Ian Melin-Jones

Distinguishing PA6 from PA66 at the push of a button: trinamiX adds new application for plastic sorting to its Mobile NIR Spectroscopy Solution

trinamiX, a wholly owned subsidiary of BASF SE, now supports the reliable differentiation between polyamide 6 (PA6) and polyamide 6.6 (PA66) with its Mobile Near-Infrared Spectroscopy Solution. Within seconds, plastic waste from the two polyamides can be sorted using a handy measuring device as part of trinamiX’s solution. With this new application, trinamiX is responding to customer wishes and expands its broad offering for plastic sorting.

PA6 and PA66 belong to the most sought-after engineering plastics. Thanks to their robustness, they are suitable for a wide range of applications – from fishing nets to resilient components. Since PA6 and PA66 have similar properties, they are used interchangeably in numerous applications – and it is virtually impossible to distinguish them with the naked eye. At the same time, the separation of PA6 and PA66 has gained traction in recent years in light of growing requirements within the recycling industry. As a result, the production of high-quality single-grade plastic recyclates - including PA6 and PA66 - is becoming increasingly lucrative.

"For many recycling companies, sorting PA6 and PA66 previously involved a cumbersome analysis process – and, therefore, proved often times neither profitable nor feasible,” explains Adrian Vogel, Manager Sales and Business Development Spectroscopy Solutions at trinamiX. "With our new application, recycling companies can quickly determine the polyamide type and process the waste streams accordingly."

Distinguishing PA6 from PA66 at the push of a button with trinamiX Mobile NIR Spectroscopy Solution. Copyright: trinamiX GmbH

Distinguishing PA6 from PA66 at the push of a button with trinamiX Mobile NIR Spectroscopy Solution. Copyright: trinamiX GmbH

Besides the recycling industry, plastics processing companies who rely on PA6 and PA66 in their products also benefit from trinamiX's new application. They are now enabled to perform a clean separation of PA6 and PA66 production rejects or waste. In-house recycling processes can thus be geared towards an optimized and more efficient use of valuable resources.

In addition to distinguishing PA6 and PA66, trinamiX Mobile NIR Spectroscopy Solution can already identify all common plastics - from classic polyolefins such as PE and PP, to PET (polyethylene terephthalate) and engineering plastics such as ABS (acrylonitrile butadiene styrene). Recycling companies as well as manufacturers, traders and processors of goods made from recyclate benefit from a flexible and mobile solution that offers user-oriented applications for the sorting of plastic components and packaging materials.

Launched last year, trinamiX’s solution combines robust hardware with intelligent data analysis and a mobile app. NIR spectroscopy is a proven technology that trinamiX has integrated into a portable format for on-site analysis. In doing so, trinamiX relies on cloud-based data processing, which ensures continuous development of the solution – there is no need to replace hardware. This way, trinamiX can continuously develop new applications and react flexibly to new challenges in the field of plastic sorting – while working closely together with customers as in the case of its new PA6/PA66 application.

About trinamiX

trinamiX GmbH develops and sells cutting-edge 3D vision and infrared sensing solutions for use in both consumer electronics devices and industrial designs. The company’s products enable humans and machines to better capture data, with the goal of understanding the world around us. This results in improved decision-making as well as stronger biometric security. trinamiX, based in Ludwigshafen, Germany was founded in 2015 as a wholly owned subsidiary of BASF SE. The company employs 170 people worldwide. Further information on www.trinamixsensing.com.

ABB urges greater adoption of high-efficiency motors and drives to combat climate change - global electricity consumption to be reduced by 10%

In a new whitepaper published this week, ABB reveals potential for significant energy efficiency improvements in industry and infrastructure enabled by the latest and most high-efficiency motors and variable speed drives. ABB calls on governments and industry to accelerate adoption of the technology to help combat climate change.

According to the International Energy Agency (IEA), industry accounts for 37% of global energy use and some 30% of global energy is consumed in buildings.

While mostly hidden from public view, electric motors - and the variable speed drives which optimize their operation – are embedded in almost every built environment. They power a vast range of applications fundamental to our modern way of life, from industrial pumps, fans and conveyors for manufacturing and propulsion systems for transportation to compressors for electrical appliances and heating, ventilation and air conditioning systems in buildings.

Photo caption: Pumping applications like this are wide spread across all industries and buildings and are a prime target for energy savings.

Photo caption: Pumping applications like this are wide spread across all industries and buildings and are a prime target for energy savings.

Motor and drive technologies have seen exceptionally rapid advancement in the past decade, with today’s innovative designs delivering remarkable energy efficiencies. However, a significant number of industrial electric motor-driven systems in operation today – in the region of 300 million globally – are inefficient or consume much more power than required, resulting in monumental energy wastage.

Independent research estimates that if these systems were replaced with optimized, high-efficiency equipment, the gains to be realized could reduce global electricity consumption by up to 10%. In turn, this would account for a significant reduction in greenhouse gas emissions needed to meet the 2040 climate goals established by the Paris Agreement.

“Industrial energy efficiency, more than any other challenge, has the single greatest capacity for combatting the climate emergency. It is essentially the world’s invisible climate solution.”, said Morten Wierod, President ABB Motion. “For ABB, sustainability is a key part of our company Purpose and of the value that we create for all of our stakeholders. By far the biggest impact we can have in reducing greenhouse gas emissions is through our leading technologies, which reduce energy use in industry, buildings and transport.

Considerable steps have already been taken to support the uptake of electric vehicles and renewable energy sources. ABB believes it is time to do the same for an industrial technology that will deliver even greater benefits for the environment and the global economy.

Photo caption - Utilizing high efficiency motor and drive technology saves energy in refrigeration systems typically found deep in the center of a food and beverage facilities.

Photo caption - Utilizing high efficiency motor and drive technology saves energy in refrigeration systems typically found deep in the center of a food and beverage facilities.

“The importance of transitioning industries and infrastructure to these highly energy efficient drives and motors to play their part in a more sustainable society cannot be overstated,” continued Morten Wierod. “With 45% of the world’s electricity used to power electric motors in buildings and industrial applications, investment in upgrading them will yield outsized rewards in terms of efficiency.”

ABB frequently assesses the net impact of its own installed high efficiency motors and drives on global energy efficiency. In 2020, it enabled 198 terawatt-hours of electricity savings – more than half of the UK’s annual consumption. By 2023, it is estimated that ABB motors and drives will enable customers globally to save an additional 78 terawatt-hours of electricity per year, almost as much as the annual consumption of Belgium, Finland or the Philippines and more than the total annual consumption of Chile.

Regulatory policies are among the main drivers of industrial investment in energy efficiency around the globe. While the European Union will be implementing its Ecodesign Regulation (EU 2019/1781) this year, which sets out stringent new requirements for an expanding range of energy efficient motors, many countries have yet to take action.

To take advantage of the tremendous opportunities afforded by energy efficient drives and motors to reduce greenhouse gas emissions, ABB says all stakeholders have a critical role to play:

- Public decision makers and government regulators need to incentivize their rapid adoption,

- Businesses, cities, and countries need to be aware of both the cost savings and environmental advantages and be willing to make the investment, and

- Investors need to reallocate capital towards companies better prepared to address the climate risk.

“While our role at ABB is to always provide the most efficient technologies, products and services to our customers, and continue to innovate for ever greater efficiency, that in itself is not enough. All stakeholders need to work together to bring about a holistic transformation in how we use energy. By acting and innovating together, we can keep critical services up and running while saving energy and combatting climate change”, concludes Morten Wierod.

ABB’s white paper “Achieving the Paris Agreement: The Vital Role of High-Efficiency Motors and Drives in Reducing Energy Consumption” can be downloaded here .

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

ABB Motion keeps the world turning - while saving energy every day. We innovate and push the boundaries of technology to enable the low-carbon future for customers, industries and societies. With our digitally enabled drives, motors and services our customers and partners achieve better performance, safety and reliability. We offer a combination of domain expertise and technology to deliver the optimum drive and motor solution for a wide range of applications in all industrial segments. Through our global presence we are always close to serve our customers. Building on over 130 years of cumulative experience in electric powertrains, we learn and improve every day.

Coalition of energy companies invest £1.6 million into demonstrating wave power for subsea projects

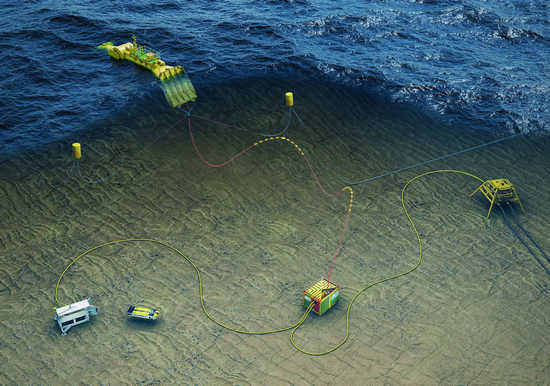

Scottish wave power experts Mocean Energy and energy storage developers EC-OG have joined forces with Chrysaor, Modus, OGTC and Baker Hughes to fund the demonstration of a wave powered renewable energy system for running subsea equipment.

- Mocean Energy, EC-OG, Chrysaor, Modus, OGTC and Baker Hughes have invested £1.6 million into a programme to develop a wave power and energy storage system for subsea projects.

- The programme will build a wave-powered renewable energy system for subsea equipment, with a goal to test at sea this year.

The programme will demonstrate how wave power coupled with underwater energy storage can be used to cost-effectively lower the carbon footprint of providing power to subsea oil and gas production equipment and autonomous underwater vehicles.

Grant funding provided by OGTC has been matched by financial and in-kind contributions from the project partners. The demonstrator will be tested onshore at EC-OG’s facility in Aberdeen in July and August 2021, with ambitions to test the system at sea later in the year.

The programme follows on from an earlier study in 2020, part funded by OGTC, undertaken by the partners. The study established the environmental benefits of the design concept that will be used for the upcoming demonstration programme.

Describing the project, Cameron McNatt, Mocean Energy’s managing director says:

“The decarbonisation of oil and gas operations is essential for the energy transition. Our technology uses renewable energy from waves to deliver low carbon power for subsea equipment, including tiebacks and future fleets of autonomous underwater vehicles (AUV’s). In this programme, we will demonstrate – in onshore conditions – how our wave device will deliver power and communication to subsea equipment.”

Commenting on the project, Paul Slorach, business development director at EC-OG says:

“EC-OG’s Halo smart subsea battery technology has been specifically developed for managing the intermittency of renewable power generation to reliably integrate renewable energy systems to high value subsea assets. Clean energy systems are an increasingly important building block of offshore developments and we’re aiming to be at the forefront of the delivery of renewable energy to the underwater environment.”

Nigel Ward, managing director at Modus added:

“This project will demonstrate the capability to provide temporary or semi-permanent modular series residency for hybrid autonomous underwater vehicles (HAUV), recharged subsea and controlled from shore using ‘over-the-horizon’ technology. This innovative and flexible approach to survey and inspection will reduce the numbers of personnel required offshore, providing significant benefits and cost savings, without compromising quality.”

John Kerr, subsea production systems and technology director for Baker Hughes, Oilfield Equipment concluded:

“Many subsea oilfield production systems will transition to all electric operations in the not too distant future, which will increase operational performance while simultaneously lowering the carbon footprint of the solution. We are excited to be part of this project as we will be able to simulate the ability of the system to power and communicate with the equivalent of a four well Baker Hughes all electric subsea production system.”

There is potential to use such systems in a number of subsea applications, including remediation of faulty umbilical cables in existing developments, as fast track solutions for single well tiebacks and as an enabler for ultra-long step out distances - greater than 200km - where local renewable power generation could make these developments more environmentally and economically viable.

Alfa Laval wins energy efficiency order in North Africa

Alfa Laval – a world leader in heat transfer, centrifugal separation and fluid handling – has won an order to supply Alfa Laval OLMI air coolers to a refinery in Egypt. The order has a value of approximately SEK 95 million and was booked in the business unit Welded Heat Exchangers of the Energy Division. Deliveries are scheduled for 2021 and 2022.

The order comprises different types of air coolers for energy efficiency duties and will be used for converting heavy crude oil into more valuable products. The air coolers, delivered stepwise, is part of a project to upgrade the refinery with more efficient technologies.

“Managing energy in a responsible way is of big importance to the energy-intensive refinery and petrochemical industries. Our energy efficient heat transfer solutions play an important role in saving energy, thereby also reducing the CO2 emissions. It has a positive impact on both our customers’ bottom line and the climate,” says Susanne Pahlén Åklundh, President of the Energy Division at Alfa Laval.

“Managing energy in a responsible way is of big importance to the energy-intensive refinery and petrochemical industries. Our energy efficient heat transfer solutions play an important role in saving energy, thereby also reducing the CO2 emissions. It has a positive impact on both our customers’ bottom line and the climate,” says Susanne Pahlén Åklundh, President of the Energy Division at Alfa Laval.

Did you know that… Refineries account for about 6-8 percent of all industrial energy consumption, and that the energy costs can represent up to 50 percent of their total operating expenditures?

This is Alfa Laval

Alfa Laval is active in the areas of Energy, Marine, and Food & Water, offering its expertise, products, and service to a wide range of industries in some 100 countries. The company is committed to optimizing processes, creating responsible growth, and driving progress – always going the extra mile to support customers in achieving their business goals and sustainability targets.

Alfa Laval’s innovative technologies are dedicated to purifying, refining, and reusing materials, promoting more responsible use of natural resources. They contribute to improved energy efficiency and heat recovery, better water treatment, and reduced emissions. Thereby, Alfa Laval is not only accelerating success for its customers, but also for people and the planet. Making the world better, every day.

Alfa Laval has 16,700 employees. Annual sales in 2020 were SEK 41.5 billion (approx. EUR 4 billion). The company is listed on Nasdaq OMX.

Pump solutions for mine water management

Mines require water. At the same time, because many mine working areas are below the water table, the removal of water is a major challenge. Water is critical for every mine site - without water the mine could not operate. Pumps are, therefore, one of the most used machines in mines today. ln this article we will review the concepts of mine water and mine water management as well as the most common pumping applications.

Mine water and mine water management

The definition of mine water is that it is not a slurry, i.e. generally it is considered to contain

- Removal of water from the mine area (mine dewatering) and removal of water from the process (process dewatering). Mine water originates from several sources. Precipitation from rainwater and subsequent floodwater or melting snow generally affects above-ground mining, whereas underground mines are affected by subterranean waterways, ore bodies containing pockets of water, or long-term rise of the water table from precipitation. Water that is removed from a mine to gain or facilitate access to an ore body is known as mine water.

- Conversely, minerals processing requires the addition of water at various stages, and this can either be reclaimed water from within the mine area or, where not sufficiently available, brought in from external sources such as town water, river or sea water.

The management of water around the mine site is referred to as mine water management. Managing the water resources is a critical task and a major challenge in mining. lt is a never ending process, and dewatering operations would normally continue even when a mine is operating at reduced capacity or temporarily shut down.

The management of water around the mine site is referred to as mine water management. Managing the water resources is a critical task and a major challenge in mining. lt is a never ending process, and dewatering operations would normally continue even when a mine is operating at reduced capacity or temporarily shut down.

Keeping the outflow of mine water higher than the inflow is imperative to enable the mining of the mineral deposit. Consequently, large quantities of water may have to be pumped continuously during the operation and maintenance of the mine working areas.

Mining companies are facing increasing pressure to control depleting resources and manage the environmental impact of operations in compliance with stringent legislation. The importance of well-designed and well-maintained mine water management cannot be stressed enough. lt plays a critical role in the mining industry today.

Challenges in mine dewatering

Mine operations are harsh environments. Mine water can range from dirty water to water containing mud, clay, grit, stones, etc., creating the need to handle an abrasive and sometimes corrosive product.

lt is important for the mine planning department to have an accurate estimate of the groundwater inflow so that the most technologies used are multi-stage deep well pumping or well suitable method for dewatering the mine can be designed. Whilst the mine area requires water removal, this may be scarce commodity in other parts of the site. The overall water management design criteria may therefore include the installation of a water treatment plant to enable the recycling of water for reuse

To determine the most suitable dewatering method for a specific type of mine, the following challenges and conditions need to be considered:

- Mine type: This generally determines the best dewatering method but may be overruled by end user preferences.

- Location: Mines in remote locations may have reduced access to adequate electrical power. Therefore, alternate technologies need to be considered.

- lncoming volume of water: lt is of critical importance to have an accurate estimate of the inflow from all possible sources.

- Mine depth: Whether an open pit or underground, the mine depth will determine whether single-lift drainage or a stage pumping system needs to be employed.

- Water properties: These will determine the dewatering system, pump technologies and construction materials. The type of pumps utilized depends on various factors, including water quality, chemical composition and solids content.

- Life of mine: lf the expected mine life is long, a more permanent system needs to be considered. ln a mine with a shorter life span, portable products or a less costly dewatering system can be used.

- Cost budget: The budget available for the dewatering system defines which methods can be considered

Water streams

Mine dewatering

There are two main types of mine dewatering, i.e. active and reactive (or passive). Active dewatering is a process used mainly around open-pit mines with the purpose of lowering the water table. This method reduces ingress and seepage of water into the mine areas, allowing safe and uninterrupted work. The technologies used are multi-stage deep well pumping or well pointing.

Reactive dewatering is used to remove water from working areas and is applicable to both open-pit and underground mines. Typical reactive applications in open-pit mines are pit dewatering, seepage water removal and flood water relief, while typical applications in underground mines are face dewatering, stage pumping, drainage of shaft bottom sump, ramp and stope pumping and main mine dewatering. Multiple pump tech- nologies can be used in these applications, including submersible, vertical, end-suction, multistage or volumetric pumps. The pump type and construction materials depend on various factors, such as water properties, the presence of abrasive solids, the concentration of solids and the location of the installation.

Process dewatering

Process dewatering generally refers to the separation of water from solids towards the later part of minerals processing. Slurry pumps are normally utilized for pumping the process water to various types of filters or into thickening and settlement tanks.

Process dewatering generally refers to the separation of water from solids towards the later part of minerals processing. Slurry pumps are normally utilized for pumping the process water to various types of filters or into thickening and settlement tanks.

Process water and treatment

Large quantities of water may be required in minerals processing. The quality of the water is highly important and therefore some level of treatment is needed before it enters the process. A combination of vertical, horizontal and submersible pumps may be used in the treatment process. The materials of construction will depend on the water source, e.g. sea water, reclaimed water, etc. The treated water is then added to the process at various stages.

lntake water

Because intake water stations may transport water into the mine from various types of sources, the technology requirements will vary accordingly. Vertical turbines and horizontal end-suction pumps are most commonly used, depending on the pump station design and configuration.

Reclaimed water

The scarcity and cost of water means that reclaiming and reuse are on the increase. Water is reclaimed from tailings ponds, lagoons and the downstream of minerals processing by vertical, horizontal and submersible pumps. lt is then treated prior to use.

Whilst water may be a nuisance, it is also essential for the mining process. The management of this precious resource is of critical importance.

Sulzer in mine water management

Sulzer offers a comprehensive portfolio of innovative pumps and agitators for mining applications, from lightweight and robust submersible dewatering pumps to wear-resistant high-lift centrifugal pumps for the removal of sludge, mud, silt, and water in abrasive and corrosive environments. With thousands of installations around the world, Sulzer's products and services have stood the test of time.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Pumps Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

- Sulzer

- mine water management

- pump solutions

- mines

- mine dewatering

- Sulzer multistage pumps

- Wear-resistant end-suction pumps

- XJ 900 high-capacity pump

- dewatering solutions

- mine dewatering solutions

- ground water control

- main mine drainage station

- open pit dewatering

- open cast dewatering

- aggregates and mining

- dewatering

- dewatering application pump

- dewatering pumps

Europe’s oil & gas industry saw a rise of 23.73% in cross border deal activity in Q4 2020

Led by PPG Industries’ $1.52bn acquisition of Tikkurila, Europe’s oil & gas industry saw a rise of 23.73% in cross border deal activity during Q4 2020, when compared to the last four-quarter average, according to GlobalData’s deals database.

A total of 73 cross border deals worth $7.58bn were announced for the region during Q4 2020, against the last four-quarter average of 59 deals.

Of all the deal types, M&A saw most activity in Q4 2020 with 69, representing an 94.5% share for the region.

Of all the deal types, M&A saw most activity in Q4 2020 with 69, representing an 94.5% share for the region.

In second place was private equity with four deals capturing a 5.5% share of the overall cross border deal activity for the quarter.

In terms of value of cross border deals, M&A was the leading category in Denmark’s oil & gas industry with $5.95bn, followed by private equity deals totalled $1.42bn.

Europe oil & gas industry cross border deals in Q4 2020: Top deals

The top five oil & gas cross border deals accounted for a 73.8% share of the overall value during Q4 2020.

The combined value of the top five cross border deals stood at $5.6bn, against the overall value of $7.58bn recorded for the quarter.

The top five oil & gas industry cross border deals of Q4 2020 tracked by GlobalData were:

- PPG Industries’ $1.52bn acquisition of Tikkurila

- The $1.42bn private equity deal with Galp Gas Natural Distribuicao by Allianz Capital Partners

- Trinseo’s $1.36bn asset transaction with Arkema

- The $745.66m asset transaction deal with OMV by EG Group

- Equinor’s acquisition of KrasGeoNac for $550m.

This analysis considers only announced and completed deals from the GlobalData financial deals database and exclude all terminated and rumored deals. Country and industry are defined according to the headquarters and dominant industry of the target firm. The term ‘acquisition’ refers to both completed deals and those in the bidding stage.

GlobalData tracks real-time data concerning all merger and acquisition, private equity/venture capital and asset transaction activity around the world from thousands of company websites and other reliable sources.

About GlobalData

4,000 of the world’s largest companies, including over 70% of FTSE 100 and 60% of Fortune 100 companies, make more timely and better business decisions thanks to GlobalData’s unique data, expert analysis, and innovative solutions, all in one platform. GlobalData’s mission is to help our clients decode the future to be more successful and innovative across a range of industries, including the healthcare, consumer, retail, technology, energy, financial and professional services sectors.

Anritsu launches new modules to make production line testing more efficient

Anritsu Corporation is pleased to announce the simultaneous launch of its TRX Test Module MU887002A, designed to improve the efficiency of production-line inspection of wireless communications devices, including 5G, and its space-saving Universal Wireless Test Set MT8872A.

With 24 RF connectors, the newly developed TRX Test Module MU887002A is a TRX module for installation in both the MT8870A and MT8872A. It supports 5G Sub-6 GHz New Radio (NR) RF tests, as well as various other simultaneous wireless communications tests, including WLAN, Bluetooth®, and GNSS. As such, this makes the inspection of wireless communications devices on the production line much more efficient.

The MT8872A is a measuring instrument designed for use in mass production and is fully compatible with the MT8870A. Its small footprint is designed to be used in narrower spaces than the standard 19” rackmount, saving space on crowded production lines.

Designed to meet the needs of manufacturers of chipsets, smartphones, wireless modules and other wireless products, Anritsu expects these new MU887002A and MT8872A solutions to save space and cut costs on production lines for wireless communication devices.

The numbers of 5G smartphones and subscribers continue to rise as commercial cellular 5G services start operations. In addition, more antennas are being built in to each 5G wireless device to achieve both higher speeds and greater capacity.

Because of this, wireless-device manufacturers need to test more antennas and are demanding a tester that can be used on the production-line to shorten inspection times.

To meet this demand, Anritsu has developed the TRX Test Module MU887002A with 24 RF connectors per module and the space-saving Universal Wireless Test Set MT8872A. These products meet manufacturers’ needs by improving the inspection efficiency of 5G wireless communications devices.

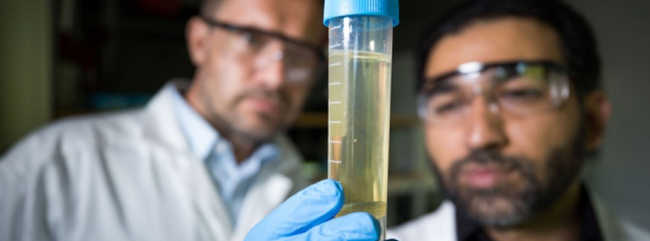

Metsä Spring invests in Montinutra, a startup that commercialises wood extract

Metsä Group’s innovation company Metsä Spring Ltd has made an equity investment in Montinutra Ltd, a startup converting forest industry side streams into high-value bioactive products. The financing round totals approximately EUR 1 million, and Metsä Spring is participating in the round with current and new private investors.

Montinutra intends to produce valuable ingredients for the cosmetics, food and beverage, and pharmaceutical industries using forest industry side streams as its raw material. Metsä Group has two spruce sawmills in Finland, which may provide sawdust for the production.

The company has several product ideas on the planning table. The company focus is first set clearly on SprucegumTM, an extract obtained from spruce sawdust. Sprucegum™ has potential for personal care, cosmetics and foodstuffs as an emulsifying and stabilising ingredient, for example. In addition, health beneficial Qusitol® obtained from sawdust, too, has shown potential for the treatment of lower urinary tract symptoms (LUTS).

“During 2021, Montinutra will build a pilot-scale production facility and will continue to develop bioactive products and customer applications. We are aiming to work very closely with few potential customers in commercialising the product applications. We are excited about the opportunity to have Metsä Spring on board as an industrial anchor investor. On top of the investment, Metsä Spring brings access to their skills and capabilities, their partner network and all in all a lot of credibility that will be required in executing our business plan”, says Jukka Mäkelä, Managing Director at Montinutra.

“Spruce extracts have been studied scientifically for decades. We are thrilled to support Montinutra’s efforts, which aim to make commercial successes of spruce extracts and later, other new wood-based products. The link to Metsä Group’s business ecosystem is strong, because our industrial side stream, spruce sawdust, is used as the raw material for making the extracts. The Sprucegum concept is a prime example of the circular economy in the making,” says Katariina Kemppainen, Investment Manager at Metsä Spring and new Board member of Montinutra.

Metsä Spring was established in May 2018 with the aim of strengthening Metsä Group’s business ecosystem in the long run with a versatile range of higher added-value products. Other investments in Metsä Spring’s portfolio include an equity investment in the start-up Woodio Ltd, as well as the projects developing textile fibres and 3D packaging products from wood pulp.

Metsä Spring

www.metsaspring.com

Innovation company Metsä Spring invests expertise and financial resources into initiatives with the ambition to reshape the forest-based bioeconomy, aiming to increase the value for Metsä Group’s stakeholders in the long-term.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

Montinutra

www.montinutra.com

Montinutra is a R&D and manufacturing company dedicated to convert forest industry side streams into valuable bioactive ingredients for the cosmetics, food and beverage, and pharmaceutical industries with our scalable technology. Our health beneficial product Qusitol® is based on strong University research and widely patent protected in the Northern Hemisphere. The company is a private limited liability company incorporated in Finland.

Time for biometric security on contactless cards: New research from TietoEVRY reveals UK consumers' contactless concerns

New market research from leading digital services and software company TietoEVRY shows that UK and European consumers are concerned about infection risk when paying in-store, with worries about theft and fraud growing as contactless limits rise. In a new white paper TietoEVRY argues that now’s the time to introduce biometric security on contactless cards.

Conducted by Zwipe on behalf of TietoEVRY during COVID-19’s “second wave” across Europe in January 2021, the research found that 83% of UK consumers are concerned about infection risk when it comes to shopping and paying in-store. The research also shows more than half (55.3%) of consumers are concerned about the safety of their payment cards as transaction limits increase.

Steve Warner, Sales Director for the UK and Ireland at TietoEVRY, said: “With the new proposed limit of £100 (€110) per transaction in the UK from 6th April 2021, it becomes possible for thieves to spend significant sums of money on unprotected contactless cards, even if theft is reported quickly. This is a real concern, and card issuing banks must act now to ensure contactless transactions remain safe and bolster consumer confidence.”

Steve Warner, Sales Director for the UK and Ireland at TietoEVRY, said: “With the new proposed limit of £100 (€110) per transaction in the UK from 6th April 2021, it becomes possible for thieves to spend significant sums of money on unprotected contactless cards, even if theft is reported quickly. This is a real concern, and card issuing banks must act now to ensure contactless transactions remain safe and bolster consumer confidence.”

TietoEVRY’s research confirms that contactless payments have become the habitual choice of 78.3% of UK consumers, with fully 90% having used contactless at some point in the last three months. This compares to 2019 information from UK Finance stating that 60% of UK adults used contactless, demonstrating how fast contactless transactions have become the norm. Other leading European markets have shown a similar shift, with contactless used by 72% of Swedish consumers and 77% of Norwegians as of January 2021.

“Our research shows just one in four UK citizens believe the current situation is sustainable”, Warner continued. “At the same time, though few are aware of biometric cards, 80% of UK consumers are telling us they want a biometric security factor on their next payment card – and more than half of them are willing to pay for it. With recent surveys telling us that one in five Brits would move bank for better services, now’s the time for banks to claim competitive advantage by offering biometric cards.”

The research reveals just under half of UK consumers (49%) would switch banks to get hold of a biometric payment card, with around half of consumers in Sweden and Norway willing to make a similar switch.

Download the white paper for more information https://www.tietoevry.com/en/campaigns/2021/biometric-cards-whitepaper/. Please also see the attached PDF's for biometric study and executive summary.

About the research: 300 British citizens were surveyed by Zwipe on behalf of TietoEVRY in January 2021. 48% of respondents were female. 8% were aged under 18, 22% between 22 and 29, 18% between 30 and 44, 31% between 45 and 60, and 21% aged 60+. Survey information for Norway and Sweden available on request.

About TietoEVRY: TietoEVRY creates digital advantage for businesses and society. We are a leading digital services and software company with local presence and global capabilities. Our Nordic values and heritage steer our success. Headquartered in Finland, TietoEVRY employs around 24 000 experts globally. The company serves thousands of enterprise and public sector customers in more than 90 countries. TietoEVRY’s annual turnover is approximately EUR 3 billion and its shares are listed on the NASDAQ in Helsinki and Stockholm as well as on the Oslo Børs. www.tietoevry.com

TietoEVRY Financial services solutions is the number 1 provider within IT, software and platform services for Financial services in the Nordics. We have largest pool of banking and financial IT and software experts in the Nordics supported by global capabilities. In total, we have over 3000 industry experts working with our 400 clients in over 50 markets around the globe.

TietoEVRY Financial Services Solutions create digital advantage for millions of customers every day, helping a wide range of Nordic and global companies in the financial services industry to digitalize business processes, secure operational efficiency and growth in an environment of constant regulatory change. Our portfolio provides a comprehensive range of services and processes, based on flexible modules and innovative scalable software platforms, from innovative real-time solutions within payments, cards and credit to running full stack operations and BPO services.

If you want to learn more, please visit: https://www.tietoevry.com/en/industries/financial-services/

Chevron Invests in Geothermal Development Company

Chevron Corporation (NYSE: CVX) has just announced an investment in Baseload Capital AB, a Sweden-based private investment company focused on development and operation of low-temperature geothermal and heat power assets.

Heat power is an affordable form of renewable energy that can be harnessed from either geothermal resources or waste heat. This investment round includes existing Baseload Capital investors Breakthrough Energy Ventures and Sweden-based investment group Gullspang Invest AB.

The Baseload investment follows last month’s announcement of funding for Eavor and expands Chevron’s capacity to gain insight into geothermal innovations such as low-temperature power generation and closed-loop geothermal technologies.

The Baseload investment follows last month’s announcement of funding for Eavor and expands Chevron’s capacity to gain insight into geothermal innovations such as low-temperature power generation and closed-loop geothermal technologies.

Chevron Technology Ventures (CTV) identifies externally developed technology with the potential to enhance the way Chevron produces and delivers affordable, reliable and ever-cleaner energy now and into the future. The investments in Baseload and Eavor are financed by CTV’s Core Venture fund which identifies companies with technology that can add efficiencies to Chevron’s core business in operational enhancement, digitalization, and lower-carbon operations.

“Chevron’s investments in geothermal power reflect our ongoing focus on helping to advance the world’s transition to a lower-carbon future,” said Chevron’s Vice President, Innovation and President of Technology Ventures, Barbara Burger. “We look forward to working with Baseload Capital and Eavor to expand geothermal resources in the U.S. and internationally.”

Chevron and Baseload are planning potential pilot projects to test new technology. Baseload Capital currently operates in Japan, Taiwan, Iceland, and the United States. As Baseload develops in these regions and expands to new markets, Chevron and Baseload will look for commercial geothermal and heat power opportunities in additional Chevron operations.

“In August, we announced that we were looking for a new strategic investor to help us accelerate deployment in our key markets,” said Baseload’s Chief Executive Officer Alexander Helling. “We couldn’t have asked for a better one. Chevron complements our group of owners and adds expertise in drilling, engineering, exploration and more. These assets are expected to accelerate our ability to deploy heat power and strengthen our way of working.”

About Baseload Capital

Baseload Capital is a specialized investment entity that funds the deployment of heat power worldwide. The company currently has subsidiaries in Iceland, Japan, Taiwan, and the U.S., which work with local communities and power companies to permit, build and commission heat power plants. By applying innovative financing structures and using subsidiaries to roll out local implementation, Baseload Capital can help nations quickly transition away from fossil fuels and toward energy independence. The result will lead to more resilient societies and a planet in balance. For more information, visit: baseloadcap.com.

About Chevron Technology Ventures

Chevron Technology Ventures (CTV) pursues and invests in externally developed technologies and new business solutions that have the potential to enhance the way Chevron produces and delivers affordable, reliable, and ever-cleaner energy. CTV leverages innovative companies and technologies to strengthen Chevron’s core operations and identifies new opportunities to shape the future of energy. For more information, visit www.chevron.com/technology/technology-ventures.