Displaying items by tag: Sulzer

Sulzer Chemtech’s technology helps vegetable oil producer enter the biofuel market

Businesses interested in producing biodiesel need advanced processing solutions that can achieve high purity levels while maximizing the recovery of this fuel. When Bremfield Sdn Bhd, a leading Malaysian vegetable oil processor, was looking to add biodiesel to its product portfolio, Sulzer Chemtech’s distillation technology offered an effective solution with a quick return on investment.

Rising demand for bio-based fuels is opening key opportunities for businesses looking to enter the biodiesel sector. This alternative to conventional fossil fuels leads to lower emissions of (CO2) and particulate matter when used.

The solution consists of a highly effective distillation train that can process 300 tonnes of biodiesel per day and deliver high purity products. A substantial advantage for companies interested in producing biodiesel is the broad variety of feedstock available. In effect, this fuel can be obtained by processing a wide range of resources, such as animal fats, vegetable oils or used cooking oil. Therefore, businesses can utilize the raw material that best fit their needs and capabilities or resources that are already part of their production systems.

The solution consists of a highly effective distillation train that can process 300 tonnes of biodiesel per day and deliver high purity products. A substantial advantage for companies interested in producing biodiesel is the broad variety of feedstock available. In effect, this fuel can be obtained by processing a wide range of resources, such as animal fats, vegetable oils or used cooking oil. Therefore, businesses can utilize the raw material that best fit their needs and capabilities or resources that are already part of their production systems.

Regardless of the chosen resource, the manufacturing process remains the same and is based on the transesterification of triglycerides in the presence of alcohol, alkaline or enzyme catalysts. As a result of this reaction, mono-alkyl fatty esters – i.e. biodiesel – are produced, together with fatty acids, particularly monoglyceride.

After the esters are formed, their purification is the next essential step in biodiesel manufacturing, as it removes impurities and reduces the concentration of monoglyceride in the end product. Systems that can achieve a high separation performance are extremely beneficial. They help producers to deliver transparent fuels with extremely low cloud and pour points that can meet even strict winter-grade specifications. These can also be mixed with conventional diesel fuels to support, among others, customers in Europe and North America.

Tapping into new opportunities

In order to further leverage its existing oil-based resources, Bremfield Sdn Bhd wanted to set up a small-scale biodiesel facility in its oil processing plant, located in Klang, Malaysia. Creating a system with limited processing capacity of 300 tonnes of biodiesel per day and the need to obtain fuels with a minimum residual concentration of monoglyceride to meet strict winter-grade specifications, were some of the main aspects that the extraction equipment within the new production line needed to account for. To develop a highly effective solution for this application, the company contacted the leading separation technology specialist, Sulzer Chemtech.

The company was able to provide a design that could process the necessary 300 tonnes of biodiesel per day with high separation and energy efficiency while offering a quick return on investment (ROI). The solution that was developed relies on a single, compact separation column, where most of the biodiesel is extracted.

Key components within the column are Sulzer Chemtech’s MellapakPlusTM structured packings to fit a high number of theoretical stages in a limited footprint, minimizing the capital expenditure while providing the vacuum conditions required for biodiesel purification and maintaining low pressure drops.

As the column needed to reach elevated temperatures (between 190 °C and 220 °C) to effectively separate the biofuel from various impurities, the set up was designed to maximize the energy efficiency of heating operations. In this way, the oil processor could maintain low running costs, quick ROI and ultimately cost- competitive biodiesel prices.

Sulzer Chemtech was also responsible for basic engineering, detail engineering, procurement of equipment and accessories, project management, commissioning and startup of the new unit. Thanks to the solution provided by the company the facility was completed in less than a year and Bremfield Sdn Bhd has met its capacity goal of 300 tonnes per day and high purity requirements by reaching monoglyceride levels lower than the necessary 0.2% w/w, thus supporting winter-grade specifications. The facility has been operating efficiently for over four years and the company has been able to support customers with high-quality biofuels.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

The Chemtech division is the global market leader in innovative mass transfer, static mixing and polymer solutions for petrochemicals, refining and LNG. Chemtech is also leading the way in ecological solutions such as biopolymers as well as textile and plastic recycling, contributing to a circular economy. Our product offering ranges from technology licensing to process components all the way to complete separation process plants. Customer support ranges from engineering and field services to tray and packing installation, tower maintenance, welding and plant turnaround projects – ensuring minimal downtime.

Improving global sustainability with a unique, green manufacturing system

Sulzer Chemtech partners with AVA Biochem to expand its portfolio of sustainable chemical production technologies

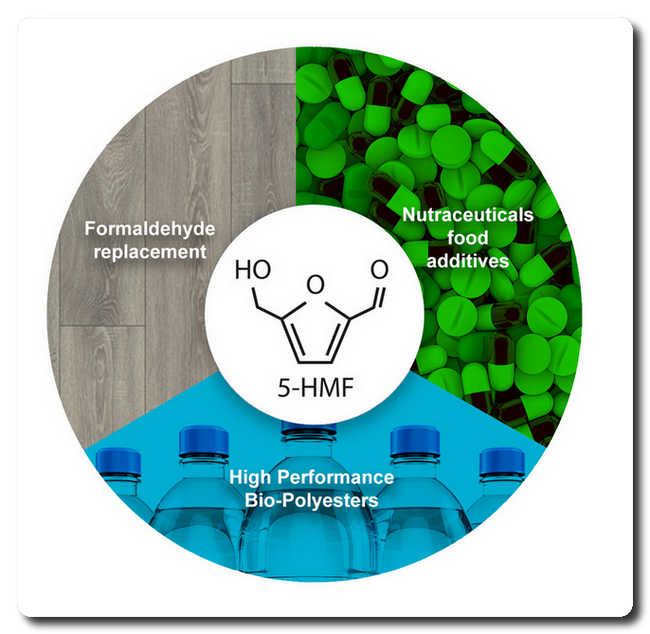

Sulzer Chemtech and AVA Biochem have entered into an exclusive license agreement to commercialize AVA Biochem’s innovative technology for the Conversion of Biomass to Renewable Industrial Substances (COBRISTM). This offers a versatile solution to produce 5-(hydroxymethyl) furfural (5-HMF), a bio-based platform chemical that is a building block for the production of a broad range of widely used chemical products.

Sulzer Chemtech has entered into an exclusive license agreement with AVA Biochem to commercialize an innovative technology for the Conversion of Biomass to Renewable Industrial Substances (COBRISTM). AVA Biochem AG is a pioneer in enabling the decarbonization of traditional chemical and adjacent B2B industries, and it is known for its proprietary water-based Hydro-Thermal Process (HTP) COBRISTM. This turns sugar-rich biomass into 5-HMF, a renewable and non-toxic compound that can be used to produce commodity chemicals. These include adhesives, food additives, textile fibers, packaging, films and fine chemicals, as well as a possible alternative to formaldehyde used in chipboards. The solution can therefore support the large-scale production of bio-based materials, enhancing the sustainability of both the manufacturing and processing sectors.

Sulzer Chemtech has entered into an exclusive license agreement with AVA Biochem to commercialize an innovative technology for the Conversion of Biomass to Renewable Industrial Substances (COBRISTM). AVA Biochem AG is a pioneer in enabling the decarbonization of traditional chemical and adjacent B2B industries, and it is known for its proprietary water-based Hydro-Thermal Process (HTP) COBRISTM. This turns sugar-rich biomass into 5-HMF, a renewable and non-toxic compound that can be used to produce commodity chemicals. These include adhesives, food additives, textile fibers, packaging, films and fine chemicals, as well as a possible alternative to formaldehyde used in chipboards. The solution can therefore support the large-scale production of bio-based materials, enhancing the sustainability of both the manufacturing and processing sectors.

Sulzer Chemtech, the leader in separation, mixing and process technology, will commercialize the licensed technology along with its proprietary key equipment for the purification of 5-HMF, such as falling film evaporators. These are already supporting operations at the unique demonstration plant in Muttenz, Switzerland, where 5-HMF is produced in different forms for a total capacity of 6 metric tons per year.

Dr. Christoph Kolano, Chief Executive Officer of AVA Biochem AG, comments: “We strive to create a circular economy that will contribute to a positive environmental future. We are at the right time and place, with a suitable commercial and industrial technology at the ready. Key topics like CO2 footprint, conversion of biomass according to Green Chemistry principles are more prominent than ever. Mindful consumers are increasingly aware of biodegradability, the impact of plastics and alternatives to fossil resources. They care about reducing waste, recycling or upcycling.” He adds: “AVA Biochem AG pioneered the Hydro-Thermal Technologies (HTx) for various applications more than a decade ago, accompanied and financed by a group of private entrepreneurs with both a sustainability mindset and a long-term perspective. Together with Sulzer Chemtech, we are bringing proven fully scalable eco-excellence to the table enabling sustainable and renewable technologies.”

By commercializing COBRISTM, Sulzer Chemtech will be able to offer a key technology to produce 5-(hydroxymethyl) furfural (5-HMF), a bio-based platform chemical for the production of a broad range of widely used products.

By commercializing COBRISTM, Sulzer Chemtech will be able to offer a key technology to produce 5-(hydroxymethyl) furfural (5-HMF), a bio-based platform chemical for the production of a broad range of widely used products.

Dr. Torsten Wintergerste, Division President Sulzer Chemtech, concludes: “We are proud to expand our portfolio of technologies for the production of renewable, bio-based and recyclable materials with AVA Biochem’s COBRISTM technology. This new solution, which includes our advanced separators, is an excellent fit with Sulzer Chemtech’s product and service offering. We look forward to implementing this technology globally to support companies in the manufacturing and processing sectors interested in improving the sustainability of their operations with this unique, green system.”

About AVA Biochem

AVA Biochem is the global leader in the industrial development, production, sale, and licensing of the 100% bio-based platform chemical 5-Hydroxy Methyl Furfural (5-HMF), a renewable and non-toxic alternative to a range of fossil-based materials. 5-HMF has a broad range of applications in the chemical, pharmaceutical, and food industries. Since 2014, Swiss-based AVA Biochem is producing high-purity 5-HMF for research purposes and specialty chemicals markets, as well as technical-grade 5-HMF for bulk chemistry applications and downstream chemicals like PEF. www.ava-biochem.com

Contact:

Dr. Christoph Kolano, Chief Executive Officer of AVA Biochem AG

AVA Biochem AG, Bahnhofstrasse 17, CH-6300 Zug, Switzerland

AVA Biochem BSL AG (Production), Rothausstrasse 61, CH-4132 Muttenz, Switzerland

Email : This email address is being protected from spambots. You need JavaScript enabled to view it.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class manufacturing facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).

The Chemtech division is the global market leader in innovative mass transfer, static mixing and polymer solutions for petrochemicals, refining and LNG. Chemtech is also leading the way in ecological solutions such as biopolymers as well as textile and plastic recycling, contributing to a circular economy. Our product offering ranges from technology licensing to process components all the way to complete separation process plants. Customer support ranges from engineering and field services to tray and packing installation, tower maintenance, welding and plant turnaround projects – ensuring minimal downtime.

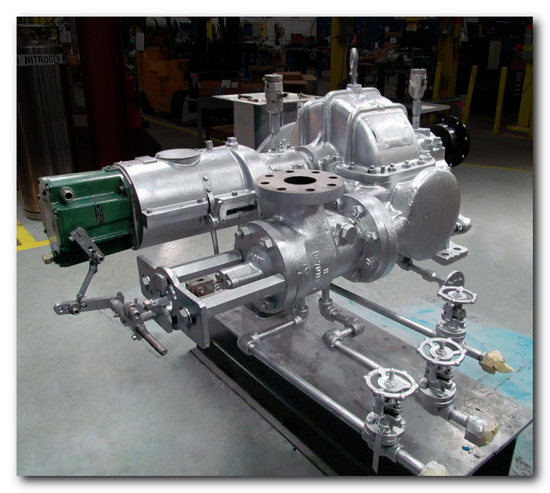

New steam turbine repair facility in Piedmont expands Sulzer’s network capability

Sulzer’s extensive repair facilities have been further enhanced with the ability to refurbish small steam turbines in Piedmont, South Carolina. This additional service complements the existing range of repairs for electric motors, pumps, compressors and generators. In addition to mechanical repairs and welding services, the service center has an experienced field services team that delivers on-site repairs around the clock.

Sulzer’s extensive repair facilities have been further enhanced with the ability to refurbish small steam turbines in Piedmont, South Carolina.

As part of the investment made by Sulzer to improve local repair facilities, the service center in Piedmont has been equipped to carry out complete refurbishments of small steam turbine packages in addition to the services already delivered. The service center can now handle steam turbines up to 750 hp and repairs include balancing as well as overhaul of the governor and trip unit.

The service center in Piedmont has been equipped to carry out complete refurbishments of small steam turbine packages including overhauls of governor and trip units.

The experienced project team of engineers, designers and field service technicians is able to deliver repairs to small steam turbines and other turbomachinery for customers involved in power generation, paper, and petrochemical, steel as well as more general industries. This most recent addition in the Sulzer portfolio minimizes transport time for steam turbine repairs in the South East USA and ensures a cost effective repair.

Repairs to steam turbomachinery such as compressors and expanders up to 750 hp are delivered by the Service Center.

Sulzer service centers act as the local point of contact for a repair of any scale, even if the equipment has to be sent to another facility for the work to be completed. In this way every service center can offer the complete range of repair services to its customers. By delivering an efficient and reliable service, Sulzer is able to minimize downtime and increase productivity for each customer.

About Sulzer:

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of over 150 technically advanced manufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace of mind to focus on their core operations.

Sulzer Rotating Equipment Services, a division of Sulzer, can accommodate all brands of rotating equipment including turbines, compressors, generators, motors and pumps. With an enviable track record, dedicated teams of on-site engineers provide best-in-class solutions to ensure that the most effective service is delivered.

Sulzer is dedicated to providing superior service solutions to a range of industries including power generation, oil and gas, hydrocarbon and chemical processing, water and air separation. Every solution is customized to suit the business needs of each application – whenever or wherever that may be.

With a long history of providing engineering service support, Sulzer is headquartered in Winterthur, Switzerland where it began in 1834. Today, with sales over US$ 3 billion and with approximately 15,000 employees, the Sulzer footprint spans across the globe. The core aim is to deliver a flexible and cost-effective service that optimizes customer operational efficiency and minimizes downtime.

For more information on Sulzer, visit www.sulzer.com

The image(s) posted with this press release may only be used to accompany this copy, and are subject to copyright. Please contact DMA Europa if you wish to license the image for further use.