Super User

ENERGY TRANSITION TO TAKE CENTRE STAGE AT SPE OFFSHORE EUROPE VIRTUAL CONFERENCE

Energy transition topics will take centre stage at the SPE Offshore Europe 2021 virtual conference taking place from 7-10 September 2021.

SPE Offshore Europe 2021 conference chair and executive vice president oilfield equipment at Baker Hughes, Neil Saunders and SPE President 2022 Kamel Ben-Naceur will welcome delegates to the 4 day, SPE-curated programme comprising of an opening plenary, 10 keynote, and 14 technical sessions incorporating more than 50 technical papers. 7 of the 10 keynote sessions and 50% of the technical programme will be related to energy transition subjects.

Keynote sessions with a net zero focus include: Delivering carbon capture, utilisation and storage; CCUS and hydrogen at scale; energy islands; roadmaps to net zero; scaling up digital to enable a low-carbon industry; facilities of the future and breaking the silo paralysis.

During the opening plenary, Chris Stark, CEO of the Committee on Climate Change will join Gordon Birrell, Executive Vice President, Production & Operations at bp; Al Cook, Executive Vice President, Development & Production International at Equinor and Phil Kirk, CEO of Harbour Energy for a panel session on the event theme ‘Oil & Gas: Working Together for a Net Zero Future’.

For the first time in the history of the biennial event, due to the coronavirus pandemic, the conference and exhibition have been split. The virtual conference will be followed by the in-person exhibition across 1-4 February 2022, which will include new keynote conference content that will be developed after the UN Climate Change Conference (COP26) taking place in Glasgow 1-12 November 2021.

With the two SPE Offshore Europe events ‘bookending’ COP26, oil and gas industry leaders, innovators and decision-makers will reconvene in person at the P&J Live in Aberdeen to advance the energy transition outcomes and realign strategies.

Neil Saunders, SPE Offshore Europe 2021 conference chair and executive vice president oilfield equipment at Baker Hughes said: “The conference programme at SPE Offshore Europe has always been a ‘must-attend’ event for those wanting to keep in touch with industry-leading thinking strategically and at a technical level. The industry’s path to decarbonisation and role in supporting net zero is top of the agenda this year, and with COP26 just seven weeks later, the programme promises to be a real curtain-opener.

“The future of oil and gas in the energy mix is in our hands and SPE Offshore Europe gives us the chance to work together, before and after COP26, to secure our place in a net zero future.”

Kevin Gallagher, SPE Offshore Europe 2021 technical committee chair and digital transformation lead, CNOOC International commented: “The offshore industry has an important role to play in the transition to the low carbon economy. The timing of the conference, prior to COP26, and content of the technical programme are both opportune and highly relevant as we experience an acceleration of the energy transition and the industry response. Audience members will have the opportunity to join high quality sessions ranging from decarbonisation, floating wind and hydrogen to drilling and decommissioning. We look forward to informative and inspiring technical sessions which prompt numerous important discussions at this pivotal time for our industry.”

The virtual conference programme will begin each day at 12 noon (BST) / 7.00am (EDT) to accommodate international participants. Full programme details and registration can be found here.

After successful offshore trials, Ampelmann’s electric A-type is ready for operations

Electric solutions, a lower carbon footprint and a strong commitment to sustainability are sure to be the future of the Walk to Work (W2W) industry. In line with that, Dutch offshore access provider Ampelmann, has announced the launch of an electric version of its signature A-type system.

Based on the technology and decade-long track record of its flagship system, the latest iteration of the A-type has seen its traditional hydraulic power train replaced by electric regenerative actuation, decreasing its energy use by more than 80%. This shift in technology does not only contribute to more environmentally friendly operations, but also makes the system significantly lighter, smaller in deck footprint and even quicker to mobilise.

The electric A-type is now fully operational after undergoing extensive offshore trials on the Horizon Star vessel in Eneco’s Princess Amalia windfarm.

“At Ampelmann, we are committed to driving our industry into a more sustainable future,” said CEO Jan van der Tempel. “The successful upgrade of the A-type to an electric system moves us directly towards that goal. This is a key milestone for our company as we continue to work towards new sustainable innovations.”

Smaller, lighter and more sustainable

The benefits of an electric W2W system are mostly two-fold. On the one hand, the electric A-type is smaller and lighter, requiring fewer resources to operate compared to its hydraulic-powered counterpart. Weight is reduced by 40% and energy use by 80%, considerably decreasing the environmental impact of the system without compromising workability specifications.

“With the implementation of electric drives, large heavy components of the hydraulic system became redundant, including the 20ft power pack container,” said Diederick Nierstrasz, Business Developer at Ampelmann. “Clients can expect the same capabilities as the non-electric A-type system, with an even higher reliability and ease of use.”

Additionally, Nierstrasz explains that the electric drives have improved the A-type’s accuracy and response time, while also eliminating the noise and vibrations the hydraulic-powered system used to produce.

Improved specifications and new possibilities on the horizon

In total, the change to electric actuation has led to an A-type with a smaller footprint, a reduction in weight and no need for an HPU on deck. The weight reduction of around 40% leads to plenty of added benefits as it makes the system suitable for smaller and lighter vessels and allows for higher vessel speeds.

In cooperation with Damen, Ampelmann has been taking steps towards the future of the offshore crew change market. The S-type, a newly designed system based on the technology of the electric A-type, is to be deployed on Damen’s new 7011 Fast Crew Supplier in Q3. The system, due to its improved specifications, is essential to the performance of the crew change operation. The new vessel is designed for a sailing speed of 40 knots, combined with a safe transfer of people in sea states up to 3m Hs in DP-mode. The combination of high transit speed and a high workability for people transfer makes this vessel a true game-changer for the marine crew change market.

The demand for safe, efficient, and sustainable crew change operations is growing in the offshore industry, and Ampelmann’s electric A-type answers to these demands. Van der Tempel considers its development therefore a great success. “This electric system is a significant step forward for our original A-type, which has been maintaining a stellar track record in the industry. The new iteration has improved plenty of important system specifications that are crucial in our journey towards more sustainable offshore operations.”

US methane emissions on track for tighter monitoring and additional regulations, says GlobalData

The US Congress recently approved a resolution that reverses a rule from President Trump’s administration, which had lowered the requirements for targeting methane emissions in oil and gas well operations. This makes a 2016 Environmental Protection Agency (EPA) rule the valid standard again with respect to reducing methane emissions and shows that that the current administration of President Biden is moving ahead with initiatives aimed at contributing to a net-zero emission targets by 2050. At the same time, the oil and gas industry is aligning with the effort, and although the degree of commitment varies across the many US operators, there is no strong confrontation to these measures, at least in their narrative, says GlobalData, a leading data and analytics company.

According to EPA, US methane emissions in 2019 amounted to 197 million annual metric tons of CO2 equivalent. Of this number, approximately 48% come from oil and gas production, and within this segment, most emissions are generated in pneumatic controllers, gathering, and boosting stations.

According to EPA, US methane emissions in 2019 amounted to 197 million annual metric tons of CO2 equivalent. Of this number, approximately 48% come from oil and gas production, and within this segment, most emissions are generated in pneumatic controllers, gathering, and boosting stations.

Adrian Lara, Senior Oil & Gas Analyst at GlobalData, comments: “Reducing emissions of methane is somehow in line with what many operators have been doing to monetize natural gas production that is otherwise flared. The main difference is that leaks of methane are normally in small volumes which don’t justify an investment for their recovery. In this respect, it is true that for small operators installing monitoring devices for leaks and replacing pneumatic controllers can be at a relatively high cost, specifically for low producing wells.

“In general, issues related to reduction of GHG emissions require a degree of government intervention to regulate and incentivize. While investors are already doing their part by scrutinizing sustainability goals of oil and gas companies, given the amount of investment needed, policy is arguably necessary for aligning the also influential oil and gas industry.

“This legislative action also allows for EPA to further establish other regulations for existing and new wells. Based on statements from major operators, their position is one of support and cooperation with government policy, both at federal and state level, on climate change actions. Still, Republican Party members argue that these reinstatement of regulations in some cases duplicate measures already in place at the state level, and that they will ultimately hurt and reduce the international competitiveness of the US oil in gas industry.”

- The rule requires oil and gas operators to plug and capture methane leaks from wells and storage tanks. It also requires cutting volatile organic compounds and toxic air pollutants such as benzene.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

AFRY assigned with planning services for the expansion of the Berlin Spandau - Nauen line (i2030) by DB AG

The project i2030 is aiming to provide an improved railway infrastructure for the greater Berlin area. As part of this, AFRY was assigned to plan the connection of the Havelland region to Berlin.

For improving the Havelland region’s link to Berlin and provide sustainable mobility in the German capital area, an attractive range of train connections is essential. This requires the expansion of the railway line between Berlin Spandau and Nauen.

For improving the Havelland region’s link to Berlin and provide sustainable mobility in the German capital area, an attractive range of train connections is essential. This requires the expansion of the railway line between Berlin Spandau and Nauen.

For a line of approximately 23 km, the expansion of the current two regional/long-distance rail tracks to four tracks, and the extension of the S-Bahn via Spandau station to Falkensee or Finkenkrug, are being analyzed by AFRY experts, who will also evaluate the construction of new stopping points in Berlin and the expansion of existing stopping points. In addition, the feasibility of an S-Bahn tunnel in the section from Stresow to Klosterbuschweg is being examined in order to generate additional capacity at Spandau station for regional and long-distance traffic.

"We are delighted to be part of this important project, which will create more climate-friendly mobility for around 3.5 million people in Berlin. AFRY has many years of experience with rail expansion projects of this kind, which we will bring to this project," says Business Unit Manager Michael Backes.

AFRY is a European leader in engineering, design, and advisory services, with a global reach. We accelerate the transition towards a sustainable society.

We are 16,000 devoted experts in infrastructure, industry, energy and digitalisation, creating sustainable solutions for generations to come.

Making Future

Celebrating global expansion: Growth drives €10 million investment for COPA-DATA

Demand for digitalization has not faltered during the pandemic. In fact, it has thrived. Automation software and digitalization expert, COPA-DATA experienced this first-hand during 2020 – increasing turnover, expanding its team, and investing in new subsidiaries. Now, the company is making a €10 million investment to headquarters in Salzburg, Austria. COPA-DATA’s momentum represents an increasing demand for digitalization in its core markets of manufacturing, energy and infrastructure, in which the company generated €54 million turnover last year.

Despite varying economic conditions in its core focus industries, the company achieved six per cent growth from annual sales during 2020. This growth represents an increasing need for digital tools to support businesses in last year’s volatile market conditions.

With its zenon software platform, COPA-DATA provides customers with a tool for data capture, analysis, machine control and automation. Deployable across manufacturing facilities, energy grids and infrastructure projects, zenon can support flexibility, efficiency, and resilience.

With its zenon software platform, COPA-DATA provides customers with a tool for data capture, analysis, machine control and automation. Deployable across manufacturing facilities, energy grids and infrastructure projects, zenon can support flexibility, efficiency, and resilience.

Investing in people and places

Recruitment has also been high on COPA-DATA’s agenda, expanding its workforce to over 300 employees worldwide in 2020. This included establishing a new team to lead COPA-DATA’s latest subsidiary, based in Riyadh in Saudi Arabia, in the Middle East. The new facility stands alongside COPA-DATA’s extensive network of local subsidiaries and partners, which now spans six continents.

These achievements have driven further investment in the company’s headquarters in Salzburg, Austria. In October 2020, the foundations were laid for a €10 million low energy facility which will accommodate a further 120 employees. The state-of-the-art site will enable COPA-DATA to better support its subsidiary networks through administrative functions, while also improving the base in which zenon is developed and engineered.

Technology for new challenges

With new iterations of zenon being developed on a yearly basis, expanding COPA-DATA’s headquarters provides opportunity to invest in the company’s engineers. An important part of this investment in 2021 is the latest major release, zenon 10, which was made available in May 2021. The updated version offers customers an integrated overall solution, which has been developed to solve the unprecedented business events that occurred in the previous twelve months.

“Fortunately, we were able to support our customers and partners with our zenon software platform to overcome the unique challenges of 2020,” said Thomas Punzenberger, Founder and CEO of COPA-DATA. “Thanks to our employees and our innovative digital solutions for the fusion of OT and IT, our business has continued to grow steadily. Even in uncertain times, our credo remains purposeful: There must be an easier way!"

COPA-DATA’s investments in people, places and technology will continue in 2021 and beyond, having used the previous year’s growth to enhance the company’s offering. During 2020, COPA-DATA responded to the pandemic-induced contact restrictions by offering a wide range of webinars and digital events. Moving forward, this approach will be further extended and supplemented with hybrid training sessions so customers can choose to participate on-site or virtually.

"During the pandemic, our focus was on keeping contact with our customers and partners as well as with each other as close as possible,” added Phillip Werr, CMO and COO at COPA-DATA. “With our virtual events 'zenonIZE' held in June 2020 and 2021, we were able to inspire over 1,000 decision makers in the industry to act right now and continue to drive digitalization forward. We thus provide existing and future users with know-how on industry-specific solutions around our zenon software platform.”

More information on COPA-DATA can be found at www.copadata.com.

About COPA-DATA

COPA-DATA is an independent software manufacturer that specializes in digitalization for the manufacturing industry and energy sector. Its zenon® software platform enables users worldwide to automate, manage, monitor, integrate and optimize machines, equipment, buildings and power grids. COPA-DATA combines decades of experience in automation with the potential of digital transformation. In this way, the company supports its customers to achieve their objectives more easily, faster and more efficiently.

The family-owned business was founded by Thomas Punzenberger in 1987 in Salzburg, Austria. In 2020, with more than 300 employees worldwide, it generated revenue of EUR 54 million.

How Digital Twins could make a success of US carbon credits

America under President Biden has re-joined the 2015 Paris Agreement and pledged a $2 trillion four-year climate plan, but a workable Cap and Trade program is seen as pivotal if the USA is to go on and hit zero carbon emissions by 2050.

Cap and Trade is a program where ‘carbon credits’ are given to high polluting companies from governments and regulatory authorities, to ‘cap’ their emission of carbon dioxide or other greenhouse gases.

Any company exceeding the agreed cap is then taxed or they can ‘offset’ by buying credits from lower emission companies with credits to spare.

One Cap and Trade carbon credit is equal to one tonne of carbon dioxide and the overall number is intended to reduce over time, thereby incentivizing companies to cut their greenhouse gas emissions.

Digital Twins could make a success of US carbon credits

Digital Twins could make a success of US carbon credits

However, many in the USA are concerned that the program gives some companies too much leeway to emit more emissions, by buying up credits and simply charging more for their products and services. Those critics have called for a solution enabling both profit and emission reduction to work in synergy for both big and small companies.

Digital Twins could be that solution. Cityzenith and its Digital Twin software platform SmartWorldOS™ can create virtual replicas of buildings and infrastructure to track, manage and optimize carbon emissions and minimize environmental damage, making emission reduction easily accessible and cost-effective.

Cityzenith founder and CEO Michael Jansen said: "Cap and Trade can work if industries have the technology and data to track and measure carbon emissions effectively so, instead of companies buying their way out of emission issues, they have the intelligence and data to lower both costs and emissions at the same time though the accuracy of Digital Twins.

"Our SmartWorldOS™ platform can handle massive data streams harnessed to cutting-edge AI We know the issues and have the capabilities to help solve them for industries across the US and worldwide."

Jansen added that Cityzenith's technology could also be a vital asset in reducing emissions across cities and urban areas – the focus of its 'Clean Cities - Clean Future' campaign:

"Despite covering only 2% of the Earth's surface, cities contribute to 70% of global carbon emissions while consuming 78% of the world's primary energy, of which we waste 67.5%. SmartWorldOS™ can provide the essential interconnectivity required to reduce these percentages."

To hear more from Cityzenith CEO Michael Jansen, please join an upcoming FREE investment webinar, ‘Investing in an AI Technology Platform for Sustainable Cities' taking place virtually on Tuesday the July 13th & 20th at 13:00 CT. To learn more about using emerging tech to combat Climate Change, please sign up here.

Cityzenith is based in Chicago with offices in London and New Delhi. The company’s SmartWorldOS™ Digital Twin platform was created for anyone designing, constructing, and managing complex, large-scale building projects, properties, and real estate portfolios but has developed to cover infrastructure, energy projects, transport, health, people movements, and whole cities. Find out more at www.cityzenith.com

The importance of proactive boiler maintenance

Thermal fluid systems are commonly made up of three key components — a thermal fluid boiler or heater, an expansion tank and thermal fluid circulating pumps. If all these components are well maintained, a thermal fluid system can last for several decades. However, because a boiler operates silently in the background of the facility, engineers often overlook it. Here Clive Jones, managing director of thermal fluid supplier, Global Heat Transfer, explains the importance of proactive boiler maintenance and offers advice on best practice.

Traditionally, industrial boilers operated for around 15 years before they needed replacing. After years of development and research into other factors that we should consider, such as size and operation hours, we now have more robust solutions that can last up to 30 years — but only if it is well maintained.

Why invest in maintenance?

When a boiler, regardless of age, shows clear signs of wear or damage, the heat transfer fluid system can have reduced functionality, reliability and safety. Under safety legislation, employers must ensure that all combustion equipment, such as boilers, incinerators and air heaters, undergoes regular inspection to check the systems are not deteriorating and causing a safety risk to workers.

Regular boiler maintenance is also key to reducing the risk of carbon monoxide and dioxide build-up that can cause serious injury and unexpected downtime. Over time, thermal fluid degradation can lead to a build-up of carbon residue, also known as ‘coke’, in the system. Without regular maintenance, the build-up of carbon can cause blockages, reducing efficiency and increasing internal pressure and the risk of pipes bursting.

Regular testing

Paying constant attention to the thermal fluid system’s condition and carrying out periodic boiler tests can help facilities managers to avoid costly downtime. We also recommend performing regular thermal fluid tests to better understand the condition of the boiler.

Engineers should periodically analyse heat transfer fluid as part of a routine thermal fluid maintenance programme, such as Global Heat Transfer’s Thermocare. Engineers should collect the thermal fluid sample when the system is hot, closed and circulating to gain an accurate representation of fluid condition and identify any signs carbon build-up.

If the boiler continues to be inefficient, businesses should consider if problems are occurring elsewhere. Blockages, faulty exchanges, or fluid pumps that are spilling oil can cause temperature problems in the system. Alternatively, electrical or chemical faults can lead to intermittent lockouts or faults in the boiler. If facilities managers do not have the expertise required to fix or maintain this complex system in-house, a thermal fluid expert can perform the relevant tests and servicing needed to extend boiler lifespan.

As the industrial boiler industry becomes more efficient and longer lasting, maintenance should not be forgotten. By taking steps to proactively maintain your fluid and heat transfer system and knowing the signs to look out for, you can protect your employees from unsafe working conditions and reduce the cost of reinstalling a new industrial boiler.

About Global Heat Transfer: Global Heat Transfer is a thermal fluid specialist, providing heat transfer engineering assistance and thermal fluid supplies. Services offered include sampling and analysis, 24 hour delivery of premium quality thermal fluids, system drain down / cleaning / waste management, planned maintenance programs and a broad portfolio of affiliated system design and installation services. It is part of the Global Group of companies.

Valmet to deliver a turnkey biopower plant to produce green electricity and heat for the city of Salzburg, Austria

Valmet will deliver a complete turnkey BioPower 5 power plant to produce green electricity and heat for the city of Salzburg, Austria. The order was placed by Salzburg AG, a leading Austrian energy and technology company.

The order is included in Valmet’s orders received of the third quarter 2021. The value of the order is not disclosed. The plant will be commissioned and started up in August 2023.

“We are constructing the Siezenheim II plant in Salzburg to increase the share of CO2-neutral district heat production to 40 percent. With the plant, it will be possible to provide 8,300 additional homes with bio district heat and 7,000 additional homes with ecologically produced power in Salzburg in the future. We have found Valmet to be an ideal partner for building our power plant,” says Siegfried Müllegger, Head of Energy Technologies, Salzburg AG.

“This is the first modular BioPower plant that Valmet will deliver to Austria, so it is a great opening for us in decarbonizing the local energy sector. High fuel flexibility, innovative technology and serviceability play key roles in this solution. The use of local renewable biomass fuels ensures reliable and sustainable energy supply and creates jobs locally,” says Markus Bolhàr-Nordenkampf, Director, Energy Sales and Service Operations, Central Europe North, EMEA, Valmet.

Technical information about the delivery

Valmet will be responsible for the engineering, procurement and construction (EPC) of the modularized BioPower 5 power plant. The scope of supply includes fuel handling, a boiler, a turbine, a flue gas cleaning system and the Valmet DNA automation system. The plant will have a maximum electrical output of about 4 megawatts (MW) and a maximum heat output of 17 MW.

Valmet’s modularized BioPower power plant is based on proven combustion technology combined with factory manufactured and tested modules. Manufacturing the modules in the factory enables faster project implementation, shorter site time and completion with better quality and lower implementation risks.

About the customer Salzburg AG

Salzburg AG is a digital technology company that offers digital solutions, products and services. The company provides the inhabitants of Salzburg an access to sustainable and climate-friendly supplies of clean energy, telecommunications, Internet and cable TV. Additionally, the company is a full-service provider in e-mobility and photovoltaics. In 2020, Salzburg AG had approximately 2,300 employees and net sales of 1.4 billion euros.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

A/S Norske Shell utilizing Kognitwin® Energy for the Ormen Lange field, creating the first ever fully integrated reservoir to market digital twin

Norske Shell is using Kongsberg Digital’s digital twin solution Kognitwin® Energy to create a virtual representation of their Ormen Lange deepwater gas field. Feeding into the onshore digital twin developed at Nyhamna gas processing facility, the two will combined become the first ever fully integrated reservoir to market digital twin.

The twin solution from Kongsberg Digital will reimagine the ways of working at Shell and unlock new value in the subsea and subsurface arena. By focusing efforts on digital solutions that scale across assets and installations it is easy to expand and integrate Ormen Lange into the existing onshore dynamic digital twin developed at Nyhamna gas processing facility, resulting in the first ever fully integrated reservoir to market digital twin.

In October 2019, Norske Shell joined forces with Kongsberg Digital to operationalize an ‘asset of the future’ through a partnership development of the Nyhamna Dynamic Digital Twin, using Kongsberg Digital’s Kognitwin Energy solution. The twin was deployed and up and running by the end of the year and since January 2020 the Nyhamna Dynamic Digital Twin has been in operation and evolving continuously through monthly product releases, focusing on safe, effective and integrated work processes and optimization of production and energy use. With Nyhamna having paved the way, the decision was made to expand the collaboration with another digital twin of the related Ormen Lange deepwater gas field, which feeds gas to Nyhamna.

Image credit: A/S Norske Shell

Image credit: A/S Norske Shell

With Ormen Lange, we are very proud to have been awarded the contract for the development of a second digital twin for Norske Shell. This is a direct result of our successful collaboration around the Nyhamna dynamic digital twin. We would particularly like to highlight a strong core product, Kognitwin Energy, rapid deployments, and fast time to value as unique differentiators in this ongoing project. Now, we are eager to help Norske Shell realize the full potential of their assets through integration of these two digital twins, says Hege Skryseth, President of Kongsberg Digital and EVP KONGSBERG.

The first version of the Ormen Lange digital twin comprises primarily data integrations and visualization of subsea 3D models including production and MEG pipelines, well surface locations and well-bore paths, seabed bathymetry data detailed around the production templates, built documentation and drawings, real time data from DCS and PI and much more. For disciplines and teams across the initial Ormen Lange user base - like Subsea Maintenance, Wells, Flow Assurance, Production Technology, Reservoir Engineering, Process Engineering and Operations - the twin provides unified data for everyone to access across the same work surface. This is the starting point of a longer journey where Kongsberg Digital and Norske Shell will continue to develop valuable features and target specific use cases to enable user groups, disciplines and teams with new ways of working.

Digital twins are technology for people. The partnership model, combining Kongsberg Digital’s digital capabilities with our own employee’s expertise in the operations and maintenance domain, has been very effective in delivering use cases that let our teams to collaborate better and become more effective. This in turn enable us to save costs and optimize production whilst improving safety and environmental impact, says Rolf Einar Sæter, Digitalisation Manager in Norske Shell.

The first version of the Ormen Lange digital twin was released to users in Norske Shell last month.

KONGSBERG DIGITAL: Kongsberg Digital, a subsidiary of KONGSBERG, is a provider of next-generation software and digital solutions, to customers within maritime, oil and gas, and renewables and utilities. The company consists of more than 500 software experts with leading competence within the internet of things, smart data, artificial intelligence, maritime simulation, automation and autonomous operations. Kongsberg Digital is the group-wide center of digital expertise for the KONGSBERG group. www.kongsbergdigital.com

KONGSBERG: KONGSBERG (OSE-ticker: KOG) is an international, leading global technology corporation delivering mission-critical systems and solutions with extreme performance for customers that operate under extremely challenging conditions. We work with nations, businesses and research environments to push the boundaries of technology development in industries such as space, offshore and energy, merchant marine, defence and aerospace, and more. KONGSBERG has about 11,000 employees located in more than 40 countries, creating a total revenue of NOK 25.6bn in 2020.

TotalEnergies looks to oil growth amid conflicting energy transformation strategy, says GlobalData

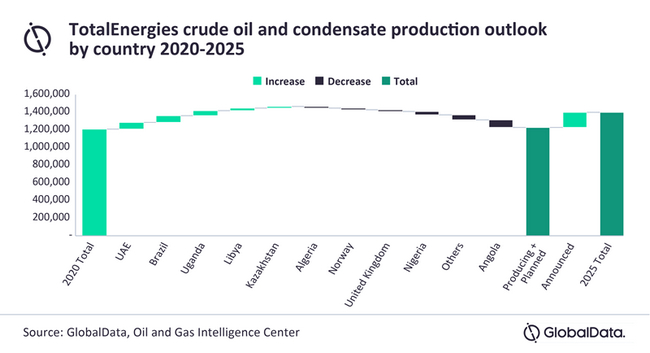

Total SE of old has recently gone through a rebranding to become TotalEnergies by an almost unanimous decision by shareholders. This rebranding is in the hopes that the company can pull itself away from the traditional business practices which focused on oil and gas developments and become more of an all-encompassing energy company. However, the company, unlike its peers, is forecast to see a material growth in its oil production over the near term, says GlobalData, a leading data and analytics company.

Conor Ward, Oil & Gas analyst at GlobalData, comments: “TotalEnergies has made significant strides to investing more heavily in its low carbon, renewables business, however, unlike most other major European oil and gas companies, TotalEnergies is forecast to see a rise in its oil production over the near term. Most of the European majors have made the commitment to pull back on oil developments and push their focus more towards gas and low carbon technologies, while TotalEnergies is proving to still be committed to large scale oil developments and within the next five years oil production is forecast to grow.”

Despite its ageing fields declining, TotalEnergies is forecast to see a steady growth in crude oil and condensate production through to 2025 from 1.2 million barrels per day to 1.23 million barrels per day equivalent. The largest portion of this growth is expected to come from its recently approved Ugandan assets surrounding Lake Albert in the west of the country, where TotalEnergies holds a 66.6% stake in a 230,000 barrel per day project.

Ward continues: “The company has a significant amount of crude oil and condensate production, which could come from unsanctioned projects such as Cameia in Angola, North Platte in the USA, and Gato Do Mato in Brazil. However, based on the decision taken in Uganda and the company’s recent acquisition in Block 20 Angola, these projects may suffer delays if the company seeks to reduce its crude oil production.”

TotalEnergies has suggested that it does not intend to reduce its scope 1 and 2 emissions in the short-term at least, meaning that many of its projects currently on hold have a higher chance of going ahead than would have been thought otherwise. The company is then planning to reduce its net scope 1 and 2 emissions from 2025 onwards and reach net zero by 2050.

Ward concludes: “For the company to continue investing in low carbon and renewable technologies, the increase in oil production and continued investment in major oil developments sends a clear signal that these types of projects continue to showcase attractive economic returns that may help the company deliver its longer-term strategic transformation goals. It remains unlikely that the company can continue to develop large scale oil projects given its long term ESG commitments.”

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.