Ian Melin-Jones

PULSE POWER - SELFRAG set to create shockwaves in mining

Swiss high tech firm, SELFRAG AG has developed a unique technology, centred on high voltage pulse power that is aimed at revolutionizing the comminution process within the mining industry. SELFRAG has already sold a number of batch units to institutes around the world, including the globally-renowned Julius Kruttschnitt Mineral Research Centre (JKMRC) in Australia, and is now in the process of developing an industrialized continuous system for mining applications.

SELFRAG’s high voltage fragmentation is a revolutionary comminution technique that uses electrical discharges to weaken and/or fragment rocks. Specialized high voltage generators are used to create very powerful underwater high voltage discharges, resulting in the formation of shockwaves that cause widespread fracturing inside the affected particle. Fracture patterns generated by high voltage breakage resemble those resulting from normal blasting, indicating that high voltage fragmentation can be thought of as a smaller-scale analogue of normal blasting using explosives.

The benefits of being selective

The SELFRAG method has two major advantages over conventional comminution. Firstly, the interaction between minerals and the induced electrical and mechanical stress fields inside a rock matrix is highly selective. This makes SELFRAG’s high voltage fragmentation exceptional at liberating minerals – ores treated using between 1 and 10 kWh/t are generally liberated both coarser and more selectively. This has been shown to improve concentrate quality for nickel and copper ores. Alternatively, this improved liberation may be used to increase the grind size of an ore, which could represent a considerable energy saving. SELFRAG’s Lab system, sold to geology and mining institutes, has proven successful in liberating zircons and other minerals for dating of rocks.

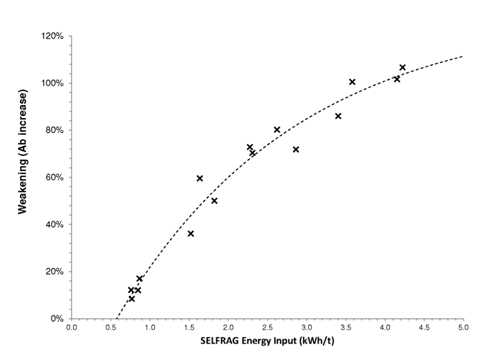

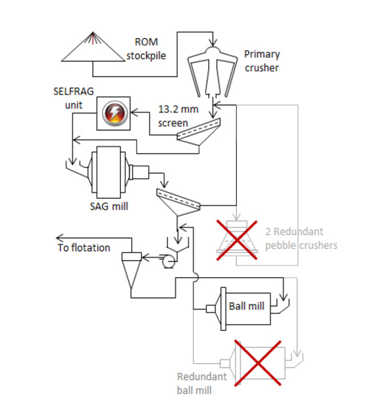

The second advantage is the ability to weaken rocks using small energy inputs; energy inputs of 1 to 4 kWh/t, have typically given weakening values of up to 160% (based on an increase in A*b values (see Figure 1) and Bond work reductions in the range of approximately 5% to 20%. JKSimMet simulations have demonstrated that these strength reductions can result in significant overall energy savings. In the case of a SABC circuit with two ball mills, power draw of the SAG mill was kept constant to produce a finer product from the weakened feed; this change in the circuit power balance was sufficient to allow shutdown of one of two ball mills, resulting in significant power savings as well as considerable reductions in other costs such as grinding media and liners (see Figure 2).

“At SELFRAG we currently have a pilot plant capable of processing up to three tonnes per hour,” explains CEO, Frédéric von der Weid. “We have been using this plant for internal development, as well as processing of bulk samples for mining and exploration companies. In the last six months, third party projects have included platinum, copper/gold and silver applications. We have also already completed engineering work on a modular 10 tph pilot unit; this modular design represents a scalable concept allowing for throughputs of 100 tph or more to be reached.” SELFRAG also offers services in high voltage characterisation of ores to the mining industry.

In addition to mining applications, SELFRAG is also actively developing exploration solutions for the diamond market, machines for the recycling of a wide variety of feed stocks, and units suitable for ultra-high purity fragmentation applications such as silicon rod crushing.

SELFRAG’s batch Lab unit is already installed in over 20 institutes around the globe, including in Australia, Japan, China, North America, and Brazil.

SELFRAG AG specialises in the development, engineering and marketing of high voltage pulse power products, plants and systems for the selective fragmentation of solids in the mining, recycling and solar industries. Founded in 2007, the company is headquartered in Kerzers in the canton of Fribourg, Switzerland and currently employs 30 staff. Privately held, investors include Affentranger Associates, Ammann Group, Credit Suisse and the Swiss Helvetia Fund.

Giselle Stefanelli

SELFRAG

Biberenzelgli 18

CH-3210 Kerzers

Switzerland

Tel: + 41 31 750 32 08

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

WATER - Aqua Pennsylvania Announces It Will Spend $230 Million on Infrastructure Improvements Statewide in 2014

Funds have been earmarked to replace aging water main across service area

Aqua Pennsylvania (Aqua) has announced the company will make $230 million in infrastructure improvements in the state throughout 2014, after completing $216 million of similar projects in 2013. Capital investments planned for the year include:

Aqua Pennsylvania (Aqua) has announced the company will make $230 million in infrastructure improvements in the state throughout 2014, after completing $216 million of similar projects in 2013. Capital investments planned for the year include:

“Much of the water infrastructure in Pennsylvania is aging and reaching the end of its useful life”

- $124 million throughout its Southeastern Pennsylvania operating division, which comprises parts of Bucks, Chester, Delaware and Montgomery counties

- $1 million throughout its Susquehanna operating division, which comprises parts of Athens Township and Athens, South Waverly and Sayre boroughs

- $10 million throughout its White Haven operating division, which comprises parts of Wyoming, Lackawanna, Luzerne, Lehigh, Monroe, Northampton, Schuylkill, Susquehanna and Carbon counties

- $8 million throughout its Honesdale operating division, which comprises parts of Lackawanna, Monroe, Pike and Wayne counties

- $16 million throughout its Roaring Creek operating division, which comprises parts of Adams, Columbia, Cumberland, Juniata, Northumberland, Schuylkill and Snyder counties

- $13 million throughout its Shenango operating division, which comprises parts of Lawrence, Mercer, Forest, Crawford, Venango, Clarion, Warren and Clearfield counties.

“Much of the water infrastructure in Pennsylvania is aging and reaching the end of its useful life,” said Aqua Pennsylvania President Steve Tagert. “Aqua is committed to making ongoing, prudent investments to update and improve our infrastructure so that we can continue to provide our customers with quality water and wastewater services. We have seen first-hand how this investment is helping to increase service reliability. For example, in our Southeastern Pennsylvania division, we experienced 27 percent fewer main breaks during the winter of 2013 – 2014 when compared to the equally brutal winter conditions of 2008 – 2009. This decrease can be credited to the more than $950 million in infrastructure investments that Aqua made in the area between 2009 and 2013. We are confident the improvements that are slated for this year will be equally as beneficial.”

Aqua Pennsylvania serves approximately 1.4 million people in 31 counties throughout the Commonwealth of Pennsylvania. Visit AquaAmerica.com for more information, or follow Aqua on Facebook at facebook.com/MyAquaAmerica and on Twitter at @MyAquaAmerica.

Aqua Pennsylvania

Donna Alston

Manager, Communications

610-645-1095

484-368-4720

This email address is being protected from spambots. You need JavaScript enabled to view it.

PRICE INCREASE - Praxair Announces Price Increases for Argon Effective May 15, 2014

Praxair, Inc. is notifying bulk and packaged industrial, and specialty customers in the United States and Puerto Rico of price increases, effective May 15, 2014, or as contracts permit, as follows:

Praxair, Inc. is notifying bulk and packaged industrial, and specialty customers in the United States and Puerto Rico of price increases, effective May 15, 2014, or as contracts permit, as follows:

- Up to 20% for argon

- Up to 15% for argon facility fees or monthly bulk product charges

Price adjustments will vary as permitted by individual supply contracts.

Over the past few years, argon demand has exceeded capacity requiring investments in production capacity upgrades and additional distribution resources. The combination of these and other investments to enhance reliability of supply have increased argon costs significantly.

About Praxair

Praxair, Inc., a Fortune 250 company with 2013 sales of $12 billion, is the largest industrial gases company in North and South America and one of the largest worldwide. The company produces, sells and distributes atmospheric, process and specialty gases, and high-performance surface coatings. Praxair products, services and technologies are making our planet more productive by bringing efficiency and environmental benefits to a wide variety of industries, including aerospace, chemicals, food and beverage, electronics, energy, healthcare, manufacturing, metals and many others. More information about Praxair, Inc. is available at www.praxair.com.

Contact:

Investors:

Kelcey Hoyt, 203-837-2118

This email address is being protected from spambots. You need JavaScript enabled to view it.

PACKAGING - Avery Dennison’s CleanFlake™ Wins Another Key Industry Award: FTA’s Environmental Excellence

The Flexographic Technical Association presented its Environmental Excellence Award for Innovations in Sustainability to Avery Dennison Materials Group at FTA’s annual forum on April 27. Avery Dennison was recognized for the CleanFlake™ portfolio, a collection of label materials developed to advance the recycling of PET containers.

“We understand that industry-transforming innovations begin with a view of the entire value chain — from responsible sourcing to end-of-life analysis”

“We understand that industry-transforming innovations begin with a view of the entire value chain — from responsible sourcing to end-of-life analysis,” said Darrell Hughes, vice president and general manager of Avery Dennison Materials Group North America. “We worked closely with stakeholders including raw material suppliers and reclaimers to solve a very real challenge: improving the recyclability of PET containers. We are proud to be offering the industry a solution that will allow more high-quality recycled PET to enter the supply stream.”

“We understand that industry-transforming innovations begin with a view of the entire value chain — from responsible sourcing to end-of-life analysis,” said Darrell Hughes, vice president and general manager of Avery Dennison Materials Group North America. “We worked closely with stakeholders including raw material suppliers and reclaimers to solve a very real challenge: improving the recyclability of PET containers. We are proud to be offering the industry a solution that will allow more high-quality recycled PET to enter the supply stream.”

Direct printing, paper labels and standard pressure-sensitive labels applied to PET bottles tend to lower the recycling efficiency and the quality of recycled PET. In 2010, 1.5 billion pounds of PET were collected for recycling in the United States, yet reclaimers reported yield losses ranging from 24.4 percent to 32.2 percent due to contamination by labels, adhesives and other components — amounting to a loss of over 40 million pounds of bottles.

CleanFlake is a patent-pending adhesive technology that “switches off” when submerged in a caustic bath so the label cleanly separates from the PET flakes. Although these labels adhere firmly to PET bottles or containers during use, they detach readily in a conventional recycling facility and rise to the surface in the float/sink separation phase, allowing clean PET flakes to sink for easier reclamation.

FTA’s Sustainability Excellence Awards recognize companies for pioneering efforts in developing innovative processes, products and management approaches that have had a positive impact on the environment. Winners were selected by the FTA Sustainability Committee.

This is the eighth industry award Avery Dennison has received for the CleanFlake Portfolio. The company received the Sustainability Award at Labelexpo 2013 in Brussels and the Global Green Award during Labelexpo 2012 in Chicago. In addition, it received the Society of Plastic Engineers Environmental Award in the Design for Sustainability category in 2013 and the Koreastar, Asiastar and Worldstar packaging awards between 2012 and 2013. Most recently, it received the Environmental Leader 2014 Product of the Year Award.

About Avery Dennison

Avery Dennison (NYSE:AVY) is a global leader in labeling and packaging materials and solutions. The company’s applications and technologies are an integral part of products used in every major market and industry. With operations in more than 50 countries and 26,000 employees worldwide, Avery Dennison serves customers with insights and innovations that help make brands more inspiring and the world more intelligent. Headquartered in Glendale, California, the company reported sales from continuing operations of $6.1 billion in 2013. Learn more at www.averydennison.com.

CHEMICALS - Clariant closes sale of Leather Services business

Clariant, a world leader in specialty chemicals, has announced the closing of the sale of its Leather Services business to Stahl Holdings B.V. as of April 30, 2014.

Clariant, a world leader in specialty chemicals, has announced the closing of the sale of its Leather Services business to Stahl Holdings B.V. as of April 30, 2014.

Stahl, majority owned by Wendel Group, is a Dutch company providing high-quality chemicals, dyes and coatings for leather and other applications. The combination of both businesses has created a global leader in leather chemicals with a higher growth profile than the standalone entities and with significant synergy potential.

As announced on October 30, 2013, Clariant has received a cash consideration and a 23% stake in Stahl for the sale of its Leather Services business. The minority shareholding will allow Clariant to participate in the upside potential of the enlarged Stahl. Wendel remains the principal shareholder of Stahl with approximately 70% of Stahl's capital.

The closing of the Leather Services transaction marks the last major step in the repositioning of Clariant's portfolio. The company has already divested the Business Units Textile Chemicals, Paper Specialties and the Business Line Emulsions on September 30, 2013, as well as the Detergents & Intermediates business on January 6, 2014.

Clariant is a globally leading specialty chemicals company, based in Muttenz near Basel/Switzerland. On December 31, 2013 the company employed a total workforce of 18,099. In the financial year 2013, Clariant recorded sales of CHF 6.076 billion for its continuing businesses. The company reports in four business areas: Care Chemicals, Catalysis & Energy, Natural Resources, and Plastics & Coatings. Clariant's corporate strategy is based on four pillars: managing businesses for profitability, research & development and innovation, growth in emerging markets, and repositioning of the portfolio.

Ulrich Steiner

Phone +41 61 469 67 45

This email address is being protected from spambots. You need JavaScript enabled to view it.

EVENT - CWIEME returns to Berlin for the 18th year running

CWIEME Berlin, the world’s largest and most comprehensive event in the coil winding, insulation and electrical manufacturing industry, returns this summer with a greater and more engaging offer to visitors.

On the 24-25th June over 7,000 engineers, designers, buyers and academics from around the world will descend on the Messe Berlin in Germany for CWIEME Berlin 2014 – the largest annual meeting place for the global coil winding, insulation and electrical manufacturing community. The three-day event, held in Germany’s buzzing capital, will feature some 750 suppliers from over 40 countries – including top names ABB, Alstom, Eurotranciatura, Hidria, Voestalpine and Von Roll – displaying the latest coils, electric motors, electromagnetic insulation materials, transformers and repairs solutions.

Now in its 18th year, CWIEME Berlin 2014 is set to be bigger and better than ever before, not least because of the wide range of products on show.

“CWIEME Berlin is not just an opportunity to source new products and suppliers, but to network, keep an eye on the competition – and learn about all the latest trends and technical advances,” says Chloe Theobald, content manager for CWIEME Berlin. “We have a fantastic seminar programme lined up for our guests this year, covering a wide range of topics across the three days.”

Learn something new

Learn something new

At CWIEME Central, the main seminar hub, visitors will benefit from technical presentations and panel discussions on topics such as:

- revenues, regulation and market opportunities for the LV and MV motor industries.

- wireless power transfer and inductive charging design for increased e-mobility.

- advances in OIP bushings for improved safety in HVDC equipment.

- REACH and the ‘Greening’ of technology debate.

- climatic resilience and risk mitigation for off-shore wind transformers.

- breakthroughs in nanoscience discoveries of new magnetic materials.

Speakers will include top industry experts:

- Professor Ivan Schuller, Director of the Center for Advanced Nanoscience (CAN) at the University of California-San Diego

- Paulo Cardano, Senior Expert OIP Bushings, Alstom Grid

- Professor Martin Doppelbauer from the Karlsruhe Institute of Technology

- Dr. Rolf Winter, Managing Director (Electrical Winding & Insulation Systems Division) at ZVEI

- Dr Faical Turki, Head of R & D, Paul Vahle GmBH

Meanwhile, CWIEME Berlin’s Machinery Trail will provide regular live product presentations and machinery demonstrations across a wide variety of exhibitor stands, allowing visitors to see the latest technology in action.

Network at the highest level

A select number of guests will also be invited to attend the exclusive CWIEME Leadership Forum, held the evening before the show. Envisaged for C-level executives from global OEMs, the CWIEME Leadership Forum will focus on the challenges and opportunities for OEMs post-recession – from responding to demand in existing and emerging markets, to considerations surrounding the proximity and profitability of geographic locations for production, skills and innovation.

Industry leaders from across the electrical manufacturing world will have the opportunity to be part of a high level discussion focusing on the shape-shifting supply chain models and evolving manufacturing ‘eco-systems’ of the present and near future. Meanwhile, keynote speaker Martin McCourt, former CEO of Dyson, currently Chairman of CAP, CliniSys Group and D.O.R.C Dutch Ophthalmic Research, will share his first-hand experience, expertise and future vision of global manufacturing.

“The CWIEME Leadership Forum is an invaluable occasion for senior directors and company decision-makers to have their say on some of the most important issues affecting global OEMs today, to benchmark against their peers and gather ideas and best practice examples – all while making top industry connections,” says Haf Cennydd, portfolio director at i2i Events Group.

Visit www.coilwindingexpo.com/berlin to register for your free visitor’s entry pass today.

CWIEME Berlin

Dates: 24th-26th June 2014

Venue: Messe Berlin, Messedamm 22, 14055 Berlin, Germany

Opening times: Tuesday and Wednesday 09:00-18:00, Thursday 09:00-16:00

Admission: An on-site registration fee of €40 will apply for those who have not already registered online.

For further information, please visit: http://www.coilwindingexpo.com/berlin

Or contact:

Jemma James

i2i Events Group

Tel: +44 (0) 203 033 2179

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Hannah Kitchener

SE10

Tel: +44 (0)207 923 5863

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

CWIEME Berlin is part of i2i Events Group. i2i Events Group enables more than 200,000 buyers and producers to meet and trade at some of the greatest exhibitions, large scale events and festivals in the world.

WATER - The right choice of biofilm carrier media used in MBBR-Technology

You will proverbially face the agony of choice upon looking for the best suitable biofilm carrier media for the MBBR-Technology in your biological wastewater treatment plant. However; when making up your purchase decision, you should not be misled into buying low-cost products for your individual case of application. The carrier-based biofilm technology for the biological wastewater treatment is known since the 19th century and particularly for this application, a wide range of different types, shapes and materials has been developed during the last decades, contemporaneously to the development of plastics engineering.

The disadvantages of the so called carrier media are not often recognized and are rarely made available to third parties by means of publications. Here, the same principle as in every market applies: each vendor or manufacturer claims to provide the “best” product. At a first glance, this topic seems to be familiar and after all, each purchaser of biofilm carrier material does not necessarily have to be an expert in this field. The purchase of a new vehicle is surely more familiar.

In the case that you should face such an important decision, please make sure to pay attention to the points described below.

First of all, it is important to specify and to determine the required biodegradation rates as an objective for the removal rates of the biodegradable substances in order to perform the design calculations, i.e. the calculation of the required amount of carrier material. By doing so, you should consider operation-related fluctuations in the pollutant concentrations of the wastewater – as long as they should not be equalized in the system upstream of the MBBR stage. Hence, every wastewater treatment solution expert should or has to, respectively, ask his customer about the influent and effluent conditions, possible toxic contaminants, application-related basics and the design temperature in order to be in the position to advise and to supply appropriately. Not only the influent and effluent parameters but also the minimum temperature and the biological/biochemical metabolism conditions are a part of the calculations. A slight deviation from the basic parameters gives ample scope to the supplier of which he will mostly take advantage of.

Hence, the first basic rule is to create an appropriate basis for each supplier which the suppliers have to strictly adhere to. This should be explicitly shown and confirmed in their related quotations.

With regard to the basic design, it is crucial to know the biodegradation rates which the supplier calculates with and which he is able to give a proof of in terms of his individual biofilm carrier. The frequently indicated active carrier surface area is indeed an indicator for the potential biodegradation performance of the carrier media, but crucial is the specification of the biodegradation performance in kg [pollutant] per m³ [carrier media] per day. The latter can refer to the COD/BOD or nitrogen load to be removed. As a result, there can be made statements regarding the required quantity of carrier media which is defined in a verifiable indication of the carrier media weight related to the volume as well as in the price related to the biodegradation efficiency per day.

Compared to the familiar purchase of a vehicle, not the engine displacement but the guaranteed speed in km/h or the maximally possible towing capacity in kg is of significance.

After having bindingly specified the aforementioned information, one should give thought to the type of the material of the carrier media and the material density. The plastic carriers offered in the market are usually made of (polyethylene [PE]) virgin material or of more affordable re-granulates (recycled material). In order to simplify the subject, let us confine to the re-granulates. The origin and the composition of the said material cannot always be exactly specified and the re-granulates may hence consist at significant percentage of different plastics which may have a negative impact on the durability (solidity, break resistance). The material density under operating conditions is of major importance. Due to the various types of the recycled plastic materials and their previous applications, re-granulates can show up a significant deviation and fluctuation in the material density. These deviations can only be rarely and consistently adjusted to new density states during the production process. A consequence of this can be a deficiency in the desired carrier movement characteristics.

A repeatedly discussed topic in the specialist press is the usage of plasticizers which can be contained in re-granulates. These plasticizers can also be applied by the manufacturer in order to adjust the material characteristics to the necessary requirements. As a future operator of a MBBR system, one should evaluate – depending on the application e.g. aquaculture, koi farming, etc. – if he would like to use carrier media possessing such negative characteristics. Undefined plastics mostly of unknown origin, such as plastic re-granulate for example, can release bisphenol A and phthalates which may cause cancer and have hormonal effects. Moreover, low-molecular phthalates (phthalate esters) turned out to be problematic since their toxicity is potentiating in conjunction with other substances, as scientifically proven. Furthermore, phthalates are suspected of causing diabetes.

The Mutag BioChip™ biofilm carrier is completely free from any phthalates or other plasticizers and does not contain bisphenol A or any other aromatic compounds. It is made of virgin polyethylene (no recycled PE), inorganic fillers, small amounts of monoester of glyceric acid (made from coconut fat; absolutely harmless), citric acid and soda (Na2CO3).

After having made up the decision on whether to use a product made of virgin material or of re-granulates, another important decision has to be made.

What is more of advantage in terms of the application: a dimensionally stable molded (PE or PP) extruded carrier, or a mechanically stressable (i.e. flexible) material? Dimensionally stable carriers often possess the disadvantage of breaking even at small mechanical stress. Furthermore, they get increasingly abraded which is due to their stiffness being stressed by kinetic energy within the MBBR (no crumple zone as available in a vehicle). Fractions at the bridges of the carriers are hence not unusual (please refer to the picture below).

A flexible and simultaneously highly wear-resistant material is more likely to be used. Sponge-type carriers are flexible indeed but they show signs of abrasion already after a short operating period. Contrary to this, highly fine-porous chip-type carriers (Mutag BioChip™) are offering all of the desired characteristics such as a high wear resistance, flexibility, virgin material and many more.

Depending on the sewage quality and the metabolic load, the carrier material may tend to excessive attachment of biomass. Tube-shaped carriers possess the negative characteristic of biomass accumulating within the inner area of the carrier. This biomass cannot be discharged and dies due to a lack of substrate supply and in aerobic applications due to a lack of oxygen supply. The dead biomass is hence blocking the active carrier surface area required for attaching biologically active biomass and reduces the biodegradation efficiency. Thin, fine-porous disk carriers (Chips) with an average thickness of approx. 1.0 mm (coin) have the advantage that the oxygen and the substrate can diffuse from both sides into the carrier to a depth of 0.5 mm. Consequently, the biofilm can be held active and will not die due to clogging.

The pictures above show several carriers which have been applied together with the disk-shaped carrier (Mutag BioChip™) in the same wastewater. Neither a clogging nor an abrasion of the chips can be observed.

Moreover, the transportation costs for the total carrier quantity as well as the filling periods are as important as a proper commissioning instruction and the support in the choice of the carrier media retention system and the aeration system.

After having reflected on the basics regarding the performance, shape, stability, wear resistance, plasticizers and their possible impacts as well as on the clogging aspect, there is one relevant factor remaining to be mentioned.

The provider or supplier of your choice, respectively, should be able to provide procedural support in the design basics as well as own plant-related references, enabling the plant operator to benefit from a wide range of substantive operational data. After the purchase, the buyer of the carrier media should be provided by the supplier with support in operational and biological matters, based on practice-oriented expert experience since in practical wastewater treatment, there are applications again and again in which technical support can be of major assistance. As with the purchase of a vehicle, not the vendor matters but the after-sales service does.

Do not let your choice get unbearable.

Bernd Jürgen Rauch

Multi Umwelttechnologie AG

For more information contact:

Tel: +49 (0) 3771 / 59 86 87 56

Fax: +49 (0) 3771 / 59 86 87 51

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

CHEMICALS - IChemE records strong performance in 2013

The Institution of Chemical Engineers (IChemE) has recorded another successful year in 2013 which saw spending on charitable activities increase to nearly £7 million (US$11.8 million).

The Institution of Chemical Engineers (IChemE) has recorded another successful year in 2013 which saw spending on charitable activities increase to nearly £7 million (US$11.8 million).

During the year, IChemE’s global membership grew by four per cent to nearly 38,000 including a record number of students starting chemical engineering courses at IChemE’s accredited universities around the world.

The highest standards of professionalism in the chemical and process industries were achieved by 460 members, who became Chartered Chemical Engineers for the first time – an increase of 15 per cent compared to 2012.

IChemE’s mission to advance chemical engineering worldwide was also supported with the appointment of 150 new Fellows.

Nearly a third of IChemE’s members (12,000) were actively involved in developing the profession in over 20 specialist fields including oil and natural gas; safety loss and prevention; food and drink; and alternative and renewable energy.

Skills and knowledge were enhanced as over 6,000 delegates took part in more than 50 online webinars, 30 conferences and events, and over 50 training courses hosted around the world.

IChemE’s chief executive, David Brown, said: “Our total income passed £7 million for the first time – up six per cent year-on-year – and robust management delivered an operating surplus which will be re-invested into the future of the profession.

“However, our excellent financial performance and success in all aspects of our business cannot be achieved without the army of volunteers that supports our work. Members of Council, national boards, special interest groups, regional member groups, whynotchemeng volunteers, conference committees, membership interviewers, report assessors, accreditation panellists, staff and more are all behind our success. We thank you all once again.”

Judith Hackitt CBE, IChemE’s president, said: “My year has flown by and it has been a pleasure and honour to serve as IChemE president. I have certainly appreciated the tremendous support from members of Council, IChemE and the broader membership, and proud that our collective efforts have contributed to another excellent performance in 2013.

“At the start of my presidency, I announced that IChemE’s technical policy, Chemical Engineering Matters, would be my focus. As my presidency comes to a close I believe we now have firm foundations to continue to engage and explain to the wider world the importance and contribution that our profession has to the success and sustainability of our planet.”

About chemical engineers

Chemical, biochemical and process engineering is the application of science, maths and economics to the process of turning raw materials into everyday products. Professional chemical engineers design, construct and manage process operations all over the world. Pharmaceuticals, food and drink, synthetic fibres and clean drinking water are just some of the products where chemical engineering plays a central role.

About IChemE

IChemE (Institution of Chemical Engineers) is the hub for chemical, biochemical and process engineering professionals worldwide. With a growing global membership approaching 38,000, the Institution is at the heart of the process community, promoting competence and a commitment to best practice, advancing the discipline for the benefit of society, encouraging young people in science and engineering and supporting the professional development of its members. For more information, visit www.icheme.org.

For further information, please contact:

Tony Osborne, communications officer, IChemE

tel: +44 (0)1788 534454

email: This email address is being protected from spambots. You need JavaScript enabled to view it.

SEMINARS - MAC to Hold Private Seminars

CHOOSING THE RIGHT NDT TECHNIQUES

SE ASIA SEMINARS BY

MAGNETIC ANALYSIS CORPORATION:

Jakarta, Indonesia — August 21, 2014

Shanghai, China — September 23, 2014

With 85+ years of experience in designing and manufacturing nondestructive test instruments and systems for the metals industry, Magnetic Analysis Corp. will be hosting its own set of seminars this year is South-East Asia.

Building on the outstanding success of MAC’s Echomac® Rotary ultrasonic testers, the company will be featuring a new Spinning Tube ultrasonic test system at both seminars. This system features a unique APC (Automatic Pitch Control) transducer carrier which contains the water couplant and follows and adjusts to the pitch of the tube as it rotates through the tester. This allows testing of a large range of pipe sizes, including large diameters, with minimal transducer adjustments, if any, during size changeovers. Further, because the transducers are under the pipe, no tight fitting glands or shoes are needed, resulting in lower water circulation requirements, fewer wear components and virtually no changes required to the basic water tank on size changeover. This Spinning Tube transducer system can also be used for testing tube ends as well as for a retrofit or upgrade of existing installations.

MAC will also have a Rotomac® eddy current rotary and coil platform on display.

Information will be presented on test systems using a combination of more than one type of test technology, a requirement to meet many of today’s stringent test standards such as API and ASTM as well as information on inspection of specific products such as heat exchanger tube, wire, and so on.

MAC’s knowledgeable field staff will provide information in multiple languages on all of Mac’s products. In Indonesia, our Guest will be Vice President Dudley Boden,Casey Powers, Systems Engineer, our Representative; Mr. Zulfikri Testindo, and David Terry; Business Development Manager for SE-Asia. In China, Our Guest will be Casey Powers, Systems Engineer and Jerry Zhu; Business Development Manager for China.

To contact us for information on how you can obtain an invitation to the events, Click Here

or email Paloma Domenico, Advertising Manager at: This email address is being protected from spambots. You need JavaScript enabled to view it.

SOLAR - global renewable energy firm to install solar systems at a further 50 UK schools

Underlining its commitment to sustainability within UK schools, global renewable energy company CBD Energy Limited (‘CBD’), is set to launch a new tranche of Energy Bonds in the weeks ahead. Having completed a successful raise - in excess of £7.5m - with its last Bond, the Company partnered with ‘Power Your Future’ ( www.poweryourfuture.co.uk ), a schools’ sustainability programme, and began construction on a series of solar installations, helping participating schools to generate their own solar energy, and in turn reduce their overheads. Projects have either been completed or are in the process of installation at 22 schools, all over the country, and aided by funding from the new Bond, CBD plans to install solar systems at a further 50 schools over the next six months.

Once completed, the entire portfolio will generate more than 3,300,000 MWh of renewable electricity per annum, and will prevent the emission of no less than 1,720 tonnes of CO2 each and every year. The savings for all the schools involved will be circa £100,000 over the course of the first year, and in excess of £2.3m over the 20 year lifetime of the installations combined.

As CBD Chairman and Managing Director, Gerry McGowan explains, “Partnering with schools and aiding their solar development was always a big priority for us, and the next Bond will help us to help even more schools. The savings generated will free up budget and enable schools to invest more heavily in educational resources, paying for a further 83 teachers (based on average salaries) or as many as 156,000 extra books.

“At the same time - and in keeping with our Company’s commitment to educate students about the importance of renewable energy - each school participating in the Power Your Future Programme will also be provided with educational materials and access to the systems’ ‘smart meter’, allowing them to track the output and carbon savings produced by their solar installation, and encouraging a lasting change in the attitudes of the next generation towards renewable energy. Altering the way our society both thinks about, and relates to, the environment is very important to us.”

CBD ENERGY RENEWS COMMITMENT TO SUSTAINABILITY WITHIN UK SCHOOLS ../2

The Power Your Future Programme involves no capital outlay on the part of the schools, and the systems are both maintained and insured by CBD - the schools benefiting from the green power generated on site at a heavily discounted rate. To date more than 100 schools have been installed through the Programme and are currently benefitting from cheaper, green energy.

About CBD Energy Limited (OTC: CBDNF)

Established in 1989, CBD Energy Limited is a diversified renewable energy company and a global leader in solar installations. Powered by a management team with deep experience in the energy sector and strong engineering capabilities, CBD is focused on the integration of residential solar, commercial and industrial solar, small utility scale solar and wind projects, in three principal markets - Australia, the US and UK.

Headquartered in Sydney, with principal regional offices in London and New York, CBD has completed projects across four continents, in countries as far-reaching as Australia, Fiji, Germany, Italy, New Zealand, the UK and the US. CBD has installed more than 17,000 residential systems and developed large renewable energy projects such as the 107MW wind farm in Taralga, NSW. CBD markets its residential and commercial solar installations under the name Westinghouse Solar, using the WESTINGHOUSE® trademark pursuant to an exclusive, long-term worldwide license.

For further information on CBD Energy Limited and its’ interests, please visit: