investment Bank backing

In line with the European Union’s push for a green transition, Volvo Car Corporation and the European Investment Bank (EIB) have signed a €420 million financing agreement in support of the Swedish carmaker’s decision to become fully electric and carbon neutral. The operation is expected to contribute to the decarbonisation of road transport, a major source of emissions and pollution globally.

- Volvo Car Corporation has signed a €420 million loan agreement with the EIB for the development of a new all-electric vehicle platform.

- The investments will cover research and development, software development and implementing next-generation manufacturing technologies for fully electric vehicles.

- The financing supports the brand’s strategy to become a fully electric car manufacturer by 2030, while simultaneously aiming to lower barriers for e-vehicle adoption.

The EIB’s funding will support the development of a new, fully electric car platform, as well as the necessary research and development and roll-out of resource-efficient, advanced manufacturing technologies for electric cars. The European Union has introduced progressively more stringent environmental regulations for road transport, with the aim of making all new passenger vehicles sold emissions free by the middle of the next decade.

The EIB’s funding will support the development of a new, fully electric car platform, as well as the necessary research and development and roll-out of resource-efficient, advanced manufacturing technologies for electric cars. The European Union has introduced progressively more stringent environmental regulations for road transport, with the aim of making all new passenger vehicles sold emissions free by the middle of the next decade.

The project is expected to result in even safer and more sustainable technologies for e-vehicles, including reduced weight and faster charging, which can help lower the barriers to purchasing an electric car. As such, the operation is fully in line with the EIB’s goal to finance a just and swift transition to a net-zero economy, both in Europe and across the world.

EIB Vice-President Thomas Östros said: “I think Sweden can be proud of the leading role Volvo Cars is taking in making the automotive industry more sustainable. Making cars that run on electricity instead of fossil fuels is only one part of the puzzle. The industry itself is still very carbon-heavy, something that Volvo Cars is actively working on changing. As the EU climate bank, this is one of the many facets in the green transition that we are financing, and we’re glad to partner with Volvo Cars to accelerate the change.”

CFO of Volvo Cars Johan Ekdahl added: “Volvo Cars continues to work diligently towards the ambition of becoming a climate-neutral company by 2040. One way in which we are aiming to do that is by eliminating tailpipe emissions from our model line-up and investing towards becoming a fully electric car company by 2030. We have a long-term relationship with the EIB and are happy that they continue to support us on that exciting transformation journey.”

Background information

The European Investment Bank (EIB) is the long-term lending institution of the European Union owned by its Member States. It makes long-term finance available for sound investment in order to contribute towards EU policy goals.

Volvo Car Corporation has been active since 1927 and is headquartered in Gothenburg, Sweden.