Ian Melin-Jones

EVENT - Planview Hosts Fifth Annual PIPELINE Conference & Hub for Innovative Product Development

Planview® will host the fifth annual PIPELINE – The Virtual Conference & Hub for Innovative Product Development – on June 6, 2014. This award-winning, online event will feature keynotes by innovation experts Michelle Greenwald and Braden Kelley discussing how organisations can spur innovation.

Planview® will host the fifth annual PIPELINE – The Virtual Conference & Hub for Innovative Product Development – on June 6, 2014. This award-winning, online event will feature keynotes by innovation experts Michelle Greenwald and Braden Kelley discussing how organisations can spur innovation.

Keynote Topic: “Catalyzing Innovation for More Methodical, Complete and Creative Ideation”

Presenter: Michelle Greenwald, a professor at the NYU Stern, Columbia, and IESE Graduate Schools of Business in New York, CEO of Inventours™, author of “Catalyzing Innovation”, and former Fortune 100 marketing executive.

Description: Michelle will discuss her breakthrough idea development model that helps organisations create, launch and grow new products and services systematically. Quite simply, it provides a framework for innovation. Michelle will share how the model can be applied to businesses. She’ll speak about the Inventours™ program designed to help global executives benchmark leading innovators around the world for new product development process improvement insights.

Keynote Topic: “Why Building an Innovation Culture Is Hard and Five Things to Make it Easier”

Presenter: Braden Kelley, author and innovation expert

Description: When it comes to innovation, far too much emphasis is placed on creativity, ideas and products. Innovation requires more than 'aha' moments. Innovation is a team sport, not an individual one, and while it may be easier for our reptilian brain to understand a single innovation hero, the truth is that every innovation figurehead from Steve Jobs to Thomas Edison had a whole lab or team of people behind them making the real innovation happen. In this session we will investigate what it takes to build a successful team of capable innovation practitioners and contributors that will effectively form a strong and sustainable innovation culture to power success for the organisation, not just for the moment, but for the lifetime of the organisation.

About PIPELINE

With more than 4,000 participants from 95 countries over the past four years, PIPELINE offers product development practitioners access to experts as well as practical information they can use right away – all from the comfort of their desks. From idea to launch to end-of-life, the content will appeal to any professional involved in the end-to-end product development process. In addition, the newly designed PIPELINE virtual platform serves as a resource center for 12 months following the live event with new content each quarter. Registrants to the conference get a free access to the resource center. PIPELINE 2013 was named Event of the Year category in Best in Biz Awards for virtual conference on innovative product development. For more information and to register, visit http://www.pipelineconference.com

About Planview

Planview is a global leader in portfolio and resource management, helping organizations drive results by optimizing the capacity of their finite people and financial resources. Market leaders across every industry rely on the company’s cloud solutions to manage portfolios across IT, product development, services and finance. Planview’s singular focus fuels a deep commitment to innovation and customer success. For more information, visit http://www.planview.com.

CONTRACT - Dutch oil and gas producer NAM renews HSE contract with Royal HaskoningDHV

Risk management for all 175 onshore and offshore NAM oil and gas facilities

Nederlandse Aardolie Maatschappij (NAM) – the joint venture between Shell and ExxonMobil – has renewed and extended its Health, Safety and Environmental (HSE) contract with Royal HaskoningDHV. The three year contract covers risk above the ground on all NAM’s 175 onshore and offshore oil and gas exploration and production sites.

The multi-million euro contract encompasses all of NAM’s offshore and onshore assets in the Netherlands and the North Sea area. Royal HaskoningDHV will support NAM to achieve the safest, most efficient and sustainable gas exploration and production.

NAM is the leading producer of natural gas in the Netherlands. Mr Eric Dorenbos, NAM’s HSE Regulatory Affairs Manager, said: “Royal HaskoningDHV’s understanding of the oil and gas industry and strong presence in the north of the Netherlands means they understand local sensitivities. They have acquired extensive knowledge of NAM’s assets and operations over recent years, and demonstrated they are a reliable and trusted partner. For this reason we want to continue our relationship with them and have therefore renewed and extended their contract for a period of three years.”

Mr Arthur Groot, Account Manager of the NAM at Royal HaskoningDHV, said: “We are helping NAM to achieve their objectives of conducting their operations in a safe, sustainable and efficient way. Our work will focus on Hazard and Effect Management, Compliance Management and Impact Assessment. This will include preparation of key documents, safety management studies, operation and contingency manuals, technical safety support and legal support.”

The delivery of Royal HaskoningDHV’s extensive range of HSE services – currently unrivalled in the Netherlands – will help NAM achieve their goals for the next three years and beyond.

Royal HaskoningDHV is an independent, international engineering and project management consultancy with more than 130 years of experience in aviation, buildings, energy, industry, infrastructure, maritime, mining, rural and urban areas, and water. Backed by the expertise and experience of 6,500 colleagues from 100 offices in 35 countries, our professionals combine global expertise with local knowledge to deliver a multidisciplinary range of consultancy services for the entire living environment. By showing leadership in sustainable development and innovation, together with our clients, we are working to become part of the solution to a more sustainable society now and into the future.

See for more information our website royalhaskoningdhv.com.

For more information:

This email address is being protected from spambots. You need JavaScript enabled to view it., Press Officer Royal HaskoningDHV, +31 88 3482026 / +31 6 29098238

GEOTHERMAL - The Geothermal potential of Tenerife

Tenerife's geothermal potential is a challenge for the island’s sustainability.

Dr Nemesio Perez, Director, Environmental Research Division, ITER (Tenerife Renewable Energy Institute) and Coordinator of INVOLCAN (Canary Island Volcano Institute)will discuss this at the conference organised by GeoTenerife taking place at the RAC Club, Pall Mall, London on Friday May 2 2014.

Spain’s first fully functional geothermal power station is to be built in Tenerife.

The island is a volcano – what is its potential to generate energy?

Dr Perez will look at public and private-sector geothermal research in Tenerife to date and how it can contribute to a more sustainable future for the island.

GeoTenerife is a British company that organizes tailor-made scientific fieldtrips, conferences and webinars. The business founders are passionate about promoting the educational potential of little-known aspects of the stunning volcanic island of Tenerife.

Please see the GeoTenerife event video at

https://www.youtube.com/watch?v=AlWBABlRiUM&feature=youtube_gdata_player

For this year’s conference, GeoTenerife is bringing some of Tenerife’s leading scientists and innovators to London to talk about their most exciting renewable energy developments and projects.

Sharon Backhouse, Director of GeoTenerife said: “I am constantly amazed by the ingenuity and perseverance of Tenerife innovators. The island has fabulous natural resources. But it’s shocking to think that around 95 per cent of its energy needs are currently met using oil. Spain as a whole produces up to 50 per cent of its electricity from wind power alone. Why not Tenerife? And this on an island blessed year-round by sun, wind, sea and volcano power!

“But now there is a new breed of innovators and politicians determined to be at the forefront of the 100% renewable campaign, working hard to tap Tenerife’s incredible resources for the future. We are delighted to bring some of them to London to talk about their achievements and ambitions”.

The timing is perfect. The latest Intergovernmental Panel for Climate Change's (IPCC) report underscores the urgent need for politicians to act now to build a more sustainable future for the planet.

In Tenerife, the new President, Carlos Alonso, is committed to pursuing policies that wean Tenerife off its traditional heavy reliance on oil for its energy needs. Speakers will look at the key steps already taken in this direction – and the science and commitment needed for the future.

www.geotenerife.com For the latest conference announcements follow us on Twitter https://twitter.com/GeoTenerife

The conference is aimed at academics, ambassadors, journalists and those in business interested in sustainable development. The conference is free of charge and open to those who meet the relevant criteria.

LAUNCH - Barrett Steel launches Engineering Division into Ireland

As part of its commitment to servicing the Irish market Barrett Steel will launch its Engineering Division into Ireland on 1st May 2014. Barrett Engineering Steel Ireland will introduce a wide range of engineering steels and alloys from its warehouse and business unit in Maghaberry, Northern Ireland.

David Reece, Commercial Manager, Barrett Engineering Steel Division, explains: “Barrett recognises the vast potential in Ireland and seeks to build on its successes. We already have a substantial presence in the North and South of Ireland with a portfolio of businesses in the General Steel and Tubular Product Divisions. This brand new business will provide the power generation, petrochemical, engineering, defence, industrial plant & quarrying industries with an extensive range of products and processing facilities. As well as offering a wide range of black and bright engineering bar in both carbon and alloy grades, the division will also provide value-added services such as sawing, drilling, heat treatment, testing and grinding. Delivery is rapid from Northern Ireland with access to additional materials through the supply chain network, ensuring products are delivered safely, in perfect condition and on time.

David Reece, Commercial Manager, Barrett Engineering Steel Division, explains: “Barrett recognises the vast potential in Ireland and seeks to build on its successes. We already have a substantial presence in the North and South of Ireland with a portfolio of businesses in the General Steel and Tubular Product Divisions. This brand new business will provide the power generation, petrochemical, engineering, defence, industrial plant & quarrying industries with an extensive range of products and processing facilities. As well as offering a wide range of black and bright engineering bar in both carbon and alloy grades, the division will also provide value-added services such as sawing, drilling, heat treatment, testing and grinding. Delivery is rapid from Northern Ireland with access to additional materials through the supply chain network, ensuring products are delivered safely, in perfect condition and on time. Despite challenging times in the industry Barrett Steel reported a near 50% increase in pre-tax profits as sales increased for the financial year to September 2013.

About Barrett Steel Ltd

Established in 1866 by Henry Barrett, Barrett Steel has expanded organically and by acquisition to become the UK's largest independent steel stockholder.

The Group now comprises 42 companies operating from 28 locations across the UK and is divided into four divisions: General Steels; Engineering Steels; Tubes; and International. Recent expansion has seen a stockholding and processing facility being opened in Houston, Texas.

The numerous steel stockholding companies and divisions operating across the UK serve customers worldwide, united in a forward-thinking philosophy, commitment to technological innovation and exacting customer service standards. Each company operates with the full backing and support of the Barrett Steel Group.

Barrett Steel's head office is located in Bradford, West Yorkshire, on the site where its nineteenth century founder, Henry Barrett, set up premises in 1910.

Barrett Steel operates to ISO: 9001 2008.

Company contact:

Chris Lamb, Group Marketing Manager, Barrett Steel, e: This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel: +44 (0)1274 682281, W: www.barrettsteel.com

AGENT - Fine Tubes appoints New Agent in Kuwait as part of Middle East strategic plan

Fine Tubes, a world-leading manufacturer and distributor of precision tubes for critical applications, is delighted to announce that it has appointed Bait Al-Aseel to act as its agent in Kuwait.

The decision forms part of Fine Tubes’ strategic plan to secure further growth in the market for exotic alloy tubing across the Middle East region. Demand for this type of tubing continues to increase in line with greater operating demands matched by a desire for an extended service life that traditional alloys are unable to achieve.

Bait Al-Aseel is a long-established and highly regarded contractor servicing the power and energy industries in Kuwait. Its prestigious client list includes Kuwait National Petroleum Company (KNPC), Kuwait Oil Company (KOC) and the Kuwaiti Ministry of Electricity and Water.

Nick Head, Fine Tubes’ Business Development Manager for Oil & Gas/Chemical Processes, commented: “The appointment of Bait Al Aseel is an important one for us and represents a significant addition to the agent partnerships we already have in Saudi Arabia, the UAE, Qatar and Oman. We’re looking forward to working closely with them to develop new opportunities in this key market.”

Faisal Al Shayeji, Bait Al Aseel’s General Manager, commented: “Fine Tubes’ expertise in manufacturing specialist corrosion resistant alloys matches the rising demand for exotic alloy tubing in Kuwait. We are excited to be representing a company capable of manufacturing this extensive range of alloys and working with the Fine Tubes sales team to acquire new business in the region.”

Established 70 years ago, Fine Tubes is a leading metal tubing manufacturer with its headquarters and production facilities in Plymouth, UK and sales offices in Germany (Munich), France (Orleans), India (New Delhi) and the US (Houston) as well as several agents across the globe.

The company manufactures both seamless and welded tubes, in a wide range of stainless steel, nickel, titanium and zirconium alloys, for critical applications in the oil and gas, nuclear and power, aerospace, chemicals and medical equipment industries.

Fine Tubes currently employs around 380 permanent staff and exports its products to over 35 countries worldwide, including Russia, India, China and the US.

Recent projects for which Fines Tubes has supplied specialist tubing include the Airbus A380 and A350 series, the Sukhoi Superjet 100, Skylon, the world’s first reusable space plane, the Gemasolar power station, and CERN’s Large Hadron Collider.

BOILER PLANT - Valmet to supply a large-scale boiler plant to Turun Seudun Energiantuotanto Oy in Finland

Turun Seudun Energiantuotanto Oy (TSE) has chosen Valmet as the boiler supplier for their upcoming power plant in Naantali, Finland. The new power plant is scheduled to start up in the autumn of 2017.

Turun Seudun Energiantuotanto Oy (TSE) has chosen Valmet as the boiler supplier for their upcoming power plant in Naantali, Finland. The new power plant is scheduled to start up in the autumn of 2017.

Valmet's delivery will include a fluidized circulating bed (CFB) boiler and flue gas cleaning equipment. The steam capacity of the boiler plant will be 390 MW. The total estimated cost of TSE's power plant investment is EUR 260 million. The share of the boiler in this kind of projects is typically one third of the total investment. The order is included in Valmet's second quarter 2014 orders received.

Investment enables use of renewable fuels

The investment will replace an old coal power plant that has been operating for 50 years in Naantali and provides an opportunity to increase renewable fuels in power generation. The new power plant will also enable to fulfil the new IEA emissions directive, which will come into effect in the European Union at the beginning of 2016.

"The power plant investment enables energy efficient, combined electricity and heat production by using renewable fuels. Our target is to maximize the use of domestic fuels in our power generation. While being more independent in fuel supply, we will also be able to affect local employment in a positive way," says Managing Director Tapani Bastman of Turun Seudun Energiantuotanto Oy.

"This order will play an important role as a reference of boiler technology supplied by Valmet. The delivery will include a large-scale multi-fuel plant, which is designed to generate power by also using bio fuels at an extremely high efficiency ratio," says Jyrki Holmala, President of the Pulp and Energy Business Line at Valmet.

Remarkable source of bio fuel in the vicinity of the power plant

The power plant will be able to use wood, straw, peat, coal, and Solid Recovered Fuel (RSF) produced from waste as fuels. According to plans, wood chips collected within a 100-150 kilometer distance from the power plant will form the main bio fuel. The plant will use approximately 0.7 million solid cubic meters of wood chips annually. Later on the amount of wood chips may be as high as 1.2 million solid cubic meters annually.

Construction of the new power plant is scheduled to start toward the end of 2014. Once finalized, the annual production at the power plant will be 900 gigawatt hours (GWh) of electricity and 1,650 gigawatt hours (GWh) of heat. The electrical power of the plant will be 142 MW, and thermal power 244 MW.

Information about Turun Seudun Energiatuotanto Oy

Turun Seudun Energiatuotanto Oy produces district heat and electricity to the cities of Turku and Naantali, and the surrounding area. The company also produces process steam for the needs of nearby companies. Turun Seudun Energiatuotanto Oy is owned by Turku Energy, Turku's neighboring cities Raisio, Kaarina, and Naantali, and Fortum Power and Heat.

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 11,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

The company has over 200 years of industrial history and was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. Valmet's net sales in 2013 were approximately EUR 2.6 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Further information, please contact:

Jyrki Holmala, President, Pulp and Energy Business Line, Valmet, tel. +358 10 676 3210

Jari Niemelä, Sales Director, EMEA, Pulp and Energy Business Line, Valmet, tel. +358 50 317 8050

VALVES - Metso’s industry-leading Neles globe valve technology selected for Abu Dhabi Oil Refinery’s (TAKREER) plant

Metso will supply industry-leading Neles® globe valve technology to Abu Dhabi Oil Refinery Company's (TAKREER) chemical refining complex in in the United Arab Emirates. The deliveries will include hundreds of Metso's Neles Globe control and on-off valves. Most of the control valves are equipped with Neles ND9000 intelligent valve controllers (FOUNDATION Fieldbus) for performance follow up and predictive maintenance, resulting improved process efficiency and uptime.

Metso will supply industry-leading Neles® globe valve technology to Abu Dhabi Oil Refinery Company's (TAKREER) chemical refining complex in in the United Arab Emirates. The deliveries will include hundreds of Metso's Neles Globe control and on-off valves. Most of the control valves are equipped with Neles ND9000 intelligent valve controllers (FOUNDATION Fieldbus) for performance follow up and predictive maintenance, resulting improved process efficiency and uptime.

The valves will be installed in a carbon black and delayed coker plant currently under construction. Once completed in December 2015, the plant will process 30,000 barrels of crude oil per day and have an annual production capacity of 40,000 tons of carbon black. The refining complex is located in Ruwais some 240 kilometers west of Abu Dhabi City in the United Arab Emirates.

South Korean Samsung Engineering, which will provide project management services for the engineering, procurement, construction and commissioning processes on a turnkey basis, has chosen Metso's valve technology for the demanding project. "It is the largest project ever executed by our company, and the total valve quantities are huge," says Mr. YunKi Sung, Vice President, Procurement Dept., Samsung Engineering. "We chose Metso as our valve partner because we can rely on fast expediting; their valve factory is conveniently located close us to us in South Korea.''

''Also, we have had good support from Metso in our past projects. To ensure smooth startups, Metso offers its wide product knowledge and application expertise, global manufacturing facilities and sourcing, full expediting and inspection support, a global service network and comprehensive startup support.''

Metso has valve technology centers and production facilities in Finland, the United States, Germany, China, South Korea, India and Brazil. Metso's deliveries will take place in August 2014.

Most comprehensive control valve range on the market

Today, Metso's control valve range is the most comprehensive one on the market. It includes globe valves, top entry rotary valves, triple eccentric disc valves, eccentric rotary plug valves, and segment valves. There is a suitable product for every application, ranging from general to severe service and from low temperature or pressure to high temperature or pressure.

Metso's control valve solutions are known for providing optimized performance and extreme reliability in demanding refining processes. "Cutting-edge valve solutions provide measurable operational efficiency and increased profitability. They increase yield, reduce energy consumption, lower maintenance costs and manage changes in the process, among others," points out Daisy Kim, Product Manager, Automation, Metso.

Reliable and safe process operation gained with Metso's technology is visible through fewer production interruptions and less downtime, longer uptime between maintenance shutdowns, as well as compliance with environmental regulations and safety legislation.

"During the engineering, procurement and construction stages of a project, cooperation with Metso means fewer engineering and planning hours, expert engineering and application support, as well as easier product sizing and selection with hi-tech tools and services," Ms Kim continues. "We also provide customers with our total project planning and management capabilities, along with application-specific valve technologies."

Experienced in valves with strong production foothold

Metso has a long track record of delivering engineered performance and reliability to the oil & gas industry through its leading product brands - Neles®, Jamesbury® and Mapag® - and has delivered millions of valves, control valves, and on-off valves globally more than 90 years, and has become one of the leading suppliers of intelligent valve controllers. Metso's valve technology and services offering helps maximize production efficiency and reduce safety risks throughout the life cycle of a plant, all the way from simplifying valve selection to improving process availability and maximizing production performance.

About the Abu Dhabi Oil Refining Company (TAKREER)

The Abu Dhabi Oil Refining Company (TAKREER) was established in 1999 as a public joint-stock company to take over the responsibility of refining operations previously undertaken by the Abu Dhabi National Oil Company (ADNOC). The company's areas of operation include the refining of crude oil and condensate, supply of petroleum products and production of granulated sulfur in compliance with domestic and international specifications.

Metso's automation solutions are designed to maximize the profitability of our customers' businesses by improving their production performance and their cost, material and energy efficiency. Our extensive range of flow control and process automation solutions and services is supported by a worldwide network of automation experts. The Automation business' biggest customer industries are oil & gas, and pulp and paper. We also have a strong growth focus in mining and construction and power generation.

www.metso.com, www.twitter.com/metsoautomation

Metso is a leading process performance provider, with customers in the mining, construction, and oil & gas industries. Our focus is on the continuous development of intelligent solutions that improve sustainability and profitability. Metso's shares are listed on the NASDAQ OMX Helsinki Ltd. Metso employs around 16,000 professionals in 50 countries. Expect results.

For further information, please contact: This email address is being protected from spambots. You need JavaScript enabled to view it.

APPOINTMENT - FireVu continues to build up business development team

Fire detection solution provider FireVu is further strengthening its business development team with the appointment of Ali Aleali in April.

Fire detection solution provider FireVu is further strengthening its business development team with the appointment of Ali Aleali in April.

Aleali moves from parent company AD Group where he was a training and communications specialist. In his new position as business development manager Aleali will concentrate on the petrochemical, chemicals, food and drink processing industries.

FireVu offers Video Smoke Detection (VSD) technology solutions, which gives early fire detection for high value assets.

Pauline Norstrom, Chief Operating Officer of AD Group, comments: Ali possesses extensive business development experience in the chemicals, food and drinks industries as well as strong academic credentials, including lecturing up to degree level, in industrial chemicals and food production applications. VDS is a proven technology with great potential and Ali's appointment will further help FireVu realise ambitious goals for 2014 and beyond.

Contact details

Rob Baker

rThis email address is being protected from spambots. You need JavaScript enabled to view it.

+44 (0) 192 870 6450

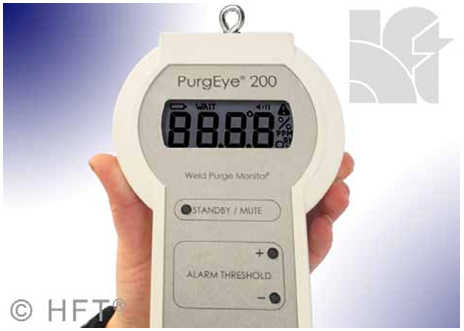

WELDING - PurgEye® 200 Weld Purge Monitor®

Weld Purge Monitors® are an essential tool for the Process Industries with various models serving different levels of weld purge requirement.

There are applications that can be satisfied with Monitors measuring down to 100 ppm and..... for the higher specification industries such as Aerospace, Food and Drinks, Semi-conductor, Biofuels etc that need to achieve oxgyen levels down to 10 ppm there are other models.

One such model has just been developed for the Process Industries and that is the PurgEye® 200 which is now rolling off the production lines partially to meet an order for 30 units from the Far East.

This is a hand held, battery driven monitor that will read very accurately down to 10 ppm.

It is probably the lowest cost Weld Purge Monitor® of its kind even though it contains an internal electro-mechanical pump for drawing samples of gas automatically over the sensor before discharging it to atmosphere.

The lifetime sensor eliminates the need for changing cells once every year or so, subject to the type

of usage the “wet” cells receive.

Alarm signals can be given by the PurgEye® 200 to show when the purge gas level is within or outside the preset range.

The PurgEye® ‘Family Range’ of Weld Purge Monitors® comprises:

- Low cost PurgEye® 100 hand held unit for measuring down to 100 parts per million

- PurgEye® 300 that accurately measures free flowing gas down to 10 ppm and less,

- PurgEye® 500 that uses an internal electro-mechanical pump to draw the gas across the sensor

- PurgEye® 600 which is a computer controlled model measuring from atmospheric oxygen levels down to 10 ppm accurately and...

- PurgEye® 1000 which has a remote sensor for accurately measuring oxygen level down to 10 ppm

- as well as the PurgEye® 200 that is described above

Further information about the exciting new Weld Purge Monitor®can be obtained from our website www.huntingdonfusion.comor writing to This email address is being protected from spambots. You need JavaScript enabled to view it.

EJECTOR - Mixing success with Landia’s aerator in Tennessee

A rugged and highly effective ejector system designed and manufactured by Landia is effectively mixing and aerating a special holding tank that receives wastewater from the Morgan County Correctional Complex (MCCX) in Tennessee.

Landia’s chopper pumps, equipped with a Venturi nozzle,which form part of the propeller-freeAirJet aeration system, have to deal with debris from a population equivalent of around 3,200, comprising around 2500 inmates and over 700 employees at the complex, which completed a major expansion in 2009.

Landia’s chopper pumps, equipped with a Venturi nozzle,which form part of the propeller-freeAirJet aeration system, have to deal with debris from a population equivalent of around 3,200, comprising around 2500 inmates and over 700 employees at the complex, which completed a major expansion in 2009.

Danny Phillips, Maintenance and Pre-Treatment Coordinator for the City of Wartburg’s Municipal Wastewater said: “Landia’s AirJet and chopper pumps are good dependable equipment, which we have no problems with. And importantly, from day one, we’ve also had great customer service from Landia who are always ready to help us achieve the best results. This definitely isn’t a company that just walks away after they’ve made a sale”.

Any trash that manages to bypass the screens at MCCX is swiftly dealt with in the holding tank by Landia’s innovative knife system, which prevents any solids from entering the chopper pump, whilst a specially designed pump volute and impeller protects the mechanical seal from rags.

Landia also has its chopper pumps installed at numerous similar establishments in the U S, including the Crittenden County Detention Center in Western Kentucky, where they have to handle a variety of solids in the wastewater, including latex gloves, grease and cutlery.