Super User

Industry leaders to speak at CWIEME Berlin 2024

The highly anticipated event, CWIEME Berlin 2024, is set to commence in just under two months’ time. With the majority of the speaker programme confirmed, now is the best time to secure a free ticket to the industry-leading event. Taking place from May 14-16 2024, this three-day exhibition will see leading professionals come together to discuss and showcase innovative products from the coil winding, transformer, generator, electric motor manufacturing and e-mobility sectors.

Taking place at the Messe Berlin, Germany, CWIEME Berlin proudly holds the title of the world’s largest exhibition dedicated to propelling the entire electrical manufacturing sector forward. Last year’s event saw more than 500 exhibitors book a stand to showcase their innovations, and over 5,000 unique visitors, solidifying its position as the ultimate global hub for the industry and primary touchpoint for industry leaders.

For 2024, the event has secured a wealth of industry professionals to participate in sessions and talks that will discuss latest innovations, technologies and key issues in the electrical engineering industry. Confirmed speakers include representatives from The International Copper Association, Syensqo, S&P Global Mobility, Siemens Energy, Thyssenkrupp Steel Europe, Hitachi Energy, SGB-SMIT GmbH, STILRIDE, Mckinsey Center for Future Mobility and Ford Europe.

The central stage will cover a host of topics such as innovation in transformers oils, driving sustainability in the manufacturing and energy sectors with a deep dive into eco-friendly practices in the steel industry, and a panel discussion on what the future holds for rare earth materials.

The e-mobility stage will host talks including a keynote speech on decarbonisation in the automotive sector, a session on the importance of reliability for electric vehicle (EV) infrastructure, a panel discussion on the emerging trends, a talk on innovations and advancements in new motor technologies, and a session on how the automotive industry can remain competitive in the age of electrification.

Another important area of the programme this year is Women in Engineering at CWIEME (WEC), where attendees will be able to see a panel discussion on diversity in the workplace and how to foster and encourage a more inclusive sector, a roundtable on cultural diversity and global collaboration, and a fireside chat about building allyship and advocacy for underrepresented groups within the industry.

For students and those new to the industry, CWIEME Berlin will also be holding a number of Future Engineer sessions on the e-mobility stage on day three. These sessions will include a panel discussion on career opportunities — providing insight into the key trends shaping the industry in 2024 and what to expect moving forward — a session exploring how the next generation can build a more sustainable industry, and a networking event to provide students the opportunity to engage with industry experts from different fields.

“The CWIEME 2024 content agenda is a great opportunity for attendees to engage and learn about current trends in the industry from some of the biggest names in the sector,” said Alexandra da Fonte Martins, senior content producer for CWIEME Berlin.

“Everyone who attends or exhibits at the show will enjoy a diverse range of content over three days, allowing them to gain insights into the latest technologies, network with industry peers and potentially forge valuable partnerships. With topics covering everything from technical advancements to sustainability and inclusivity, CWIEME Berlin 2024 promises to be a comprehensive platform for exploration, learning and growth in the electrical manufacturing industry.”

To register for a free attendee ticket and view the confirmed 2024 programme, please visit the CWIEME Berlin website.

About CWIEME Berlin: CWIEME Berlin, one of the premier events in the world of electrical engineering, stands as an essential destination for both experts and enthusiasts. This yearly occasion, situated in the heart of Europe, presents an unparalleled opportunity for networking, knowledge acquisition and the exploration of cutting-edge industry developments.

New gas pipeline repair technology slashes carbon emissions by 95%

Innovative new technology used to isolate gas pipelines in need of repair or maintenance has shown to prevent gas leakages and cut carbon dioxide emissions by 95% compared with venting pipeline contents to atmosphere - the equivalent of switching off 1,760 gas boilers for a year or taking 1,000 cars off the road

The UK’s National Gas, which owns and operates over 7,600km of gas pipelines underground, has successfully adopted STATS Group’s Remote Tecno Plug® (RTP) on a recent project near St Cyrus in Scotland.

The RTP was trialled to reduce the emissions released during pipeline isolation, a crucial process used by operators to stop gas from leaking while they perform upgrades and maintenance on the pipes. Usually, this is done through reducing the volume of gas in the pipeline by a process called recompression and then venting the remaining gas to atmosphere.

STATS Group personnel monitoring a 48in Remote Tecno Plug, St Cyrus, Montrose

STATS Group personnel monitoring a 48in Remote Tecno Plug, St Cyrus, Montrose

The efficient use of the RTP allows the work to be undertaken more quickly, with zero leaks during operations, improving safety and with the overall discharge of greenhouse gases significantly reduced.

Project managers estimated that traditional venting techniques would have emitted 233 tonnes of gas. However, the RTP reduced emissions to 9.5 tonnes, saving gas released into the atmosphere, but also resulting in significant cost savings of over £100,000 of gas not wasted.

This success has prompted National Gas to formalise a policy encouraging the use of this RTP technology in future isolation projects across the UK - with potential for these tools to be adopted by the individual gas distribution networks across the UK in future.

The UK has a legal obligation to reach net zero emissions by 2050 to address climate change, but gas is still integral to the UK, keeping the lights on and industries fuelled. It’s also important for the country’s energy security, making it resilient to demand spikes or pressures on the system.

STATS Group's 48in Remote Tecno Plug in situ St Cyrus, Montrose

STATS Group's 48in Remote Tecno Plug in situ St Cyrus, Montrose

The gas emission savings on the project near St Cyrus was the equivalent of switching off 1,760 gas boilers for a year or travelling 5.9 million miles in a 2018 Ford Fiesta - equal to removing more than 1,000 cars off UK roads for a year.

Kirsty McDermott, Senior Engineer at National Gas, said: “Using plugs like the RTP can greatly reduce emissions for temporary pipeline isolations, and on this project emissions were reduced by up to 24 times compared to traditional recompression methods.

“In addition to the environmental and economic benefits relative to reduced venting requirements, carrying out the trial work allowed us to interrogate the integrity of our pipelines and ensure they continue to deliver energy to where it’s needed across the UK.”

Neil Mackay, Group Senior Business Development Manager at STATS, said:

“This was the first use of our innovative pipeline isolation plug technology on the National Transmission System and following the successful outcome on the project, National Gas will update existing policies to make the use of isolation tools business as usual, which in turn will reduce barriers, increase efficiency and enable more critical maintenance work to be completed.”

STATS' RTP technology successfully sealed a 56km-long, 48-inch pipeline, ensuring a leak-proof and fail-safe isolation. It maintained full pressurisation at 55bar in the initial use of RTP on the National Transmission System, which surpasses traditional methods like venting or recompression. The technology offered secure double blocking and monitored isolation, allowing safe and efficient maintenance activities, such as welding.

In addition to operational phase tests, extensive integrity tests, independently evaluated by Specialist Engineering 3rd Parties DNV and Pipeline Integrity Engineers (PIE), were conducted to ensure the technology's reliability and safety. This work will allow for future projects to consider isolation tools in different applications.

Based in Kintore near Inverurie in Aberdeenshire, STATS employs more than 380 staff in the UK, North America, the Middle East and Australasia and is a market leader in the supply of pressurised pipeline isolation, hot tapping and plugging services to the energy industry.

Remote Tecno Plug® (RTP) - is a hydraulically activated mechanical plug featuring locks and dual elastomer seals. This provides leak-tight double block and monitored isolation, enabling maintenance or repair activities to take place safely and efficiently.

STATS provides specialist engineering services for the maintenance, integrity and repair of oil, gas and petrochemical installations and infrastructure.

STATS have gained an excellent reputation for providing a responsive, client-centred approach combined with expertise and innovative products which enhance safety and environmental performance, reduce system or plant downtime, improve asset performance, and support decommissioning and abandonment.

The group operates from its headquarters in Kintore, Aberdeenshire, in the UK; Edmonton, Canada; Houston, USA; Abu Dhabi, Saudi Arabia, Oman and Qatar in the Middle East; Kuala Lumpur in Malaysia and Perth, Australia.

On 5 July 2023, STATS was acquired by Japan Stock Market listed Mitsui and Co Ltd, becoming part of Mitsui’s Iron & Steel Business Unit.

Mitsui is a global trading and investment company with a diversified business portfolio that spans approximately 63 countries in Asia, Europe, North, Central & South America, The Middle East, Africa and Oceania. Listed on the Japanese stock market (Prime Market), the group has over 46,000 employees with annual revenues of US$107bn and total assets in excess of US$115bn.

Website: www.statsgroup.com

Website: www.mitsui.com

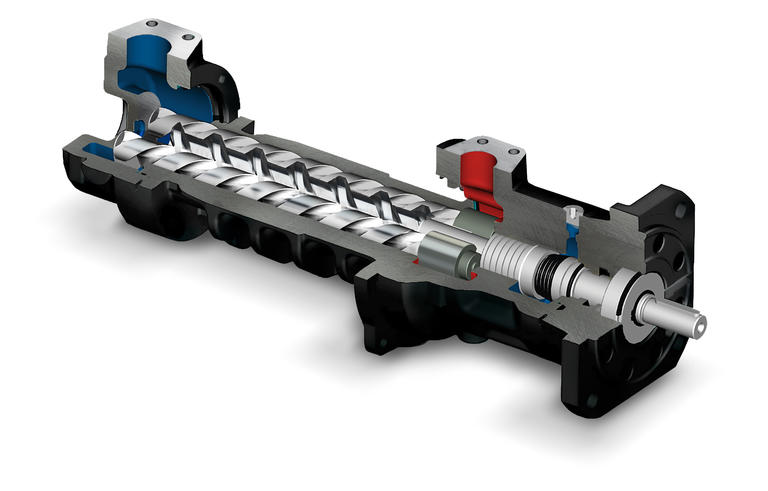

CIRCOR Highlights IMO LB6D 3-Screw Pumps for Lease Automatic Custody Transfer (LACT) Boost Applications

Engineered for maximum performance and accuracy and minimum of operating expenses

CIRCOR International, Inc., a leading manufacturer and marketer of differentiated technology products and sub-systems, announces its new IMO LB6D 3-screw pumps, ideal for use in oil and gas industry lease automatic custody transfer (LACT) applications. Built to last for LACT boost operations, the IMO LB6D pumps are engineered for maximum functional performance and the minimum of operating expenses.

“We are excited about this new product introduction,” said Chris Sahlman, CIRCOR vice president and general manager for Pumps Americas. “CIRCOR has a long legacy of providing robust heavy and medium gravity crude oil pipeline pumps with our IMO brand. The LB6D allows us to better serve the market on lighter crudes.”

With IMO LB6D three-screw pumps, LACT system builders and oil drillers have a pump they can rely on despite challenging crude oil viscosities and oil contaminants prevalent in harsh field conditions. The screw pumps offer high-pressure boost advantages, with boost oil pressure better than typical gear pump solutions. They also offer less downtime; new pump technology forms protective closures around contaminants, reducing or eliminating costly maintenance intervals experienced from direct wear on gear pumps. The IMO LB6D Series’ wear resistance increases service life based on competitive laboratory accelerated wear testing.

“Advancements in CIRCOR technology has allowed us to develop a proprietary manufacturing process which extends the mean time between failure,” said Kent Jackson, Sr. product manager. “Our new design greatly reduces our customers’ operating life cycle costs.”

The IMO LB6B pumps feature thoughtful engineering, with surface hardness similar to ceramic in the housing bores and a silicon carbide mechanical seal design for limited distortion.

IMO pumps are available for a very wide range of fluids, with viscosity from 1.5 to more than 100,000 centistoke (cSt) and temperatures ranging from 0 to 500oF. They are offered for flow rates from 2-3,300 gallons per minute and pressures up to 2,500 pounds per square gauge.

To learn more about CIRCOR’s pumps for LACT applications, please visit: https://pumps.circor.com/lact-applications#31076.

About CIRCOR International, Inc.

CIRCOR International, Inc. designs, manufactures and markets differentiated technology products and sub-systems for markets including oil & gas, industrial, aerospace & defense and commercial marine. CIRCOR has a diversified flow control product portfolio with recognized, market-leading brands that fulfill its customers’ mission critical needs. The company’s strategy is to grow organically and through complementary acquisitions; simplify CIRCOR’s operations; achieve world class operational excellence; and attract and retain top talent. For more information, visit the company’s pump website at www.pumps.circor.com.

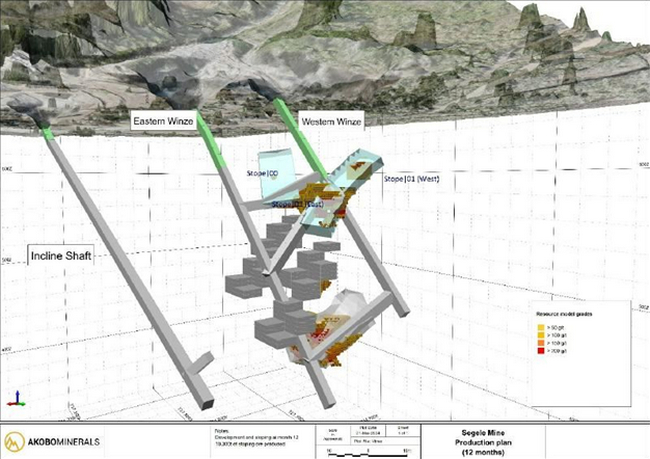

Akobo Minerals AB releases updated and improved production mine plan for first 12 months

The Scandinavian-based Ethiopian gold exploration and mining company has today released an improved gold production mine plan for its first 12 months of mining operations in the Eastern and Western winzes (tunnels). The updated plan improves the current production schedule and will have a significant effect on the initial revenue and EBITDA from the Segele mine. Most of the improvements will come in the first part of production.

Table 1: Comparison to previously released revenue and EBITDA estimates

|

|

Updated version |

Previous version* |

Difference |

|

12 months revenue** |

39,0 mUSD |

29,4 mUSD |

9,6 mUSD |

|

12 months EBITDA |

28,8 mUSD |

20,0 mUSD |

8,8 mUSD |

* Source: 27 Feb 2024. Press release: Agreement on debt restructuring, Private Placement successfully completed, announcement of rights issue and proposed conversion of unsecured debt

** Gold price estimate of 1950 USD per ounce

Following from the advanced operational understanding developed over the last few months of owner operator mining and hiring of a Mine Planner, the company has revised its mine plan and estimations for the first 12 months of gold production. Due to the specific nature of the Segele ore body, the mining will focus on developing stopes (pockets) targeting the high-grade gold areas of the ore body first. The very first Stope 00 developed will be a trial stope in an area that is not explored, before moving into the identified gold rich ore body. The trial stope will give valuable information and experience regarding geology, stope practice and feed to commission the plant. The next Stope 01 is then expected to be one of the best stopes in the life of the mine.

The mine plan primarily focuses of the upper part of the resource and the first 12 months of production. Future optimisation will extend this plan and recover more gold. The optimised part of the mine plan indicates a recovery of 77 % with potential upside. The following assumptions have been used:

- 50 % of crosscuts counted as ore with a grade of 22.7 g/t

- No ore recovery from winzes and incline shaft (Upside)

- No pillar drawing/pillar robbing at the end of LOM (upside)

- No use of backfill to recover barrier pillars (upside)

Table 2: Details of initial stope-groups to be mined, representing next 12 months of production. Showing gold endowment from Segele SRK Mineral Resource Estimate*

|

Stope group no. |

Avg. grade |

Tonnage |

Ounces |

Classification** |

|

1 (group) |

74.61 g/t |

4,272 t |

10,248 oz |

Indicated mineral resource estimate |

|

2 (group) |

43.78 g/t |

6,167 t |

8,680 oz |

Indicated mineral resource estimate |

|

3 (group) |

15.99 g/t |

5,203 t |

2,676 oz |

Indicated mineral resource estimate |

* Mineral Resource Estimate of 94ktons at an average grade of 22.7g/t and totally 69k ounces. The Mineral Resources are reported above a 2.65g/t Au cut off (22 April 2022)

** Source: 22nd April 2022. Press release: Akobo Minerals reports significant gold mineral resource increase and classification upgrade which underpins strong mine economics.

The updated mine plan uses the SRK Mineral resource model as it’s basis. The production schedule is adjusted according to the actual mine development plan.

Early production plan for Western and Eastern Winzes (Stope group 1 and 2 from Table 2). High grades areas indicated.

In conclusion, while we acknowledge the ongoing challenges in our operational environment that have created significant delays, including procurement and logistics issues, we want to assure our stakeholders that we are fully committed to addressing these obstacles. Though uncertainties still persist and may impact our future progress, we remain focused on diligently working through these challenges day by day, with the aim of achieving our production goals.

About Akobo Minerals

Akobo Minerals is a Scandinavian-based gold exploration and boutique mining company, currently holding an exploration license covering 182 km2 and a mining license covering 16 km2 in the Gambela region and Dima Woreda, Ethiopia. The company has established itself as the leading gold exploration company in Ethiopia through more than 13 years of on-the-ground activity, which has now been enhanced further with the development of its Segele mine.

Akobo Minerals’ Segele mine has an Inferred and Indicated Mineral Resource of 68,000 ounces, yielding a world-class gold grade of 22.7 g/ton. Still open to depth, the gold mineralised zone continues to expand and will have a positive impact on future resource estimates and the life expectancy of the mine. The exploration license holds numerous promising exploration resource-building prospects in both the vicinity of Segele and in the wider license area.

Akobo Minerals has an excellent relationship with local communities all the way up to national authorities and the company places environment and social governance (ESG) at the heart of its activities – as demonstrated by a planned, industry-leading, extended shared value program.

Akobo Minerals has built a strong local foothold based on the principles of sound ethics, transparency and communication, and is ready to take on new opportunities and ventures as they arise. The company is uniquely positioned to become a major player in the future development of the very promising Ethiopian mining industry. The company is headquartered in Oslo and is publicly listed on the Euronext Growth Oslo Exchange and the Frankfurt Stock Exchange under the ticker symbol AKOBO. For US investors, Akobo Minerals AB (OTCQX: AKOBF) is traded on the OTCQX Best Market, adhering to high financial standards, best practice corporate governance, and compliance with U.S. securities laws. Additionally, the company has a professional third-party sponsor introduction, and investors can access current financial disclosures and Real-Time Level 2 quotes for the company on www.otcmarkets.com.

Akobo Minerals places great emphasis on meeting and exceeding industry standards, fully complying with all aspects of the JORC code, 2012. For detailed information on their adherence to this code, please refer to https://www.jorc.org/. Akobo Minerals' unwavering commitment to ethical practices, community engagement, and environmental responsibility positions them as a formidable force in the evolving landscape of the Ethiopian mining sector.

France: TotalEnergies Ranks First in Latest National Tender for Rooftop Solar Projects

TotalEnergies strengthens its position as the market leader in rooftop solar installations in France by ranking first in the latest call for tenders issued by the French Energy Regulatory Commission (CRE), winning more than 80 MWp or 22% of the capacity awarded.

This new success strengthens TotalEnergies’ position as one of the major developers in France for solar installations on rooftops with a capacity exceeding 500 KWp. This includes installations such as building rooftops, greenhouses, warehouses, canopies and agrivoltaic shades.

By solarizing its B2B customers’ sites, TotalEnergies supports the energy transition of businesses across various sectors. TotalEnergies sells renewable electricity to its customers, which is generated on their own sites, allowing them to significantly reduce their electricity bills while reducing their carbon footprint.

“We are very proud of this performance which attests to our expertise in rooftop photovoltaics, a fast-growing market,” said Marin de Montbel, Managing Director, TotalEnergies Renewables France.“All these new projects confirm our status as a key partner to companies engaged in the energy transition and the decarbonization of their operations in France.”

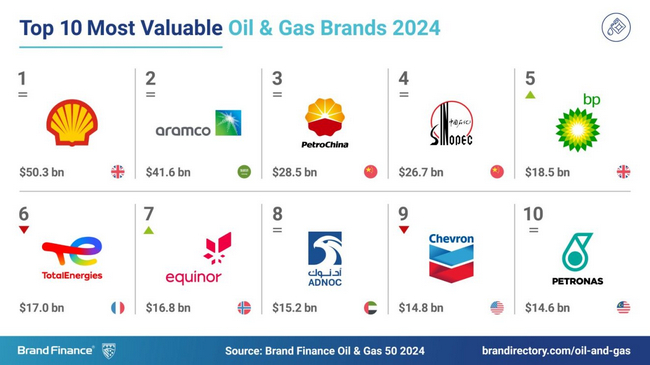

Shell’s resilience: Oil & Gas giant endures transition to retain top brand value ranking

New data from Brand Finance highlights stability for top oil and gas brands globally

- Shell, Aramco, PetroChina, and Sinopec maintain positions as the world’s most valuable oil and gas brands, with BP re-entering the top five ranking

- QatarEnergy, Pioneer Natural Resources, and EOG Resources emerge as fastest-growing brands

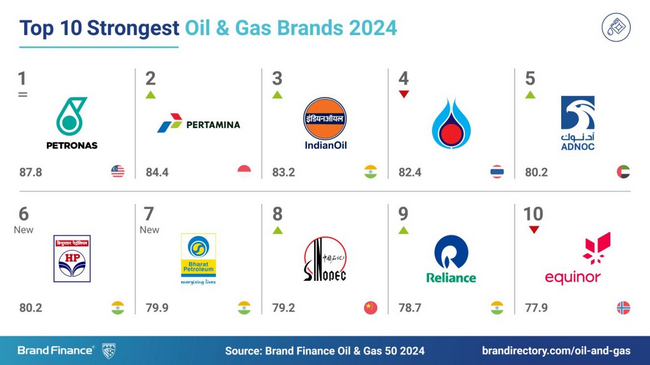

- PETRONAS reigns as the sector’s strongest brand, showcasing enduring brand strength leadership

Shell powers on as the world’s most valuable oil and gas brand, according to a new report from Brand Finance, the world's leading brand valuation consultancy. Recording a 4% increase in brand value to USD50.3 billion, Shell has remained resilient despite facing challenges such as falling revenues, a decline in enterprise value, and a drop in Brand Strength (BSI) score. Brand Finance research shows Shell’s decline in brand strength is primarily caused by lower recommendations, expectations, and current revenue.

Elsewhere, Aramco, PetroChina, and Sinopec remain in second, third, and fourth, respectively. BP has re-entered the top five, having dropped in the ranking the previous year.

Savio D’Souza, Senior Director, Brand Finance commented:

"As Shell continues to uphold its position as the world’s leading Oil & Gas brand, it highlights the remarkable stability of the brand in spite of questions about the long-term corporate strategy of the company. Correspondingly, the top 10 Oil & Gas brands have different views on their role in the energy transition; it remains to be seen which brand positioning drives the optimal value to the respective businesses in the long term."

QatarEnergy has emerged as the oil and gas sector’s fastest-growing brand, experiencing an 82% brand value surge to reach USD3.2 billion. This growth is largely attributed to the successful integration of Qatargas into the QatarEnergy brand. The strategic rebranding to QatarEnergy LNG has consolidated the brand and underscored its commitment to liquified natural gas (LNG) in the energy transition.

Behind QatarEnergy, Pioneer Natural Resources is the second-fastest growing brand, up 35% to USD4.5 billion, followed by EOG Resources, up 35% to USD3.5 billion. Brand Finance research shows EOG Resources’ growth is fuelled by decentralised exploration efforts, highlighted by discoveries in Ohio Utica Combo, South Texas Dorado, and Southern Powder River Basin. EOG's focus on multiple prospects underscores its ability to expand its portfolio and boost revenue.

PETRONAS remains the oil and gas sector’s strongest brand, retaining its AAA brand strength rating despite facing significant global challenges. However, according to Brand Finance research, customers are concerned about the reduced value for money amidst higher energy prices, underscoring the need for PETRONAS to carefully manage its pricing strategies to maintain its competitive edge and customer loyalty.

Every year, leading brand valuation consultancy Brand Finance puts 5,000 of the biggest brands to the test, and publishes over 100 reports, ranking brands across all sectors and countries. The world’s top 50 most valuable and strongest oil and gas brands are included in the Brand Finance Oil & Gas 50 2024 ranking.

Brand value is understood as the net economic benefit that a brand owner would achieve by licensing the brand in the open market. Brand strength is the efficacy of a brand’s performance on intangible measures relative to its competitors.

The full ranking, additional insights, charts, more information about the methodology, and definitions of key terms are available in the Brand Finance Oil & Gas 50 2024 ranking.

About Brand Finance

Brand Finance is the world’s leading brand valuation consultancy. Bridging the gap between marketing and finance for more than 25 years, Brand Finance evaluates the strength of brands and quantifies their financial value to help organisations of all kinds make strategic decisions.

Headquartered in London, Brand Finance has offices in over 20 countries, offering services on all continents. Every year, Brand Finance conducts more than 5,000 brand valuations, supported by original market research, and publishes over 100 reports which rank brands across all sectors and countries.

Brand Finance also operates the Global Brand Equity Monitor, conducting original market research annually on over 5,000 brands, surveying more than 150,000 respondents across 38 countries and 31 industry sectors. Combining perceptual data from the Global Brand Equity Monitor with data from its valuation database enables Brand Finance to arm brand leaders with the data and analytics they need to enhance brand and business value.

In addition to calculating brand value, Brand Finance also determines the relative strength of brands through a balanced scorecard of metrics evaluating marketing investment, stakeholder equity, and business performance. Compliant with ISO 20671, Brand Finance’s assessment of stakeholder equity incorporates original market research data from over 100,000 respondents in 38 countries and across 31 sectors.

Brand Finance is a regulated accountancy firm, leading the standardisation of the brand valuation industry. Brand Finance was the first to be certified by independent auditors as compliant with both ISO 10668 and ISO 20671 and has received the official endorsement of the Marketing Accountability Standards Board (MASB) in the United States.

Can technology save the planet?

Can technology save the planet? The sentiment at the World Economic Forum annual conference in Davos evoked an overwhelming yes. Next generation technologies have undeniable potential. Yet, the success of these technologies hinges on how we navigate their implementation.

Here, Stefan Reuther, Member of the Executive Board at automation supplier COPA-DATA, reflects on the World Economic Forum (WEF) annual conference — what change is required to achieve the twin transition?

Pillars of change

Talent development was discussed at Davos 2024 as a critical factor in ensuring a smooth transition to next-gen technologies. It's not merely about technical skills, but cultivating a mindset of adaptability and continuous learning. As technology evolves, so must our workforce. Initiatives like training programs and upskilling efforts are pivotal in equipping our teams to leverage these advancements effectively.

A robust data backbone is equally crucial. This involves establishing reliable systems for capturing, processing and analyzing data across the entire manufacturing ecosystem. This is essential to provide real-time insights and predictive maintenance, enhancing decision-making in a wide variety of settings.

Industry standards also play a part in fostering interoperability and ensuring quality of new technologies. To get the best out of our tech, we must streamline the development of common protocols and best practices. While this may take time, standardization will further facilitate the integration of new technologies in the long term.

Governments and regulators play a critical role in shaping the landscape of next-gen technologies. They yield power to create an environment where knowledge is shared, resources are mobilized and technology is deployed carefully. While it is crucial not to overregulate new tech, following sensible approaches is a good thing. This is particularly important for technologies that can be used to tackle pressing challenges like climate change.

Actions for the twin transition

The concept of the twin transition — the phrase used to describe the convergence of the digital and green transitions — took center stage at Davos 2024. Recognizing the urgency of climate change, the community discussed the need for actionable solutions to accelerate the reduction of emissions.

It is clear there’s a need for industry-specific solutions for sustainability. While we may all be aiming for similar goals, such as reducing Scope 3 emissions, the methodologies of doing so will differ. Collaborative research and development (R&D) and the sharing of best technology practices will be key to uplift the sustainability of the entire supply chain.

This impacts traceability, transparency and trust. In a previous COPA-DATA article, I discussed the role of independent software vendors (ISVs) in the twin transition. Transparency is key for the success of ISVs, particularly those that use open automation like COPA-DATA. Our software platform allows users to choose any system, equipment or software and ensures it can communicate seamlessly with a no-code approach. Moving away from silos and vendor-lock in is crucial for empowering businesses to understand their data and improve their environmental impact.

This transparency of data is similarly crucial for integrating sustainability into product design and manufacture — another topic discussed at Davos. In addition to considerations like material selection and lifecycle management, businesses can make significant improvements to their emissions by tackling energy intensive processes in their product manufacture. It is impossible to do this without transparent technology that captures and visualizes energy consumption in a harmonized way.

In asking whether technology can save the planet, we find ourselves at the nexus of possibility and responsibility. The discussions at Davos 2024 illuminated the potential of technology to achieve the world’s sustainability needs, but also emphasized the urgent need for collaborative action and change to implement these technologies effectively.

As we reflect on the insights gained and the challenges ahead, we see that there are plenty of options to improve and we must do it now to preserve a future worth living. One thing becomes clear: It’s not about the planet, it’s about us and the lives of our offspring.

To learn more about COPA-DATA, visit the website here.

About COPA-DATA

COPA-DATA is an independent software manufacturer that specializes in digitalization for the manufacturing industry and energy sector. Its zenon® software platform enables users worldwide to automate, manage, monitor, integrate and optimize machines, equipment, buildings and power grids. COPA-DATA combines decades of experience in automation with the potential of digital transformation. In this way, the company supports its customers to achieve their objectives more easily, faster and more efficiently. The family-owned business was founded by Thomas Punzenberger in 1987 in Salzburg, Austria. In 2022, with more than 350 employees worldwide, it generated revenue of EUR 69 million.

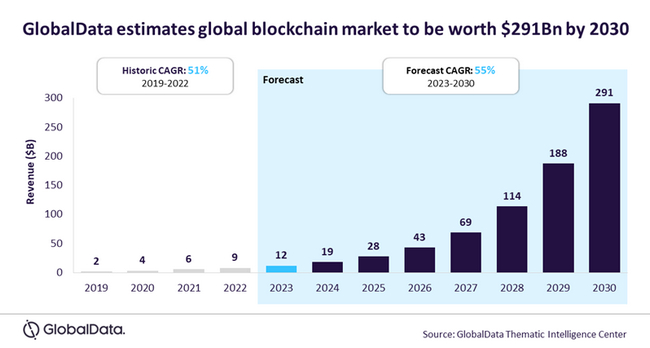

Evolving blockchain technology can transform diverse oil and gas applications, says GlobalData

Blockchain is emerging as a technology that demands attention within the oil and gas sector. It presents novel approaches to service contracts, review pricing, and support the entirety of the transaction life cycle. It thus promises potential cost reductions and enhanced process efficiencies. Moreover, the advantages of blockchain in the oil and gas industry manifest through enhanced transparency, compliance, and data security, says GlobalData, a leading data and analytics company.

GlobalData’s thematic report, “Blockchain in Oil and Gas,” provides an overview of the blockchain technology and its potential implications in oil and gas operations. It also highlights the role of major oil and gas companies, such as ADNOC, BP, Eni, Equinor, Repsol, and Shell in the development of blockchain to address their challenges.

Ravindra Puranik, Oil and Gas Analyst at GlobalData, comments: “While the initial use focused on supply chain optimization, blockchain has evolved considerably in recent years to support transaction processing with smart contracts. Moreover, the establishment of consortiums has helped to standardize protocols and exchange best practices. With the maturation of the technology, its adoption is expected to expand, ushering in improved transparency, efficiency, and security in operations.”

Blockchain has a range of compelling applications within the oil and gas industry. It has the potential to accelerate digital transformation using sensors and cloud computing. The tokenization of physical assets has also emerged as a promising application.

Puranik continues: “Tokenization involves digitizing a tangible asset for managing big data or safeguarding sensitive information. It has the potential to streamline bureaucratic processes during the production, transportation of processing of a natural resource across various jurisdictions. A token can facilitate transparency in tracking the movement of natural resources throughout the developmental phases. This transparency not only highlights opportunities to minimize waste but also aids in identifying potential irregularities, thereby aiding the sector in fortifying its reputation at a time when it faces challenges from alternative energy sources.”

With the hype around blockchain subsiding, adoption is quietly increasing, focusing on practical benefits and efficiency gains rather than technological novelty. The realization that blockchain’s fit may not be universal, coupled with the importance of having a strong digital infrastructure in place, will continue to drive the trend toward meaningful implementation.

Puranik concludes: “As sensor technology reaches its peak within the industry amid rising adoption of the Internet of Things (IoT), blockchain facilitates the direct storage of transactions and accounting data on these devices. By linking assets directly to service contracts, blockchain significantly diminishes processing time and fundamentally alters contracting by providing secure collaboration. Although adoption is currently in its early stages, the potential of blockchain in the oil and gas sector is poised for substantial growth as companies recognize its full capabilities.”

- Quotes provided by Ravindra Puranik, Oil & Gas Analyst at GlobalData

- Information based on GlobalData’s thematic report: Blockchain in Oil and Gas

- This press release was written using data and information sourced from proprietary databases, primary and secondary research, and in-house analysis conducted by GlobalData’s team of industry experts

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, financial, technology and professional services sectors.

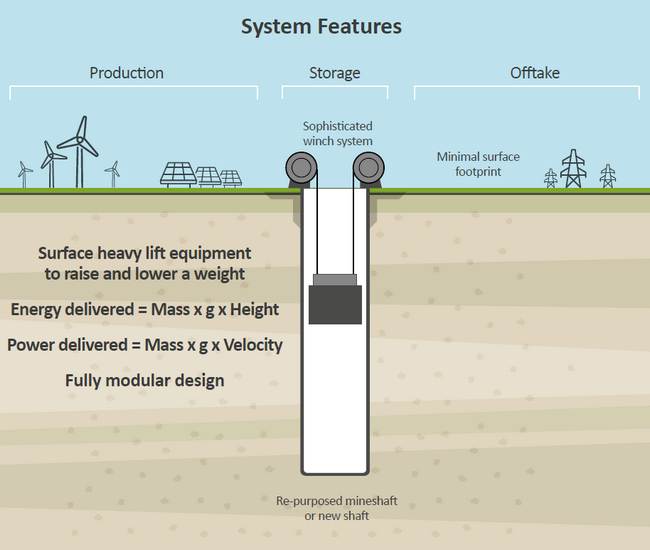

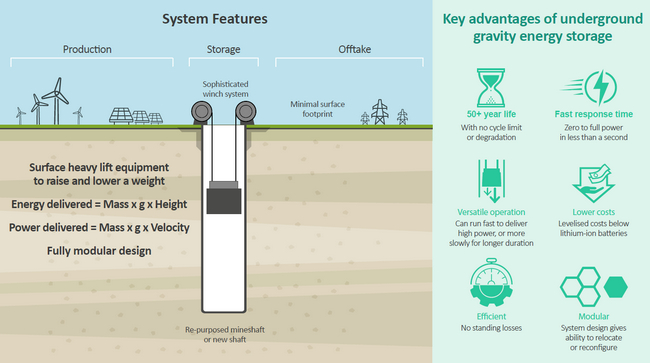

Slovenian coal mine looks to gravity energy storage for green future

An operational coal mine in Slovenia has become the latest mine in mainland Europe to look to underground energy storage.

The Velenje mine in the northeastern part of Slovenia is currently a fully operational lignite mine, with six working shafts and more than 1,600 mine employees.

The mine operators have now commissioned a feasibility study to examine how underground gravity energy storage – provided by Edinburgh firm Gravitricity – could offer a low carbon future as the mine winds down operations in the 2030s.

Gravitricity has developed a unique energy storage system, known as GraviStore, which raises and lowers heavy weights in underground shafts – to offer some of the best characteristics of lithium-ion batteries and pumped hydro storage.

Velenje is the latest mine to look to gravity storage, following mine sites in Finland, Germany, and the Czech Republic.

The mine’s parent company HSE Group is already Slovenia’s largest producer of renewable electricity, and any future storage scheme could potentially be combined with on-site solar generation to support the country’s transition to net zero.

Gravitricity engineers have already visited the site to assess the technical feasibility of installing systems in two specific shafts one of which is a ventilation shaft which may become available for a potential pilot project, which could start as early as next year.

Gravitricity Engineering Project Manager Nigel Voaden said:

“The Velenje mine could be very well suited to future energy storage schemes as the operational shafts are both deep and in excellent condition and we are grateful to the mine’s operators for commissioning this study. Any future project could offer a new future to many of the hundreds of people who work at the mine today.”

“The survey includes an all-site assessment looking at energy demand, production, and storage, provides an initial calculation of the potential energy storage capacity for each of the six shafts on site, and completes a technical feasibility assessment for the installation of two GraviStore systems,” Voaden says.

Following submission of Gravitricity’s findings, the Velenje mine operators will have the opportunity to consider a second phase of the feasibility study prior to any final decision on a pilot scheme.

Gravitricity is currently fundraising on the Crowdcube platform and has already passed its £500,000 funding target.

Gravitricity is raising £500,000 investment on Crowdcube. Capital At Risk.

About Gravitricity

Gravitricity uses heavy weights suspended in a deep shaft by cables attached to winches. When there is excess electricity, for example on a windy day, the weight is winched to the top of the shaft ready to generate power. This weight can then be released when required – in less than a second – and the winches become generators, producing either a large burst of electricity quickly, or releasing it more slowly depending on what is needed.

See short (30 second) ‘how it works’ animation here.

Unlike batteries, the Gravitricity system can operate for decades without any reduction in performance. Gravitricity has an expanding portfolio of intellectual property in underground energy storage including eight granted patents and a further two pending. The idea of using gravity to store energy is not new. Britain already relies on a number of pumped storage hydro schemes, such as Cruachan Power Station, where water is pumped uphill to be released when required.

Gravitricity is advancing a number of full-scale GraviStore projects, including a plan to transform state owned mine infrastructure in the Czech Republic into an energy store.

About Velenje coal mine

Despite the national and global trends aiming to transition to a low-carbon or carbon-neutral society, Premogovnik Velenje (Velenje Coal Mine), an associated company of Holding Slovenske Elektrarne, is still an important and indispensable pillar of the Slovene energy industry. Together with Termoelektrarna Šoštanj (Šoštanj Thermal Power Plant), it has been striving for decades to ensure undisturbed and reliable power supply for one third of Slovenia.

We are immensely proud that the foundations of today's image of the Šaleška dolina Valley are based on mining, as the Velenje Coal Mine has been the main driving force of development of the entire region since 1875, and its impact is often seen beyond the valley, as well.

We have extracted over 259 million tonnes of coal from the depths of the Šaleška dolina Valley. From the initial 3,500 tonnes in 1887, the biggest breakthrough in production happened in the 1980s, when mechanised mining equipment was gradually introduced, which helped us achieve the milestone of over 5 million tonnes of extracted coal per year. Nowadays, our production, which is primarily dependent on the consumption by the Šoštanj Thermal Power Plant, is around 2-2.5 million tonnes of coal per year.

Our story is based principally on tradition and our know-how, technological equipment, and technologies that we developed. We participate in some key development and research projects, co-financed by the European funds, which support high-technology development. Every year, our innovations are among the recipients of the highest regional and national awards. For years, we have been spreading knowledge, experience, technology, and equipment abroad.

Energy is the means for achieving our goals. By innovative thinking and professional and efficient work, we can improve the competitive position of the entire Velenje Coal Mine Group

Support whenever it’s needed

Remote support proves vital to efficient and competitive milling operations

70 per cent of manufacturers surveyed by Deloitte say they have integrated advanced technologies, like data analytics and cloud computing, into their manufacturing processes. But, as manufacturers increasingly embrace digitalisation, competition is sure to intensify — and the vital role of predictive maintenance mustn’t be overlooked. Here, Gary Kernaghan, automation manager at Technidrive, the specialist supplier of industrial drives, electrical motors and gear units explains why remote maintenance is vital if manufacturers are to stay competitive.

Deloitte's survey found that nearly half of manufacturers are already using IoT sensors, devices and digitalised systems. Industry 4.0 will continue to revolutionise all areas of manufacturing — including the global feed grain market, which is poised to grow from $50.0 billion in 2024 to $70.0 billion by 2034, according to Future Market Insights. The growth will be driven by factors such as the expanding livestock industry, the surge in population and rising demand for high-quality animal feeds.

With the continued rise of Industry 4.0, we can expect to see digitalisation and AI algorithms become the norm with industrial milling machinery in the coming years.

Another essential factor in optimal machine performance is predictive maintenance, crucial in preventing unscheduled downtime and breakdowns. Predictive maintenance has been gaining traction for a few years now. 98 per cent of manufacturers surveyed in Pricewaterhouse Coopers (PwC)’s Digital Factories 2020 report said they expected predictive maintenance would increase their manufacturing efficiency.

Nevertheless, in 2024, manufacturers must overcome a number of hurdles if they are to implement an effective predictive maintenance strategy. Indeed, Deloitte cites several challenges: “Economic upheaval, a tight labour market, rising costs and continued supply chain stresses.” These factors, says the report, “underline the importance of agility, resilience, and efficiency in manufacturing operations.”

Traditional approaches to maintenance are increasingly at odds with these challenges. For instance, a maintenance engineer might drive five hours to perform a 15-minute adjustment on a piece of equipment. Or skilled engineers may be needed onsite continually for ongoing repairs and diagnostics. Manufacturers can ill afford such inefficiencies, time and costs, or labour shortages, in today’s competitive markets.

So what can be done? Deloitte recommends that “technology is poised to play a significant role” — but that is only half of the story. What if advanced technologies like data analytics and cloud computing can also open up manufacturers to an entire world of skilled, expert support? Specifically, remote maintenance.

98 per cent of manufacturers surveyed by PwC said they expect predictive maintenance to increase their manufacturing efficiency.

98 per cent of manufacturers surveyed by PwC said they expect predictive maintenance to increase their manufacturing efficiency.

Remote access

Remote maintenance will be vital to more efficient milling operations. First, let’s consider the more familiar concept of remote IT support for office environments. The service provider uses online tools and software to connect to a client's computer or network, and solve issues from a distant location. This concept can also be applied to milling machinery.

Connecting to an office worker’s Mac or Windows PC is one thing, but how does remote maintenance work in more complex industrial manufacturing environments? A simple approach is demonstrated by Technidrive, whereby preloaded tablet devices are supplied to the customer. The tablet is equipped with remote access software, specifically TeamViewer, allowing seamless and cybersecure communication between the customer’s in-house operators and Technidrive’s experienced maintenance team, as part of its Technicare remote support offering.

Technidrive's remote support offering is particularly advantageous for feed milling applications because it allows for quick diagnostics and troubleshooting, without the need for costly and time-consuming on-site visits. Take the example of a variable speed drive (VSD) that controls the speed of motors powering various machinery like conveyors and crushers. If a VSD malfunctions, it can halt the entire milling process, leading to significant downtime and loss of production.

Technidrive collaborates with leading manufacturers like WEG to integrate advanced technologies into milling equipment including PLCs, HMIs and soft starters and also WEG’s CFW700 variable speed drive (VSD). The VSD has built-in USB connectivity, which makes it easy for maintenance engineers to connect to the device remotely through a tablet. USB capabilities can be retrofitted into existing hardware or control systems. With remote support capabilities, Technidrive can provide immediate assistance.

Through remote access, Technidrive engineers can analyse real-time data from the VSD. If the VSD displays abnormal behaviour such as overheating or erratic speed control, mill operators can initiate a remote diagnostic session. Technidrive can rapidly identify the root cause of the issue, and guide operators through troubleshooting steps or adjust parameters remotely to restore normal operation.

In the cloud

Over the coming years, cloud computing and the IoT will further enhance manufacturers’ predictive maintenance strategies. Cloud-based platforms allow for real-time data collection and analysis, enabling machine shop owners and operators to monitor and optimise operations remotely. IoT sensors can be integrated into machinery and equipment to provide real-time data on performance and maintenance needs, and support swift resolutions to problems.

Data combined with the cloud could offer a wealth of remote maintenance possibilities. Perhaps satellite-based internet services like Starlink could support advanced remote maintenance in isolated locations? For now, remote support is emerging as a vital tool, facilitating seamless communication with milling equipment and ensuring operational excellence in the evolving Industry 4.0 landscape.

About Technidrive: Founded in 1998, Technidrive creates industrial drive solutions for the recycling, quarry, food, and dairy industries. Technidrive excels in innovation by continually developing solutions to meet and exceed market trends.

The company specialises in electric motors, industrial gear units and electrical automation. Technidrive is a WEG Premier Partner and Bonfiglioli BEST Partner; these accolades enable the company to house a state-of-the-art assembly centre and hold the most extensive stock in Ireland. The team's combined experience has allowed Technidrive to become a leader in industrial drive solutions. For more information, visit www.technidrive.co.uk