Displaying items by tag: WatsonMarlow

Watson-Marlow to Showcase Award-Winning Fluid Management Technology at the 2024 Wine & Grape Symposium

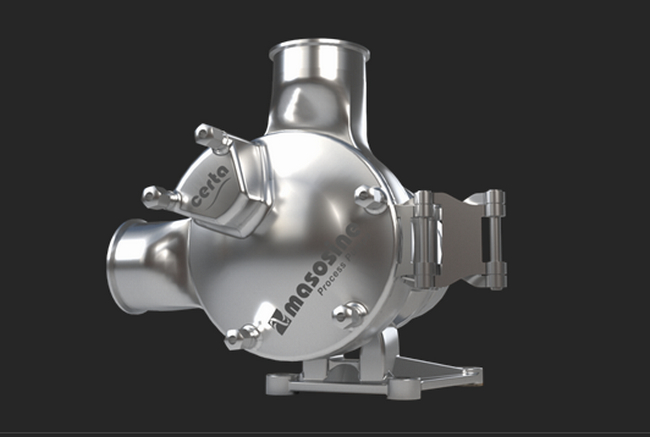

Watson-Marlow Fluid Technology Solutions (WMFTS) will be exhibiting its award-winning fluid management technology at the Wine & Grape Symposium from January 23rd to 25th at the SAFE Credit Union Convention Center in Sacramento, California. At this leading event for enology, viticulture, and winegrape growing, WMFTS will showcase its technology at Booth 808 alongside Crush Fabricators, a custom stainless steel fabrication shop that uses WMFTS’s Certa Compact pump in their wine production.

Vintners at the show can experience first hand how WMFTS’s MasoSine Certa Sine® and Bredel line of pump solutions expand productivity and increase efficiency levels while maintaining pump quality. These pumps allow vintners to tackle complex challenges in the winemaking process, such as the handling of sensitive fluids and slurries with different viscosity levels and particulate sizes.

Certa Sine pumps deliver a gentle pumping action that is ideal for highly viscous fluids via its sophisticated sinusoidal design. Built to the EHEDG Type EL Aseptic Class I standard with 3A and FDA certifications, these pumps are an ideal solution for winemaking, eliminating the risk of aeration and unwanted oxygenation. With a max flow rate of 1124 GPM under 217 psi max operating pressures, Certa Sine® ensures a smooth product flow.

Certa Sine pumps deliver a gentle pumping action that is ideal for highly viscous fluids via its sophisticated sinusoidal design. Built to the EHEDG Type EL Aseptic Class I standard with 3A and FDA certifications, these pumps are an ideal solution for winemaking, eliminating the risk of aeration and unwanted oxygenation. With a max flow rate of 1124 GPM under 217 psi max operating pressures, Certa Sine® ensures a smooth product flow.

The Certa Compact pump is the latest member of WMFTS’s family of Certa Sine pumps. With an innovative space-saving model, the Certa Compact enables 20% footprint reduction while maintaining the integrity of a premium pump. This unique pump is ideal for applications up to 87 PSI, and its novel design empowers vintners to maximize space without compromising pump quality.

WMFTS’s Bredel line of peristaltic hose pumps offers many benefits to wineries and bottling centers, with large-capacity pumps designed to handle heavy slurries with a high density of suspended particles. Peristaltic pumps ensure safe transfer of grape and berry must by pumping the must through a secure hose without seals or contact with moving parts. In addition to the transfer of must, Bredel pumps can successfully transfer wines between storage tanks and barrels by offering accurate and repeatable metering capabilities.

Visit WMFTS at the Wine & Grape symposium to see for yourself how cutting-edge fluid transfer technology can transform your business, while also providing high energy efficiency and low maintenance that leads to substantial cost savings.

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions is an award-winning, global leader in fluid management technology and for over 60 years has engineered components and systems for customers in the food processing and handling, pharmaceutical and industrial markets. The company is part of Spirax-Sarco Engineering plc, a FTSE 100 company. Learn more at www.wmfts.com

Watson-Marlow Fluid Technology Solutions Creates Pumps Ideal for Applications In the Over-the-Counter Pharmaceutical and Nutraceuticals Market

Watson-Marlow Fluid Technology Solutions (WMFTS) creates powerful and precise pumps that are ideal for applications in the over-the-counter pharmaceuticals and nutraceuticals market. Over-the-counter pharmaceuticals and nutraceuticals demand utmost accuracy and safety throughout the production process. With comprehensively validated performance and convenient clean-in-place maintenance, the highly controlled and hygienic flow of WMFTS pumps help achieve the rigorous quality required for these specialised products.

The MasoSine Certa Sine® sinusoidal pump is certified up to EHEDG Type EL Aseptic Class I standards, ensuring a clean transfer of products such as suppositories and oils. The pump also handles viscosity remarkably well. In fact, it is the best NIPR/NPSHR product in the market. This helps to transfer products such as gels, ointments, and creams while reducing the risk of cavitation. And with one shaft, one rotor, one seal, and no timing gears, the pump ultimately accomplishes a lower total cost of ownership than lobe pumps.

For products like cough syrup, Watson-Marlow and Bredel peristaltic pumps provide gentle handling and dependability. These FDA compliant pumps perform metering with pinpoint accuracy, providing perfect dosing to ensure the consistency of the end product. These peristaltic pumps also provide unique benefits for pharmaceuticals and nutraceuticals, such as vitamins, supplements, pills, and fish oils. These pumps reduce waste and cut costs by delivering fluids with extreme accuracy. The complete closure of the tube when it is squeezed also isolates the fluid, eliminating the risk of cross contamination.

Products such as over-the-counter pharmaceuticals and nutraceuticals play a vital role in people’s health. And so, they deserve the most powerful and precise pump the market has to offer. For more information about the diverse range of pumps that WMFTS delivers, visit https://www.wmfts.com/en-us/masosine/sinusoidal-pumps/certa-plus-process-pump/.

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions is an award-winning, global leader in fluid management technology and for over 60 years has engineered components and systems for customers in the food processing and handling, pharmaceutical and industrial markets. The company is part of Spirax-Sarco Engineering plc, a FTSE 100 company. Learn more at www.wmfts.com

Watson-Marlow introduces KROHNE flowmeter to safeguard accuracy of fluid flow

Watson-Marlow Fluid Technology Solutions (WMFTS) today announces the company now offers the KROHNE FLEXMAG 4050 C ® electromagnetic flowmeter for biopharmaceutical customers. As a highly accurate and reliable flow measuring system that seamlessly integrates with other WMFTS products, it reinforces the company’s position as a provider of total-solution packages for customers utilizing fluid path processes.

Superior accuracy with the electromagnetic flowmeter

With the KROHNE FLEXMAG 4050 C electromagnetic flowmeter, WMFTS customers can verify the accurate flow conditions of compatible Watson-Marlow pumps. The KROHNE flowmeter is the first single-use electromagnetic flowmeter on the market.

Unlike other single-use flowmeter technologies, such as those which use ultrasonic technology, the KROHNE flowmeter provides accurate readings independent of pressure, temperature and viscosity of the fluid. The KROHNE flowmeter provides a completely stable, direct and accurate fluid flow measurement that does not drift over time.

With a simple exchange between two different flow tube sizes, the flow measurement system can accommodate two different flow ranges with no need to recalibrate. The transmitter and flow tube are factory calibrated and do not require further adjustment on site.

Tony Barrass, Pumps and Drives Portfolio Manager at Watson-Marlow said:

“Because of its superior accuracy and repeatability, the KROHNE flowmeter is a world class product. It joins many carefully selected products in our portfolio that are compatible with Watson-Marlow pumps. With the KROHNE flowmeter, we are further able to support customers looking for a total solutions package.”

A customizable solution for bioprocessing

Creating a sterile fluid path is crucial in the biopharmaceutical industry. The flowmeter features a disposable, biocompatible and gamma stable flow tube that easily integrates into customized single-use assemblies. The FLEXMAG 4050 C flow tubes are manufactured at an ISO 13485 certified site, and production takes place in an ISO Class 7 cleanroom environment. Fluid contact materials are made from biocompatible material. The flow tube is gamma stable up to 50 kGy with fluid contact materials made from biocompatible material.

Part of the Watson-Marlow compatible accessory range, the KROHNE flowmeter is exclusively available as a package with the following Watson-Marlow pumps and/or puresu® assemblies:

- PROFINET® and EtherNet/IP™ 500, 600 and 700 series Watson-Marlow process pumps

- puresu® assemblies

This new offering from Watson-Marlow is ideal for customers in the life sciences or biopharmaceutical industry involved in a range of bioprocessing applications, including filtration processes, chromatography, and buffer or media preparation.

For more information, visit www.wmfts.com.

Watson-Marlow Highlights Qdos Chemical Metering Pumps

Watson-Marlow Fluid Technology Solutions (WMFTS) highlights its range of Qdos chemical metering pumps for chemical processing and OEM applications.

- Pumps are ideal for chemical processing and OEM applications

The Qdos range features a simple drop-in installation that eliminates the ancillary equipment required by diaphragm pump alternatives while maintaining accurate, linear, and repeatable metering for all chemical processing conditions.

Qdos peristaltic chemical metering pumps have flow rates ranging from 0.001 to 32 USGPH at up to 100 psi with +/- 1% accuracy. An intuitive menu offers advanced control features including fluid level monitoring, line priming, fluid recovery, leak detection, and flow calibration.

Qdos pumps are available with either 110V AC or 12-24V DC. The 12-24V DC power option increases the range of Qdos applications involving remote applications where 110V AC power supply is not available.

Qdos pumps offer long maintenance intervals, and have no valves or seals to clog, leak or corrode. Furthermore, the pumps feature no-tools maintenance with quick and easy pump head replacement, reducing the impact of process downtime and lowering the total cost of ownership.

Built for simplicity in installation, operation, and maintenance the Qdos range of pumps are adaptable to fit all chemical processing and OEM applications.

To learn more about Qdos, visit: https://www.wmfts.com/en-us/watson-marlow-pumps/cased-pumps/qdos-metering-pump/.

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions is an award-winning, global leader in fluid management technology and for over 60 years has engineered components and systems for customers in the food processing and handling, pharmaceutical and industrial markets. The company is part of Spirax-Sarco Engineering plc, a FTSE 100 company. Learn more at www.wmfts.com

Watson-Marlow to Showcase Qdos Chemical Metering Solutions and Bredel Heavy Duty Sludge Pumps at WEFTEC 2022

Visit Booth 7047 to view reliable and cost-effective pump technology

Watson-Marlow Fluid Technology Solutions (WMFTS) is showcasing its reliable and cost-effective pump technology for the water and wastewater industries at WEFTEC 2022, the water quality event. WEFTEC 2022 will be held at the Ernest N. Morial Convention Center, New Orleans, Louisiana from October 10-12, 2022. Visit booth 7047 to see its Qdos range of peristaltic chemical metering pumps with new Qdos mounting solutions and the Bredel line of heavy-duty sludge pumps.

On display at the booth will be the Qdos range of chemical metering pumps, ideal for myriad chemical metering applications in water and wastewater treatment facilities. With accurate linear flow rates from 0.001 to 31.7 gallons per hour at 100 psi irrespective of fluid viscosity, Qdos pumps were specifically designed to reduce chemical metering costs compared to conventional solenoid or stepper-driven diaphragm metering pumps and do so with safety being a top priority.

Qdos pumps are offered with wall, floor or tote mounting options via standard and custom skid systems and enclosures. Qdos skid and POD systems feature a calibration column, pressure gauge isolator, pressure relief valve and piping. A pressure relief valve ensures pump and piping are protected against over-pressure. The POD system offers additional protection from environmental conditions, but the secondary containment also protects operators. When utilized with a Qdos pump, the POD offers double containment for additional safety. All Qdos pumps and mounting options come with a three-year warranty.

The Bredel heavy-duty sludge pumps, also on display, are ideal for most sludge types including centrifuge and belt press feed. They feature only one wearing part – the hose – so there are no rotors, stators, U-joints or lobes to replace and no mechanical seals or packing to leak. Providing superior abrasive handling, Bredel pumps can handle flows to 475 gallons per minute (GPM) with a suction lift to 30 feet, and are dry running and reversible.

Bredel hose pumps and Qdos chemical metering pumps do not require high-cost ancillaries such as degassing or back pressure valves, nor run-dry protection or seal-water flush systems to operate and both pump ranges provide long maintenance intervals, lowering the total cost of ownership. The sealed Qdos ReNu pumphead with integral leak detection eliminates operator exposure to dangerous chemicals and does not require the pump to run during servicing.

Also at the booth, will be the revolutionary CWT peristaltic pump. This pump is the world's first peristaltic pump that does not require a tube or hose and offers multiple times the life of traditional tubing pumps.

About Watson-Marlow Fluid Technology Solutions

Watson-Marlow Fluid Technology Solutions is an award-winning, global leader in fluid management technology and for over 60 years has engineered components and systems for customers in the food processing and handling, pharmaceutical and industrial markets. The company is part of Spirax-Sarco Engineering plc, a FTSE 100 company. Learn more at www.wmfts.com

New parts provide even more ease-of-use, hygiene and safety for Watson-Marlow Certa pump users

Watson-Marlow Fluid Technology Solutions (WMFTS) is now fitting newly-designed components to its class-leading range of MasoSine Certa pumps, benefiting companies with COP (clean-out-of-place) or post-CIP (clean-in-place) inspection requirements. Already cleaner than any lobe or circumferential piston pump, Certa pumps featuring the new parts — which include a new O-ring seal system, hexagonal locking screw and weld-on hinge — elevate ease-of-use, hygiene and safety to even higher levels.

In combination with optimal process efficiency and minimal TCO (total cost of ownership), Certa pumps meet the highest standards in hygiene and cleanability. Designed primarily for CIP processes, Certa pumps do not require stripping down to component level for cleaning between batches or before use. However, some customer processes stipulate regular strip-downs regardless, either to clean the pump as part of a COP requirement, or to check for cleanliness after a CIP cycle. The new components for the Certa range have been designed with these processes in mind.

“The new O-Ring seal system is designed for applications that require frequent assembly/disassembly procedures,” explained Florian Walter, Product Manager for MasoSine. “It’s available for all MasoSine Certa pump sizes and can be retrofitted to existing pumps without the need of a pump modification. The O-Ring seal system is also less expensive than a mechanical seal,” Walter said.

“Another important ease-of-use improvement on the latest Certa pumps is the introduction of a hexagonal locking screw,” added Walter. “Now, users can easily release the new locking screw to remove the pump rotor, without special tools. Just like the new O-Ring seal, the locking screw is purpose-designed for frequent disassembly/re-assembly.

“With safety in mind, a new weld-on hinge option is now available for the Certa 400 and larger pump models. This new hinge option takes the weight of the front cover, thus allowing users to have their hands free for cleaning or inspection of the pump rotor or gate,” concluded Walter.

Watson-Marlow announces ground breaking of new state-of-the-art manufacturing facility in Devens, MA

Watson-Marlow is pleased to announce the ground breaking of its new state-of-the-art manufacturing facility in Devens Massachusetts. A celebration ceremony is being held on Thursday, November 18th at 16 Bulge Road in Devens MA at 10:00 AM. The new facility will be dedicated to Watson-Marlow’s range of industry leading products, including peristaltic pumps, tubing, fluid path solutions and BioPure components.

The Devens, MA 150,000 square foot (14,000 square metres) facility will be close to the life sciences hub in the Cambridge/Boston area. The site will incorporate a suite of eight ISO14644-1 Class 7 cleanrooms, warehousing and offices, with space for two further cleanrooms within the initial footprint. With segregated cleanroom and non-cleanroom production capabilities, Watson-Marlow’s new facility will strengthen the support the Company provides to customers in the region across its core sectors of pharmaceutical and biotechnology, medical diagnostics, and process industries.

“The new U.S. facility is an important milestone in the Watson-Marlow company history and marks a significant commitment to serving our customers in the Americas region.” Says Andrew Mines, Watson-Marlow Managing Director, “This exciting development is bringing us closer to our customers whose purpose is to help the world around us, from advancing cell and gene therapies through to ensuring people have access to clean drinking water. Together we will continue to develop market-leading fluid management solutions to engineer a more sustainable future. A huge thanks goes to the Watson-Marlow, BioPure, Americas and Watson-Marlow Central Support teams that are making this happen, as well as to our parent Company, Spirax-Sarco Engineering who have enabled us to make such a significant investment in our future.”

Watson-Marlow is an award-winning employer and this new facility will bring significant job opportunities to the local area, with over 150 positions coming available. Production at the new facility will replicate that of Watson-Marlow’s European sites, ensuring continued product quality for customers, by using the same raw materials, components, processes and work instructions. Completion of the facility is due in late 2022, with the first products due to be shipped from the site in late Q4.

Part of Spirax-Sarco Engineering plc, a FTSE100 Company, Watson-Marlow specialises in high-quality fluid management solutions for the life sciences and process industries. This significant investment in the expansion of its manufacturing capacity will support the Company’s future growth in the Americas.

Watson-Marlow Fluid Technology Group (WMFTG) is the world leader in peristaltic pumps and associated fluid path technologies. The Group comprises ten established brands, each with their own area of expertise. Together they provide leading engineering solutions across the food, pharmaceutical, chemical and environmental industries.

WMFTG is headquartered in the United Kingdom with international operations in 44 countries and employing over 1750 people globally.

Watson-Marlow is a wholly owned subsidiary of multi-national industrial engineering Group, Spirax-Sarco Engineering plc, a constituent of the FTSE 100, with strategically located manufacturing plants around the world and over 8,200 employees, including 1,950 direct sales and service engineers.

As a leading engineering group, we have an ethical responsibility to manage our economic, environmental and social impacts, while helping our customers and suppliers to do the same. In August this year, WMFTG committed to achieving net zero carbon by 2030.

Further information can be found at www.wmftg.com

Watson-Marlow announces details of the new U.S. manufacturing facility bringing them closer to customers in the region

Watson-Marlow is pleased to announce that construction began in October 2021, on a new state-of-the-art manufacturing facility in the United States, with first production due in late 2022. Following an announcement made earlier this year, the Company is pleased to provide further details about the new facility which will be dedicated to its range of industry leading products, including peristaltic pumps, tubing, fluid path solutions and BioPure components.

Part of Spirax-Sarco Engineering plc, a FTSE100 Company, Watson-Marlow specializes in high-quality fluid management solutions for the life sciences and process industries. This significant investment in the expansion of its manufacturing capacity will support the Company’s future growth in the Americas.

Located in Devens, Massachusetts, USA, the 150,000 square foot (14,000 square metres) facility will be close to the life sciences hub in the Cambridge/Boston area. The site will incorporate a suite of eight ISO14644-1 Class 7 cleanrooms, warehousing and offices, with space for two further cleanrooms within the initial footprint. With segregated cleanroom and non-cleanroom production capabilities, Watson-Marlow’s new U.S. facility will strengthen the support the Company provides to customers in the region across its core sectors of pharmaceutical and biotechnology, medical diagnostics, and process industries.

“The new U.S. facility is an important milestone in the Watson-Marlow company history and marks a significant commitment to serving our customers in the Americas region.” Says Andrew Mines, Watson-Marlow Managing Director, “This exciting development is bringing us closer to our customers whose purpose is to help the world around us, from advancing cell and gene therapies through to ensuring people have access to clean drinking water. Together we will continue to develop market-leading fluid management solutions to engineer a more sustainable future. A huge thanks goes to the Watson-Marlow, BioPure, Americas and Watson-Marlow Central Support teams that are making this happen, as well as to our parent Company, Spirax-Sarco Engineering who have enabled us to make such a significant investment in our future.”

Watson-Marlow is an award-winning employer and this new facility will bring significant job opportunities to the local area, with over 150 positions coming available. Production at the new facility will replicate that of Watson-Marlow’s European sites, ensuring continued product quality for customers, by using the same raw materials, components, processes and work instructions. Completion of the facility is due in late 2022, with the first products due to be shipped from the site in late Q4.

Watson-Marlow Fluid Technology Group (WMFTG) is the world leader in peristaltic pumps and associated fluid path technologies. The Group comprises ten established brands, each with their own area of expertise. Together they provide leading engineering solutions across the food, pharmaceutical, chemical and environmental industries.

WMFTG is headquartered in the United Kingdom with international operations in 44 countries and employing over 1750 people globally.

Watson-Marlow is a wholly owned subsidiary of multi-national industrial engineering Group, Spirax-Sarco Engineering plc, a constituent of the FTSE 100, with strategically located manufacturing plants around the world and over 8,200 employees, including 1,950 direct sales and service engineers.

As a leading engineering group, we have an ethical responsibility to manage our economic, environmental and social impacts, while helping our customers and suppliers to do the same. In August this year, WMFTG committed to achieving net zero carbon by 2030.

Further information can be found at www.wmftg.com