Displaying items by tag: PP Control & Automation

PP Control & Automation aims to be top of the crops with £3m AgriTech ‘outsourcing’ opportunity

One of the UK’s leading strategic outsourcing manufacturing specialists has launched a five-point mandate to explore a potential £multi-million opportunity in the AgriTech sector.

PP Control & Automation (PP C&A), which supports 20 of the world’s leading machinery builders, believes its ability to deliver cost savings, ‘scale-up potential’ and speed to market will be essential for companies looking to deliver new innovations that will drive global food security.

It is already in the final stages of negotiations with one critical supplier to the sector and is now targeting over £3m of work in this arena in the next eighteen months.

Part of the Manufacturing Assembly Network (MAN), PP C&A has also signed-up as the latest member of the Agri-EPI Centre Network.

Part of the Manufacturing Assembly Network (MAN), PP C&A has also signed-up as the latest member of the Agri-EPI Centre Network.

The latter, which was established as part of the UK Government’s AgriTech Strategy to develop, fund and commercialise new precision agricultural technologies, is doing amazing work to bridge the gap between the people creating the innovations and those who will benefit from them.

“We’ve had so many conversations with AgriTech innovators over the last twelve months, some of which are now reaching a conclusion and how they manufacture at scale,” explained Garry Myatt, Sales Director at PP Control & Automation.

“Our world class facility in the West Midlands can be the perfect ‘outsourcing’ home for these types of projects and we believe that the best way of spreading the message is by collaborating with partners like the Agri-EPI Centre.”

He continued: “We can help people build smart tractors, automated irrigation systems and machines that transform traditional farming into a data-driven operation that boosts crop yields, conserves resources and reduces waste.

“Our membership of Agri-EPI Centre will open new doors, create more partnerships and, through its calendar of events, we’ll have every opportunity to showcase the PP C&A capabilities.”

PP Control & Automation will be pushing its 5-point outsourcing mandate when targeting customers involved in AgriTech.

It starts with the company’s expertise and in-depth manufacturing knowledge that can cater for the intricacies of this industry and flows through cost efficiencies gained from resource allocation, supply chain optimisation and scale-up capacity.

By outsourcing non-core functions, machine builders and innovators can focus on the R&D activity that makes them different, whilst flexibility to grow in keeping with market fluctuation can be achieved easily.

Finally, PP C&A can deliver complete quality assurance that aligns with specific AgriTech regulations, with UL508a accreditation already in place for dealing with the North American market.

Garry went on to add: “Our manufacturing capability has touched more than 20 different sectors, ranging from automotive, aerospace and med tech to food weighing, production and clients involved in the circular economy.

“Now is the time for us to take our proven track record and open it up to OEMs and machinery builders who are striving to deliver sustainable food security.”

Paige Boardman, Membership Engagement Manager at Agri-EPI Centre, concluded: “We are thrilled to have PP C&A on-board and look forward to working together moving forward.

“Garry and his team will be able to benefit from our wide-reaching network and the array of events we host both on and off the farm.

“We have a large variety of companies attend and there are always new people to talk to and opportunities to uncover – many of which could be suitable for PP Control & Automation.”

For further information, please visit www.ppcanda.com

Hedinn fishing for efficiencies as PP C&A helps it deliver €11m deal

One of the UK’s leading strategic manufacturing outsourcing specialists is celebrating a fifth birthday of supplying the fishing sector in style by supporting a new €11m project.

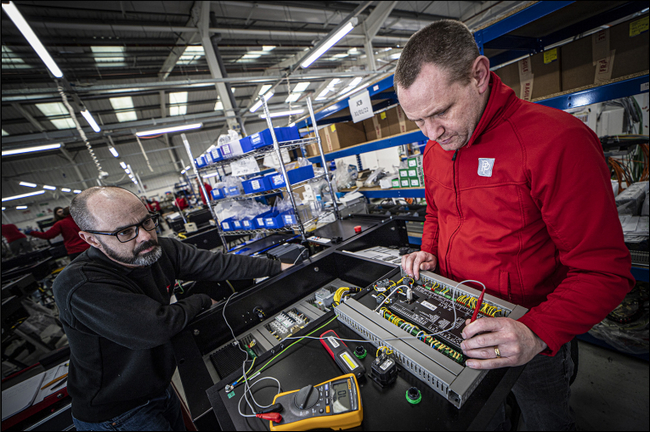

PP Control & Automation, which employs more than 230 people at its world class facility in Cheslyn Hay, will provide complete electrical build services on the dual Hedinn HPP-10000s that are destined for Sildarvinnslan, Iceland’s biggest fishmeal and fish oil producer.

Capable of turning 380 tonnes of fish waste and offal into high quality protein meal and oil for animal feed, the plants are the largest ever delivered and will involve PP C&A assembling sensors, prefabricated cables, junction boxes and I/O cabinets, labels for sensors and motor isolator switches.

The technology here utilises significantly less energy than existing traditional methods, is 30% more compact and has 30% fewer components. Importantly, it also offers the dual benefits of increased profitability and greener environmental performance, attributes very much in demand.

Tony Hague, CEO of PP Control & Automation, picked up the story: “Hedinn was our first involvement in the fishing industry and the relationship underlines how a lot of the values of strategic outsourcing transcend all sectors.

“By working with a specialist, we have given it access to skill, capability and capacity, which, in turn, has led to faster builds, improved product quality and the ability to cost-effectively scale.”

He added: “As the partnership has developed, we have also collaborated to look at standardising some of the manufacturing processes across all its different protein plants. This can only be done so far, but we have certainly reached a stage where increases in volumes can be easily met.”

Ragnar Sverrisson, Managing Director of Hedinn, added his support: “The Sildarvinnslan deal is a major project for our business and one we can deliver on time and to budget thanks to our team of experts and the support we receive from PP C&A.

“As a strategic partner, it has access to our whole electrical package, which means it holds a comprehensive understanding of the requirements for each build and any customisation that needs to be incorporated. The workmanship is second to none and wiring faults are virtually non-existent, which gives us great confidence and a significant commercial advantage.”

Since the first project, PP Control & Automation has helped produce the HPPm-2000, HPP-5000, HPPsh-300 and HPP-15000, a mixture of land and at sea solutions for using 100% of fish waste and offal to produce high quality protein meal and oil for animal feed.

The partnership has evolved so that Hedinn can importantly focus more of its time and resource on the design and development of its plants, as well as providing a quality service to its growing legion of global customers.

Today, the Icelandic business employs 120 people and has a group turnover of approximately €30m, with HPP Solutions launched in January as a standalone business to help drive its HPP division.

PP C&A’s Tony Hague concluded: “It’s great news that we can celebrate 5 years of working together by supporting Hedinn with such a landmark project. Everything is in place in the UK to scale volumes as interest in the technology will grow – a real UK/Icelandic success story!”

For further information, please visit www.ppcanda.com or follow @ppcanda on twitter. More details on Hedinn can be found at www.proteinplant.is

PP Control & Automation launches PP+ to help bridge ‘valley of death’

One of the UK’s leading strategic manufacturing outsourcing specialists is aiming to help domestic businesses cross the well-publicised ‘valley of death.

PP Control & Automation (PP C&A), which already works with over 20 of the world’s leading machinery manufacturers, is launching PP+, a unique ecosystem of experts that will help start-ups, SMEs and multi-nationals take advantage of scale-up opportunities and the commercialisation of new technologies.

The initiative works by offering a single point of contact for management teams that, after an initial consultation, will be connected to market leaders in design, engineering, legislation and approvals, sales and marketing and PR.

They will also receive support in accessing funding, management coaching and a clear route to some of the best academic and R&D knowledge in the UK.

Already signed up to deliver their expertise are Cucumber PR, Institute for Clean Growth & Future Mobility at Coventry University, the Manufacturing Assembly Network (MAN), Product Approvals, S2F Marketing and the Silverstone Technology Cluster.

Tony Hague, CEO of PP C&A, said: “The UK has a wealth of innovative engineering and manufacturing companies that often come up with new concepts and ideas that have true commercialisation potential and the opportunity to scale – however, they simply don’t have the capacity or additional expertise to realise these fantastic ideas.

“We have seen first-hand these challenges are often down to lack of available resource, advice and ‘bandwidth’ and we want to do something to change this.”

He continued: “Utilising our wider network of partners, we have put some real thought and energy into how we can develop our unique outsourcing offer so we can help support and signpost as many organisations as we can to ensure growth and prosperity within UK manufacturing.”

The PP+ ecosystem starts with an initial discovery session to outline the business goals of the client, the market opportunity and any potential barriers to success.

This is facilitated by PP C&A, S2F Marketing and Cucumber PR, with a clear strategy formulated that identifies where access to the wider network of experts is required.

To unlock their potential, they’ll need scaling-up coaching, sales consultation, and marketing and PR strategy.

Furthermore, as they grow, there will be opportunity to enter international markets where legislative demands bring new challenges and complexity, as well as a need to make efficiencies through design optimisation and access to academia and engineering groups.

“PP C&A can be the key to this sought-after access thanks to its well-established partner network,” continued Tony.

“New market footholds generally exist where disruptive innovations originate, and novel technologies can be deployed to change the way a sector or even the world behaves.

“This disruption is often the starting point, but there is only a small window of opportunity to make sure this same disruption becomes a sustainable business.”

He added: “PP+ is here to deliver immediate expertise, knowledge and a track record of bringing new products to market. It’s all about unlocking and commercialising the ideas to make UK manufacturing stronger and more successful.”

Pim van Baarsen, CEO of Silverstone Technology Cluster (STC), offered his support: “I’m delighted that we can be part of this venture and we look forward to working with Tony and the rest of the team to help the UK prosper.

“It’s great to see PP C&A setting up initiatives like PP+, which will undoubtedly prove valuable for early-stage innovators and fast-growing companies that could really use the expertise on offer.

“The STC has a vast network of relevant businesses that we can connect people to, in order to get their projects off the ground, both from a technological, as well as a management and finance point of view.”

Just a week into the launch and PP Control & Automation is already in conversation with several potential users of the new ecosystem.

It is also exploring extending the network even further to encompass even more specialisms.

For further information, please visit www.ppcanda.com