Global technology company ABB has today launched its Tundish EMS solution to enable steelmakers to overcome the limited ability of the tundish vessel in controlling the flow of molten metal, and therefore steel quality and temperature.

- ABB’s new Tundish EMS (electromagnetic stirring) offering will improve quality, productivity and profitability in billet and bloom casting and metal powder production

- The new technology enables steel plant operators to overcome challenges of controlling flow, steel quality and temperature in tundish not yet solved by furniture systems

- Solution will match the industry’s higher requirements for steel cleanliness

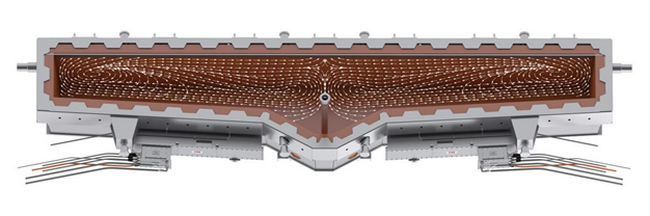

Tundish EMS is placed on the outside of the tundish and uses non-contact electromagnetic stirring technology to generate an electromagnetic field that creates a stirring effect in the bath melt. This continuous stirring significantly increases mixing zone volume for virtually the entire tundish, with higher flow speeds, elimination of dead zones and homogenization of temperature.

Tundish EMS is placed on the outside of the tundish and uses non-contact electromagnetic stirring technology to generate an electromagnetic field that creates a stirring effect in the bath melt. This continuous stirring significantly increases mixing zone volume for virtually the entire tundish, with higher flow speeds, elimination of dead zones and homogenization of temperature.

Adoption of this electromagnetic stirring technology will be particularly important for steelmakers with multiple casting strands coming from one tundish. It will mean greater removal of inclusions, resulting in smoother, cleaner steel and reductions in nozzle clogging.

By creating a stirring flow throughout the entire tundish melt bath, Tundish EMS delivers rapid homogenization of temperature and chemical composition that results in better quality steel, more uniform and repeatable casting conditions across multiple strands and overall improved quality, productivity and profitability in billet and bloom casting and metal powder production.

“The new Tundish EMS is a result of ABB’s know-how in stirrer design and unrivalled process insight gained from thousands of installations as well as track record in collaborative product development,” said Zaeim Mehraban, Global Sales Manager, Metallurgy Products at ABB. “It allows steelmakers to overcome a challenge that tundish furniture has not yet been able to solve. As well as increasing quality, productivity and profitability, Tundish EMS uses non-contact electromagnetic stirring technology which extends lifespan and means almost no maintenance is required.”

Tundish EMS offers several new functionalities including flexibility in stirring force and direction and the ability to stir and control the flow field in the whole melt volume of the tundish. This means that steelmakers no longer have to rely solely on the limited ability of tundish furnishings for control of molten metal flow, where often significant dead zones lead to temperature variations and where smaller inclusions or inclusion clusters cannot be removed. A variety of Tundish EMS installation configurations are available for most tundish types.

Tundish EMS enhances quality, productivity and profitabilty in a number of ways. As well as improving non-metallic inclusion removal and overall steel cleanliness, it also provides temperature homogenization and stability throughout the entire tundish melt bath, reducing superheat and enhancing uniformity of temperature across various strands. Overall process repeatability and reliability is improved and costs are reduced by lowered consumption of tundish furniture such as dam, weir and baffle materials.

ABB offers the world's most comprehensive range of EMS for both steel and aluminium production processes, delivering metallurgical improvements that are proven to increase productivity, end-product quality and reduce operating costs for electric arc, ladle and aluminium furnaces, as well as thick and thin slab and billet and bloom casters.

A complete range of products, services and end-to-end solutions that improve productivity, quality, safety and cost-efficiency in iron, steel, aluminium and other metals production processes are available through ABB. Across the whole metals value chain, ABB demonstrates a commitment to optimize operations with high performance products and digital solutions.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries.

ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our # 1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations. go.abb/processautomation