High Performance Recyclable Stretch Film with Multi-Metal Corrosion Inhibitors and ESD protection!

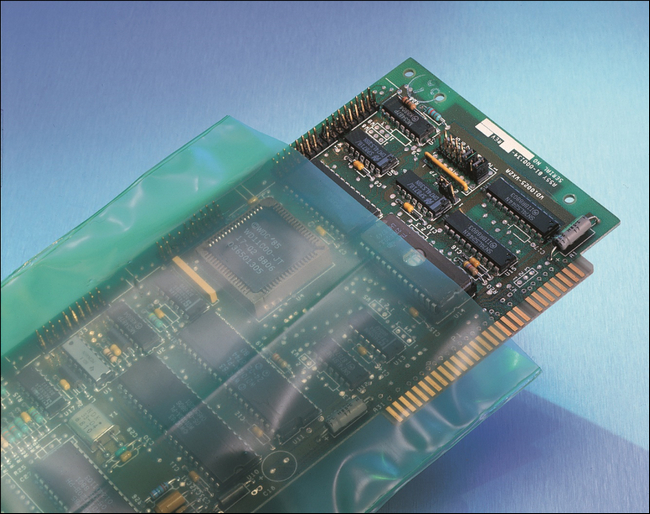

We are proud to announce that Cortec® Laboratories have developed new specialty film for electronics, munitions, fertilizers and several other industrial applications where static discharge could result in dangerous packaging conditions. EcoSonic® VpCI® Static Dissipative Stretch Film meets the anti-static requirements under MIL-PR F-81705 E in the form of a high performance stretch film with multi-metal corrosion inhibitors and ESD protection!

The poor electrical conductivity of plastic film requires special attention in packaging applications where static discharges are unacceptable. Pressure and friction during stretch-wrapping applications will produce static discharges.

These can be quite significant and cannot be dissipated by grounding.

The film will provide excellent multi-metal corrosion protection and eliminate normal stretch film static as well as costly barrier packaging. With superior holding force of the film package integrity and appearance will be improved.

This stretch film is fully recyclable and safe to handle and apply. EcoSonic ® VpCI ® Static Dissipative Stretch Film does not interfere with electrical, optical, or mechanical surface properties.

Some of the benefits are:

- Meets static decay requirements per MIL-PRF-81705 E

- Provides multi-metal corrosion protection

- Eliminates normal stretch film static

- Eliminates costly barrier packaging

- Fully recyclable in applicable facilities

- Safe to handle

- Does not interfere with electrical, optical, or mechanical surface properties

EcoSonic® VpCI® Static Dissipative Stretch Film can be used on standard manual and automatic stretch wrapping equipment. It is ideal for packaging and unitizing of loads in any application that dictates the absence of electrical shock, such as the following:

- Computers and telecommunications equipment

- Laboratory instruments

- Electrical panels/components

- Marine, aerospace, and military instruments

- Medical devices sensitive to electrical interference

- Munitions

- Loads of gun powders and finished explosives

- Volatile products in controlled environments

- Loads in fertilizer plants where nitrites and nitrates are present

EcoSonic® VpCI® Static Dissipative Stretch Film delivers puncture resistance and load holding, which allows a user to down-gauge, contain aggressive loads, and produce a better package at reduced cost.

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide. ISO 9001, ISO 14001:2004, & ISO 17025 Certified. Cortec Website: http://www.cortecvci.com