Industrial augmented reality (AR) promises to eliminate human error at process facilities: carrying out double checks on operators actions, walking them through procedures, and providing feedback on whether tasks were completed properly and any problems that may arise.

Omega Simulation Co. Ltd. (OSC), a JV between Yokogawa Electric Corp. and Mitsui Chemicals Inc. is one of the pioneers of this technology. Since its formation in 2007, it has been developing advanced simulation systems based on Yokogawa's control & instrumentation technologies and Mitsui expertise in modelling simulation.

Dynamic simulators are widely used for operations training but OSC aims to extend this to every stage of a plant lifecycle - from the EPC phase to providing operational assistance and plant optimisation by recognising and predicting plant and process conditions.

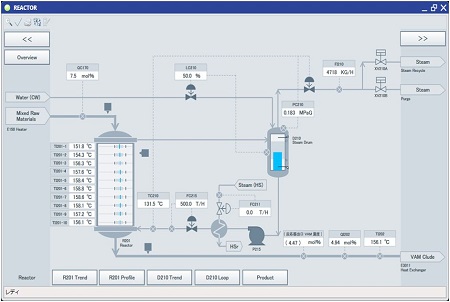

These efforts have led to the launch of Mirror Plant, which is claimed to be an industry first for the use of online simulator technology in optimising the safety and efficiency of industrial process facilities. It is designed, particularly, to help operators in industries, such as oil & gas and petrochemicals, who are often required to adjust many variables in real-time.

For example, chemical plant operators need to adjust the state of catalysts and the composition of the reagents and product materials in a chemical reactor in real time. However, explains Yokogawa, many of the process variables are difficult to measure or cannot be measured directly.

Synchronised with the plant control system, the simulator is said to visualise the internal state of a plant process and make accurate predictions on various process parameters, explains a Yokogawa press release.

A proprietary function adjusts model parameters to visualise the current state of the plant, and up to several hours ahead. It can also be used at plant locations where it is not possible to measure temperature or pressure.

A field test conducted 2011-13 at a Mitsui Chemicals plant showed that the technology could efficiently stabilise and optimise the operation of a distillation tower, Yokogawa has reported.

Related article

TECHNOLOGY - Yokogawa develops 'industry-first' process simulator