A manufacturer of PET (polyethylene terephthalate) bottles frequently had to replace the linear guides on its blow moulding machines. However, after switching to NSK’s RA series roller guides, there have been no failures for over a year, producing annual cost savings in maintenance, spare parts and downtime of €60,000.

Dissatisfied with the number of linear guide failures on its blow moulding machines, the manufacturer invited NSK to investigate several faulty guides. Expert analysis identified the cause to be end cap damage, which was occurring due to the combination of short stroke movements, short cycle times, frequent start-stop operation and increased displacement force during start-up.

A manufacturer of PET bottles is benefitting from NSK RA series roller guides on its blow moulding machines. Photo: Shutterstock

A manufacturer of PET bottles is benefitting from NSK RA series roller guides on its blow moulding machines. Photo: Shutterstock

Given this application profile and the damage that was taking place, NSK recommended that the plastics processor installed RA series roller guides. These guides offer, among other things, very high load-carrying capacity and motion accuracy, extreme rigidity, smooth running, and long service life under conditions of short cycle rates and high loads.

A principal design feature of the RA series are its spacers, which perform a restraining function between each of the rollers. These spacers reduce roller skew and ensure smooth running, as well as lower displacement force during start-up.

The user followed the recommendation and, on a trial basis, equipped one of its blow moulding machines with NSK RA series roller guides. This machine ran for more than a year without any problems or breakdowns, reducing production downtime costs to zero. NSK's cost savings analysis showed that the retrofit of this one machine alone resulted in a saving of €59,500.

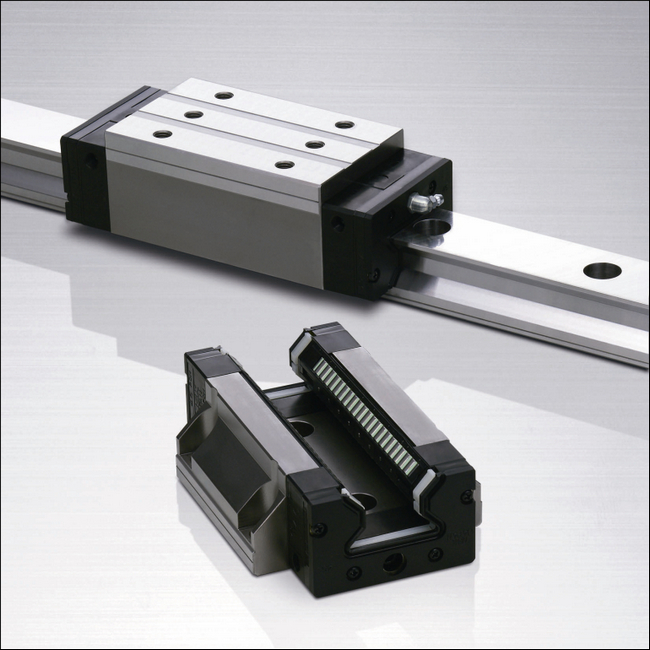

NSK RA series roller guides offer high load capacity and rigidity to meet the needs of a wide range of applications. Photo: NSK

NSK RA series roller guides offer high load capacity and rigidity to meet the needs of a wide range of applications. Photo: NSK

In the light of this outcome, the PET bottle manufacturer had no hesitation in upgrading its other blow moulding machines.

About NSK Europe

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 30,400 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2020, the more than 4,350 employees of NSK Europe Ltd. generated sales of over € 792 million.

www.nskeurope.com