Displaying items by tag: KROHNE

Automated Real-Time Liquid Natural Gas Custody Transfer System Provides Product Quality and Quantity Transparency

Eliminates disputes and reduces maintenance costs

By John de Viet, Solutions Development & Sales Support Manager at KROHNE Marine,

With the skyrocketing cost of fuel, the value of any mistakes made while loading and unloading liquid natural gas (LNG) carriers is increasing. This makes it even more important for plant and instrumentation managers to have access to the most accurate measurement tools. New automated systems provide transparency in measuring fuel quantity and quality, improving trust between buyer and seller. These new tools can reduce maintenance costs by as much as 25-50 percent annually and can also avoid costly disputes at terminals, estimated at between $1-10 million per year.

Determining quality and quantity while loading and unloading of LNG carriers

Loading and unloading of liquid natural gas (LNG) carriers requires documentation of both the quantity and quality of the LNG transferred. As per gas sales purchase agreement (GSPA) this information, recorded in a quality certificate, and a bill of lading, is usually derived from multiple instruments and independently operated systems. Plant managers have typically used manual data collection, calculation, and verification systems to obtain the required information.

Quantity is typically determined with level measurements taken on the LNG vessel; these measurements are the input for the bill of lading. Quality is determined in a laboratory using samples collected during the (un)loading operation, with the results used to prepare the quality certificate. Data is manually processed primarily in Excel-based worksheets, without traceable references to instrument uncertainties and standards and with no dynamic validation.

Accurate calculations have been made even more complicated by the fact that LNG is a mixture of gas and liquid. Unlike transfer standards for oil or gas, which are well-defined and well-known, those for LNG are less advanced. Many operators have had to rely on collecting information from independent systems doing just a portion of the measurements, with no one fully integrated measurement system. The existing manual quantity and quality data collection systems have led to a variety of potential problems:

- Introduction of human error during data collection.

- Certificates of quality are produced using distributed control system (DCS) historians or external plant information systems, including the PI real-time data management software and MS Excel. None of these systems are designed and dedicated for custody transfer applications.

- Data is transferred through multiple interfaces with the possible loss of resolution or loss of data due to filtering (ISO demands up to 6th decimal point).

- Calculations have not been validated or certified by an independent body such as NMi.

- Quality data is not traceable, and measurements are often not in compliance with ISO/GPA standards.

- There is no dynamic validation of data while LNG loading is in progress.

- Validation of data is often done after the shipload, with no way of reconciling if equipment had developed faults during the loading.

- Contractual clauses differ, which could lead to incorrect interpretations and calculations.

- Overall loading system is difficult for authorities to audit.

New automated systems eliminate uncertainty disputes

New automated systems are now available that eliminate uncertainty disputes, reduce maintenance costs, and make loading and unloading of LNG carriers at terminals easier and more efficient. Among these is the KROHNE LNG-Quality Release System (L-QRS), a software offering that collects all relevant information needed to determine the amount of energy transferred during LNG vessel loading and unloading operations. See Figure 1 for a graphic overview of typical loading/unloading points in the LNG value chain.

This automated system processes information in an NMi-certified SUMMIT 8800 flow computer to allow the operator real time monitoring of batch quantity and quality. It uses on-line measurements and certified statistical calculations, including quality and outlier calculations, energy calculations, loading mass balance and billing reports on vapor returns. A gas chromatograph analyzes samples in real-time while the ship is being loaded. See Figure 2.

The applied flow computer software provides the quality release certificate and the bill of lading instantaneously once the batch is completed. Instant availability of bill of lading and quality certificates avoids costly retrospective corrections of the bill of lading and quality certificates once the vessel has departed. The system incorporates an analyzer management and data acquisition system, which ensures full traceability of the instrumentation and optimizes maintenance cycles. Estimates suggest that maintenance costs can be reduced by 25-50 percent. Data is securely stored and, together with the certified calculation, fully auditable.

The fully automated information flows eliminate human errors in the data processing that can arise when copying measurement data among different systems. Simply avoiding LNG quality disputes has the potential to save terminals from $1-10 million per year. Because the automated system is certified by NMi and compliant with such international standards as ISO 8943, GPA 2172, ASTM 4784, GIIGNL, it also avoids discussions over the amount of energy transferred. Increased availability of critical instruments ensures constant and reliable quality measurements, resulting in less product give-away due to a lower system uncertainty.

Designed for mid-size and large liquefaction and regasification LNG terminals, it can be installed in both new and existing LNG terminals and can be sized to the available infrastructure.

Once the automated system is installed and operational, plant managers experience improvements in maintenance costs, a reduction in the number of disputes, and improved availability, resulting in less product give-away.

Basic L-QRS functionality is available using only the Summit 8800 flow computer in combination with existing instrumentation. Depending on the level of existing automation, this provides automated calculations, outlier detection, standard reporting and time stamped measurement registration. The system can be further enhanced with a user-friendly HMI, customized reports and an integrated analyzer/instrument management system. The latter enables the operator to optimize its maintenance program and reduces costs, provides detailed information about instrument availability and full traceability of the calibration records.

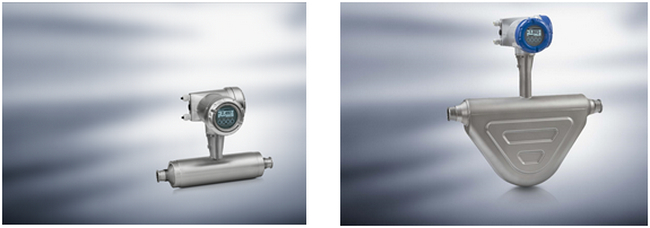

A further level of performance is achievable by adding custody transfer LNG flowmeters like the OPTIMASS 6400 Coriolis mass flowmeter, which features advanced entrained gas management (EGM). For larger line sizes the ALTOSONIC 5 ultrasonic flowmeter can be used. Ultimately, and even higher level of overall system performance can be reached by adding an on-line LNG sampling and analyzer system. This way all the relevant parameters related to quantity and quality are available in real-time and the full benefits of L-QRS are realized.

Given the increasing expense of fuel and the transitioning of fuel types, LNG operators need more robust and reliable metering and measuring systems. New systems like the L-QRS can go a long way to meet traceable custody transfer data standards while avoiding costly disputes, retroactive corrections, and product give-away.

About KROHNE Marine:

The KROHNE Marine team, based in Norway, is a dedicated expert division with over 60 years of experience in the marine industry. Since 1957, our highly qualified team of Engineers has provided the Global Marine Industry with certified systems, products, measurement solutions, and services. We have gained extensive knowledge of what it takes to deliver high-quality products and solutions to ship owners, managers, and yards through long-term and close collaboration with our customers. Our systems are installed on a wide range of vessels, from small inland vessels to large seagoing ships. https://krohne.com/en/industries/marine-industry

About KROHNE:

KROHNE is a world-leading manufacturer and supplier of solutions in industrial process instrumentation. The North American subsidiary, KROHNE Inc., is headquartered in Beverly, MA (USA) and provides service and sales throughout the region.

About the Author

John De Viet works at KROHNE Solution in Breda, The Netherlands where KROHNE’s measurement system solutions are developed for all industries.

KROHNE to Showcase TIDALFLUX 2300 F at Florida Water Resources Conference 2023

KROHNE, Inc. announces that it will be showcasing the TIDALFLUX 2300 F Electromagnetic Flowmeter, a flow measurement solution ideal for partially filled pipes, at the Florida Water Resources Conference 2023 from May 31 - June 3, 2023, at the Gaylord Palms Resort in Kissimmee, Florida. Attendees can view KROHNE’s unique electromagnetic flowmeters at booth #534.

Visit KROHNE at booth #534 to learn about their meters and measuring solutions

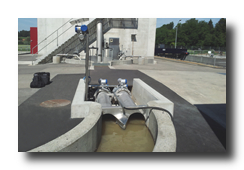

The TIDALFLUX 2300 F provides reliable flow measurement in pipes between 10 and 100 percent full. It features a non-contact sensor that is unaffected by oils and fats floating on the surface. Its smooth surface prevents buildup, minimizing the need for regular cleaning.

Available in diameters to fit pipes up to 72 inches, TIDALFLUX 2300 F has high chemical and an abrasion resistant polyurethane liner to provide exceptional durability. The electromagnetic flowmeter features an integrated, non-contact capacitive level measurement and a Class 1 Division 2 rating for use in hazardous environments. TIDALFLUX 2300 F is an excellent choice for municipal or industrial wastewater transport application, and can also be used for measurement of effluent brine from dredging, mining or sea/well water injection applications.

Wet-calibrated at the factory using a direct volume comparison, TIDALFLUX 2300 F does not require on-site calibration. The meter’s accuracy in partially filled pipes is <1 percent of full scale, and the accuracy in full pipes is <1 percent of the measured value.

A good choice for use in the presence of hydrogen sulfide (H2S) in wastewater applications, the TIDALFLUX 2300 F replaces open channel measurements with an in-line closed measurement solution that provides a safe and clean working environment. The electrodes are mounted at a height of 10 percent from the pipe bottom, ensuring that they are always wetted to avoid corrosion, which increases electrode life span. The capacitive level sensors are integrated in the liner, and are unaffected by H2S and any residues that may be floating on the water surface or particles in the water.

TIDALFLUX 2300 F is available with the IFC 300 F (PF) remote converter in field housing. This means that the IFC 300’s extended diagnostic functions, including application and device diagnostic as well as out-of-spec tests, are now available for TIDALFLUX. For subsoil installation or applications in areas that can be partially flooded, TIDALFLUX 2300 F can be ordered with an IP68 protection rating which features a special coating.

KROHNE will also have the WATERFLUX 3070 battery powered electromagnetic flowmeter on display as well as the OPTIWAVE 1400 among other measuring solutions. The WATERFLUX 3070’s unique rectangular sensor design provides bi-directional flow measurement over a wide dynamic range and good low flow performance. The water meter’s optimal pressure and temperature sensors allow it to be used in leak detection, quality control, and pressure management systems. The OPTIWAVE 1400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in water and wastewater applications. It is equally suited for continuous, non-contact level measurement of water from springs, rivers, lakes or the sea as well as rainwater, wastewater, sludge or other liquids in storage applications.

For more information, speak with the KROHNE experts in booth #534 at the Florida Water Resources Conference or visit www.us.krohne.com.

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it., www.us.krohne.com.

KROHNE Offers Full Instrumentation Portfolio for Produced Water

KROHNE, a world-leading manufacturer and supplier of solutions in industrial process instrumentation, highlights its market-leading instrumentation portfolio for managing produced water. Throughout the water management process, from collection to transportation and injection, KROHNE’s OPTIFLUX electromagnetic flowmeters cut costs while providing peak levels of performance for operators.

- Reduce pump costs throughout the process of produced water management

KROHNE's products facilitate accurate, reliable measurement, provide instrument diagnostics, and reduce cost to help operators overcome challenges that arise while managing produced water during oil and gas production. OPTIFLUX electromagnetic flowmeters avoid moving parts entirely to avoid wear and measurement inaccuracy due to drifting. These flowmeters are full bore and do not require flow conditioners or strainers. OPTIFLUX flowmeters work free-of-charge alongside KROHNE’s OPTICHECK verification software, which provides easy on site meter verification without requiring the meter to be removed from service. This combination of instrumentation and software provides real time diagnostic information, flow rates and totals, and conductivity information, which are all made available via Modbus.

OPTIFLUX electromagnetic flowmeters are available in multiple models. The OPTIFLUX 2050 is designed for basic water and wastewater applications such as flow and conductivity measurement. It has multiple outputs and a choice of liners including hard rubber. The OPTIFLUX 4300 serves advanced process and custody transfer (CT) applications. A market leader for water injection applications, this model has achieved pressure ratings up to 2500 pounds. It supports all types of connections, from RF and FF to RTJ and Clamp, and more. With robust, fully welded construction, this model is approved for hazardous areas and well suited for demanding environments due to its corrosion resistant materials.

KROHNE’s product portfolio has a long standing track record in industries such as oil and gas and water and wastewater treatment. Its factory inventory of standard meter configurations are available for fast delivery, and its team stands ready at all hours to provide technical support over mail or phone free of charge.

Contact us for special pricing information at This email address is being protected from spambots. You need JavaScript enabled to view it..

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.us.krohne.com

KROHNE to Showcase Wide Range of Water and Wastewater Products at WEFTEC 2022

Visit Booth 5829 to learn more about the latest flow and level instrumentation

KROHNE, Inc. will showcase a wide range of its industry-leading water and wastewater products, including the latest version of the OPTISONIC 6300 clamp-on ultrasonic flowmeter at WEFTEC 2022, Booth 5829. The Water Environment Federation Technical Exhibition and Conference will be held October 10-12, 2022, at New Orleans Morial Convention Center, in New Orleans, Louisiana. Also to be showcased are TIDALFLUX 2300, KROHNE’s unique flow meter for partially filled pipes; WATERFLUX 3070 water counter with flexible power concept; and a new generation of liquid and solids level measurement products featuring better measurement performance, enhanced software and an improved and more powerful signal processor and the OPTISONIC 7300 ultrasonic meter for biogas applications. KROHNE representatives will be available at the booth to discuss technology, products and applications in detail.

The newest iteration of the KROHNE OPTISONIC 6300, the ultrasonic clamp-on flowmeter for permanent mount installation will be featured. It is particularly suitable for flow measurement of liquids at any location where inline measurement is not possible or desirable. The flowmeter features new robust stainless steel clamp-on rails which can be very easily attached to virtually any pipe up to 160" diameters with metal straps or with newly available magnetic mounts. All versions come with a wall-mounted or field-mounted ultrasonic signal converter.

TIDALFLUX 2300, KROHNE’s unique flow meter for partially filled pipes, will also be highlighted. The meter can measure flows in pipes between 10 and 100 per cent full and its non-contact sensor is not affected by oils and fats floating on the surface. In addition, TIDALFLUX has a broad diameter range to fit pipes from 8 to 64 inches and has high chemical and abrasion resistance to provide exceptional durability.

TIDALFLUX 2300, KROHNE’s unique flow meter for partially filled pipes, will also be highlighted. The meter can measure flows in pipes between 10 and 100 per cent full and its non-contact sensor is not affected by oils and fats floating on the surface. In addition, TIDALFLUX has a broad diameter range to fit pipes from 8 to 64 inches and has high chemical and abrasion resistance to provide exceptional durability.

The WATERFLUX meter features precise measurement with no need for upstream or downstream piping, has no moving parts, and is maintenance-free. This electromagnetic unit can be powered by a standalone battery or with solar power or even line power. It is a great choice for drinking water applications and ideal where power is unavailable. WATERFLUX is also available with UI1203 or Modbus-based network communications as well as optional built-in pressure, and temperature measurement within the flow sensor body. The addition of pressure and temperature is very useful for leak detection or district network pressure monitoring.

The OPTISONIC 7300 biogas version is ideal for methane gas applications in wastewater treatment facilities. The 2-beam ultrasonic flowmeter provides excellent long-term measurement stability and repeatability. Now Class 1, Div. 1 approved, it delivers high performance over a wide bi-directional flow range of ± 30 m/s (± 90 ft./s) with 1% accuracy. The converter features a variety of measurement diagnostics and available methane content output.

Visitors to the booth can also get a look at the newest radar and guided wave radar (TDR) level measurement devices on the market. Radars such as the OPTIWAVE 7500 (80 GHz) for liquids in narrow vessels with internal obstructions and the OPTIWAVE 6400 (24 GHz) for granulates or rocks and the OPTIWAVE 6500 (80 GHz) for powders and dusty atmospheres will be on display along with OPTIFLEX TDR level devices.

KROHNE’s full product line for use in the water and wastewater industry will also be shown at the booth.

About KROHNE

KROHNE, celebrating 100 years in 2021, is a family-owned worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING email: This email address is being protected from spambots. You need JavaScript enabled to view it.

KROHNE Highlights OPTIMASS Products, TSS 7000, and more at PROCESS EXPO 2022

KROHNE, Inc. announces it will highlight a range of innovative flowmeters for food applications at PROCESS EXPO 2022, which takes place February 15 – 16 at the Sacramento Convention Center in Sacramento, CA. Stop by Booth 609 to see KROHNE OPTIMASS Coriolis mass flowmeters in action, demonstrating continuous flow measurement, even with entrained gas and air of up to 100 percent (EGM™). Also on display will be OPTISENS TSS 7000.

The KROHNE OPTIMASS Coriolis mass flowmeters on display are ideal for all process and custody transfer applications. Measuring mass, volume flow, density and concentration of liquids and gases, OPTIMASS is available in several designs, from twin bent to single straight tube. All OPTIMASS flowmeters provide continuous flow measurement, even with entrained gas of up to 100 percent (EGM™). This makes them a great choice for dairy milk receiving, mayonnaise and shortening with up to 20 percent entrained nitrogen (N2), and ice cream overrun measurement applications.

The OPTIMASS 1000 is designed with a close-coupled twin tube configuration with an optimized flow splitter, manufactured to be highly durable and capable of handling flow rates, even in the face of pressure fluctuations.

Also on display will be KROHNE OPTISENS TSS 7000, a total suspended solids sensor for hygienic applications. The sensor comes with Tri-Clamp or VARIVENT® connection and is particularly suitable for concentration measurement in milk separation, fruit processing and other food and beverage applications. However, it can also be the perfect fit for hygienic concentration measurement of other process industries (e.g. for monitoring steam and cooling water circuits).

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it., www.us.krohne.com.

KROHNE announces that Branom Instrument Company is their new Sales Representative for Northern California

KROHNE’s established partner in Washington and Oregon is expanding their reach

KROHNE, a world-leading manufacturer and supplier of solutions in industrial process instrumentation, announces that Branom Instrument Company, with its headquarters in Seattle, WA, is the manufacturer’s representative for all served industries throughout the Northern California region as of January 1st, 2022.

Branom is replacing ACS Instrumentation & Valves, Inc, KROHNE’s long-time representative in the area. ACS has opted to end their operations and KROHNE appreciates their support and efforts while serving our mutual customers in the region.

Branom is replacing ACS Instrumentation & Valves, Inc, KROHNE’s long-time representative in the area. ACS has opted to end their operations and KROHNE appreciates their support and efforts while serving our mutual customers in the region.

About Branom:

Since 1947, Branom Instrument Co. has been providing customers with best-in-class process instrumentation for control and monitoring of flow, gas and liquid analytics, level, pressure, temperature, and automation. Learn more about Branom at www.branom.com

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.us.krohne.com

KROHNE Announces New LNG-Quality Release System for Real-Time LNG Transfer

Avoids costly disputes and eliminates data processing errors

KROHNE, a world-leading manufacturer and supplier of solutions in industrial process instrumentation, announces the LNG-Quality Release System (L-QRS), a quality-measurement software system for real-time product release of liquid natural gas (LNG) loading. L-QRS offers a vast improvement in real-time LNG transfer. Unlike existing methods that rely on dynamic measurement using flow meters along with lab analysis of a representative LNG sample, the L-QRS system measures LNG quality directly during loading. After loading has been completed, the system immediately generates a certificate of quality and bill of lading, thus avoiding costly disputes once the vessel has departed. Fully automated information flows also eliminate human data processing errors. The L-QRS can typically pay for itself by simply avoiding one or two LNG-quality disputes.

Released to the oil and gas market at the end of 2020, L-QRS uses on-line measurements and certified statistical calculations, including quality and outlier calculations. Samples go directly into a gas chromatograph while the ship is being loaded. Providing the instant availability of the certificate of quality avoids costly sample handling, laboratory testing, and retrospective corrections of the bill of lading and quality certificates. KROHNE supports the L-QRS from nearly 100 countries, including several offices in the U.S.

The L-QRS combines analyzer management and data acquisition (AMADAS) functionality, using control charting techniques and statistical process control to determine the performance, availability, and maintainability of the process analyzers — and other critical instruments — to always ensure the best results and availability. It is certified by NMi, an independent, internationally accredited metrology institute, and compliant with ISO 8943, GPA 2172, ASTM 4784, and GIIGNL. KROHNE can also add other standards upon request.

Integrating Calsys®, KROHNE’s AMADAS package, reduces maintenance costs by an average of 25 percent, while the increased availability of critical instruments (>95 percent) ensures constant and reliable quality measurements. This structured and consistent validation of analyzers and instruments provides traceability and auditability. L-QRS data is securely stored and, together with the certified calculation, is fully traceable and auditable.

The L-QRS software is configured to work with existing infrastructure, instrumentation, and analyzers, such as gas chromatographs. The core software runs on a SUMMIT 8800 Custody Transfer flow computer, with the operator interface integrated in the central HMI. Additional benefits include trend insight and alarm management as well as integration with plant management and control systems.

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries.

visit www.us.krohne.com

KROHNE to Showcase Wide Range of Water and Wastewater Products at WEFTEC 2021

Visit Booth 3619 to learn more about the latest flow and level instrumentation

KROHNE, Inc. will showcase a wide range of its industry-leading water and wastewater products, including the latest version of the OPTISONIC 6300 clamp-on ultrasonic flowmeter at WEFTEC 2021, Booth 3619. The Water Environment Federation Technical Exhibition and Conference will be held October 18-20, 2021, at McCormick Place, Chicago, IL. Also to be showcased are TIDALFLUX 2300, KROHNE’s unique flow meter for partially filled pipes; WATERFLUX 3070 water counter with flexible power concept; and a new generation of liquid and solids level measurement products featuring better measurement performance, enhanced software and an improved and more powerful signal processor and the OPTISONIC 7300 ultrasonic meter for biogas applications. KROHNE representatives will be available at the booth to discuss technology, products and applications in detail.

KROHNE, Inc. will showcase a wide range of its industry-leading water and wastewater products, including the latest version of the OPTISONIC 6300 clamp-on ultrasonic flowmeter at WEFTEC 2021, Booth 3619. The Water Environment Federation Technical Exhibition and Conference will be held October 18-20, 2021, at McCormick Place, Chicago, IL. Also to be showcased are TIDALFLUX 2300, KROHNE’s unique flow meter for partially filled pipes; WATERFLUX 3070 water counter with flexible power concept; and a new generation of liquid and solids level measurement products featuring better measurement performance, enhanced software and an improved and more powerful signal processor and the OPTISONIC 7300 ultrasonic meter for biogas applications. KROHNE representatives will be available at the booth to discuss technology, products and applications in detail.

The newest iteration of the KROHNE OPTISONIC 6300, the ultrasonic clamp-on flowmeter for permanent mount installation will be featured. It is particularly suitable for flow measurement of liquids at any location where inline measurement is not possible or desirable. The flowmeter features new robust stainless steel clamp-on rails which can be very easily attached to virtually any pipe up to 160"diameters with metal straps or with newly available magnetic mounts. All versions come with a wall-mounted or field mounted ultrasonic signal converter.

TIDALFLUX 2300, KROHNE’s unique flow meter for partially filled pipes, will also be highlighted. The meter can measure flows in pipes between 10 and 100 percent full and its non-contact sensor is not affected by oils and fats floating on the surface. In addition, TIDALFLUX has a broad diameter range to fit pipes from 8 to 64 inches and has high chemical and abrasion resistance to provide exceptional durability.

The WATERFLUX meter features precise measurement with no need for upstream or downstream piping, has no moving parts, and is maintenance-free. This electromagnetic unit can be powered by a standalone battery or with solar power or even line power. It is a great choice for drinking water applications and ideal where power is unavailable. WATERFLUX is also available with UI1203 or Modbus based network communications as well as optional built in pressure, and temperature measurement within the flow sensor body. The addition of pressure and temperature is very useful for leak detection or district network pressure monitoring.

The WATERFLUX meter features precise measurement with no need for upstream or downstream piping, has no moving parts, and is maintenance-free. This electromagnetic unit can be powered by a standalone battery or with solar power or even line power. It is a great choice for drinking water applications and ideal where power is unavailable. WATERFLUX is also available with UI1203 or Modbus based network communications as well as optional built in pressure, and temperature measurement within the flow sensor body. The addition of pressure and temperature is very useful for leak detection or district network pressure monitoring.

The OPTISONIC 7300 biogas version is ideal for methane gas applications in wastewater treatment facilities. The 2-beam ultrasonic flowmeter provides excellent long term measurement stability and repeatability. Now Class 1, Div. 1 approved, it delivers high performance over a wide bi-directional flow range of ± 30 m/s (± 90 ft./s) with 1% accuracy. The converter features a variety of measurement diagnostics and available methane content output.

Visitors to the booth can also get a look at the newest radar and guided wave radar (TDR) level measurement devices on the market. Radars such as the OPTIWAVE 7500 (80 GHz) for liquids in narrow vessels with internal obstructions and the OPTIWAVE 6400 (24 GHz) for granulates or rocks and the OPTIWAVE 6500 (80 GHz) for powders and dusty atmospheres will be on display along with OPTIFLEX TDR level devices.

KROHNE’s full product line for use in the water and wastewater industry will also be shown at the booth along with several newly available application and educational videos stemming from its recent 100 year virtual fair event, KROHNE Insights.

About KROHNE

KROHNE, celebrating 100 years in 2021, is a family-owned worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, visit www.us.krohne.com

KROHNE Announces TIDALFLUX 2300 F Electromagnetic Flowmeter

KROHNE, Inc. announces the TIDALFLUX 2300 F, a unique electromagnetic flow meter that provides reliable flow measurement in pipes between 10 and 100 percent full. It features a non-contact sensor that is unaffected by oils and fats floating on the surface. Available in diameters to fit pipes up to 64 inches, TIDALFLUX 2300 F has high chemical and abrasion resistance to provide exceptional durability. The electromagnetic flowmeter features an integrated, non-contact capacitive level measurement and an approval for ATEX zone 1 for use in hazardous environments. TIDALFLUX 2300 F is an excellent choice for municipal or industrial wastewater transport application, and can also be used for measurement of effluent brine from dredging, mining or sea/well water injection applications.

Wet-calibrated at the factory using a direct volume comparison, TIDALFLUX 2300 F does not require on-site calibration. The meter’s accuracy in partially filled pipes is <1 percent of full scale, and the accuracy in full pipes is <1 percent of the measured value.

Wet-calibrated at the factory using a direct volume comparison, TIDALFLUX 2300 F does not require on-site calibration. The meter’s accuracy in partially filled pipes is <1 percent of full scale, and the accuracy in full pipes is <1 percent of the measured value.

A good choice for use in the presence of hydrogen sulfide (H2S) in wastewater applications, the TIDALFLUX 2300 F replaces open channel measurements with an in-line closed measurement solution that provides a safe and clean working environment. The electrodes are mounted at a height of 10 percent from the pipe bottom, ensuring that they are always wetted to avoid corrosion, which increases electrode life span. The capacitive level sensors are integrated in the liner, and are unaffected by H2S and any residues that may be floating on the water surface or particles in the water.

Ranging from diameters DN200…1600 / 8…64 inches, the TIDALFLUX 2300 F features a measuring tube with an abrasion-resistant polyurethane liner and high chemical resistance. Its smooth surface prevents buildup of fat and other deposits, minimizing the need for regular cleaning.

TIDALFLUX 2300 F is available with IFC 300 F (PF) remote converter in field housing. This means that the IFC 300’s extended diagnostic functions, including application and device diagnostic as well as out-of-spec tests, are now available for TIDALFLUX. For subsoil installation or applications in areas that can be partially flooded, TIDALFLUX 2300 F can be ordered as a protection rating IP68 version with special coating.

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it.

KROHNE Now Manufactures WATERFLUX 3000 Meter Sensor in Beverly MA Facility

Production highlights commitment to manufacturing in the US

KROHNE, Inc. announces that it now produces the WATERFLUX 3000 water meter, the newest sensor design in its family of magmeters, at its state-of-the-art manufacturing and calibration facility located in Beverly, MA. The sensor is available in sizes ranging from 1 to 24 inch but at the outset, meters produced here will be limited to a maximum size of 6 inches.

KROHNE, Inc. announces that it now produces the WATERFLUX 3000 water meter, the newest sensor design in its family of magmeters, at its state-of-the-art manufacturing and calibration facility located in Beverly, MA. The sensor is available in sizes ranging from 1 to 24 inch but at the outset, meters produced here will be limited to a maximum size of 6 inches.

When combined with the IFC 070 battery powered converter electronics the resulting WATERFLUX 3070 is the first all-in-one water meter with available integrated pressure and temperature sensor. The new integrated pressure and temperature sensor option allows WATERFLUX to be used for a wide variety of drinking water network tasks, including pressure monitoring, maintaining the water balance, and district zone management. It can also be used for leak detection in drinking water networks when comparison of pressure and flow values is used as the leak detection method. The meter’s unique sensor design can be installed without the need for any upstream or downstream piping to meet its accuracy specifications.

For locations where 110…230V AC or 10…30V DC power source is available, WATERFLUX 3000 can also be combined with other converters such as the IFC-050, -100 or -300 series.

About KROHNE

KROHNE is a worldwide technological leader in the development, manufacture and distribution of accurate, reliable and cost-effective measuring instruments for the process industries. KROHNE focuses on forming partnerships with its customers to provide them with the most reliable and innovative solutions available in the marketplace. For more information about KROHNE’s complete line of measuring instrumentation for the process industries, contact KROHNE at 1-800-FLOWING (978-535-6060 in MA); fax: (978) 535-1720, email: This email address is being protected from spambots. You need JavaScript enabled to view it.